- Home

- /

- Types

- /

- Quartz Rod

- /

- Premium Quartz Optical Fiber...

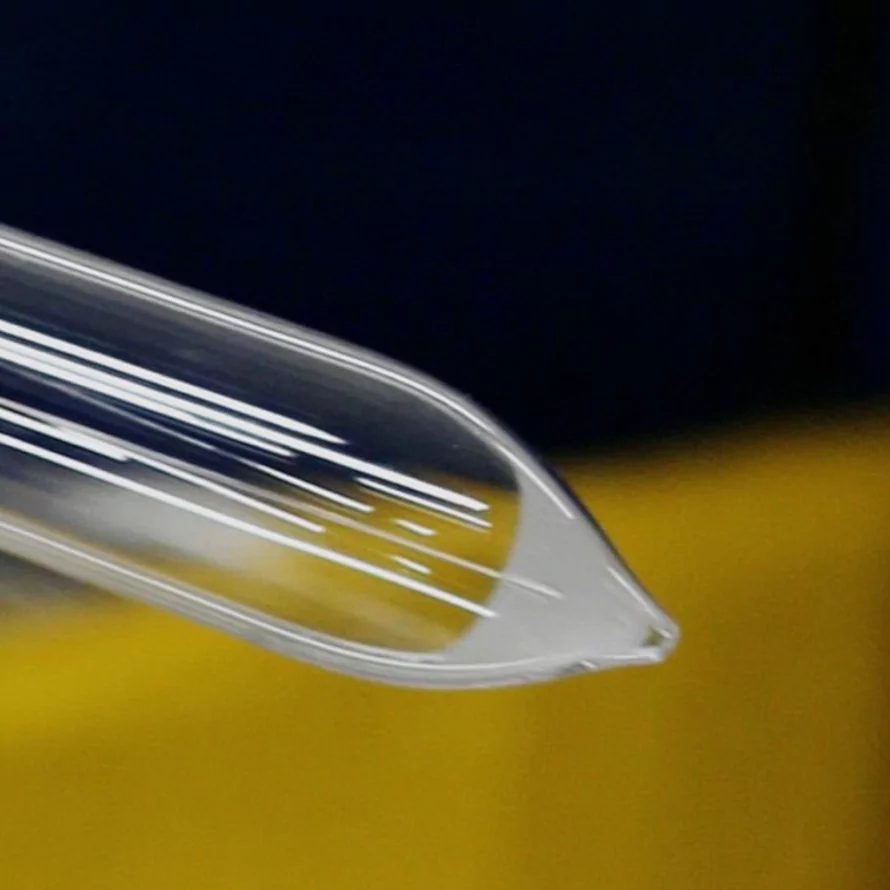

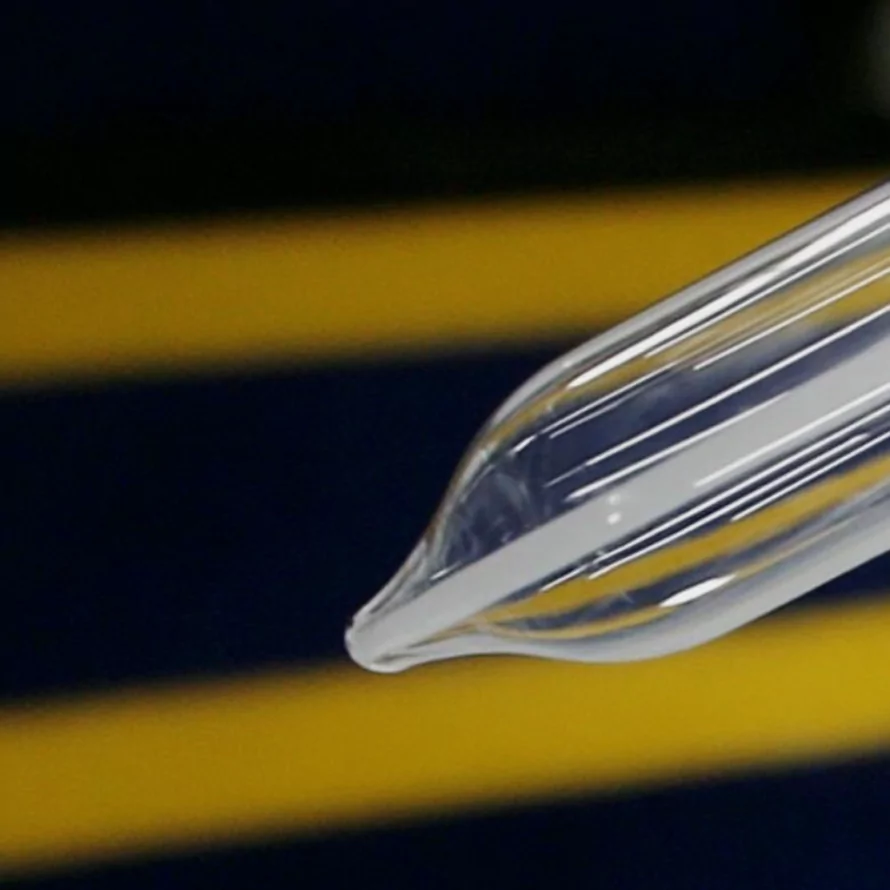

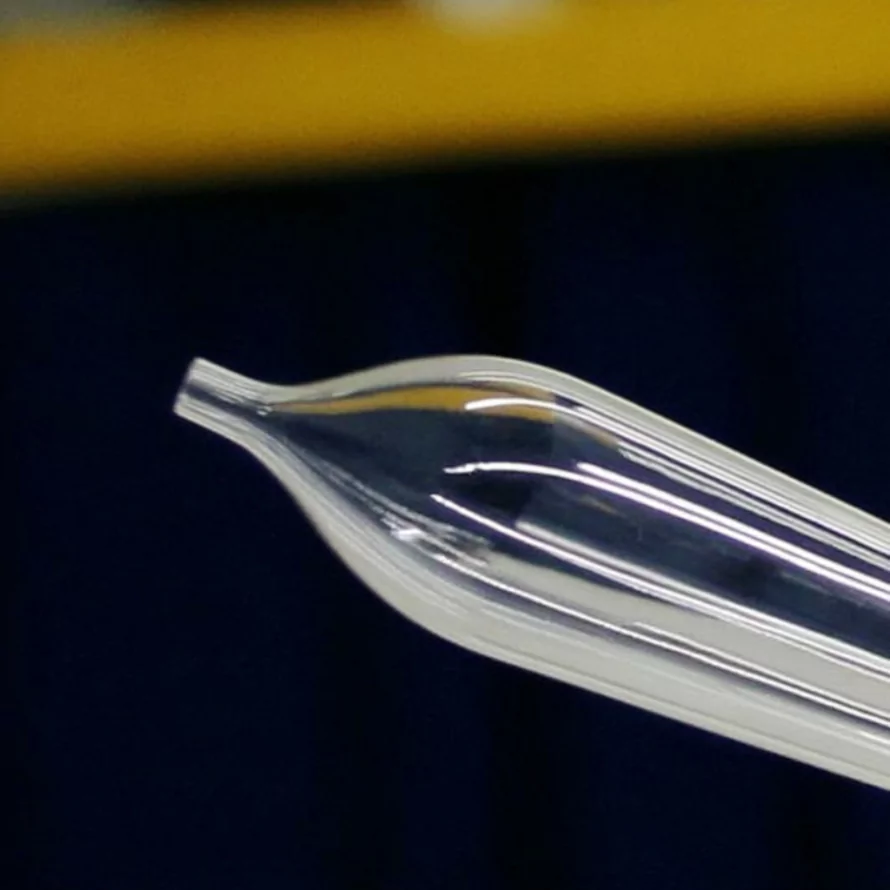

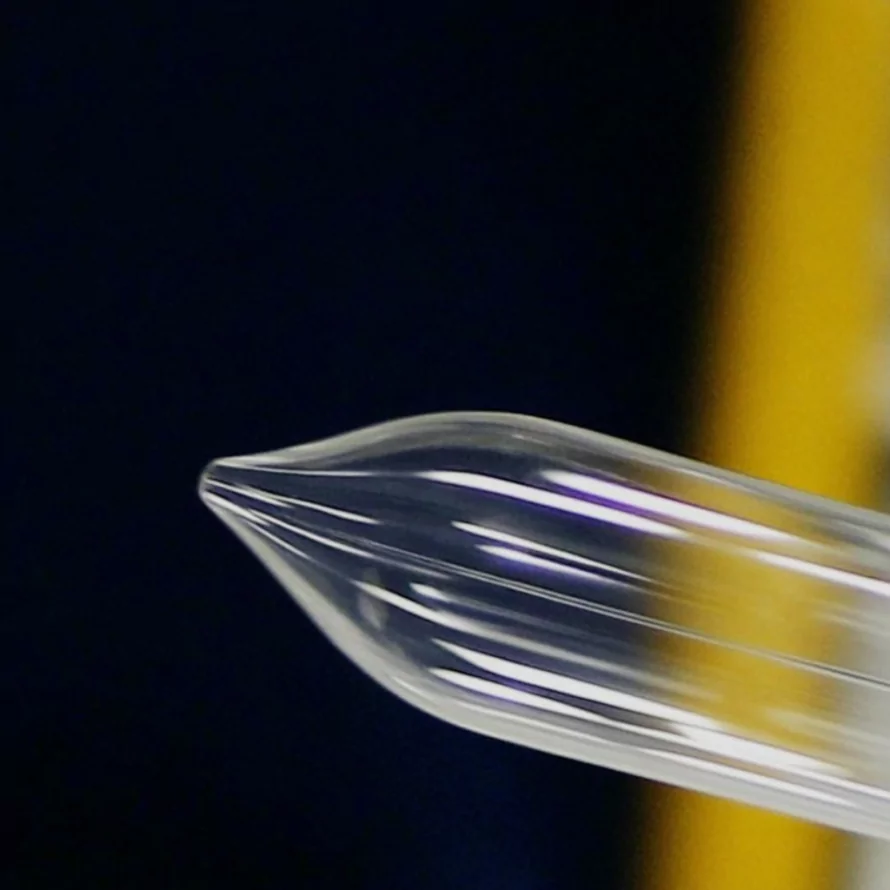

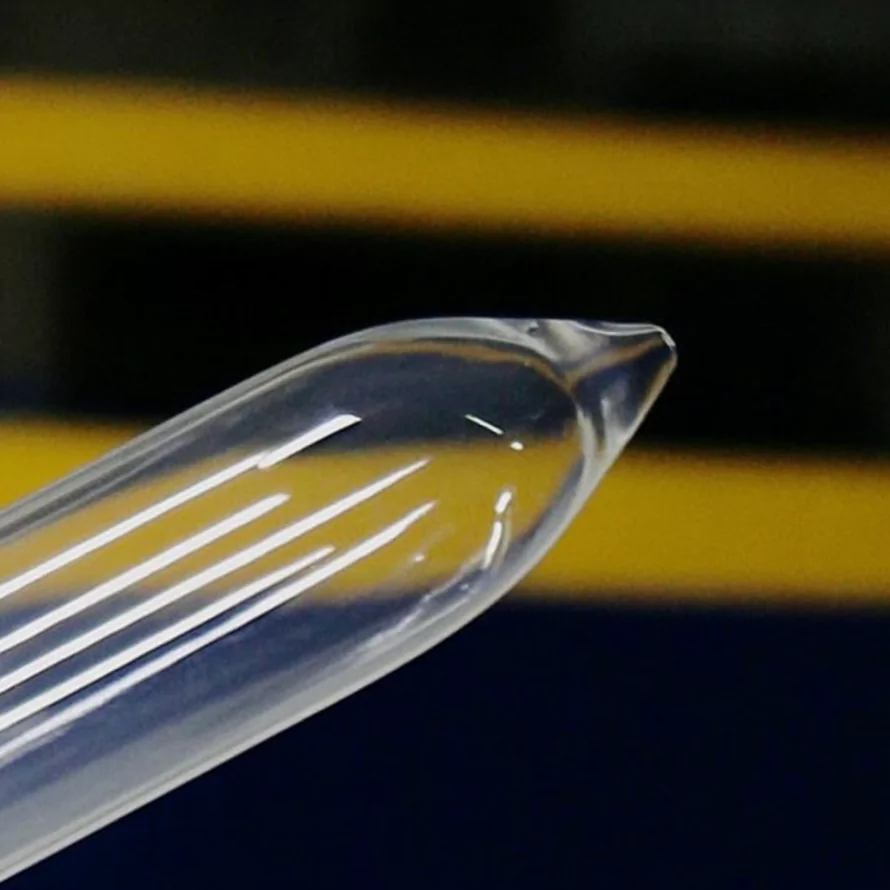

Premium Quartz Optical Fiber Preform Rod for Fiber Drawing -TOQUARTZ®

With 99.98%+ SiO₂ purity, these optical grade quartz rods deliver exceptional light transmission, thermal stability, and dimensional precision needed for demanding fiber optic manufacturing processes.

Features of Fused Quartz Optical Fiber Preform Rod

Mechanical Strength

With a fracture modulus exceeding 350MPa, our fused quartz rods offer exceptional durability and handling characteristics during the fiber drawing process. This strength ensures stability and consistency during manufacturing operations.

Optical Transparency

TOQUARTZ® fused quartz optical fiber preform rods feature >90% transmission across 200-2500nm wavelength range, ideal for telecommunications and specialty fiber applications. The high optical clarity ensures minimal signal loss in the final fiber product.

Thermal Stability

With a softening point of approximately 1730°C, our quartz optical fiber preform rods can withstand extended use at 1100°C and short-term exposure up to 1450°C. The low thermal expansion coefficient (5.5×10⁻⁷ /°C) ensures dimensional stability during the fiber drawing process.

High Chemical Purity

With ≥99.98%+(max. up to 99.995%) SiO₂ content, our quartz rods ensure minimal impurities that could affect fiber transmission characteristics. The material exhibits excellent resistance to acids, alkalis, molten salts, and fluorinated gases, crucial for various fiber optic applications.

- High Purity: ≥99.98%+ SiO₂ content

- Tight tolerance control (±0.1mm)

- Customizable

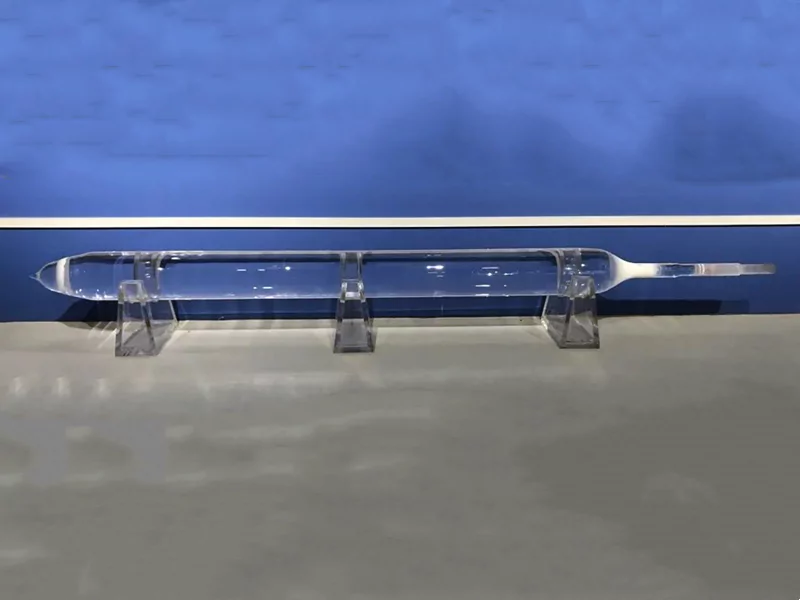

Technical Specifications & Dimension of Quartz Glass

Optical Fiber Preform Rods

Technical Specifications of Quartz Glass Optical Fiber Preform Rods

Geometric Properties

| Property | Specification |

| Preform Outer Diameter (O.D.) | 130-150 (±5) [mm] |

| Tolerance of O.D. | ≤5 [mm] |

| Effective Length | ≥1600 [mm] |

| Effective Weight | ≥45 [Kg] |

| Non-circularity | ≤1% |

| Core/Cladding Concentricity Error | ≤0.5 [mm] |

| Bow | ≤1.0 [mm/m] |

Physical Properties

| Property | Value |

| Density | 2.2 g/cm³ |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C |

| Thermal Conductivity | 1.4 W/(m·K) |

| Softening Point | ~1730°C |

| Annealing Point | ~1215°C |

| Working Temperature (long-term) | ≤1100°C |

| Working Temperature (short-term) | ≤1450°C |

| Mechanical Strength (Fracture Modulus) | ≥350 MPa |

Optical Properties of Drawn Fiber (G.652.D Standard)

| Property | Specification |

| 1310nm Attenuation | ≤0.344 [dB/km] |

| 1383nm Attenuation | ≤0.344 [dB/km] |

| 1550nm Attenuation | ≤0.204 [dB/km] |

| 1625nm Attenuation | ≤0.244 [dB/km] |

| 1285-1339nm Dispersion | ≤3.5 [ps/(nm·km)] |

| Zero Dispersion Wavelength | 1312±12.4 [nm] |

| 1310nm Mode Field Diameter (MFD) | 9.2±0.44 [μm] |

| 1550nm Mode Field Diameter (MFD) | 10.4±0.8 [μm] |

Size of Fused Quartz Optical Fiber Preform Rods

| Model | Diameter (mm) | Length (mm) | Notes |

| AT-SIO-OF001 | 130 | 1500~3000 | Typical value |

| AT-SIO-OF002 | 150 | 1500~3000 | Typical value |

| AT-SIO-OF003 | 180 | 1500~3000 | Typical value |

| AT-SIO-OF004 | 200 | 1500~3000 | Typical value |

| AT-SIO-OF005 | 80~190 | 1000~3000 | Custom sizes |

TOQUARTZ® Solving Critical Challenges with Fused Silica

Optical Fiber Preform Rods

Quartz Glass Optical Fiber Preform Rods for Telecommunications Infrastructure

Quality inconsistencies in preform rods directly impact fiber drawing efficiency and result in high rejection rates, affecting production schedules and costs.

Key Advantages

-

Ultra-low OH Content for Signal Clarity

<20 ppm OH content ensures minimal attenuation at 1383nm, critical for G.652.D fiber performance. -

Batch-to-Batch Refractive Index Uniformity

Refractive index variation <0.0003 across batches ensures consistent fiber geometry and signal dispersion. -

Bubble-Free Cladding Zone (≤0.5mm)

Strict control of cladding bubble size and count (≤8/meter for 0.5–1.0mm) reduces fiber breakage during high-speed drawing.

TOQUARTZ® solution

A German Tier-1 telecom fiber manufacturer faced 14% fiber rejection due to OH peaks at 1383nm and inconsistent RI profiles.

TOQUARTZ® delivered preforms with <20 ppm OH and RI deviation <0.0003, reducing rejection to 2.1% and improving draw yield by 11.6%.

This enabled the client to meet a 6-week delivery deadline for a 5G infrastructure project, avoiding €18,000 in late penalties.

The customer has since adopted TOQUARTZ as a preferred supplier for all G.652.D fiber preforms.

Fused Quartz Optical Fiber Preform Rods for Specialty Fiber Research

Traditional suppliers often have long lead times for custom preforms, delaying critical research timelines and increasing project costs.

Key Advantages

-

Custom Dopant Integration (Er, Yb, Ge, P)

Supports rare-earth and index-modifying dopants with ±0.1 mol% precision for experimental fiber development. -

Rapid Prototyping Lead Time (≤3 Weeks)

Custom preforms delivered in ≤21 days from drawing approval, enabling agile research iteration. -

Precision Core/Cladding Ratio Control

CCDR tolerance within ±1.5% ensures accurate mode field diameter for specialty fiber testing.

TOQUARTZ® solution

A Japanese photonics lab developing erbium-doped fibers for medical lasers faced 8-week delays from local suppliers.

TOQUARTZ® delivered 3 custom-doped preforms (Er³⁺, CCDR 0.42) in 17 days, enabling on-time submission of a national grant prototype.

The lab reported 98.7% dopant uniformity and <0.2 dB/km attenuation at 1550nm in test fibers.

This accelerated their R&D cycle by 5 weeks and secured ¥12M in follow-up funding.

Fused Silica Optical Fiber Preform Rods for Industrial Sensing Applications

Supply disruptions and inconsistent material properties directly impact sensor performance and reliability.

Key Advantages

-

Thermal Stability in Harsh Environments

Withstands continuous operation at 1100°C and short-term peaks at 1450°C, ideal for oil & gas or aerospace sensors. -

Low Dopant Diffusion for Long-Term Accuracy

Dopant migration <0.05% over 1000 hours at 900°C ensures stable sensor calibration over time. -

Just-in-Time Stocking Program

Supports monthly delivery scheduling with ≤2% variance in RI and geometry, reducing inventory risk.

TOQUARTZ® solution

A U.S. fiber sensor OEM for oilfield monitoring experienced $25,000 losses from a 2-week line halt due to supplier delay.

TOQUARTZ® implemented a JIT program with monthly delivery of 10 preforms (RI deviation <0.0002, OD ±0.1mm).

Sensor drift tests showed <0.03% deviation after 1200 hours at 950°C, exceeding client specs.

The client reduced buffer stock by 40% and improved delivery reliability to 98.5% over 6 months.

TOQUARTZ® Customization Options for Fused Quartz Glass

Optical Fiber Preform Rods

Custom Specifications of Quartz Optical Fiber Preform Rod

Dimensional Parameters

- Custom outer diameters (80-190mm)

- Adjustable preform length (1000-3000mm)

- Specialized end tapers and geometries

Material Specifications

- Numerical aperture (NA) optimization

- Core-cladding diameter ratio (CCDR)

- Refractive index profiles (step or graded)

Core Doping Options

Customize core material composition with various dopants to achieve specific optical properties for your application requirements.

- Germanium doping (GeO₂)

- Phosphorus doping (P₂O₅)

- Rare earth elements (Er, Yb, Nd)

Refractive Index Profiles

Select from various refractive index profiles to optimize mode field diameter, dispersion, and other optical characteristics.

- Step-index profiles

- Graded-index profiles

- Custom index profiles for specialty fibers

Quality Control Options

Choose from enhanced quality control procedures to ensure your preforms meet or exceed your fiber manufacturing specifications.

- Enhanced surface inspection

- Tighter dimensional tolerances

- Detailed material composition analysis

Usage Guide of Quartz Glass Optical Fiber Preform Rods

Handling Procedures

- Always wear powder-free gloves when handling optical preforms to avoid contamination

- Use dedicated tools and fixtures designed for quartz preform handling

- Avoid contact with other materials that may cause surface scratches

- Maintain a clean environment with HEPA filtration during handling

Storage Recommendations

- Store in original packaging in a clean, dry environment

- Maintain controlled temperature (20-25°C) and humidity (<50%)

- Use dedicated storage racks with soft contact points

- Avoid exposure to sunlight and UV radiation

Preparation for Drawing

- Clean preforms using isopropyl alcohol and lint-free wipes

- Conduct visual inspection under controlled lighting

- Allow preform to reach room temperature if stored in cooler conditions

- For best results, follow manufacturer-recommended preheating protocol

Optimal Drawing Parameters

- Recommended furnace temperature: 1900-2100°C (varies by preform composition)

- Optimize feed rate based on preform diameter and desired fiber dimensions

- Maintain consistent drawing tension for uniform fiber diameter

- Consult with TOQUARTZ engineers for specific recommendations based on your drawing tower configuration

Ready to Discuss Your Custom Quartz Optical Fiber Preform Requirements?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How do I determine the right quartz optical fiber preform rod specifications for my application?

A: Selecting the right preform specifications depends on several factors including your target fiber dimensions, optical requirements, and drawing equipment capabilities. Key parameters to consider include the numerical aperture (NA), core-cladding diameter ratio (CCDR), outer diameter, and desired refractive index profile. Our engineering team can help you determine the optimal preform specifications based on your end-use requirements and provide technical guidance throughout the selection process.

Q: How do I ensure the quartz optical fiber preform rod will produce fibers with low attenuation?

A: Low fiber attenuation starts with high-quality preforms. Key factors include: 1) High material purity (≥99.995% SiO₂) to minimize impurity-related absorption, 2) Low hydroxyl (OH) content to reduce absorption peaks, 3) Minimal bubble and inclusion defects to reduce scattering losses, 4) Proper core-cladding interface quality, and 5) Controlled dopant distribution. Our preforms are manufactured with strict quality control to ensure these parameters are optimized for low-loss fiber production.

Q: What is the typical yield when drawing fiber from your quartz optical fiber preform rods?

A: Yield depends on several factors including preform quality, drawing equipment, and operator expertise. With TOQUARTZ® preform rods, customers typically achieve yields of 85-95% usable fiber length from the theoretical maximum. Our controlled manufacturing process minimizes defects that could cause fiber breaks during drawing. For optimal yields, we recommend following our handling and preparation guidelines and maintaining proper drawing tower calibration and environmental controls.

Q: What is the maximum temperature quartz optical fiber preform rods can withstand during drawing?

A: TOQUARTZ® fused silica preform rods can withstand the high temperatures required for fiber drawing, typically 1900-2200°C in the drawing furnace hot zone. The softening point of the material is approximately 1730°C, and it becomes sufficiently viscous for fiber drawing at temperatures above this. The exact optimal drawing temperature will depend on the specific preform composition, dopants, and desired fiber drawing parameters.

Q: How do I calculate the fiber length that can be drawn from a specific quartz optical fiber preform rod?

A: The theoretical fiber length can be calculated using the formula: L = (D_preform/D_fiber)² × L_preform, where L is length, and D is diameter. For example, a 150mm diameter, 1000mm long preform drawn to a 125μm fiber could theoretically yield approximately 1,440 kilometers of fiber. However, practical yields are typically 85-95% of this theoretical maximum due to setup losses, end effects, and potential breaks during drawing.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.