Custom Premium Quartz Plates

Factory-direct high-purity quartz plates with exceptional thermal stability, optical clarity & chemical resistance

- 99.98% SiO₂ Purity (max. up to 99.995%)

- Custom Sizes Available

- No Minimum Order

TOQUARTZ® Quartz Plate Product Range

TOQUARTZ® offers an extensive selection of standard and custom quartz plates to meet diverse application requirements across industries.

What Is a Quartz Plate?

A quartz plate is a high-purity silica glass sheet manufactured from fused silica (SiO₂) with exceptional thermal, optical, and chemical properties. Unlike conventional glass, quartz plates offer superior performance in extreme environments, making them ideal for scientific, industrial, and optical applications requiring precision and durability.

Outstanding Properties of Fused Quartz Plate

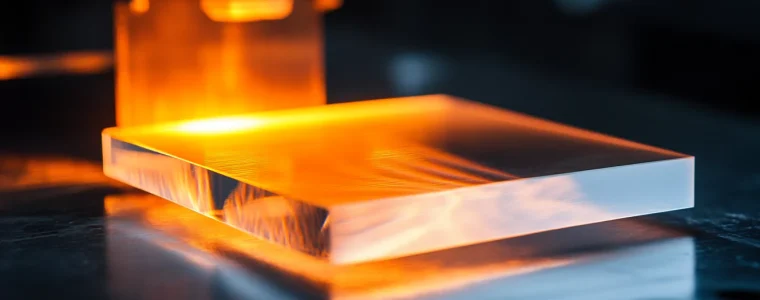

Exceptional Thermal Stability

TOQUARTZ® quartz plates can withstand continuous operation at 1100°C and short-term exposure up to 1450°C. With a low thermal expansion coefficient, they resist thermal shock and maintain dimensional stability under extreme temperature fluctuations.

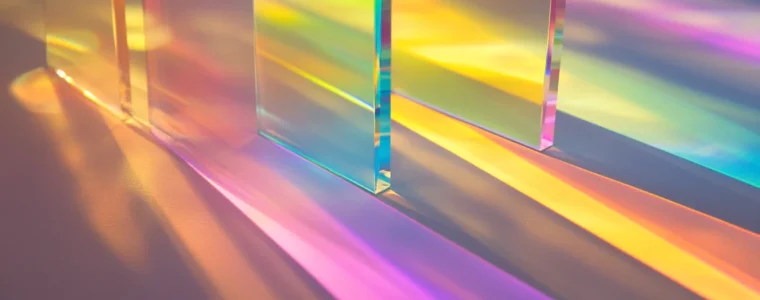

Superior Optical Transmission

Our quartz plates deliver excellent transparency across UV to IR spectrum. They provide >93% transmission in visible light range and >80% in UV spectrum, making them perfect for optical windows, UV applications, and precision instruments.

Impressive Chemical Resistance

Quartz plates exhibit exceptional resistance to almost all acids, bases, and corrosive substances (except hydrofluoric acid). This chemical inertness makes them ideal for laboratory equipment, chemical processing, and harsh environment applications.

High Mechanical Strength

With a fracture modulus exceeding 350MPa, our quartz plates offer superior durability and mechanical integrity. Their low friction coefficient ensures extended service life in high-flow applications and demanding mechanical environments.

Fused Silica Plate Applications

TOQUARTZ® high-purity quartz plates serve critical functions across multiple industries where precision, thermal stability, and optical clarity are paramount.

Fused Quartz Plate in Laboratory Equipment

TOQUARTZ® quartz plates are essential components in analytical instruments, microscopy platforms, and chemical reaction vessels where material stability and optical clarity are critical.

- Quartz petri dishes for controlled experiments

- Quartz sample holders for spectroscopy

- Quartz sheet for analytical processes

- Quartz sight plate for reaction chamber windows

Quartz Glass Plate for Optical & UV Applications

Quartz plates excel in UV sterilization systems, photolithography equipment, and optical instruments requiring high transmission across broad wavelength ranges.

- UV lamp windows and shields

- Optical filters and beam splitters

- Photomask substrates

- Laser system components

Industrial Fused Quartz Plate Parts for Industrial & Thermal Processing

High-temperature applications rely on quartz plates for their exceptional thermal stability and resistance to thermal shock in furnaces and heating systems.

- Infrared heating windows

- High-temperature sight glasses

- Furnace viewports

- Thermal insulation barriers

Quartz Glass Plate Specifications & Quality

TOQUARTZ® quartz plates meet rigorous quality standards with ISO certification, REACH compliance, and RoHS certification, ensuring consistent performance for demanding applications.

Technical Specifications

| Property | Specification |

| Material Purity | ≥99.98% SiO₂(max. up to 99.995%) |

| Standard Thickness Range | 0.5mm – 100mm |

| Surface Flatness | ≤0.02mm per 100mm |

| Visible Light Transmission | ≥93% (at 2mm thickness) |

| UV Transmission (254nm) | ≥80% (at 2mm thickness) |

| Maximum Working Temperature | 1100°C (continuous), 1450°C (short-term) |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷/K |

| Electrical Resistivity | >10⁷ Ω·m |

| * Custom specifications available upon request | |

Quality Assurance

ISO 9001:2015 Certified

Our manufacturing processes adhere to rigorous quality management standards, ensuring consistent product quality and customer satisfaction.

REACH Compliant

All TOQUARTZ® quartz plates comply with EU REACH regulations, ensuring they’re free from harmful substances and safe for global distribution.

RoHS Certified

Our products meet RoHS standards, confirming they’re free from restricted hazardous substances and environmentally responsible.

TOQUARTZ Quality Control

AI-Powered Raw Material Vetting

Eliminate impurity risks in high-purity quartz sand (99.98% SiO₂ baseline, max. up to 99.995% )

Real-Time Process Optimization

Maintain precise dimensional tolerance during forming process

Multi-Axis Performance Validation

Ensure functionality under extreme operating conditions

Traceable Compliance Documentation

Guarantee material traceability for critical applications

Customer-Centric Quality Proofing

Align validation methods with client-specific operational demands

TOQUARTZ® Quartz Plate Customization: Capabilities & Engineering Support

TOQUARTZ® specializes in custom quartz plate manufacturing to meet your exact specifications, with no minimum order quantity requirements.

Precision Engineering Support

Our engineering team works directly with your technical staff to interpret drawings and optimize designs for manufacturability, reducing sample failure rates by over 70% compared to industry averages.

Flexible Dimensions & Tolerances

We accommodate custom sizes with precision tolerances down to ±0.1mm for most applications, with select capabilities for ±0.05mm tolerance for high-precision optical components.

Specialized Surface Treatments

Options include polished, ground, or etched surfaces according to your application requirements, with surface roughness control for optical and mechanical applications.

Rapid Prototyping

Initial samples delivered in just 5-7 days, allowing you to validate designs quickly and proceed to production with confidence. This rapid turnaround has helped clients meet critical project deadlines.

No Minimum Order Quantity

Whether you need a single prototype or thousands of production units, we accommodate orders of any size without MOQ restrictions, making us ideal for specialized equipment manufacturers.

How We Offer Premium Fused Silica Plates With No MOQ

TOQUARTZ® has optimized our manufacturing processes to efficiently produce both small and large orders without compromising on quality or delivery times.

Efficient Production Scheduling

We've developed a dynamic production scheduling system that combines similar material orders, allowing us to process small batches alongside larger runs without efficiency loss.

Extensive Raw Material Inventory

We maintain comprehensive stock of various thickness quartz blanks, eliminating long lead times typically associated with small orders and enabling rapid production starts.

Modular Manufacturing Equipment

Our production line features quick-change tooling and modular setups that minimize changeover times between different product specifications, making small runs economically viable.

Specialized Small-Batch Processing Team

We've established a dedicated team specifically trained in small-batch and prototype production, ensuring these orders receive the same attention to quality as large production runs.

Long-Term Partnership Focus

We view small initial orders as the beginning of valuable long-term relationships. Our data shows that 78% of customers who start with small orders become regular clients within 6 months.

Fused Quartz Products Fabrication Processing丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Why Choose TOQUARTZ® for Fused Quartz Plates

Partner with TOQUARTZ® for superior quality, flexible ordering, and exceptional service that keeps your projects on schedule and within budget.

Factory-Direct Pricing

As a manufacturer, we eliminate middlemen markups, offering premium quartz plates at competitive prices while maintaining exceptional quality standards.

Rapid Delivery

With extensive inventory of standard sizes and efficient production capabilities, we deliver standard products within 24 hours and custom orders in just 10-15 days.

No Minimum Orders

Unlike competitors requiring large minimum purchases, we accept orders of any size, making us ideal for specialized projects and small-batch production needs.

Engineering Support

Our technical team provides comprehensive drawing assistance and material selection guidance, ensuring your specifications are optimized for performance and manufacturability.

Consistent Quality

Our rigorous quality control processes ensure dimensional accuracy and material consistency across batches, reducing your assembly issues and product failures.

Responsive Communication

Our English-proficient technical team provides prompt responses to inquiries, typically within 24 hours, ensuring clear communication throughout your project.

FAQs

Q: What is the difference between quartz plates and regular glass plates?

A: TOQUARTZ® quartz plates are made from high-purity fused silica (SiO₂), offering superior thermal resistance (up to 1100°C continuous use), excellent UV transmission, exceptional chemical resistance, and lower thermal expansion compared to conventional glass. These properties make quartz plates ideal for high-temperature, optical, and laboratory applications where standard glass would fail.

Q: What is the minimum order quantity (MOQ) for custom quartz plates?

A: TOQUARTZ® has no minimum order quantity requirement. We accept orders for single pieces, small batches, or large production runs. Our flexible manufacturing process allows us to efficiently produce custom quartz plates in any quantity while maintaining consistent quality and competitive pricing.

Q: Can TOQUARTZ® produce quartz plates with holes, slots, or other features?

A: Yes, we offer comprehensive machining capabilities for quartz plates, including precision drilling, slotting, edge profiling, and custom shapes. We can produce plates with multiple holes, complex cutouts, beveled edges, and other specialized features according to your engineering drawings or specifications.

Q: What is the maximum temperature that quartz plates can withstand?

A: TOQUARTZ® quartz plates can withstand continuous operation at temperatures up to 1100°C and short-term exposure up to 1450°C. They maintain dimensional stability and mechanical integrity even under rapid temperature changes, making them ideal for high-temperature applications where conventional materials would deform or fail.

Q: Are TOQUARTZ® quartz plates suitable for UV applications?

A: Yes, our high-purity quartz plates offer excellent UV transmission properties, with typical transmission rates exceeding 80% in the UV spectrum (254nm) and over 93% in the visible light range. This makes them ideal for UV sterilization equipment, photolithography, spectroscopy, and other UV-dependent applications.

Q: What is the difference between clear quartz plates and milky quartz plates?

A: Clear quartz plates (fused silica) offer excellent optical transparency across UV to IR spectrums, making them ideal for optical applications. Milky quartz (microcrystalline) plates have a translucent white appearance and provide superior thermal shock resistance, making them preferred for certain high-temperature applications where optical clarity is less important than thermal performance.

Q: How should quartz plates be cleaned and maintained?

A: Clean TOQUARTZ® quartz plates using mild detergent solutions, followed by rinsing with deionized water and isopropyl alcohol. Avoid hydrofluoric acid, which can etch quartz. For optical applications, use lint-free wipes and avoid abrasive materials. Store plates in clean, dust-free environments to maintain optical and surface properties.

Q:Can TOQUARTZ® produce quartz plates with anti-reflection coatings?

A: While we specialize in manufacturing high-quality base quartz plates, we can coordinate with trusted partners to provide anti-reflection coatings and other specialized optical treatments. Please specify your coating requirements when inquiring, and we’ll provide appropriate solutions or recommendations.

Contact Us for Premium Quartz Plates Today

Ready to discuss your quartz plate requirements? Our technical team is standing by to provide expert guidance, custom solutions, and competitive quotes.