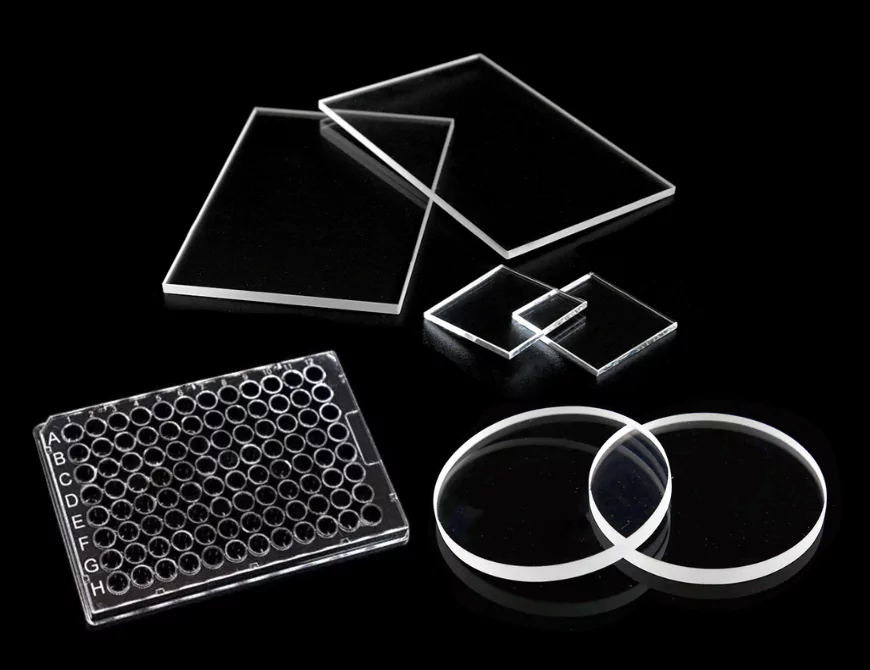

What Laser Damage Threshold Requirements Govern AR-Coated Quartz Disc Selection?

Engineer’s framework for selecting AR-coated quartz discs based on laser damage threshold. Includes fluence calculations, safety margins, and application-specific criteria.