- Home

- /

- Types

- /

- Quartz Bottle

- /

- Reaction-Optimized Single Neck Flat...

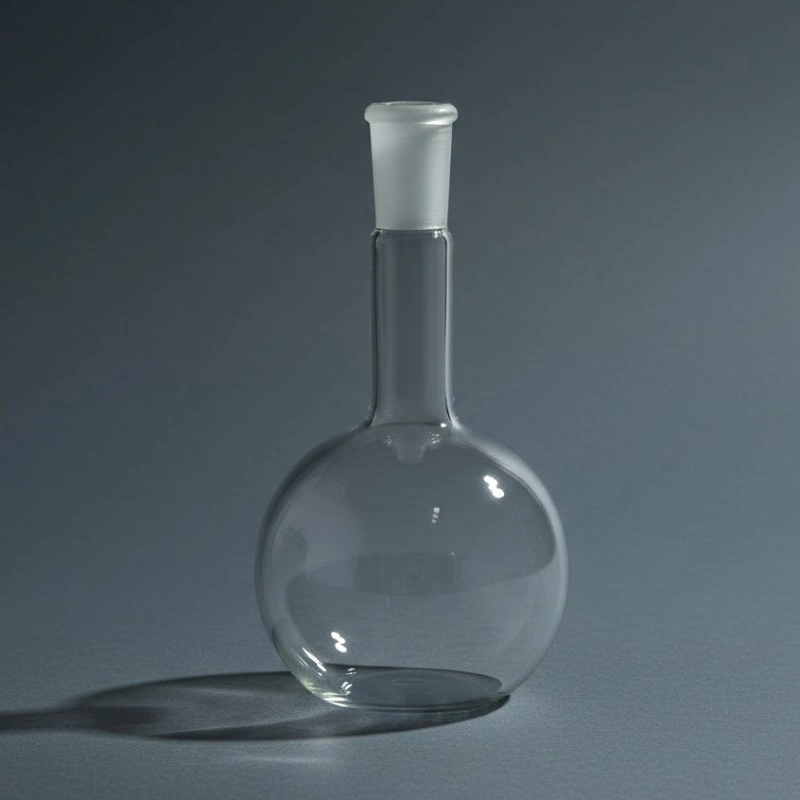

Reaction-Optimized Single Neck Flat Bottom Quartz Flask for Laboratory Applications -TOQUARTZ®

Features of Single Neck Flat Bottom Quartz Flask

Physical Characteristics

- High mechanical strength with fracture modulus >350 MPa

- Precision ground joints with standard sizes (19/22, 24/40, etc.)

- Flat bottom design for stability on laboratory surfaces

Chemical Properties

- Exceptional resistance to acids (except HF) and bases

- Stable against molten salts and fluorinated gases

- High purity silica (99.99% SiO₂) for contamination-free reactions

- Non-reactive surface prevents catalytic effects on sensitive reactions

Thermal Properties

- Temperature resistance up to 1200°C for high-heat reactions

- Excellent thermal shock resistance, withstanding rapid temperature changes

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C) for dimensional stability

- High thermal conductivity (120-160 W/m·K) for efficient heat transfer

- Material: 99.99% SiO

- Acid/Alkali Resistant

- Custom Sizes Available

Technical Specifications & Dimensions of Quartz Glass Flask

Technical Specifications of Single Neck Flat Bottom Fused Quartz Flask

Physical Properties

| Property | Value | Unit |

| Maximum Working Temperature | 1200 | °C |

| Softening Point | 1730 | °C |

| Density | 2.2 | g/cm³ |

| Thermal Conductivity | 1.4 | W/m·K |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ | /°C |

Chemical Properties

| Component | Content | Unit |

| SiO₂ | ≥99.99 | % |

| Al₂O₃ | ≤20 | ppm |

| Fe₂O₃ | ≤0.2 | ppm |

| Na₂O | ≤0.5 | ppm |

| OH Content | ≤5 | ppm |

Dimensions of Flat Bottom Quartz Glass Flask with Single Neck

| Model | Capacity (ml) | Joint Size | Diameter × Height (mm) | SiO₂ Content (%) |

| AT-SY-SP1001 | 25 | 19 | 41*85 | 99.99 |

| AT-SY-SP1002 | 50 | 19 | 55*94 | 99.99 |

| AT-SY-SP1003 | 50 | 24 | 55*94 | 99.99 |

| AT-SY-SP1004 | 100 | 19 | 65*109 | 99.99 |

| AT-SY-SP1005 | 100 | 24 | 65*109 | 99.99 |

| AT-SY-SP1006 | 150 | 19 | 75*121 | 99.99 |

| AT-SY-SP1007 | 150 | 24 | 75*121 | 99.99 |

| AT-SY-SP1008 | 250 | 24 | 84*130 | 99.99 |

| AT-SY-SP1009 | 500 | 24 | 115*152 | 99.99 |

| AT-SY-SP1010 | 1000 | 24 | 135*213 | 99.99 |

| AT-SY-SP1011 | 2000 | 24 | 170*258 | 99.99 |

TOQUARTZ® Solving Laboratory Challenges with Single Neck Flat Bottom Quartz Flasks

Single Neck Flat Bottom Quartz Flasks for High-Temperature Chemical Synthesis

Key Advantages

-

Temperature stability up to 1200°C

Maintains structural integrity during extended high-heat operations, eliminating mid-experiment failures. -

Exceptional thermal shock resistance

Withstands rapid temperature changes without cracking, critical for dynamic reaction protocols. -

Minimal thermal expansion

Low coefficient of 5.5×10⁻⁷/°C prevents dimensional changes that compromise seal integrity.

TOQUARTZ® solution

A German chemical research institute reported recurring equipment failures when conducting metal-organic framework synthesis at 750°C. After switching to TOQUARTZ single neck flat bottom quartz flasks, they eliminated vessel failures completely and reduced experiment cycle time by 27%, saving approximately €8,500 in materials and labor costs per research project.

Single Neck Flat Bottom Quartz Glass Flasks for Corrosive Media Applications

Key Advantages

-

Superior acid resistance

Withstands concentrated acids (except HF) without etching or releasing contaminants into solutions. -

Alkali resistance at elevated temperatures

Maintains integrity even with hot concentrated bases that would attack borosilicate glass. -

Long-term chemical stability

Non-reactive surface prevents ion leaching and maintains solution purity during extended reactions.

TOQUARTZ® solution

A Japanese pharmaceutical R&D laboratory conducting stability testing with aggressive solvents reported that TOQUARTZ single neck flat bottom quartz flasks extended vessel lifespan by 5-7 times compared to their previous glassware. This resulted in a 92% reduction in vessel-related experiment failures and reduced annual laboratory supply costs by approximately ¥875,000.

Single Neck Flat Bottom Fused Quartz Flasks for Precision-Critical Applications

Key Advantages

-

Precise dimensional control

Manufactured to tolerances of ±0.1mm, ensuring consistent fit with laboratory apparatus and accessories. -

Standardized ground joint compatibility

Precision-ground joints ensure leak-free connections with other laboratory components. -

Batch-to-batch consistency

Rigorous quality control ensures uniformity across production runs for predictable experimental results.

TOQUARTZ® solution

An American university research laboratory specializing in photochemical reactions reported reducing their equipment compatibility issues by 93% after switching to TOQUARTZ single neck flat bottom quartz flasks. Previously experiencing joint leakage rates of 14-17%, they achieved leak rates below 1% with our precision-manufactured vessels, saving approximately 42 research hours per month and reducing sample loss by 87%.

TOQUARTZ® Quartz Flask Customization Services

Dimensional Customization

- Custom capacity (25ml to 2000ml)

- Modified neck diameter and length

- Specialized wall thickness requirements

- Non-standard bottom shapes

- Specialized height-to-diameter ratios

Technical

Modifications

- Custom ground joint standards

- Reinforced rim and bottom designs

- Surface treatment options

- Calibration marks for volume measurement

- Specialized surface finish requirements

Specialized Applications

- High-pressure applications

- Photochemical reaction optimization

- Integrated thermowell options

- Ultra-high purity requirements

- Customized for specific instruments

Customization Process

Initial Consultation

- TOQUARTZ® engineers discuss your application needs and technical challenges for custom single neck flat bottom quartz flasks.

Technical Drawing & Feasibility Review

- We evaluate your provided drawings or help create one for your quartz flask, ensuring dimensional and thermal compatibility.

Material Selection & Specification Confirmation

- Based on your use case, we confirm quartz purity, wall thickness, joint type, and other key specs for your custom quartz glass flask.

Prototype Development (Optional)

- For complex or high-precision quartz flask designs, we offer sample prototyping to validate fit, function, and performance.

Usage Guidelines of Single Neck Flat Bottom Quartz Flask

Proper handling and maintenance of quartz flasks are essential to ensure optimal performance, safety, and longevity. The following guidelines will help you maximize the benefits of your TOQUARTZ single neck flat bottom quartz flasks.

Proper Handling & Safety

- Always inspect for cracks or damage before use, especially after exposure to thermal or mechanical stress

- Avoid direct flame contact with the quartz surface; use diffuse heating methods when possible

- Heat and cool gradually (at rates below 150°C/min) to prevent thermal shock

- Use proper support structures when heating; never place hot vessels directly on cold surfaces

- Always wear appropriate PPE including heat-resistant gloves and eye protection when handling hot vessels

Cleaning Procedures

- Rinse immediately after use to prevent residue hardening

- For routine cleaning, use warm water with mild laboratory detergent

- For persistent residues, soak in appropriate solvent based on contaminant type

- For inorganic deposits, aqua regia or other acid cleaning solutions may be used (except HF)

- Rinse thoroughly with deionized water after cleaning with any chemicals

- Avoid abrasive cleaning methods that may scratch the surface

Drying & Storage

- Air dry in a dust-free environment or use filtered compressed air

- For complete drying, place in a laboratory oven at 105-110°C for 30-60 minutes

- Store in clean, dust-free cabinets away from potential impact sources

- Use soft padding between vessels to prevent contact damage

- For long-term storage, cover openings with clean aluminum foil or appropriate stoppers

Maximizing Lifespan

- Avoid rapid temperature changes exceeding 150°C/minute

- Never expose to hydrofluoric acid (HF) which attacks quartz

- Prevent alkali metal contamination at high temperatures

- Use appropriate supports and clamps to prevent mechanical stress

- For vacuum applications, verify the flask is rated for the intended pressure differential

- Establish regular inspection procedures to identify early signs of devitrification or damage

Need Technical Support for Your Application?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a single neck flat bottom flask used for?

A: Single neck flat bottom quartz flasks are primarily used for chemical reactions, heating liquids, distillation processes, and as reaction vessels in laboratory settings. They’re particularly valuable for high-temperature applications (up to 1200°C), reactions involving corrosive chemicals, and experiments requiring high purity and optical clarity. The flat bottom design provides stability on laboratory surfaces, while the single neck allows for attachment of condensers, thermometers, or other apparatus using standard ground joints.

Q: What are the safety precautions for single neck flat bottom quartz flasks?

A: When working with quartz flasks, observe these safety precautions:

1. Always inspect for cracks or damage before each use

2. Use proper support equipment (clamps, stands, heat-resistant surfaces)

3. Heat and cool gradually to prevent thermal shock

4. Wear appropriate PPE including heat-resistant gloves and eye protection

5. Never seal a heated flask completely as pressure buildup can cause explosion

6. Use appropriate ventilation when working with volatile or hazardous substances

7. Follow standard laboratory safety protocols for chemical handling

8. Never use direct flame on a single point of the flask surface

9. Do not exceed the maximum temperature rating (1200°C)

10. Be aware that quartz becomes increasingly brittle after repeated exposure to very high temperatures

Q: How to clean a flat bottom quartz flask?

A: For effective cleaning of quartz flasks:

1. Rinse immediately after use with appropriate solvent to prevent residue hardening

2. For routine cleaning, use laboratory detergent and warm water

3. For organic residues, soak in appropriate solvents (acetone, alcohols, etc.)

4. For inorganic deposits, aqua regia or chromic acid cleaning solutions are effective (CAUTION: these are highly corrosive)

5. For stubborn residues, a solution of KOH in ethanol or isopropanol can be effective

6. Avoid abrasive cleaning methods that could scratch the surface

7. Never use hydrofluoric acid (HF), which attacks quartz

8. After chemical cleaning, rinse thoroughly with deionized water

9. For ultra-high purity applications, perform final cleaning with high-purity solvents

10. For sterilization, autoclaving or dry heat sterilization methods are suitable

Q: How to dry a flat bottom quartz flask?

A: Proper drying techniques for quartz flasks include:

1. Air drying: Place flask upside down on a clean drying rack in a dust-free environment

2. Compressed air: Use filtered, oil-free compressed air for quick drying

3. Oven drying: Place in laboratory oven at 105-110°C for 30-60 minutes

4. Vacuum drying: Connect to a vacuum system to accelerate drying of hard-to-reach areas

5. Solvent rinsing: For water-sensitive applications, rinse with acetone or ethanol before drying

6. Heat gun: Carefully use a laboratory heat gun on low setting (keep moving to avoid thermal stress)

7. For trace analysis work, perform final drying in a clean environment to prevent contamination

Q: How to store flat-bottom quartz flasks?

A: Proper storage extends the life of your quartz flasks:

1. Store in a clean, dust-free cabinet or drawer dedicated to glassware

2. Use soft padding materials between flasks to prevent contact and scratching

3. Store flasks upright or inverted on a clean surface, never on their sides where they could roll

4. Cover openings with clean aluminum foil, glass stoppers, or purpose-made caps to prevent dust contamination

5. For long-term storage, wrap in lint-free paper or cloth and place in a padded container

6. Keep away from areas with heavy traffic or potential impact

7. Avoid storing near chemicals that could create corrosive vapors

8. Label storage areas to prevent improper handling by untrained personnel

9. For especially valuable or precision flasks, consider dedicated storage containers with custom foam inserts

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.