High-performance systems regularly encounter intense heat fluctuations that threaten material integrity and process reliability. In these settings, the choice of glass directly impacts both operational safety and long-term functionality.

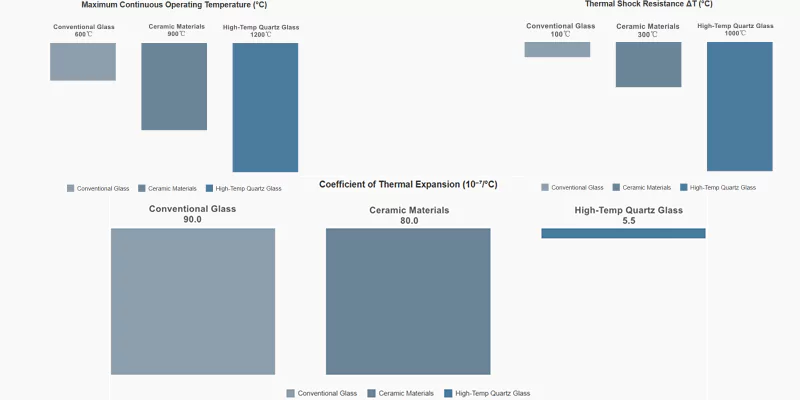

High-temperature quartz glass withstands continuous operation up to 1200°C and thermal shock events exceeding 1000°C temperature differentials due to its ultra-low thermal expansion coefficient (5.5×10⁻⁷/°C) and exceptional structural stability. This enables critical applications in semiconductor processing, aerospace systems, and high-energy lasers where conventional materials fail catastrophically under thermal stress.

In the following sections, we will uncover why standard materials quickly reach their thermal limits and how quartz glass enables advanced engineering in extreme environments. Prepare to discover key performance criteria, real-world application guidance, and actionable selection frameworks for your next high-stakes project.

Why Does High-Temperature Quartz Glass Excel in Extreme Thermal Applications?

Technical requirements often exceed what ordinary glass can offer, especially at elevated temperatures. High-temperature quartz glass represents a specialized solution tailored for such demanding scenarios.

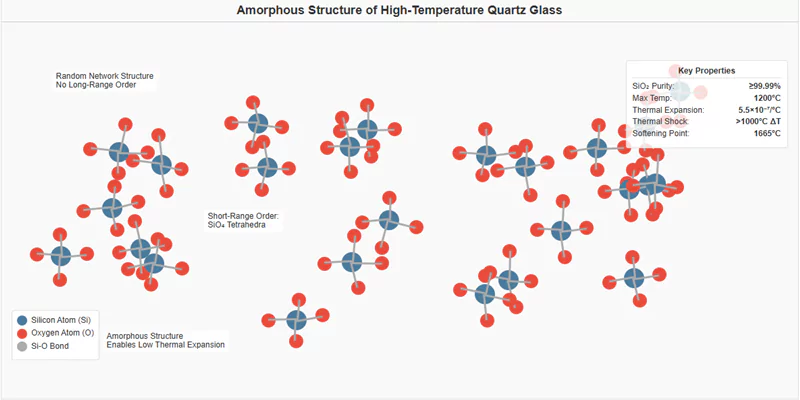

High-temperature quartz glass is a highly pure, amorphous silica material engineered for extreme thermal environments due to its minimal thermal expansion and robust atomic structure, making thermal performance its defining feature.

Quartz glass is fundamentally different from standard soda-lime or borosilicate glasses. It is manufactured through the melting of pure silicon dioxide (SiO₂), which eliminates impurities and endows the glass with its signature resistance to deformation under heat. While its low thermal expansion coefficient (typically 5.5×10⁻⁷/°C) ensures dimensional stability, its high softening point (>1650°C) prevents sagging or warping—both prerequisites in semiconductor, aerospace, and energy applications.

In engineering terms, the criticality of thermal performance is not abstract: even a minor mismatch in expansion between a glass component and its mounting hardware at high temperature can lead to catastrophic fracture. Similarly, continuous operation near 1200°C or rapid swings of several hundred degrees per second require a material engineered not just to survive, but to perform predictably and safely.

Core Properties of High-Temperature Quartz Glass

| Property | Value/Range | Industry Standard (Test Method) | Contextual Note |

|---|---|---|---|

| SiO₂ Purity (%) | ≥ 99.99 | ASTM E1479 | High purity eliminates weaker phase regions |

| Continuous Operating Temp (°C) | 1050–1200 | ASTM C162 | Non-deforming, dimensional stability |

| Maximum Short-Term Temp (°C) | 1300–1500 | ISO 7884 | No softening, no structure loss |

| Thermal Expansion (×10⁻⁷/°C) | 5.0–5.5 | ASTM E831 | Reference: room temperature to 900°C |

| Thermal Conductivity (W/m·K) | 1.38 (25°C) | ASTM C408 | Ensures stable heat flux, avoids hot spots |

| Softening Point (°C) | 1665 | ASTM C338 | No significant flow below this temperature |

| Thermal Shock Resistance (ΔT, °C) | >1000 | ASTM C1525 | Withstands rapid, extreme temperature changes |

Why Does High-Temperature Quartz Glass Outperform Conventional Glass in Extreme Thermal Environments?

Material failure arises when the environment exceeds what standard compositions can tolerate—an ever-present reality in advanced thermal systems.

Extreme thermal environments demand specialized glass solutions because only select materials can survive the simultaneous assaults of high temperature, rapid thermal cycling, and aggressive atmospheres without distortion, loss of function, or catastrophic failure.

Unlike conventional glass, which softens, warps, or shatters beyond 500–650°C, high-temperature quartz glass maintains structural and optical clarity even after repeated cycles up to 1200°C. For engineering projects—ranging from semiconductor batch processing to rocket engine windows—the tolerance for failure is essentially zero. Residual stress, chemical corrosion, and thermal gradient-induced fracture drive the need for both high intrinsic strength and compositional purity. In many cases, failure impairs millions of dollars worth of product or causes irreversible equipment contamination.

Furthermore, quartz glass solutions enable predictable performance in environments characterized by:

- Large, instantaneous swings in temperature (thermal shock)

- Exposures to fast process heating/cooling rates

- Aggressive oxidizers, vacuum, or inert atmosphere operation

- Where even limited outgassing or softening is unacceptable

Environmental Challenges and Quartz Glass Solutions

| Environmental Factor | Typical Industrial Condition | Standard Glass Response | Quartz Glass Response |

|---|---|---|---|

| Continuous High Temperature | 900–1200°C in reactors/furnaces | Sagging, deformation | Maintains shape, clarity |

| Rapid Temperature Cycling | ±400–1000°C, seconds to minutes | Cracking, shattering | Withstands 1000°C+ ΔT |

| Oxidizing/Corrosive Atmosphere | Aggressive gases, plasma | Devitrification, corrosion | Minimal interaction |

| High Precision Optics | Fused lens, viewports in vacuum | Optical distortion | Stable refractive index |

What Makes Quartz Glass Indispensable for Extreme-Temperature Engineering in Semiconductors and Aerospace?

Stable operation under extremes is the foundation of modern high-tech infrastructure. Systems ranging from microchip fabrication to next-generation propulsion architectures rely on superior thermal glass components.

Every major industry that operates above the limit of standard glass depends on the performance of high-temperature quartz glass for safety, productivity, and process yield.

![]()

The following use cases illustrate the breadth and specificity of quartz glass in high-temperature engineering.

Key High-Temperature Application Sectors Supported by Quartz Glass

| Application Sector | Typical Temperature (°C) | Quartz Function | Critical Performance Drivers |

|---|---|---|---|

| Semiconductor Fabrication | 600–1200 | Furnace tubes, boats, jigs | Dimensional stability, purity |

| Aerospace & Defense | 800–1500 | Windows, domes, shields | Optical clarity, shock resistance |

| High-Power Lasers | 400–1000 | Lenses, filters | Transmission stability, heating |

| Analytical Instruments | 300–950 | Cuvettes, cells | Chemical/thermal corrosion |

| Solar Thermal Systems | 800–1100 | Covers, receivers | UV/IR transmission, durability |

Semiconductor Furnace Components

In fabrication lines, every heating and cooling cycle exposes furnace components to relentless thermal cycling that would destroy ordinary materials.

Quartz glass forms the backbone of semiconductor furnace tubes, boats, and carriers as it sustains hundreds of process runs at temperatures from 900–1200°C without shape loss or contamination.

The ultra-high purity and thermal expansion match between quartz tubes and process mounts ensures not only extended component life but also yield consistency in advanced chip processes requiring atomic-level precision.

Aerospace and Defense Systems

Aerospace applications demand transparent, structurally robust materials for optical windows, radomes, and heat shields that must survive plasma, re-entry, and hypersonic flight.

Quartz glass optics and protection plates offer stable refractive properties and resist erosion, devitrification, and thermal shock far beyond what even advanced ceramics provide. This reliability underpins mission-critical systems in satellites, missile seekers, and high-atmosphere aircraft.

Why Is Thermal Stability Fundamental to Quartz Glass Performance in Critical Industrial Applications?

Maintaining both dimensional and structural integrity under heat is not optional but a baseline requirement for high-performance industrial workflows.

Exceptional thermal stability allows quartz glass to act as a reliable carrier, envelope, or optical interface in environments where temperature is dynamic and unpredictable, supporting both safety and throughput.

The consequence of small changes in shape or volume—caused by thermal expansion—ranges from seal failure and vacuum leaks to wafer breakage or even uncontrolled equipment shutdown.

Industries rely on quartz glass in the following roles:

- Crucibles for single-crystal silicon growth in photovoltaic production

- Light guides and protective tubes in high-wattage UV curing systems

- Analytical sensor housings in chemical reactors

- Encapsulation of thermally sensitive components, combining zero outgassing with long-term heat resistance

For all of these, thermal stability is the invisible influence that preserves alignment, maintains vacuum tightness, and ensures process repeatability.

Industrial Process Roles and Quartz Advantages

| Industrial Role | Thermal Environment (°C) | Quartz Stability Function | Failure Avoided by Quartz |

|---|---|---|---|

| Crystal Growth (Si, Ge) | 1420 (Si melt temp) | Maintains geometry at high temp | Shape loss, contamination |

| UV Lamp Protection | 600–900 | Optical clarity, durability | UV attenuation, fractures |

| Analytical Monitoring | 400–950 | Non-reactive, stable envelope | Signal drift, sample loss |

| Thermal Test Windows | 1000+ | No warping, stays transparent | Pressure/vacuum breach |

What Defines the Thermal Operating Boundaries for Safe Quartz Glass Performance?

Precision in the upper and lower boundaries of material capability determines safe operating envelopes and maintenance cycles.

Quartz glass is specified for continuous operation up to 1200°C, maximum short-term exposures to 1300–1500°C, and thermal shock over 1000°C temperature deltas—far above standard technical glass.

Beyond certain limits, quartz glass may experience:

- Viscous flow or softening (above 1665°C)

- Devitrification (crystallization under extreme temperature/time)

- Minor structural fatigue after thousands of thermal cycles

Operating well within the boundaries of thermal endurance preserves lifetime and prevents unplanned failures.

Quartz Glass Operating Temperature Boundaries

| Operating Condition | Endurance Value | Threshold Behavior | Notes |

|---|---|---|---|

| Continuous Use (°C) | 1050–1200 | Stable, no deformation | For most industrial designs |

| Short-Term Peak (°C) | Maximum 1300–1500 | Maintains integrity, softens near top | Short excursions only |

| Softening Temp (°C) | 1665 | Loss of rigidity, flow | Surpasses safe design range |

| Thermal Shock (ΔT,°C) | >1000 | Intact after rapid cycling | e.g., room temp ⇄ 1000°C |

How Does Quartz Glass Survive Thermal Shock Exceeding 1000°C Without Catastrophic Failure?

Thermal shock is the abrupt expansion or contraction due to instant temperature changes—an event that fractures most materials.

Quartz glass prevents system failures in thermal shock scenarios mainly through its extraordinarily low expansion coefficient. It tolerates temperature changes exceeding 1000°C with negligible risk of cracking or catastrophic breakage.

From sudden exposure to hot gases, radiant heat pulses, or rapid water quenching, quartz’s structure flexibly absorbs inter-atomic strain. As a benchmark, a typical quartz rod fully survives immersion from room temperature into a 1000°C furnace—a feat no ordinary glass matches.

The primary engineering benefit: reliable shutdown or safety cycles, even under unplanned or emergency conditions.

Comparative Thermal Shock Resistance

| Material Type | Max Survived ΔT (°C) | Typical Failure Mode | ASTM C1525 Test Result |

|---|---|---|---|

| Soda-Lime Glass | 60–100 | Cracks/shatters | Fails at low ΔT |

| Borosilicate Glass | 150–230 | Partial cracking | Degrades over cycles |

| Quartz Glass | >1000 | No visible failure | Retains properties |

How Does Quartz Glass Maintain Optical Stability Under Extreme Thermal Gradients?

High thermal environments often demand not only mechanical stability but also unchanging optical performance for sensors, lasers, and sight windows.

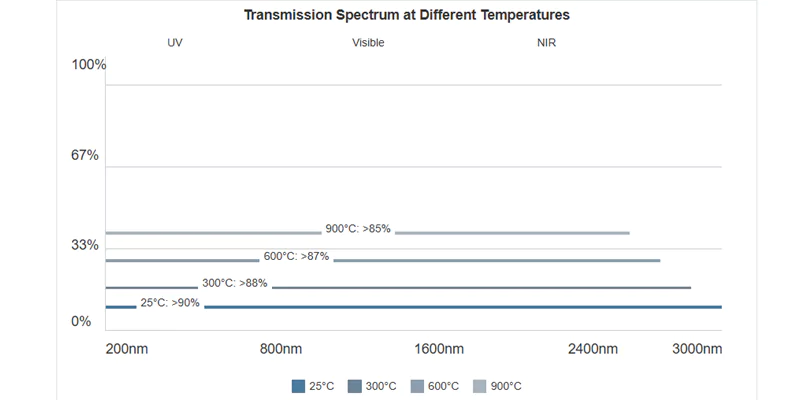

Quartz glass preserves optical properties—transmission, refractive index, and minimal birefringence—across even intense temperature gradients.

Under high temperature, quartz glass:

- Maintains >90% transmission in the UV and visible range (200–2500nm)

- Retains a stable refractive index (n ≈ 1.4585 at 589nm, 25°C) with minimal drift up to 1000°C

- Minimizes thermally induced defects and coloration thanks to high purity

This reliability enables use in laser windows, high-intensity lamps, and high-vacuum viewports for spectroscopy or process monitoring.

Temperature-Dependent Optical Properties

| Optical Parameter | Standard Value | High-Temperature Stability | Test Reference (ASTM) |

|---|---|---|---|

| Transmission (220–2500nm) | >90% | >85% up to 900°C | E903, D1003 |

| Refractive Index (589nm) | 1.4585 (25°C) | ±<0.0003 Δn at 1000°C | D1218 |

| Birefringence (stress opt.) | <10 nm/cm | No significant change | F218 |

What Makes Quartz Glass the Preferred Choice for Thermal-Critical Applications?

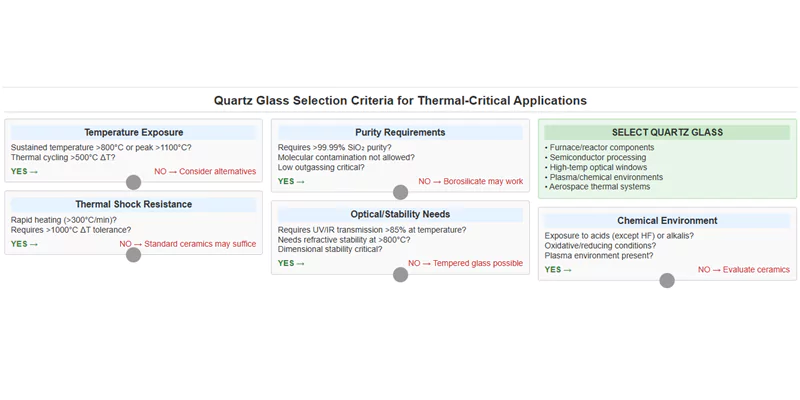

Selection extends beyond just the upper temperature rating—it demands a full assessment of cycle frequency, optical clarity, chemical exposure, and application-specific tolerances.

Engineers should select quartz glass for thermal-critical applications when environments combine high consistent temperature, rapid swings, purity requirements, and functional longevity pressures.

Common triggers where quartz becomes the preferred material include:

- Furnace or reactor parts exposed to >800°C or severe multicycle regimes

- Optical windows requiring transmission stability at heat

- Environments with oxidative, reducing, or plasma conditions

- Applications where outgassing or molecular contamination is not allowed

Quartz Glass Selection Triggers

| Trigger Question | Quartz is Preferred When: | Alternate Materials Unsuitable When: |

|---|---|---|

| Sustained temp >800°C? | Yes | Standard glass/ceramics deform |

| Rapid heating (>300°C/min) or delta >500°C? | Yes | Others crack, lose mechanical integrity |

| Requires >99.99% SiO₂ purity? | Yes | Lower grades outgas or corrode |

| Strict optical/stability requirements at heat? | Yes | Optical glass yellows, refractive drift |

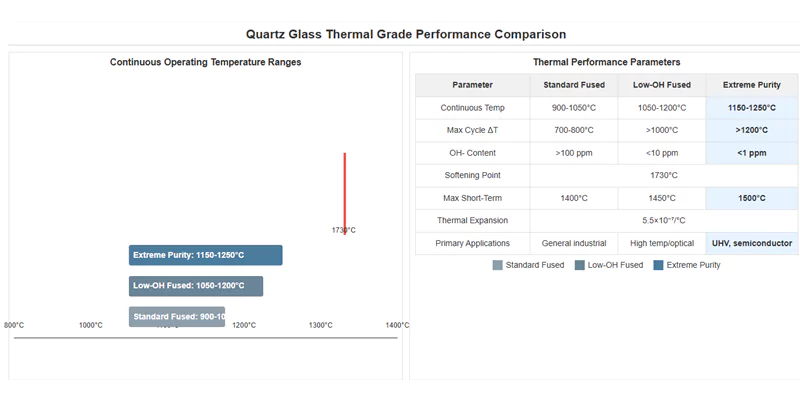

How Do Thermal Performance Grades Determine Quartz Glass Selection for Specific Applications?

Application-specific requirements often drive the choice between “standard” and “high-purity/extreme-thermal” grades of quartz glass. Each grade is tailored to balance cost, performance, and environment tolerance.

Different thermal grades of quartz offer varying combinations of mechanical endurance, softening point, and price, reflected in their suitability for continuous operation, thermal cycling, or peak heat exposure.

Standard fused quartz works for most operations up to 1050°C, while high-purity, low-hydroxyl versions excel at >1150°C, aggressive cycling, or stringent outgassing regimes.

Comparison Table: Quartz Thermal Grades

| Grade Type | Recommended Continuous Temp (°C) | Max Cycle ΔT (°C) | OH- Content (ppm) | Application Focus |

|---|---|---|---|---|

| Standard Fused | 900–1050 | 700–800 | >100 | General industrial |

| Low-OH Fused (Type I) | 1050–1200 | >1000 | <10 | High temp/optical |

| Extreme Purity | 1150–1250 | >1200 | <1 | UHV, semiconductor |

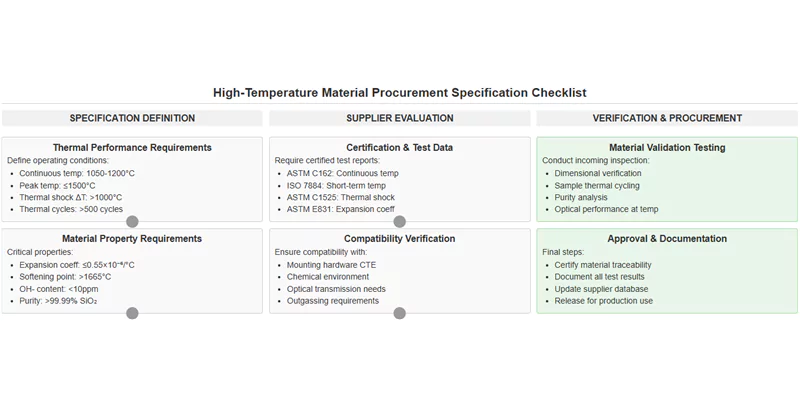

What Key Thermal Parameters Should Engineers Specify When Procuring Quartz Glass for Critical Applications?

The challenge in procurement is ensuring all critical parameters match the operating scenario—not just maximum temperature, but cycling, mechanical, and purity requirements.

The most vital thermal specifications include continuous and peak operating temperature, thermal shock resistance (ΔT), expansion coefficient, softening point, and purity grade; all should be explicitly requested along with test data for application fit.

When issuing a procurement request, engineers should consider:

- Operating temperature envelope and swing rate

- Frequency and duration of thermal cycling, with cycle count required

- Thermal expansion match with hardware

- Optical or UV transmission needs

- Chemical/atmospheric compatibility

- Certified test data (e.g., ASTM C1525 for cycling)

High-Temperature Quartz Procurement Criteria

| Specification | Required Value/Range | Relevance to Performance | Data/Test Standard |

|---|---|---|---|

| Operating Temp | 1050–1200°C | Prevents deformation/flow | ASTM C162 |

| Short-Term Temp | Up to 1500°C | Temporary thermal excursions | ISO 7884 |

| Thermal Shock (ΔT) | >1000°C | Survival of sudden shifts | ASTM C1525 |

| Expansion Coefficient | ≤0.55×10⁻⁶/°C | Dimensional fit, stress control | ASTM E831 |

| OH- Content | <10ppm (if required) | Outgassing and optical quality | In-house/third party |

| Certification/Test Data | Required | Application-specific fit | Submit with RFQ |

What Verification Standards Ensure Quartz Glass Reliability in Critical Thermal Applications?

Verification requires formal data, not just supplier claims. Comprehensive qualification of quartz glass rests on testing results, certificates, and—critically—thermal cycling evidence.

Temperature performance standards for quartz glass are validated through standardized laboratory tests (such as ASTM C1525 for cycling, C162 for temperature, and E831 for expansion) and test certifications provided with shipments.

For mission- and safety-critical systems, always require:

- Lab test certificates per batch

- Customized cycling results matching use profile

- Third-party validation or in-process monitoring reports

Failure to secure or inspect these can result in premature field failures, unexpected downtime, or rejected product lots.

Typical Temperature Performance Verification Documentation

| Verification Item | Data Provided | Recommended Test/Standard | Frequency |

|---|---|---|---|

| Batch Test Certificate | Full property sheet | ASTM/ISO methods | Every batch |

| Thermal Cycling Test | ≥1000 cycle report | ASTM C1525 | Once per design type |

| Softening/Flow Point Proof | Lab measurement | ASTM C338 | Per supplied grade |

| Expansion Coefficient | Measured result | ASTM E831 | Supplier validation |

What Standards Govern Safety and Quality Assurance in High-Temperature Quartz Glass Applications?

Safety, quality, and cross-vendor comparability are all governed by strict international and national standards for high-temperature glass.

Core standards for high-temperature quartz glass include ASTM C162 (composition, process), ASTM C1525 (thermal cycling), ISO 7884 (high temperature viscosity/softening), and additional test methods for expansion, purity, and optical behavior.

Adherence to these ensures components meet design intent and pass both regulatory and customer audits.

Major Standards Governing Quartz Glass

| Standard | Governing Body | Coverage | Typical Application |

|---|---|---|---|

| ASTM C162 | ASTM International | Composition, manufacturing, dimensions | General procurement |

| ASTM C1525 | ASTM International | Thermal cycling, shock resistance | Critical system rating |

| ISO 7884 | ISO | High temperature softening, viscosity | Process tubes/windows |

| ASTM E831 | ASTM International | Thermal expansion determination | Machining, integration |

| ASTM E1479 | ASTM International | Purity testing (trace elements, OH content) | UHV, semiconductor |

Decision Framework for Selecting Quartz Glass in Extreme Thermal Applications

For those balancing cost, performance, and risk in extreme thermal settings, a clear checklist-based approach accelerates optimal choices.

Below is a streamlined decision framework that consolidates all prior information for practical procurement or design use.

High-Temperature Quartz Glass Selection Checklist

| Step | Key Question | Recommended Action | Why It Matters |

|---|---|---|---|

| 1 | What is the max continuous and peak temperature? | Select appropriate grade (Std, Low-OH, HP) | Prevents deformation, ensures endurance |

| 2 | What is the thermal cycling profile (ΔT, freq)? | Specify cycle count + ASTM C1525 data | Avoids premature cracking/failures |

| 3 | Are optical or high-purity attributes needed? | Choose low-OH/HP quartz + verify specs | Ensures stability, avoids contamination |

| 4 | Chemical/atmospheric compatibility? | Validate material performance in situ | Maintains integrity in corrosion/oxidation |

| 5 | Can the supplier provide full test certificates? | Require batch/test results on delivery | Confirms compliance, supports audits |

| 6 | Industry standards required for your market? | Specify ASTM/ISO standard in contract | Streamlines procurement, guarantees quality |

| 7 | Any custom cutting or machining required? | Order as per dimensional/finishing spec | Supports integration, avoids post-machining |

Conclusion

High-temperature quartz glass ensures reliability and safety for advanced thermal applications where conventional options fall short.

Navigating the complexities of extreme heat management presents unique engineering challenges. Leverage TOQUARTZ’s factory-direct expertise and rapid-turn custom manufacturing—supported by experienced engineers—for a tailored solution to your high-temperature quartz glass application.

FAQ (Frequently Asked Questions)

What is the lead time for custom high-temperature quartz glass parts?

Typical lead times range from 2–4 weeks depending on part complexity, with standard-stock items shipping within 24 hours. For urgent requirements, expedited production and international shipping are available.

How can I verify the thermal cycling resistance before purchasing?

Request the supplier’s ASTM C1525 thermal cycling test reports and specify the number of cycles (matching your application) to ensure the material meets expected life standards before procurement.

Are there risks associated with cutting or machining quartz glass after delivery?

Yes—machining can introduce microcracks, reducing thermal shock resistance. It is recommended to order parts pre-machined or request engineering support for post-processing guidance.

What documentation should be included in a high-temperature quartz glass procurement package?

Each shipment should include batch-specific certificates (with SiO₂ purity, thermal properties, and test method references), thermal shock/cycling test data, and compliance with specified industry standards (e.g., ASTM C162, C1525).