- Home

- /

- Types

- /

- Quartz Tube

- /

- Custom Precision-Fit Connector Ground...

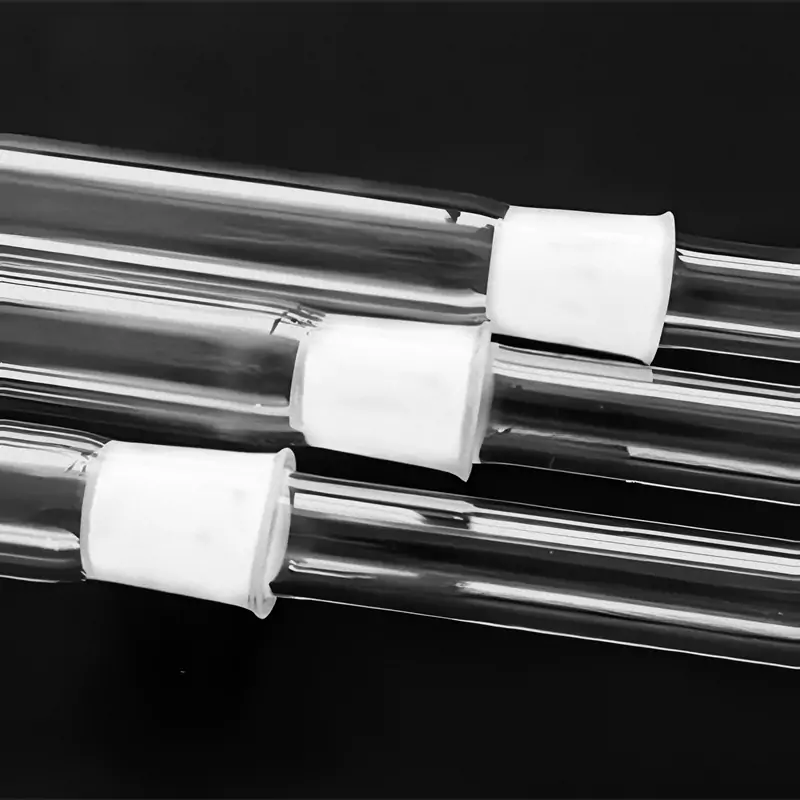

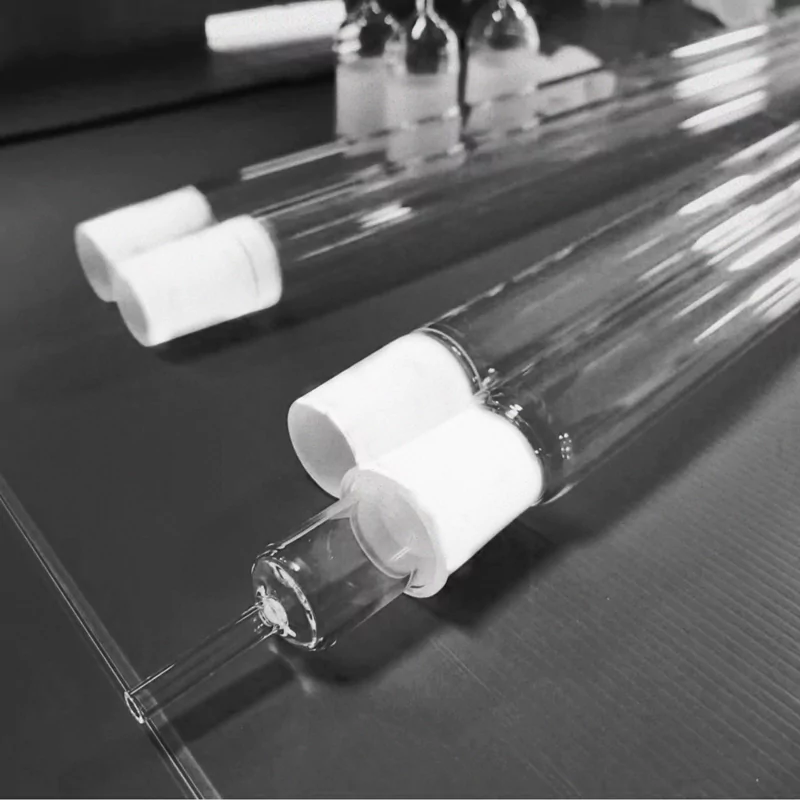

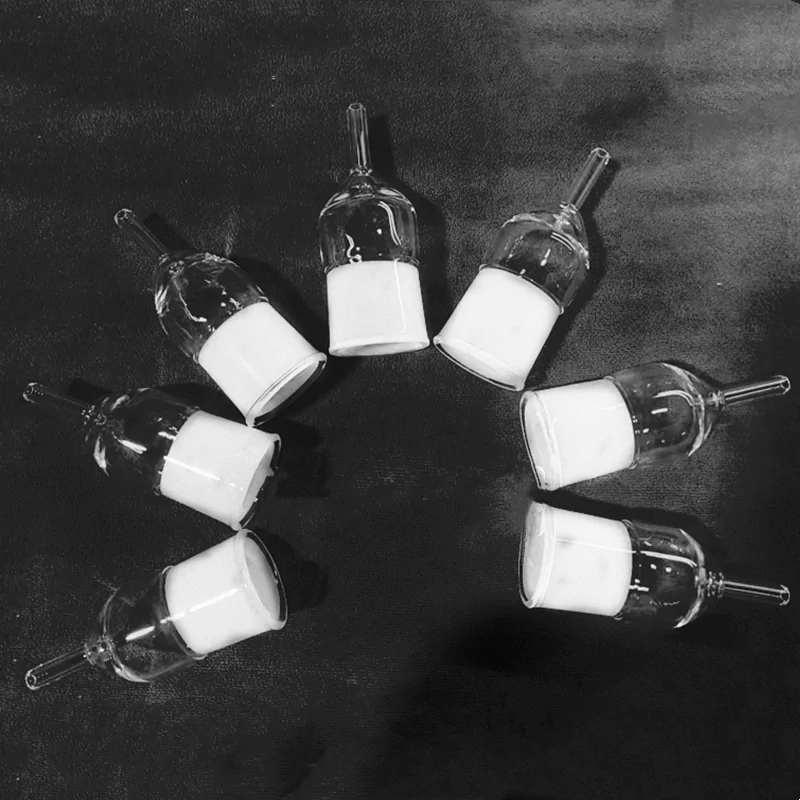

Custom Precision-Fit Connector Ground Joint Quartz Tube for Analytical Instrumentation-TOQUARTZ®

Key Features of Ground Joint Quartz Tube

TOQUARTZ® ground joint quartz tubes combine precision engineering with high-purity materials to deliver exceptional performance in demanding laboratory and industrial applications. These specialized components feature standardized ground glass joints that ensure reliable, leak-proof connections in complex experimental setups and industrial processes.

Thermal Properties

- Working temperature up to 1,200°C with softening point at 1,700°C

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C) ensures dimensional stability

- Excellent thermal shock resistance, withstanding rapid temperature changes of >1,000°C

Chemical Resistance

- Resistant to most acids, bases, and organic solvents (except HF)

- Ultra-high purity (≥99.99% SiO₂) prevents contamination in sensitive processes

- Trace metal impurities below 1-2 ppm, ideal for analytical applications

Precision Ground Joints

- Standard taper ground glass joints (14/20, 19/22, 24/40, 29/42 sizes available)

- Precise grinding to ±0.1mm tolerance for leak-free connections

- Compatible with standard laboratory glass joints and fittings

- Light transmission (>93%) from UV to IR range

- Volume resistivity >10¹⁸ Ω·cm

- Low dielectric constant (3.8 at 1MHz)

Technical Specifications of Ground Joint Quartz Glass Tube

TOQUARTZ® ground joint quartz tubes are manufactured to exacting standards with precise dimensional control and material properties. The following specifications provide detailed information about the physical, thermal, optical, and mechanical characteristics of our products.

| Property | Value | Test Method |

| Physical Properties | ||

| Material Composition | ≥99.99% SiO₂ | ICP-MS |

| Density | 2.2 g/cm³ | ASTM C693 |

| Hardness | 5.5-6.5 Mohs / 580 Knoop | ASTM C730 |

| Thermal Properties | ||

| Maximum Working Temperature | 1,200°C (continuous) | ASTM C1659 |

| Softening Point | 1,700°C | ASTM C338 |

| Coefficient of Thermal Expansion | 5.5 × 10⁻⁷ /°C (20-300°C) | ASTM E228 |

| Optical Properties | ||

| UV-VIS-NIR Transmission | ≥93% (220-2500nm) | ASTM E275 |

| Refractive Index | 1.458 (589.3nm) | ASTM D542 |

| Dimensional Specifications | ||

| Standard Joint Sizes | 14/20, 19/22, 24/40, 29/42 | ISO 383, ASTM E676 |

| Wall Thickness | 1.5-3.0mm (standard) | ±0.1mm tolerance |

| Length Range | 50-1000mm (standard) | ±0.5mm tolerance |

TOQUARTZ® Solving Challenges with Ground Joint Quartz Tube

Ground Joint Quartz Tubes for High-Temperature Chemical Reactions

Key Advantages

-

Joint seal integrity at 1,100°C

Standard taper joints maintain vacuum-tight seals under sustained 1,100°C operation without deformation. -

Corrosion resistance in acid vapor environments

Withstands continuous exposure to HCl, HNO₃, and SO₂ vapors at 900°C with no surface degradation after 72 hours. -

No trace metal leaching under thermal load

ICP-MS tests confirm <0.5 ppm total metal leaching after 48h in 850°C mixed acid vapor conditions.

TOQUARTZ® solution

A German chemical synthesis lab faced seal failures using borosilicate joints above 600°C, causing 3–4 weekly experiment interruptions. TOQUARTZ® supplied custom 24/40 ground joint quartz tubes rated for 1,100°C, which maintained seal integrity for over 500 hours of continuous operation. Post-run analysis showed no joint deformation or contamination, reducing downtime by 92% and increasing batch yield consistency.

Ground Joint Quartz Glass Tubes for High-Vacuum Systems

Key Advantages

-

Vacuum integrity to 10⁻⁶ Torr at 800°C

Leak rate <1×10⁻⁷ mbar·L/s verified under thermal cycling from 25°C to 800°C. -

Joint taper precision within ±0.05 mm

Ensures consistent sealing force and minimal grease migration in UHV setups. -

Low outgassing quartz surface (<0.01 mg/cm²)

Surface-treated inner walls reduce background signal interference in mass spectrometry.

TOQUARTZ® solution

A Japanese vacuum instrumentation OEM reported micro-leaks in glass joints after 20 thermal cycles, affecting mass spec calibration. TOQUARTZ® delivered ±0.05 mm tolerance quartz joint tubes with annealed tapers, tested to 10⁻⁶ Torr at 800°C. After 100+ thermal cycles, vacuum integrity remained stable, reducing recalibration frequency by 70% and improving instrument uptime.

Ground Joint Quartz Tubes for Optical & Spectroscopic Applications

Key Advantages

-

UV transmission >91% at 254 nm

Measured at 1.0 mm thickness, enabling accurate UV-C detection and sterilization monitoring. -

No birefringence after 1,000°C exposure

Optical homogeneity maintained after 100h thermal soak, verified via polarimetry. -

Joint alignment deviation <0.03 mm

Ensures optical path consistency in multi-component spectroscopic assemblies.

TOQUARTZ® solution

A U.S. environmental monitoring firm experienced signal drift in UV spectrometers due to joint misalignment and glass darkening. TOQUARTZ® provided optically aligned quartz joint tubes with 91% UV transmittance. After 2,000 hours of UV-C exposure, signal stability improved by 28%, and recalibration intervals extended from 30 to 90 days.

TOQUARTZ® Customized Services for Ground Joint Quartz Tube

TOQUARTZ® specializes in custom quartz fabrication services tailored to your specific requirements. Our engineering team works closely with clients to design and manufacture ground joint quartz tubes with unique specifications and configurations beyond standard catalog offerings.

Custom Dimensions

- Non-standard diameters (3mm to 120mm)

- Custom wall thicknesses (0.5mm to 5mm)

- Extended lengths up to 2 meters

- Precision tolerances (±0.1mm)

Specialized Configurations

- Multi-joint assemblies

- Custom angle configurations

- Integrated frits or restrictors

- Specialized joint types and sizes

Material & Surface Options

- Ultra-high purity options (99.995% SiO₂)

- Fire-polished or precision-ground ends

- Opaque or translucent options

- Special annealing for stress relief

Usage Guidelines for Ground Joint Quartz Tube

Proper handling, installation, and maintenance of ground joint quartz tubes ensures optimal performance and extended service life. The following guidelines provide essential information for correctly working with these specialized components in laboratory and industrial applications.

Handling & Installation

-

Clean before use:

Wash with laboratory-grade detergent, rinse thoroughly with deionized water, followed by acetone or methanol rinse. Air dry or use filtered compressed air. -

Joint lubrication:

For vacuum applications, use high-vacuum grease sparingly on ground joints. For high-temperature applications, use appropriate temperature-resistant lubricant or dry-seal connections. -

Support properly:

Always provide adequate support for quartz assemblies. Avoid cantilevering heavy components off joint connections. Use appropriate laboratory stands and clamps with soft padding to prevent stress points. -

Thermal gradients:

Avoid rapid, localized heating. Ensure even temperature distribution, especially during heating and cooling cycles. Pre-heat components gradually when possible.

Maintenance & Storage

-

Regular inspection:

Periodically check ground joints for chips, cracks, or excessive wear. Inspect for devitrification (cloudy appearance) after high-temperature use, which may indicate reduced mechanical strength. -

Cleaning:

Remove residues promptly after use. For stubborn deposits, use appropriate solvents or mild acid solutions (avoid HF). Ultrasonic cleaning is effective for precision components. -

Storage:

Store in clean, dust-free containers. Separate ground joint components to prevent sticking or damage. Use soft padding between components and store in a dry environment. -

Extending service life:

Rotate usage of ground joints when possible to distribute wear. Re-grind joints professionally when sealing performance deteriorates but material remains otherwise sound.

Free Engineering Consultation for Ground Joint Quartz Tube Applications

Whether you need assistance with material selection, dimensional specifications, or system integration,

our experts can provide technical guidance to ensure optimal performance.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the difference between ground joint quartz tubes and standard glass joints?

A: Ground joint quartz tubes are made from high-purity fused silica (SiO₂ ≥99.99%), while standard laboratory glass joints typically use borosilicate glass. Quartz offers significantly higher temperature resistance (up to 1,200°C vs. ~500°C for borosilicate), superior chemical resistance, better thermal shock resistance, and enhanced optical properties, especially in UV transmission. Our ground joint quartz tubes maintain dimensional stability at high temperatures where standard glass would soften or deform.

Q: Are your ground joint quartz tubes compatible with standard laboratory glassware?

A: Yes, TOQUARTZ® ground joint quartz tubes are manufactured to comply with international standards including ISO 383 and ASTM E676, ensuring compatibility with standard laboratory glassware. We offer common joint sizes (14/20, 19/22, 24/40, 29/42) that match standard taper joints used in laboratory setups worldwide. This compatibility allows for seamless integration with existing borosilicate glass components while providing the enhanced performance characteristics of high-purity quartz in critical areas of your system.

Q: What is the maximum temperature my ground joint quartz tube can withstand?

A: TOQUARTZ® standard ground joint quartz tubes can be used continuously at temperatures up to 1,200°C, with short-term exposure capability up to 1,450°C. The softening point of the high-purity fused quartz is approximately 1,700°C. However, for applications involving ground joints, we recommend not exceeding 1,100°C at the joint interface to maintain seal integrity. For higher temperature applications, we can provide specialized designs with stress-relieved joints or alternative sealing mechanisms.

Q: How do ground joint quartz tubes perform in vacuum systems?

A: TOQUARTZ® ground joint quartz tubes excel in vacuum applications due to several key properties. They feature extremely low outgassing characteristics, maintaining vacuum integrity to 10⁻⁶ torr or better. The precision-ground joints (±0.1mm tolerance) ensure excellent sealing when used with appropriate vacuum greases or PTFE sleeves. Quartz’s low thermal expansion coefficient (5.5×10⁻⁷/°C) maintains dimensional stability during thermal cycling, preserving vacuum integrity. Additionally, our high-purity material (≥99.99% SiO₂) minimizes contamination risks in sensitive vacuum processes. For ultra-high vacuum applications, we can provide specially processed tubes with enhanced surface finishing and thorough degassing.

Q: How do I specify the correct ground joint quartz tube for my application?

A: To specify the correct ground joint quartz tube, provide the following information:

(1) Joint size (e.g., 24/40) and type (male/female);

(2) Tube inner diameter, outer diameter, and wall thickness;

(3) Overall length and any specific dimensional requirements;

(4) Operating temperature range and exposure to thermal cycling;

(5) Chemical environment and any special purity requirements;

(6) Vacuum requirements if applicable;

(7) Any additional features needed (side arms, multiple joints, custom angles).

Our engineering team is available for consultation to help determine the optimal specifications for your application. We can also work from technical drawings or reverse-engineer from existing components.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.