- Home

- /

- Types

- /

- Quartz Bottle

- /

- Research-Grade Single Neck Round...

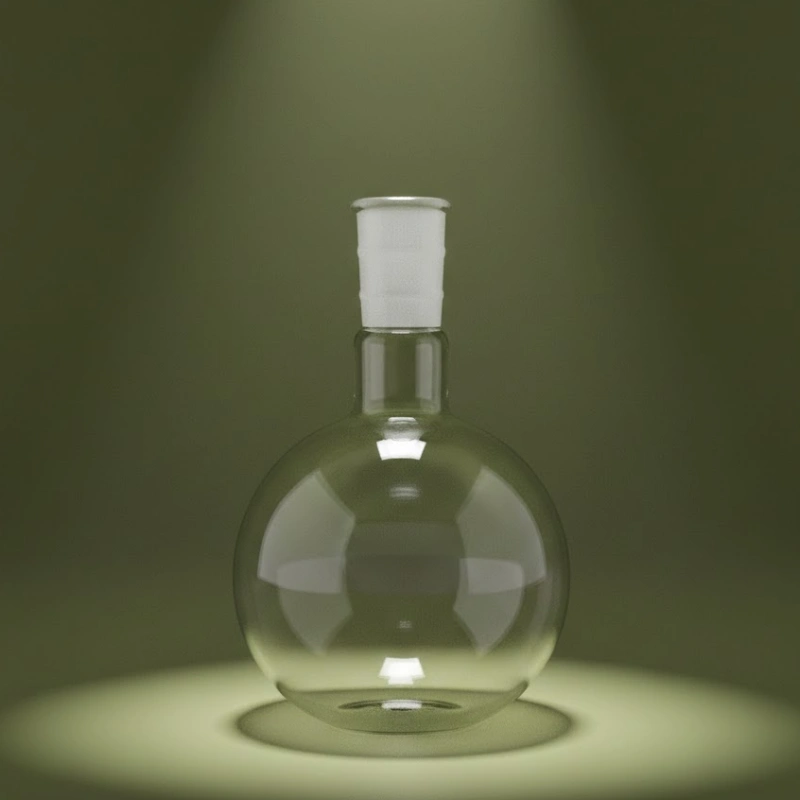

Research-Grade Single Neck Round Bottom Quartz Flask for Chemical Reactions -TOQUARTZ®

Features of High Purity Single Neck Round Bottom Quartz Flask

Thermal Conductivity

With thermal conductivity of 120-160 W/m·K, these flasks provide efficient heat transfer during heating and cooling processes, ensuring uniform temperature distribution.

Chemical Resistance

Exceptional resistance to acids, bases, and corrosive chemicals, making these flasks ideal for aggressive chemical reactions. The inert surface prevents contamination and ensures reaction purity.

Thermal Stability

Withstands temperatures up to 1200°C with exceptional thermal shock resistance. The low coefficient of thermal expansion (5.5×10⁻⁷/°C) ensures dimensional stability during rapid temperature changes.

Optical Clarity

High transparency across visible and UV spectrum allows clear observation of reaction processes. The material provides over 90% transmission in the 200-2000nm wavelength range.

- Material: 99.99% SiO

- Acid/Alkali Resistant

- Custom Sizes Available

Technical Specifications & Dimensions of Quartz Glass Flask

Technical Specifications of Single Neck Round Bottom Quartz Glass Flask

Physical Properties

| Property | Value |

| Density | 2.2 g/cm³ |

| Hardness (Mohs) | 5.5-6.5 |

| Tensile Strength | 48-51 MPa |

| Compressive Strength | 1100-1400 MPa |

| Thermal Expansion | 5.5×10⁻⁷/°C |

| Thermal Conductivity | 120-160 W/m·K |

| Max Operating Temp | 1200°C |

Optical Properties

| Property | Value |

| Refractive Index (589nm) | 1.4585 |

| UV Transmission (200nm) | ≥80% |

| Visible Light (400-700nm) | ≥93% |

| IR Transmission (2000nm) | ≥90% |

| OH Content | ≤8 ppm |

Chemical Properties

| Component | Value |

| SiO₂ Content | ≥99.99% |

| Al₂O₃ | ≤15 ppm |

| Fe₂O₃ | ≤0.2 ppm |

| CaO | ≤0.4 ppm |

| Na₂O | ≤0.3 ppm |

| K₂O | ≤0.3 ppm |

| Li₂O | ≤0.1 ppm |

Dimensions of Round Bottom Quartz Glass Flask with Single Neck

| Model | Capacity (ml) | Joint Size | Diameter × Height (mm) | SiO₂ Content (%) |

| AT-SY-SP1001 | 25 | 19 | 41*85 | 99.99 |

| AT-SY-SP1002 | 50 | 19 | 55*94 | 99.99 |

| AT-SY-SP1003 | 50 | 24 | 55*94 | 99.99 |

| AT-SY-SP1004 | 100 | 19 | 65*109 | 99.99 |

| AT-SY-SP1005 | 100 | 24 | 65*109 | 99.99 |

| AT-SY-SP1006 | 150 | 19 | 75*121 | 99.99 |

| AT-SY-SP1007 | 150 | 24 | 75*121 | 99.99 |

| AT-SY-SP1008 | 250 | 24 | 84*130 | 99.99 |

| AT-SY-SP1009 | 500 | 24 | 115*152 | 99.99 |

| AT-SY-SP1010 | 1000 | 24 | 135*213 | 99.99 |

| AT-SY-SP1011 | 2000 | 24 | 170*258 | 99.99 |

TOQUARTZ® Solving Research Challenges with Single Neck Round Bottom Quartz Flasks

Single Neck Round Bottom Quartz Flasks for High-Temperature Chemical Reactions

Key Advantages

-

Thermal Endurance up to 1200°C

TOQUARTZ flasks maintain structural integrity in continuous operations at 1100–1200°C without deformation or cracking. -

Thermal Shock Resistance ΔT > 800°C

Engineered to withstand rapid temperature changes, tested with direct 800°C-to-room-temperature quenching cycles. -

No Softening Below 1600°C

Made from fused quartz with a softening point of 1683°C, ensuring zero sagging during prolonged high-heat exposure.

TOQUARTZ® solution

A German chemical equipment OEM reported repeated failures of borosilicate flasks during 700°C catalyst testing, causing 2-week delays and €8,000 in losses. After switching to TOQUARTZ flasks, they completed 180+ thermal cycles at 1150°C with zero breakage, reducing downtime by 100% and improving test throughput by 22%.

Single Neck Round Bottom Fused Quartz Flasks for Precision Chemical Synthesis

Key Advantages

-

Precise Dimensional Control

Manufactured with ±0.2mm tolerance for consistent experiment conditions -

Superior Chemical Resistance

Inert to virtually all acids and solvents, preventing reaction contamination -

Batch-to-Batch Consistency

Ensures reproducible experimental results across multiple production runs

TOQUARTZ® solution

A US university research laboratory reported a 12% rejection rate with standard laboratory flasks due to dimensional inconsistencies, significantly affecting research progress. After implementing TOQUARTZ single neck round bottom quartz flasks with precise ±0.2mm tolerances, they reduced rejection rates to under 1% and improved experiment reproducibility by 15%, as documented in their published research methodology.

Single Neck Round Bottom Quartz Glass Flasks for Advanced Materials Research

Key Advantages

-

99.99% SiO₂ Verified Purity

Each flask is manufactured from certified fused quartz with ≤15 ppm total metallic impurities. -

Ultra-Low Alkali Content (Na₂O ≤ 0.3 ppm)

Minimizes ion leaching during nanomaterial synthesis, ensuring uncontaminated reaction environments. -

OH Content ≤ 8 ppm

Low hydroxyl levels reduce outgassing and prevent interference in high-vacuum or inert gas systems.

TOQUARTZ® solution

A Japanese nanomaterials lab faced 3% yield loss due to trace alkali contamination from standard glassware. After adopting TOQUARTZ flasks with verified 99.99% SiO₂ and Na₂O ≤ 0.3 ppm, they achieved 100% batch purity across 12 synthesis runs, improving catalyst performance by 17% and eliminating the need for post-synthesis purification.

TOQUARTZ® Quartz Flask Customization Services

Customized Design Options

-

Custom Capacities:

Beyond standard sizes (25ml-2000ml), we can produce custom volumes based on your specific requirements -

Specialized Joint Sizes:

Non-standard joint sizes and types including custom angles and specialized connections -

Wall Thickness Variations:

Custom wall thicknesses for specific thermal or pressure requirements -

Dimensional Modifications:

Custom neck lengths, body dimensions, and overall flask proportions -

Surface Treatments:

Custom surface finishes including precision polishing, frosting, or calibration markings

Customization Process

-

Requirement Analysis

Our technical team works with you to understand your specific application needs and technical requirements -

Technical Drawing Review

We can work from your existing drawings or develop new technical specifications based on your requirements -

Prototype Development

For complex designs, we can produce prototype samples for testing and validation -

Production & Quality Control

Strict manufacturing controls ensure your custom flasks meet all specifications -

Expedited Delivery

Custom orders are prioritized for efficient production and shipping

Usage Guidelines of Single Neck Round Bottom Quartz Flask

Proper handling, cleaning, and storage of quartz flasks ensures maximum performance and extended service life. Follow these best practices to maintain the integrity of your TOQUARTZ single neck round bottom quartz flasks.

Handling & Operation

-

Temperature Control:

Always heat and cool gradually. Avoid sudden temperature changes exceeding 200°C to prevent thermal shock. Use proper heating equipment like heating mantles or sand baths rather than direct flame. -

Support Systems:

Always use appropriate clamps and supports. The flask should be supported at the neck with cushioned clamps to distribute weight evenly and prevent stress points. -

Joint Connections:

Use appropriate greases or PTFE sleeves for ground joint connections.

Ensure joints are properly seated to prevent leakage and glass fusion

at high temperatures. -

Physical Impact:

Handle with care. Despite high temperature resistance, quartz remains susceptible to mechanical shock. Avoid impacts and scratches which can create stress points.

Cleaning & Storage

-

Cleaning Method:

Rinse with appropriate solvents followed by deionized water. For stubborn residues, use dilute acid baths (HCl or HNO₃) followed by thorough rinsing. Avoid abrasive cleaners that can scratch the surface. -

Drying Technique:

Air dry in clean environment or oven dry at 105-110°C. For ultra-clean applications, final rinse with high-purity solvents (acetone or methanol) and dry in a clean oven. -

Storage Conditions:

Store in clean, dry cabinets away from other glassware to prevent contact damage. Use soft padding between vessels and avoid stacking heavy items on top of flasks. -

Long-term Maintenance:

Periodically inspect for microcracks or surface abrasions. Flasks with visible damage should be removed from high-temperature service to prevent failure during operation.

Need Expert Assistance with Laboratory Quartz Products?

for your application or discuss custom requirements for your laboratory or industrial process.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a single neck round bottom quartz flask used for?

A: Single neck round bottom quartz flasks are primarily used for high-temperature chemical reactions, distillation processes, and synthesis of sensitive compounds. They’re ideal for applications requiring excellent thermal stability, chemical resistance, and optical clarity, such as organic and inorganic synthesis, material science research, and specialized chemical manufacturing processes. Their round bottom design provides even heating distribution and prevents sample accumulation in corners.

Q: What precautions should be taken when using a round bottom quartz flask?

A: When using round bottom quartz flasks, always heat and cool gradually to prevent thermal shock. Use appropriate support like cork rings or heating mantles to stabilize the flask during use. Avoid direct flame contact and use distributed heat sources. Handle with care as quartz is resistant to heat but remains brittle to mechanical impact. Always inspect for cracks before high-temperature applications, and use appropriate joint grease or PTFE sleeves for ground glass connections to prevent seizing.

Q: How to clean a round bottom quartz flask?

A: To clean a round bottom quartz flask: First rinse with appropriate solvents to remove residues (acetone for organic compounds, water for water-soluble materials). For stubborn residues, use dilute acids (like 10% HCl or HNO₃) followed by thorough rinsing with deionized water. Avoid abrasive cleaners that can scratch the surface. For ultra-clean applications, perform a final rinse with high-purity solvents. Specialized laboratory glassware detergents can also be effective for routine cleaning. Always rinse thoroughly with deionized water as the final step.

Q: How to dry a round bottom quartz flask?

A: To dry a round bottom quartz flask: For standard applications, air dry in a clean, dust-free environment or use a laboratory drying oven at 105-110°C. For moisture-sensitive applications, rinse with anhydrous acetone or ethanol before drying to remove water more effectively. For ultra-clean requirements, perform final rinses with high-purity solvents and dry in a clean oven. Vacuum drying can be used for faster results. Always allow the flask to cool gradually to room temperature after oven drying to prevent thermal stress.

Q: How to store round-bottom quartz flasks?

A: Store round-bottom quartz flasks in clean, dry cabinets away from other glassware to prevent contact damage. Use flask stands, cork rings, or specialized storage racks designed for round-bottom vessels. Avoid stacking heavy items on top of flasks. For standard joint flasks, consider using plastic joint protectors to prevent dust accumulation and protect ground glass surfaces. Store in a low-traffic area to minimize accidental impacts. Periodically inspect stored flasks for cracks or damage before returning to service.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.