Laboratory-Grade Quartz Bottles For Critical Research Applications

TOQUARTZ® Premium laboratory containers with superior thermal stability, exceptional chemical resistance, and customization flexibility for research professionals.

- No Minimum Orders

- Thermal Stability to 1200°C

- Custom Design Support

TOQUARTZ® Quartz Boat Product Range

TOQUARTZ® offers a comprehensive range of high-quality fused quartz boats for various industrial applications, from standard models to fully customized solutions.

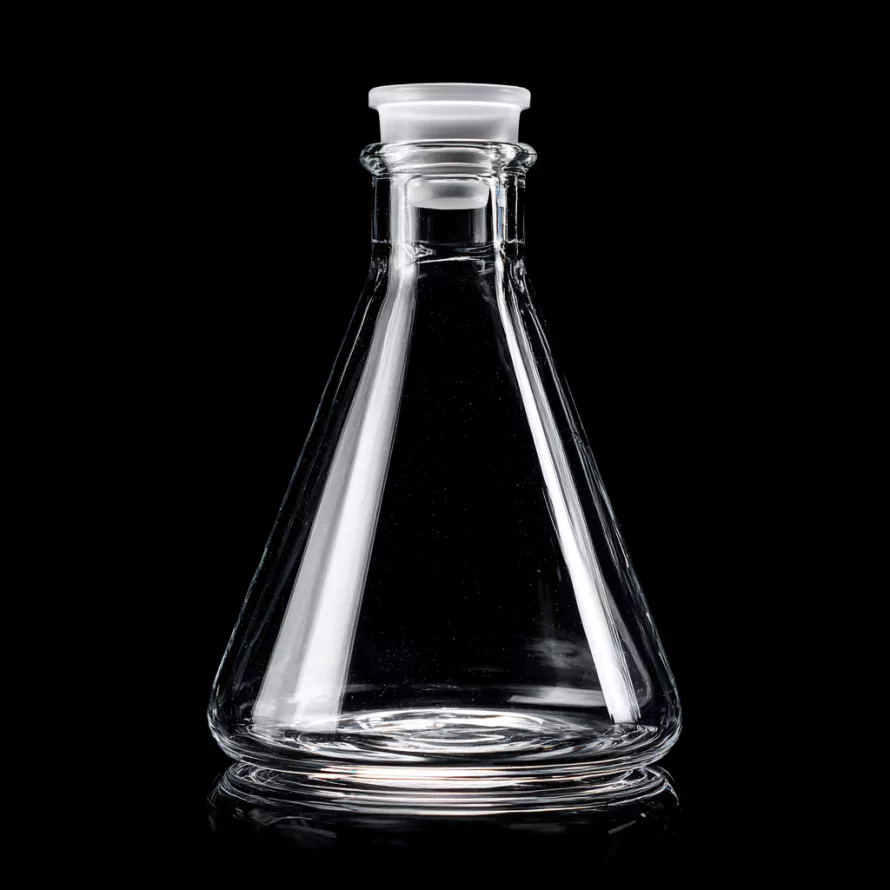

What Is a Quartz Lab Bottle

A quartz lab bottle is a laboratory container made from high-purity fused silica (SiO₂), designed for storing, mixing, and processing materials under extreme conditions. Unlike standard glass labware, quartz lab bottles offer exceptional thermal stability, chemical resistance, and purity for specialized scientific applications.

Key Characteristics of TOQUARTZ® Quartz Laboratory Bottles

TOQUARTZ® Quartz laboratory bottles offer exceptional thermal resistance, chemical stability, and high purity, making them ideal for demanding scientific applications.

Thermal Properties

TOQUARTZ® lab-grade quartz bottles withstand temperatures exceeding 1200°C with minimal thermal expansion (5.5×10⁻⁷/°C), making them ideal for high-temperature reactions and thermal shock applications where conventional glassware would fail.

Chemical Resistance

TOQUARTZ® fused quartz bottle labware remains stable against acids, alkalis, molten salts, and fluoride gases, providing reliable performance in aggressive chemical environments where material integrity is critical.

High Purity Material

The high purity quartz bottles contain ≥99.99% SiO₂, ensuring minimal contamination risk for sensitive experiments and research applications requiring controlled environments.

Low Thermal Expansion

With thermal conductivity of 120–160 W/m·K, our quartz laboratory grade bottles provide efficient heat transfer while maintaining dimensional stability, critical for controlled experimental conditions.

TOQUARTZ® Fused Quartz Lab Bottles Applications

Quartz lab bottles are used across high-temperature reactions, corrosive chemical storage, and ultra-pure sample preparation in advanced research environments.

Lab-grade Quartz Bottle for High-Temperature Chemical Reactions

Quartz lab bottles, particularly flask variants, serve as ideal reaction vessels for high-temperature synthesis processes in material science and chemical research, where thermal stability up to 1200°C is essential.

High Purity Quartz Bottle for Corrosive Reagent Storage

Quartz reagent bottles and threaded quartz bottles provide safe, non-contaminating storage for highly corrosive chemicals such as hydrofluoric acid, concentrated acids, and aggressive solvents that would damage conventional containers.

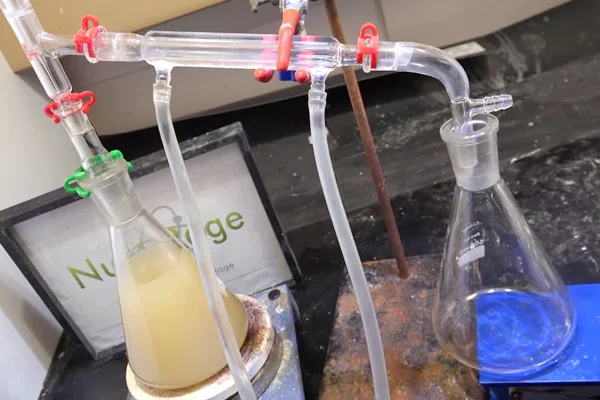

Quartz Glass Bottle for Controlled Atmosphere Experiments

Quartz source bottles and specialized custom quartz labware enable precise gas-phase reactions and atmosphere-controlled experiments essential for developing advanced materials and studying reaction kinetics.

Fused Quartz Labware Bottle for Sample Preparation & Analysis

Quartz beakers and wide mouth quartz bottles provide contamination-free environments for preparing ultra-pure samples in trace element analysis, environmental monitoring, and quality control applications where material purity is para

Quartz Lab Bottle for Waste Collection & Containment

Quartz waste bottles provide safe containment for reactive byproducts, aggressive waste streams, and hazardous materials that require chemical stability and thermal resistance for safe handling and temporary storage.

Quality Assurance for TOQUARTZ® Lab-Grade Quartz Bottles

TOQUARTZ® quartz bottle products meet rigorous quality standards to ensure consistent performance in demanding laboratory environments.

ISO Certified

TOQUARTZ® manufacturing processes adhere to ISO 9001 quality management standards, ensuring consistent product quality.

REACH Compliant

TOQUARTZ® quartz laboratory products comply with REACH regulations for safe use in research and industrial applications.

RoHS Certified

TOQUARTZ® products meet RoHS standards, ensuring they’re free from restricted hazardous substances.

TOQUARTZ Quality Control

AI-Powered Raw Material Vetting

Eliminate impurity risks in high-purity quartz sand (99.98% SiO₂ baseline, max. up to 99.995% )

Real-Time Process Optimization

Maintain precise dimensional tolerance during forming process

Multi-Axis Performance Validation

Ensure functionality under extreme operating conditions

Traceable Compliance Documentation

Guarantee material traceability for critical applications

Customer-Centric Quality Proofing

Align validation methods with client-specific operational demands

TOQUARTZ®Custom Quartz Bottle Solutions & Services

TOQUARTZ® offers comprehensive customization capabilities to meet your specific quartz bottle requirements with precision and expertise.

Engineering & Design Support

TOQUARTZ® technical team provides expert guidance throughout your custom fused quartz bottle labware project, addressing the specific challenges that German, Japanese, and American laboratories have reported with other suppliers.

-

Technical Drawing Assistance

Our engineers help refine your concepts into manufacturable designs, solving the drawing assistance issues reported by Canadian clients. -

Material Selection Guidance

Expert recommendations on optimal quartz grades for your specific application requirements and operating conditions. -

Design Feasibility Assessment

Evaluation of your design specifications to ensure manufacturabi

Specialized Manufacturing Services

TOQUARTZ® offers advanced manufacturing capabilities for custom quartz bottle labware, solving the 6+ week delivery delays reported by German clients and the tolerance issues experienced by American laboratories.

-

Precision Tolerance Manufacturing

Achieving ±0.1mm tolerance on standard products, addressing the 12% return rate issues reported in American labs due to tolerance failures. -

Rapid Prototyping

Quick turnaround on prototype development for verification before full production, reducing project delays by up to 70%. -

Specialized Surface Treatments

Options for fire polishing, annealing, or specialized coatings to enhance performance characteristics for specific applications.

How We Deliver Premium Quartz Bottles Without MOQ Restrictions

TOQUARTZ® has optimized its manufacturing processes to offer high purity quartz bottles without minimum order quantities, providing unmatched flexibility for researchers and specialized manufacturers.

Efficient Inventory Management

TOQUARTZ® strategic inventory system maintains stock of common fused quartz bottle labware components and raw materials, enabling rapid response to small-batch orders while maintaining cost efficiency.

- Standardized component system

- Just-in-time manufacturing approach

- Regular stock replenishment cycles

Modular Production System

TOQUARTZ® advanced modular manufacturing process allows us to produce custom quartz bottle labware efficiently even for small quantities, reducing setup costs typically associated with small-batch production.

- Flexible workstation configuration

- Quick-change tooling systems

- Optimized setup procedures

Specialized Craftsman Team

TOQUARTZ®skilled artisans specialize in small-batch quartz laboratory grade bottle production, combining traditional craftsmanship with modern technology to deliver exceptional quality regardless of order size.

- Master craftsmen with 15+ years experience

- Continuous skills development program

- Cross-trained production teams

Quartz Bottle Manufacturing Process丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Why Choose TOQUARTZ® for Quartz Bottles

We deliver exceptional value through our specialized expertise in quartz bottle manufacturing and customer-focused approach.

Custom Design Solutions

TOQUARTZ® specializes in creating custom quartz bottle labware tailored precisely to your specifications. Our engineering team provides comprehensive design support from concept to production.

- Technical drawing assistance for custom designs

- Specialized features (custom ports, fittings, dimensions)

- Prototyping and sample development

No Minimum Order Quantity

Unlike most manufacturers, TOQUARTZ® offers lab-grade quartz bottles with no minimum order requirements, perfect for specialized research projects and small-scale applications.

- Order exactly what you need, when you need it

- Ideal for pilot projects and specialized research

- Flexible quantity scaling as your needs grow

Rapid Response Time

24-hour quotation response and expedited shipping options for time-sensitive projects.

Quality Guarantee

Every quartz bottle undergoes rigorous testing to ensure exceptional performance.

Competitive Pricing

Direct factory pricing eliminates middlemen, offering premium quality at competitive rates.

FAQs

Q: What is a quartz lab bottle?

A: A quartz lab bottle is a high-purity laboratory container made from fused silica (SiO₂), designed for storing, transporting, or reacting chemicals under extreme conditions where regular glass would fail.

Q: What temperatures can quartz bottles withstand?

A: TOQUARTZ® quartz bottles can withstand temperatures exceeding 1200°C with minimal thermal expansion, making them ideal for high-temperature applications where conventional glassware would deform or break.

Q: What chemicals are incompatible with quartz bottles?

A: While quartz is highly resistant to most chemicals, concentrated hydrofluoric acid (HF) and hot phosphoric acid can attack the silica structure. Also, molten alkali metals can react with quartz at high temperatures.

Q: What is the typical purity of TOQUARTZ® quartz bottles?

A: Our standard quartz bottles contain ≥99.99% SiO₂, with trace impurities below 100ppm, ensuring minimal contamination for sensitive laboratory applications.

Q: What is the difference between quartz and glass labware?

A: Quartz labware is made from high-purity SiO₂ (≥99.99%) while borosilicate glass contains additional elements like B₂O₃, Na₂O, and Al₂O₃. Quartz offers superior thermal stability (1200°C+ vs. 500°C), better chemical resistance, and higher purity.

Q: How do quartz bottles compare to PTFE containers?

A: Quartz bottles offer superior temperature resistance (1200°C+ vs. 260°C for PTFE), better mechanical strength, and superior transparency, while PTFE may offer better resistance to HF and some specialized applications.

Q: Can TOQUARTZ® help with designing custom quartz bottle solutions?

A: Yes, our engineering team provides comprehensive design assistance, from conceptualization to technical drawing refinement, helping you create the optimal quartz container solution for your specific application.

Q: Where can I buy custom quartz laboratory containers?

A: TOQUARTZ® specializes in manufacturing custom quartz laboratory containers with no minimum order requirements. Contact us directly to discuss your specific design needs and requirements.

Ready to Advance Your Research with Premium Quartz Lab Bottles?

Contact our technical team to discuss your specific requirements, request a quote, or learn more about our quartz bottle solutions.

- Direct factory pricing with no intermediaries

- Expert engineering support for custom designs

- No minimum order quantity requirements

- Fast delivery with 24-hour shipping for stock items

- Comprehensive supply chain management services