Quartz Glass Applications Across Critical Industries

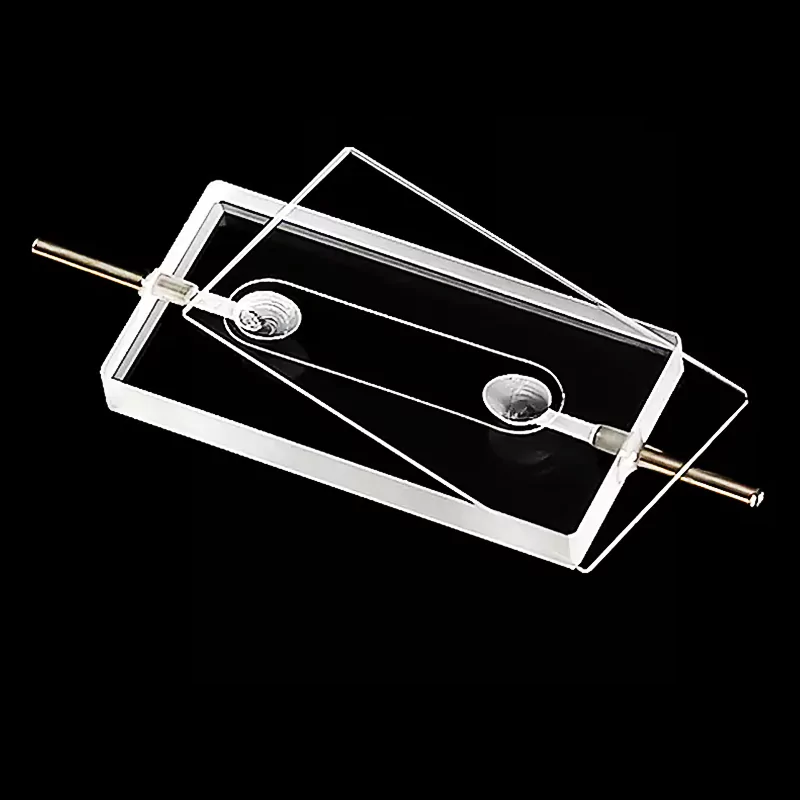

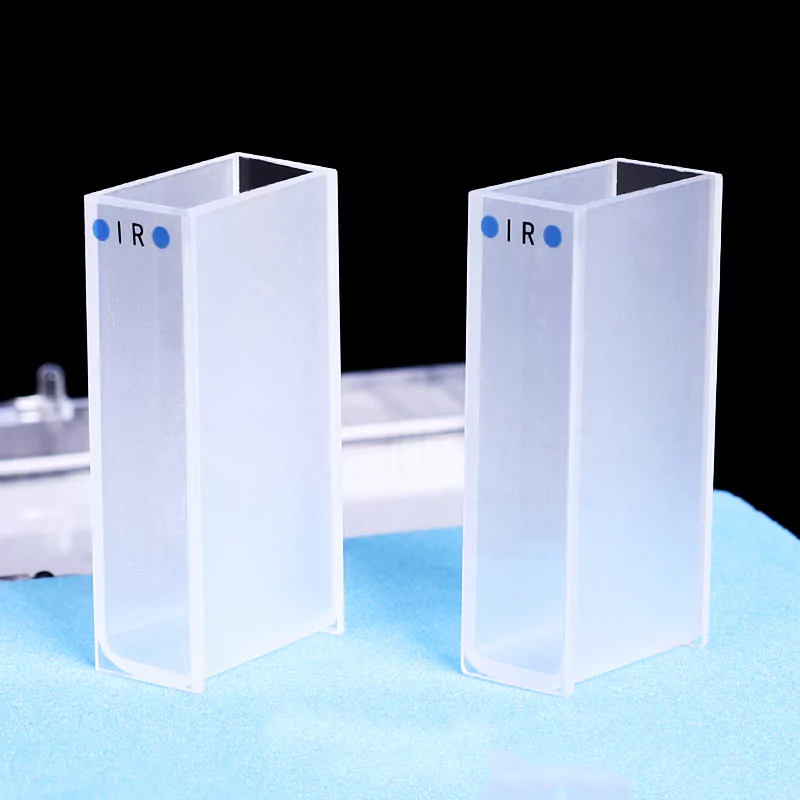

Quartz Labware

TOQUARTZ® quartz laboratory equipment sets the standard for durability and excellence in extreme scientific and industrial settings. Engineered for precision, it ensures unmatched reliability where conventional materials falter under pressure.

- Thermal resistance to 1600°C minimizes expansion in critical heat processes.

- Chemical inertness against aggressive solvents preserves experiment integrity under stress.

- Full UV-to-IR spectral transparency enhances accuracy for optical analysis.

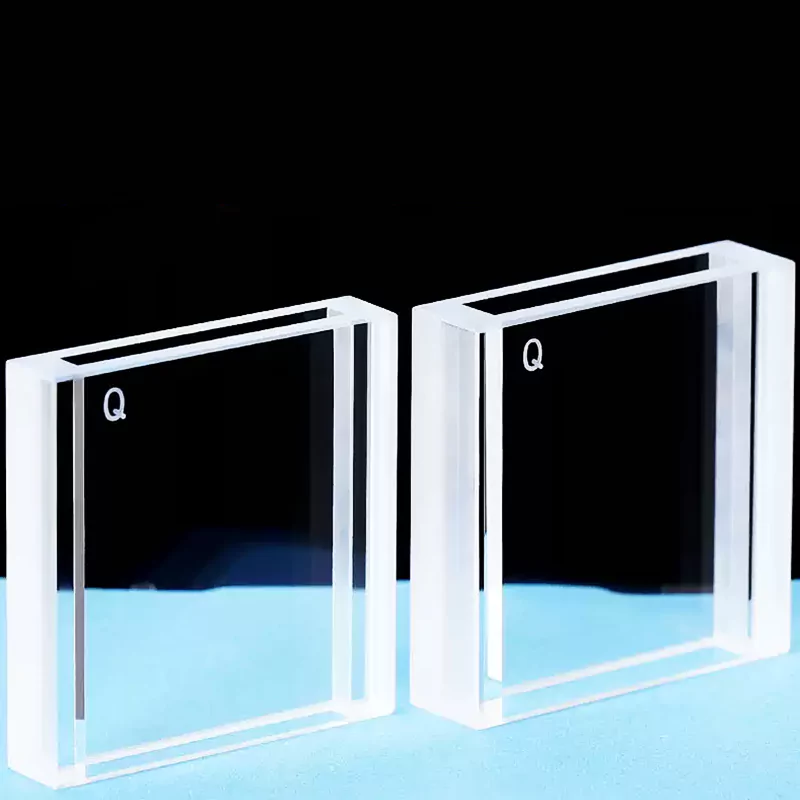

Optical Quartz Glass

TOQUARTZ® Optical Quartz Glass delivers uncompromising performance for critical UV and IR applications demanding precision and durability. Engineered for extreme environments, it combines high-purity fused silica with advanced optical properties essential for scientific and industrial systems.

- Maximizes UV-C transmission (95%+ at 254nm) for sterilization efficacy

- Near-zero autofluorescence guarantees spectroscopic accuracy under prolonged exposure

- Sustains IR transparency at 1200°C with minimal thermal shift

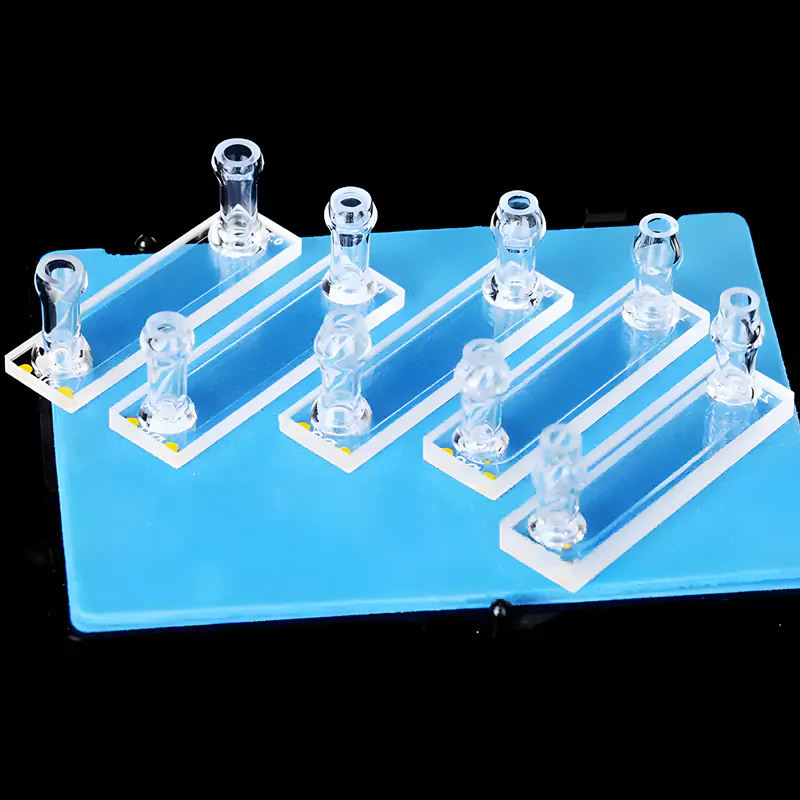

Photovoltaic Quartz Glass

TOQUARTZ® quartz glass components redefine reliability in extreme thermal and corrosive solar manufacturing environments. Engineered for semiconductor and photovoltaic excellence, these solutions deliver uncompromised material stability at the industry’s most demanding thresholds.

- 1600°C thermal resilience ensures stable diffusion furnace performance

- 99.995% SiO₂ purity prevents dopant contamination in cell production

- Fluorine-gas resistance eliminates degradation in etching processes

Photovoltaic Quartz Glass

TOQUARTZ® quartz glass components redefine reliability in extreme thermal and corrosive solar manufacturing environments. Engineered for semiconductor and photovoltaic excellence, these solutions deliver uncompromised material stability at the industry’s most demanding thresholds.

- 1600°C thermal resilience ensures stable diffusion furnace performance

- 99.995% SiO₂ purity prevents dopant contamination in cell production

- Fluorine-gas resistance eliminates degradation in etching processes

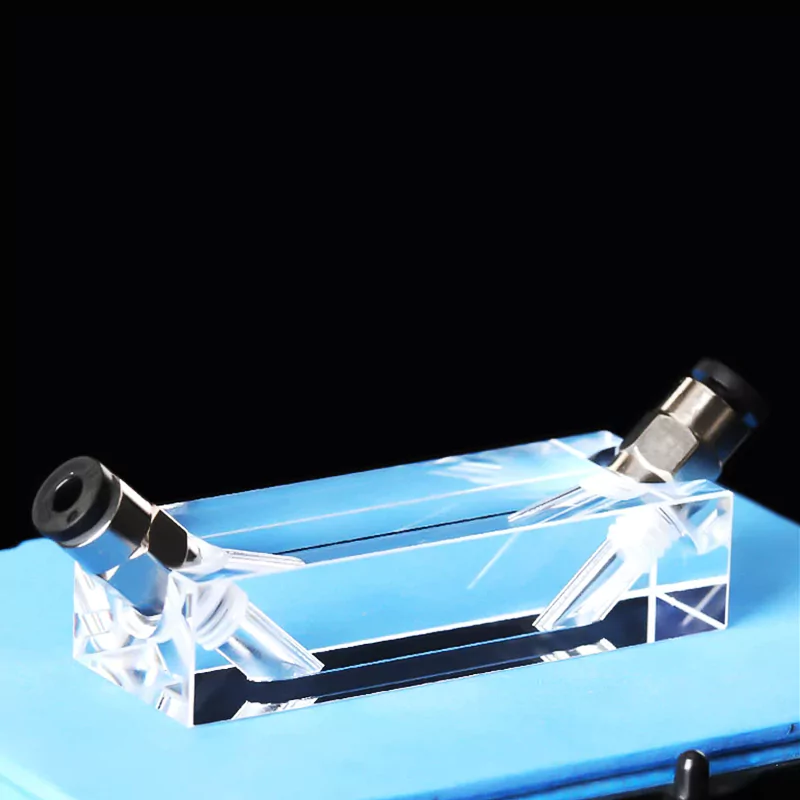

Semiconductor Quartz Glass

TOQUARTZ® semiconductor quartz glass components are precision-engineered to withstand the rigorous demands of advanced wafer fabrication and high-temperature thermal processes. Engineered from ultra-pure materials, they ensure contamination-free performance throughout the semiconductor manufacturing lifecycle.

- 1500°C thermal stability maintains dimensional integrity during rapid thermal processing

- >99.99% SiO₂ purity eliminates ionic contamination sources in diffusion steps

- HF gas & acid resistance preserves structural integrity in etching chambers

Industrial Quartz Glass

TOQUARTZ® industrial quartz glass components deliver uncompromised performance under extreme thermal, chemical, and mechanical stress across critical sectors. Engineered with >99.995% SiO₂ purity, our solutions prevent contamination while enabling precision in high-stakes industrial processes.

- 1600°C thermal stability sustains integrity in vacuum furnace environments

- Acid/chlorine-gas resistance prevents degradation in chemical reactors

- Customizable via CNC/laser machining meets exact dimensional tolerances