- Home

- /

- Applications

- /

- Semiconductor Quartz Glass

- /

- Customized Thermal-Stable Quartz Wafer...

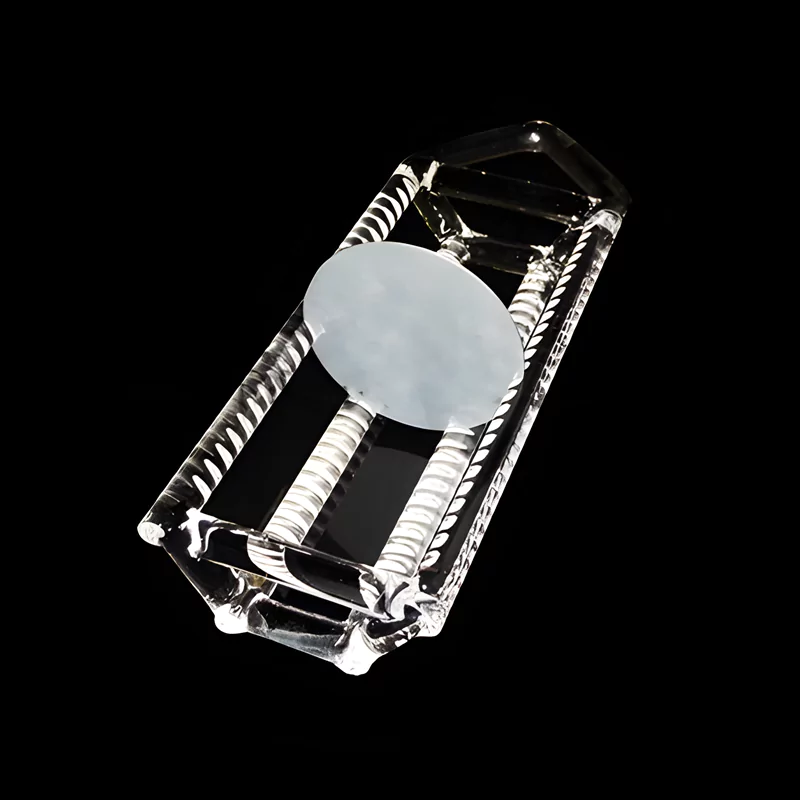

Customized Thermal-Stable Quartz Wafer Boat for Semiconductor & Solar Processing -TOQUARTZ®

The silicon wafer carrier quartz boats feature thermal stability up to 1100°C, superior corrosion resistance, and high electrical resistivity (7×10⁷ Ω·cm).

Features of Quartz Wafer Boat

Material Excellence

- High Purity: up to 99.995% SiO₂ content ensures minimal contamination in critical processes

- Superior Strength: Flexural strength up to 350 MPa withstands handling stresses

- Chemical Stability: Resistant to acids, alkalis, molten salts, and fluorinated gases

Thermal Performance

- High Temperature Stability: Maintains structural integrity at 1100°C for continuous operation

- Low Thermal Expansion: Coefficient of 5.5×10⁻⁷/°C minimizes warping during thermal cycling

- Thermal Conductivity: 120-160 W/m·K for efficient heat transfer during processing

Practical Advantages

- Extended Lifespan: Low wear rate extends service life in production environments

- Electrical Insulation: High resistivity (7×10⁷ Ω·cm) prevents electrical interference

- Optical Properties: Refractive index of 1.4585 for specialty applications

- Minimize Dopant Interference

- Warpage-Free Alignment

- Thermal Cycling Resistance

Technical Specifications of Quartz Wafer Boat

Technical Specifications of Quartz Glass Wafer Boat

Physical Properties

| Property | Value | Unit |

| Density | 2.2 | g/cm3 |

| Flexural Strength | 48 | MPa |

| Elastic Modulus | 72 | GPa |

| Poisson’s Ratio | 0.14-0.17 | – |

| Compressive Strength | 1100 | MPa |

| Bending Strength | 67 | MPa |

| Moh’s Hardness | 5.5-6.5 | – |

Thermal Properties

| Property | Value | Unit |

| Maximum Working Temperature (long-term) | 1100 | °C |

| Maximum Working Temperature (short-term) | 1300 | °C |

| Thermal Conductivity | 1.4 | W/m·K |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ | /°C |

Optical & Electrical Properties

| Property | Value | Unit |

| Refractive Index | 1.4585 | – |

| Specific Resistance | 7×10⁷ | Ω·cm |

Customized Dimensions of Fused Quartz Wafer Boat

TOQUARTZ® can accommodate custom specifications based on client requirements. Contact our engineering team for detailed dimensional specifications and custom sizing options.

TOQUARTZ® Solving Critical Challenges with Quartz Wafer Boat

Quartz Glass Wafer Boats for Semiconductor Diffusion Processes

Key Advantages

-

Dimensional Stability at 1100°C

TOQUARTZ® wafer boats maintain <0.15mm deformation after 100 cycles at 1100°C in diffusion furnaces. -

Ultra-Low Ionic Contamination

ICP-MS testing confirms Na⁺, K⁺, and Fe³⁺ ion levels below 0.1 ppm, minimizing dopant interference. -

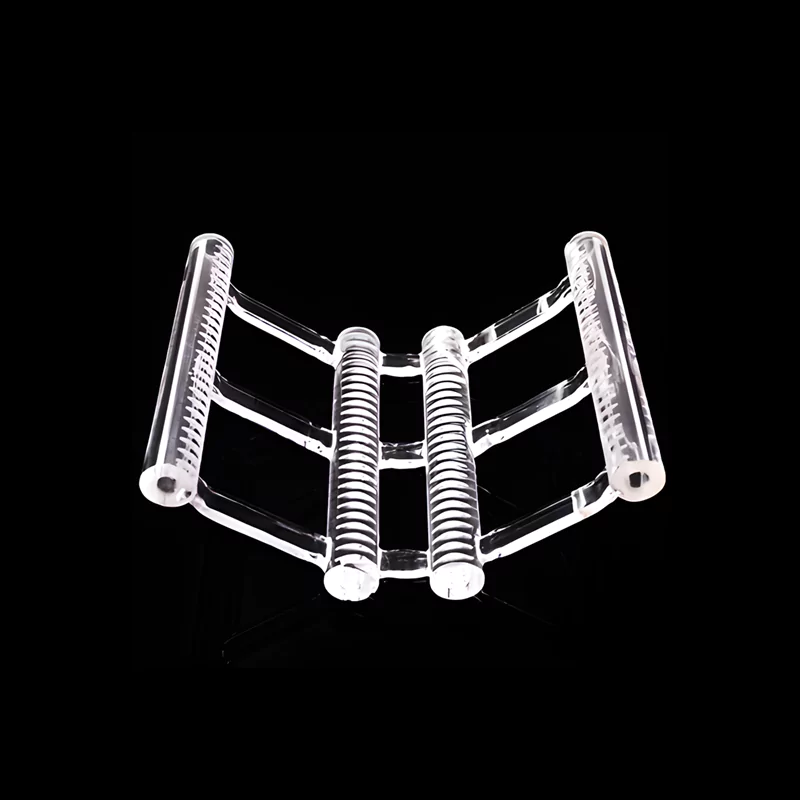

Slot Parallelism Control

Slot-to-slot parallelism deviation is controlled within 0.05mm across 25-slot configurations.

TOQUARTZ® solution

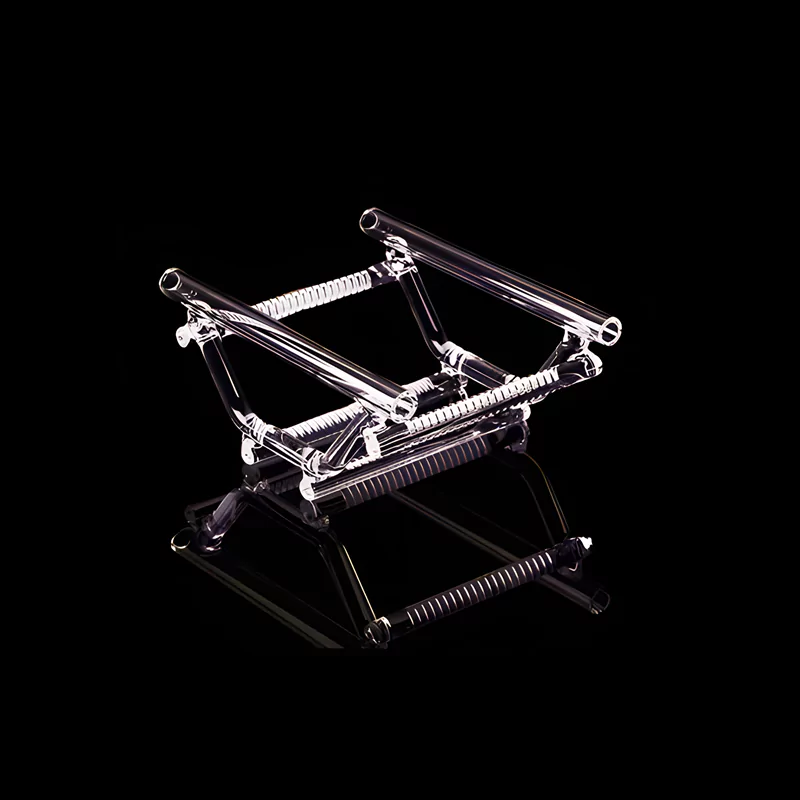

A U.S.-based semiconductor equipment integrator required quartz boats for 8-inch wafers that could maintain structural integrity and prevent contamination during 1030°C diffusion. Their previous supplier’s boats warped after 60 cycles, causing wafer misalignment and yield loss.

TOQUARTZ® implemented a dual-stage annealing process and acid leaching protocol, delivering boats that remained dimensionally stable after 120+ cycles with no detectable ionic residue.

Fused Quartz Wafer Boats for Solar Cell Production

Key Advantages

-

Thermal Cycling Resistance

TOQUARTZ® boats withstand over 200 thermal cycles (20–1100°C) without microcrack propagation. -

High Slot Uniformity for Mass Loading

Slot pitch deviation is controlled within ±0.03mm across 100-slot solar wafer carriers. -

Warpage-Free Alignment

Post-cycle flatness deviation remains under 0.2mm after 180 cycles in inline diffusion systems.

TOQUARTZ® solution

A Polish solar module manufacturer faced wafer breakage and misalignment during high-throughput diffusion due to slot deformation in their existing quartz boats.

TOQUARTZ® redesigned the slot geometry using FEM simulation and reinforced the base structure. After 180 thermal cycles, the boats maintained alignment within 0.2mm deviation, reducing wafer breakage by 27% and improving cell efficiency consistency across batches.

Fused Silica Wafer Boats for Research Applications

Key Advantages

-

Non-Standard Wafer Compatibility

Supports wafer diameters from 2" to 8" with mixed-slot configurations for hybrid experiments. -

Rapid Prototyping Precision

CNC-controlled slot machining ensures repeatability across small-batch custom orders. -

Geometry Adaptability

Supports asymmetric or partial-slot designs for edge-focused thermal studies.

TOQUARTZ® solution

A German university lab required quartz boats for a prototype process involving 6" wafers with asymmetric heating zones and non-standard slot spacing.

TOQUARTZ® applied 5-axis CNC machining and digital slot mapping to meet the lab’s unique geometry and thermal profile requirements. The boats passed internal alignment tests and enabled the lab to complete 3 experimental runs without structural failure or slot deviation.

TOQUARTZ® Customization Services for Quartz Glass Wafer Boat

Dimensional Customization

- Custom length, width, and height specifications

- Specialized wall thickness for thermal requirements

- Dimension tolerance to be otherwise stated or required by the user.

Special Design

Features

- Custom slot count from 5 to 200+ positions

- Variable slot spacing for different wafer thicknesses

- Specialized slot geometries for edge protection

Performance Optimization

- Polished surfaces for reduced particle generation

- Ground finish for improved thermal characteristics

- Special cleaning protocols for ultra-high purity applications

Custom Design Process

Requirement Collection & Technical Consultation

- We begin by gathering detailed application data, including wafer size, slot count, furnace type, and thermal conditions. Clients may submit drawings or consult directly with our quartz engineering team.

Quartz Wafer Boat Design & Simulation

- Our engineers create 2D/3D CAD models of the custom quartz wafer boat, incorporating FEM thermal stress analysis and slot geometry optimization to ensure dimensional stability and thermal performance.

Prototype Manufacturing & Validation

- We produce a prototype using CNC machining and precision slotting tools. Each custom quartz wafer boat undergoes dimensional inspection, thermal shock testing, and slot alignment verification before approval.

Batch Production & Delivery

- Upon prototype approval, we initiate batch production with full QC documentation. Standard lead time is 15–20 business days. For urgent projects, expedited quartz wafer boat manufacturing is available.

Usage Guide of Quartz Wafer Boat

Handling Procedures

- Handle with clean gloves to prevent contamination and fingerprints which can cause defects at high temperatures.

- Avoid impact or dropping, as quartz is susceptible to chipping and cracking despite its high-temperature resistance.

- Use dedicated storage racks with soft contact points to prevent scratching when not in use.

- Transport quartz wafer boats in protective packaging to minimize risk of damage.

Temperature Management

- Do not exceed the maximum operating temperature of 1100°C for continuous use or 1350°C for short-term operations.

- Avoid rapid thermal cycling; ramp rates of 5-8°C/minute or less are recommended to prevent thermal shock.

- Allow sufficient cooling time before handling or cleaning to prevent thermal stress fractures.

- Use temperature-calibrated furnaces to prevent inadvertent overheating beyond specified limits.

Chemical Compatibility

- Quartz is an acidic material; avoid contact with alkaline compounds (sodium/potassium compounds, water glass) at high temperatures.

- Compatible with most acids, but hydrofluoric acid (HF) will etch quartz and should be avoided.

- Avoid metal contamination which can cause devitrification (crystallization) of quartz at high temperatures.

- Clean with appropriate solvents/acids based on your process requirements; consult our technical team for specific recommendations.

Maintenance & Cleaning

- Regularly inspect for cracks, chips, or devitrification which can compromise structural integrity.

- Clean using ultrasonic baths with appropriate chemicals for your specific contaminants.

- For persistent deposits, piranha solution (H₂SO₄:H₂O₂) or RCA cleaning methods may be appropriate (consult safety guidelines).

- Document usage cycles to anticipate replacement needs before failure occurs.

For application-specific handling guidelines or troubleshooting assistance, contact our technical support team who can provide customized recommendations based on your specific process parameters.

Need Engineering Support for Your Quartz Wafer Boat Requirements?

Contact us today to discuss your custom quartz wafer boat requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the definition of a quartz wafer boat?

A: A quartz wafer boat is a high-purity quartz carrier used to hold and transport silicon wafers during high-temperature thermal processing operations in semiconductor and solar cell manufacturing. These boats feature precision-machined slots to maintain consistent wafer spacing and positioning.

Q: What are the main applications for quartz wafer boats?

A: Quartz wafer boats are primarily used in semiconductor diffusion and oxidation processes, solar cell manufacturing, LED production, and materials research where high temperature stability and material purity are critical requirements.

Q: What makes quartz the preferred material for wafer boats?

A: High-purity quartz is preferred for wafer boats due to its exceptional thermal stability, minimal thermal expansion, chemical inertness, and high purity (typically 99.995% SiO₂), which prevents contamination during high-temperature processing.

Q:What is the maximum temperature a quartz wafer boat can withstand?

A: TOQUARTZ® quartz wafer boats can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1300°C. The quartz wafer boat temperature limit is determined by its softening point and the onset of devitrification (crystallization).

Q: Do you provide technical support for quartz wafer boat design?

A: Yes, TOQUARTZ® engineering team provides comprehensive design support to optimize your quartz wafer boat for specific processing conditions. We can suggest modifications to improve thermal performance, mechanical stability, and service life.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.