TOQUARTZ® Engineered Quartz Rod for

Demanding Industrial Applications

Precision-engineered quartz rods designed for high-temperature, corrosive, and optical-critical environments — with no MOQ and rapid delivery from TOQUARTZ®.

- Designed for Extreme Environments

- Engineer-assisted Custom Quartz Rods

- No MOQ, Order Any Quantity

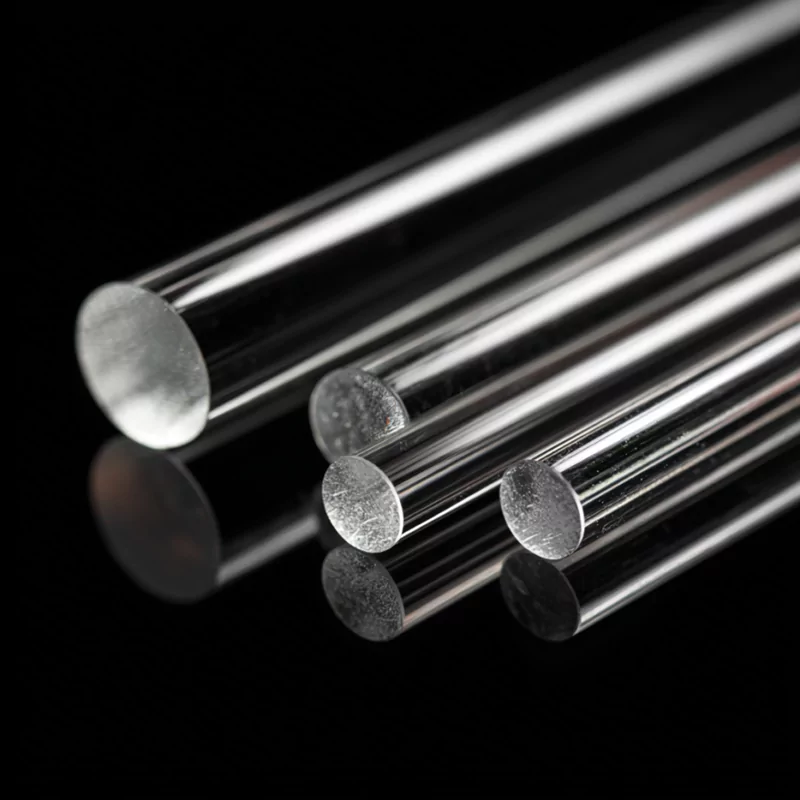

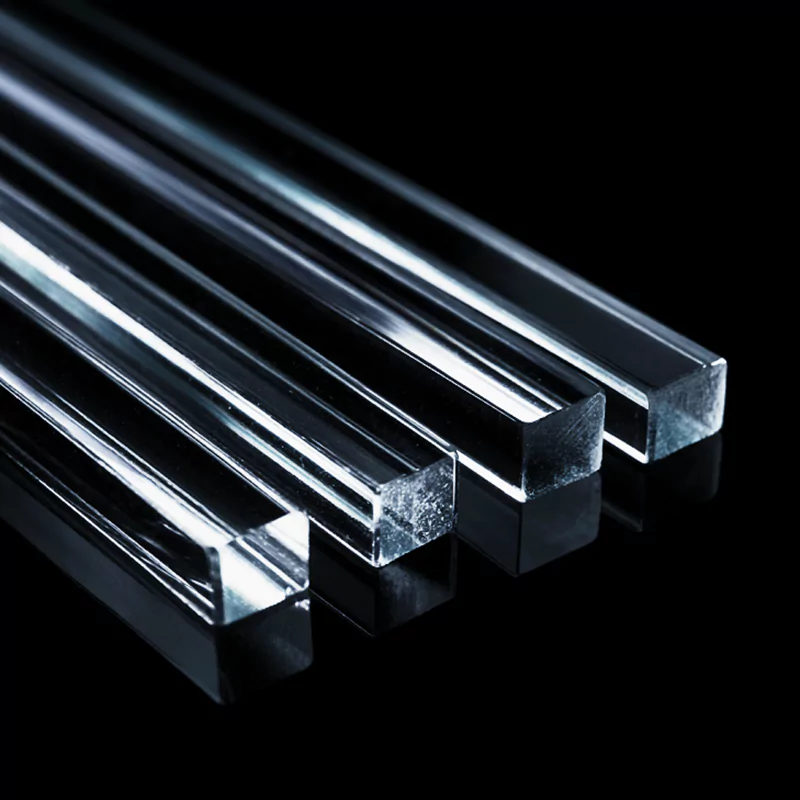

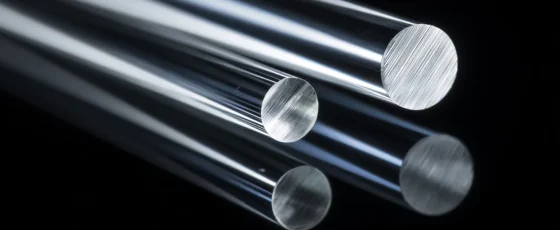

TOQUARTZ® Quartz Rod Product Range

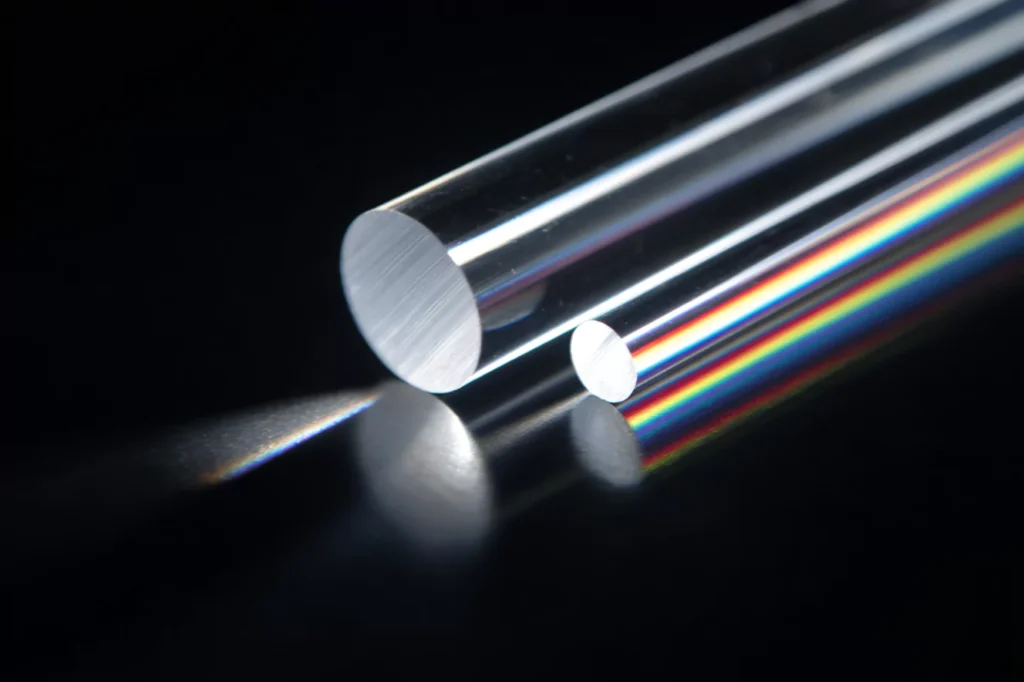

TOQUARTZ® offers a comprehensive range of high-quality quartz glass rods, fused quartz groove rods, and quartz optical fiber preform rods in various shapes and specifications to meet your exact requirements.

What Is a Quartz Rod?

A quartz rod is typically a cylindrical or shaped rod made from high-purity fused silica (SiO₂), characterized by exceptional thermal, optical, and chemical properties. Quartz glass rods are manufactured through melting high-purity silica at temperatures exceeding 1700°C, resulting in an amorphous material with outstanding performance characteristics for various industrial and scientific applications.

Key Properties of Fused Quartz Rod

Based on the wavelength range they are designed for, quartz rods can be categorized into three main series: visible light series (glass rods), ultraviolet-visible light series (quartz rods), and infrared light series (infrared rods). Fused quartz rods are primarily used in the ultraviolet light range, while glass rods are more commonly used in the visible light range.

Chemical & Thermal Properties

- High strength with fracture modulus exceeding 350MPa for fused silica rods

- Exceptional thermal stability up to 1450°C+ for quartz glass rods

- Superior corrosion resistance against acids, bases, molten salts, and fluorinated gases

- High thermal conductivity (120–160 W/m.K)

Optical Characteristics

- Premium quartz glass rods with transmittance >80% at 200nm wavelength

- Wide wavelength transmission range (120nm-4500nm) with no absorption peaks

- Bubble-free and streak-free composition in premium fused quartz rods

- Precision optical properties with group error ≤0.3%

Mechanical & Processing Features

- Extremely wear-resistant with low friction coefficient for high-flow applications

- Highly customizable wall thickness, length, and bending angles for quartz glass rods

- Excellent electrical insulation properties ideal for specialized applications

- Precise bonding capabilities withstanding multiple atmospheres of pressure

TOQUARTZ® Fused Silica Glass Rod Applications

TOQUARTZ® premium quartz rods serve various industries with their exceptional thermal stability, optical clarity, and chemical resistance properties. TOQUARTZ® products are engineered to meet the demanding requirements of these specialized applications.

Fused Quartz Rod for Optical Instrument Manufacturing

TOQUARTZ® High-purity fused quartz rods are essential components in laser systems, optical windows, and fiber optic components where precise light transmission properties are critical.

- Laser beam delivery systems

- Optical collimators and beam shapers

- Precision optical interfaces

Quartz Glass Rod for Laboratory Equipment Manufacturing

TOQUARTZ® Quartz glass rods provide exceptional performance in high-temperature reactors, heating elements, and crucibles used in laboratory and research environments.

- High-temperature reaction vessels

- Atmosphere protection devices

- Quartz heating tubes and elements

Fused Silica Rod for UV/IR Light Source Manufacturing

TOQUARTZ® Fused Silica rods are integral to UV sterilization lamps and IR heating elements, providing the necessary temperature resistance and optical transmission properties.

- UV sterilization lamp

- IR heating rod housings

- Medical and industrial sterilization equipment

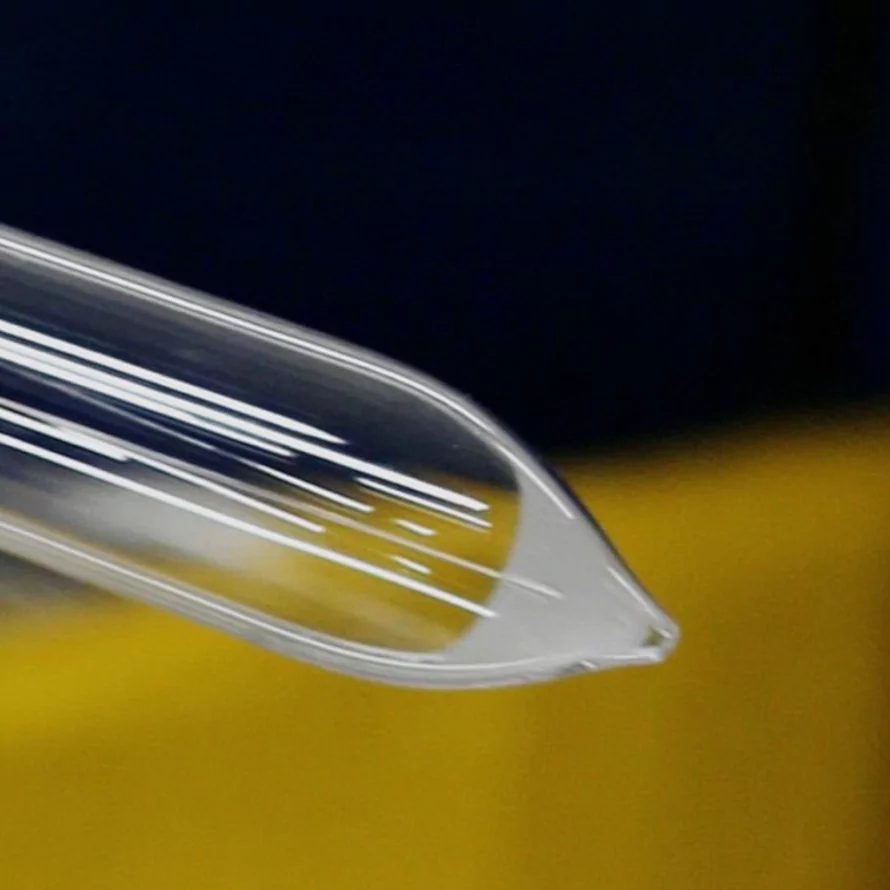

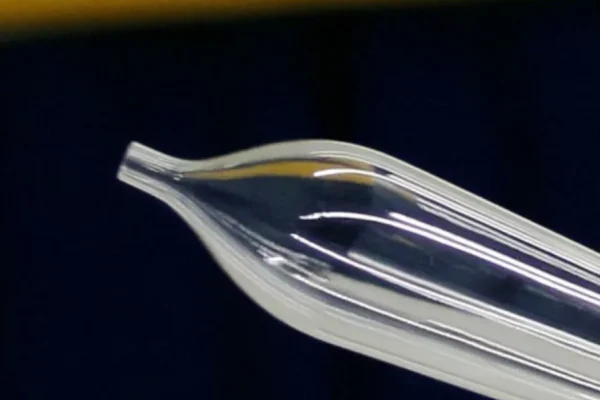

Quartz Rod for Fiber Optic Manufacturing

TOQUARTZ® High-purity quartz fiber preform rods are the essential starting material for drawing optical fibers, requiring exceptional purity, concentricity, and thermal stability.

- Telecommunication fiber drawing

- Specialty fiber manufacturing

- Fiber optic sensor components

Quality Assurance for TOQUARTZ® Fused Silica Glass Rod

At TOQUARTZ, we maintain rigorous quality control standards to ensure our fused quartz rods products meet the highest industry specifications.

ISO-Certified

TOQUARTZ® quartz rod manufacturing processes adhere to ISO quality standards, ensuring consistent product quality.

REACH Compliance

All our quartz glass rods comply with REACH regulations for safe use in various applications.

RoHS Certified

TOQUARTZ® fused quartz rod products meet RoHS standards for environmental safety and compliance.

TOQUARTZ® Quality Control Process for Quartz Rods

Material Inspection

Every batch of raw materials for our fused quartz rods undergoes thorough chemical analysis for purity verification.

Dimensional Testing

Precise dimensional measurements ensure all quartz glass rods meet specified tolerances for your applications.

Optical Transmission Testing

Rigorous optical testing confirms our quartz rods meet transmission specifications across specified wavelength ranges.

Thermal Resistance Verification

Each batch of fused silica rods undergoes thermal stability testing to ensure performance at extreme temperatures.

Surface Quality Inspection

Rigorous visual and instrumental inspection ensures bubble-free, high-quality surfaces on all quartz rod products.

Final Performance Testing

Comprehensive testing of finished quartz glass rods to validate all specified mechanical and optical properties.

TOQUARTZ® Custom Quartz Rod Solutions & Engineering Support

TOQUARTZ® specializes in developing tailored fused silica rod solutions to address your specific technical requirements and solve your most challenging application problems.

Customization Capabilities

Precision Dimensional Customization

TOQUARTZ® manufactures quartz rods to your exact dimensional specifications with tolerances as tight as ±0.1mm for critical applications.

Custom Shapes & Profiles

Beyond standard cylindrical fused quartz rods, we produce square, half-round, and custom profile shapes to fit specialized equipment.

Special Surface Treatments

Custom surface finishes for quartz glass rods, including polished, ground, or specialty etched surfaces for specific optical properties.

Specialized Purity Levels

Production of quartz optical fiber preform rods with purity levels up to 99.995% SiO₂ for sensitive applications requiring minimal impurities.

Engineering Support Process

Technical Consultation

Initial discussion of your application requirements and performance needs for quartz rods.

Design Optimization

TOQUARTZ® engineers review and optimize your designs for manufacturability and performance.

Prototype Development

Rapid production of sample fused silica rods for testing and validation.

Production & Quality Control

Scaled manufacturing with comprehensive QC processes to ensure consistent quality.

How TOQUARTZ® Can Make No MOQ for Quartz Rods Possible

While most manufacturers require large minimum orders for fused quartz rods, TOQUARTZ® has developed an innovative production and inventory system that enables us to efficiently fulfill orders of any size without compromising quality or delivery speed.

Strategic Inventory Management

We maintain extensive stock of standard fused quartz rod sizes and specifications for immediate fulfillment of any order volume.

Flexible Production Capabilities

Our manufacturing processes are optimized for both large-scale production and small custom batches of quartz glass rods.

Efficient Order Processing

Streamlined systems allow us to process orders for fused silica rods of any size with the same attention to detail and quality control.

Quartz Glass Rod Manufacturing Process丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Why Choose TOQUARTZ® for Your Quartz Rod Needs

TOQUARTZ stands apart as a premier supplier of fused silica glass rods with our commitment to quality, customization capabilities, and exceptional service.

Custom Solutions for Every Project

At TOQUARTZ, we specialize in providing tailored quartz rod solutions to meet your exact specifications. Our engineering team works directly with you to understand your application requirements and develop the perfect product.

-

Expert Engineering Support

Our team of product engineers provides technical assistance from design to production for your fused quartz rod projects. -

Drawing Assistance

We help optimize your technical drawings to ensure manufacturability of custom quartz glass rods. -

Prototype Development

Rapid prototype development of specialized fused silica rods for testing before full production.

No Minimum Order Quantity Required

Unlike many suppliers, TOQUARTZ accommodates both small-batch orders and large production runs of fused silica rods. We understand your project needs may vary and we've structured our operations to be flexible.

-

Single Piece Orders Welcome

Order just what you need for R&D, replacement parts, or low-volume production of quartz rods. -

Rapid Shipping on All Orders

Fast 24-hour shipping available on standard quartz glass rod products regardless of order size. -

Volume Discounts Available

Attractive pricing scales for larger orders of fused quartz rods without forcing minimum quantities.

FAQs

Q: What are the maximum temperature limits for TOQUARTZ quartz rods?

A: TOQUARTZ® fused quartz rods can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1450°C. This exceptional thermal stability makes our quartz rods ideal for high-temperature applications in various industries.

Q: Can TOQUARTZ® provide custom dimensions for quartz glass rods?

A: Yes, TOQUARTZ® specializes in custom quartz rod manufacturing. We can produce quartz glass rods to your exact specifications, including custom diameters, lengths, shapes, and surface finishes. Our engineering team can work from your drawings or collaborate to develop specifications.

Q: Can TOQUARTZ® provide quartz rods for UV light transmission applications?

A: Yes, TOQUARTZ® offers specialized quartz rods with excellent UV transmission properties. Our high-purity fused silica rods provide superior transmission in the UV spectrum, making them ideal for UV sterilization, analytical instruments, and UV curing applications.

Q: What shapes of quartz rods does TOQUARTZ® offer?

A: TOQUARTZ® manufactures quartz glass rods in various shapes, including cylindrical rods, square rods, half-round rods, and custom profiles. Our versatile manufacturing capabilities allow us to produce quartz rods in almost any cross-sectional shape required for your application.

Q: Does TOQUARTZ® offer bulk pricing for large quartz rod orders?

A: Yes, TOQUARTZ® offers volume-based pricing tiers for bulk orders of quartz rods. Our pricing structure provides cost advantages for larger quantities while maintaining our no-MOQ policy for customers who need smaller amounts of fused quartz rods.

Q: How to cut quartz rod?

A: Cutting a quartz rod, especially a high-purity fused silica rod, requires specialized tools and techniques to avoid cracking or contamination. The most common method is using a diamond saw or laser cutter under controlled conditions. For best results:

· Use a water-cooled diamond blade to minimize thermal stress.

· Secure the fused silica rod firmly to prevent vibration.

· Cut slowly and evenly to avoid microfractures.

· After cutting, polish or flame-finish the ends if optical clarity is required.

Q: How do TOQUARTZ® quartz rods perform in corrosive environments?

A: TOQUARTZ® quartz glass rods exhibit exceptional resistance to most acids, bases, and corrosive chemicals. They are stable in contact with molten salts and fluorinated gases, making our quartz rods ideal for harsh chemical environments in laboratory and industrial settings.

Q: Can TOQUARTZ® manufacture quartz fiber preform rods?

A: Yes, TOQUARTZ® specializes in manufacturing high-purity quartz fiber preform rods for optical fiber drawing applications. Our preforms feature exceptional purity, homogeneity, and precise dimensional control to support both telecommunication and specialty fiber production.

Ready to Source High-Quality Quartz Rods?

Contact TOQUARTZ today to discuss your quartz glass rod requirements. Our team is ready to provide expert assistance and competitive quotes.

- Direct factory pricing with no intermediaries

- Expert engineering support for custom designs

- No minimum order quantity requirements

- Fast delivery with 24-hour shipping for stock items

- Comprehensive supply chain management services