Selecting the right fused quartz tube is essential for demanding industries seeking high purity, thermal performance, and reliable optical transmission.

Fused quartz tubes deliver superior results in extreme environments by providing outstanding thermal stability, exceptional optical clarity, and low contamination risk for critical processes in semiconductors, furnaces, optics, and specialty systems.

This comprehensive technical guide will show how fused quartz tubes outperform alternatives and provide practical frameworks for engineering selection, specification verification, and application optimization.

What Are the Core Properties and High-Performance Application Foundations of Fused Quartz Tubes?

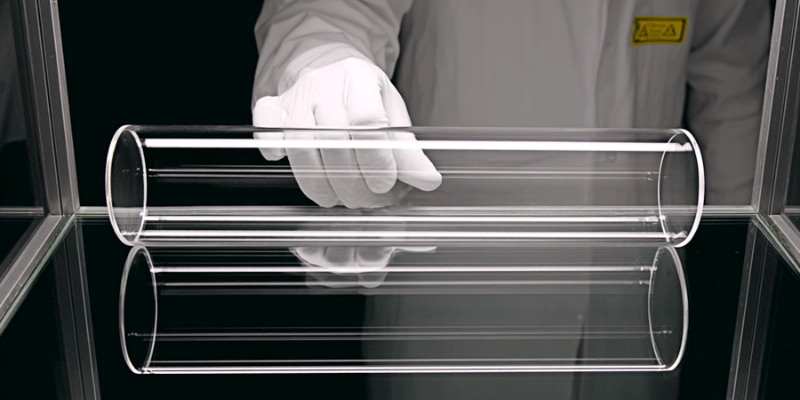

Fused quartz tubes are manufactured from ultra-high purity silica, resulting in exceptional resistance to heat, thermal cycling, and chemical attack. They are structurally stable at up to 1,200°C and exhibit low thermal expansion, preventing cracking or warping even during rapid temperature changes.

Their extremely low content of metal impurities means fused quartz tubes do not leach contaminants—a key factor for semiconductor and chemical applications. The glass is also highly resistant to nearly all acids and bases except hydrofluoric acid, ensuring longevity in harsh process environments.

In addition to thermal and chemical capabilities, fused quartz tubes support optical clarity. This allows engineers to visually monitor reactions or use the tubes for light transmission in spectrometry and laser-guided systems. These combined properties make fused quartz unique for advanced, high-stress applications.

Which Critical Industrial Applications Depend on Fused Quartz Tube Performance?

Fused quartz tubes are vital in a broad range of industrial sectors, where their purity and resilience enable reliable operation under demanding conditions.

They serve as the backbone for critical processes in semiconductors, heat treatment, precision optics, and specialized chemical or nuclear applications.

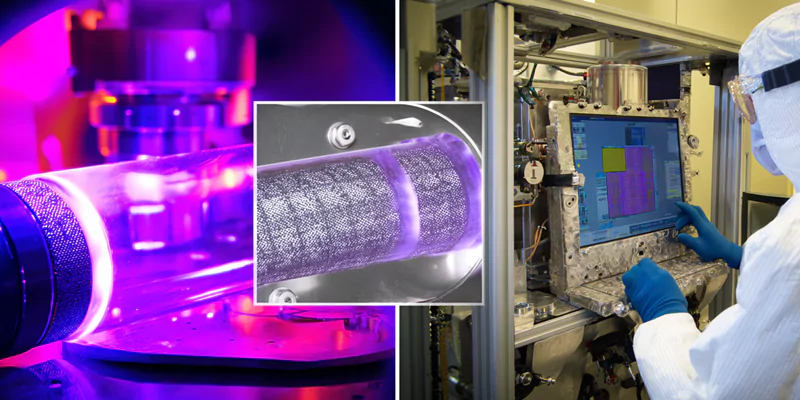

Semiconductor Manufacturing: CVD Reaction Chambers and Diffusion Furnace Core Components

In the semiconductor industry, fused quartz tubes are key parts of chemical vapor deposition1 chambers and diffusion furnaces. Their high purity prevents metal contamination that could harm wafer substrates. Their thermal shock resistance allows repeated rapid cycling with less risk of sudden failure.

Fused quartz tubes provide a chemically stable barrier that does not interact with reactive gases. This is crucial for ensuring uniform thin-film deposition and oxidation processes. Their surface smoothness also contributes to clean gas flow and wafer suspension.

Regular maintenance and careful installation ensure long-term performance within fabrication lines. Investing in high-grade fused quartz minimises process downtime and maximizes chip yields over the product lifecycle.

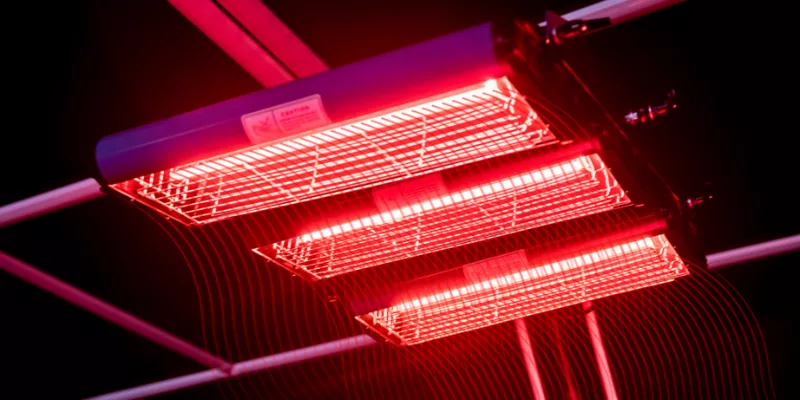

High-Temperature Heat Treatment Systems: Annealing and Sintering Furnace Temperature Solutions

Heat treatment systems rely on fused quartz tubes to withstand high operational temperatures during annealing, calcination, and sintering. The tubes maintain their shape and seal integrity at up to 1,200°C. This ensures uniform heat exposure and reliable containment of workpieces or chemical loads.

The low coefficient of thermal expansion (about 0.5 × 10⁻⁶/K) significantly reduces the risk of cracking or distortion, even with frequent load cycling. This makes fused quartz a superior alternative to ceramics or standard glass for continuous or batch processes.

Long service life helps reduce maintenance costs and production stoppages. The material’s predictability enables precise thermal control and consistent results in advanced furnace operations.

Precision Optical Systems: UV Laser and Spectrometer Transmission Components

Precision optical systems use fused quartz tubes as light guides, spectrometer cells, or UV laser housings. The material’s high transmittance in the UV and visible spectrum preserves signal intensity for analytical and photonic equipment.

Fused quartz is virtually free of autofluorescence and absorbs minimal light, supporting accurate measurements in spectrophotometry or molecular analysis. Its superior geometry tolerances mean less optical distortion for systems requiring exact calibration.

Durability and minimal outgassing make fused quartz tubes ideal for use in cleanrooms and sensitive instrumentation. Routine cleaning and quality checks ensure continued high optical performance.

Specialized Application Extensions: High-Purity Chemical Transport and Nuclear Industry Applications

In chemical transport systems, fused quartz tubes safely convey corrosive or high-purity fluids without introducing trace contaminants. The material’s inertness is vital for maintaining the integrity of process streams, especially in pharmaceutical or microelectronics manufacturing.

Nuclear industry applications leverage fused quartz tubes for fuel handling, sample isolation, or as shielding sleeves. Their combination of thermal resistance and low neutron activation enables safe, stable operation under intense radiation and heat.

Complex, industry-specific designs are often custom fabricated to meet unique process specs. Engineers should work closely with trusted suppliers to optimize tube dimensions, joints, and mounts.

How Do Thermal and Optical Properties Support Extreme Environment Applications for Fused Silica Tubes?

Fused quartz (silica) tubes excel in maintaining mechanical integrity and optical function under extreme conditions. Their continuous working temperature is commonly 1,050–1,200°C, with intermittent peaks reaching even higher.

Their low thermal expansion coefficient means they absorb less stress when rapidly heated or cooled, making them ideal for processes with frequent cycling. This property dramatically reduces the risk of breakage or leaks.

Optically, fused quartz tubes transmit more than 90% of UV and visible light. This performance is key for UV curing2, photolithography, and spectroscopy. The tubes retain this clarity across their service life, supporting consistent process monitoring and control.

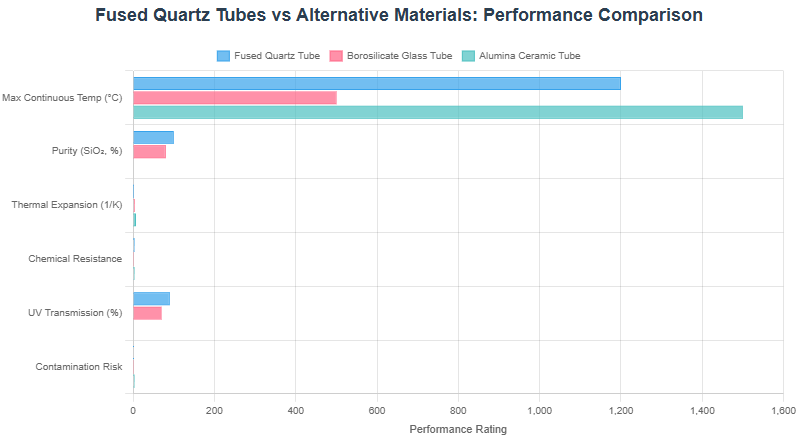

Fused Quartz Tubes vs Alternative Materials: Performance Comparison for Engineering Selection

When selecting high-temperature tubing, engineers must compare performance, durability, and compatibility across multiple materials.

Fused quartz tubes outclass borosilicate glass and most ceramics in purity, temperature rating, and chemical inertness.

Fused Quartz Tube Performance Comparison

| Property | Fused Quartz Tube | Borosilicate Glass Tube | Alumina Ceramic Tube |

|---|---|---|---|

| Max Continuous Temp (°C) | 1,200 | 500 | 1,500 |

| Purity (SiO₂, %) | ≥99.995 | ~80 | N/A |

| Thermal Expansion (1/K) | 0.5 × 10⁻⁶ | 3.3 × 10⁻⁶ | 6–8 × 10⁻⁶ |

| Chemical Resistance | Excellent | Good | Excellent (alkali resistant) |

| UV Transmission (%) | >90 | <70 | Opaque |

| Contamination Risk | Very Low | Medium | Low |

| Application Example | CVD, UV optics | Labware, general heating | Furnace tubes, combustion |

How Do Manufacturing Processes Impact Fused Silica Tube Performance and Quality?

The consistency and quality of fused silica tube manufacturing directly affect tube performance, life expectancy, and reliability under field conditions.

Raw materials are carefully purified, and melting is performed in contamination-controlled environments to ensure ultra-high SiO₂ content and minimal foreign inclusions.

Precision forming, annealing, and custom finishing are critical to achieve tight tolerances and flawless surfaces. Choosing a reputable supplier ensures that each tube meets documented ISO and ASTM quality standards, supporting technical and regulatory compliance.

Technical Specification Verification Guide: Critical Parameters for High Temperature Quartz Tubes

Verifying technical specifications is crucial before placing an order or installing tubes in process lines.

Confirm all relevant thermal, optical, mechanical, and chemical parameters for your use scenario.

Thermal Performance Parameters: Operating Temperature and Thermal Shock Resistance

Always check the manufacturer's rated maximum continuous operating temperature. Standard fused quartz tubes operate at 1,050–1,200°C and can withstand shocks above ΔT≥1000°C. Review test reports and avoid running near the upper performance limit for extended periods.

Thermal shock resistance depends on wall thickness and mounting system as well as intrinsic material properties. Consult with engineering and supplier experts to optimize design.

Proper selection by these criteria helps prevent failures and costly replacements in high-value applications.

Critical Optical Indicators: UV Transmission and Refractive Index Specifications

Fused quartz tubes offer UV transmission greater than 90% (200–400 nm) and refractive index uniformity within ±0.0005. These specifications ensure maximum efficiency in optical and photonic systems.

Consistent high UV transmission supports precise photochemical processing and advanced analytical measurements. Before procurement, request batch inspection data and verify with your own spectrophotometry if necessary.

If your process uses lasers or relies on optical monitoring, tight optical tolerances are essential for long-term accuracy and stability.

Mechanical and Chemical Specifications: Dimensional Tolerances and Purity Standards

For most advanced applications, check that tube diameter, wall thickness, and length hold tolerances of ±0.2–0.5 mm or better. This improves equipment integration and process repeatability.

Purity must consistently reach ≥99.995% SiO₂, with metal impurities kept below 1 ppm or as specified. Request ICP-OES or GDMS reports with each batch.

Chemical compatibility is essential for longevity. Double check material certificates for resistance to specific acids, bases, or solvents present in your process stream.

What Application Scenarios Require Fused Quartz Tubes Over Alternative Materials?

Choosing fused quartz tubes requires a structured analysis of application needs against material performance profiles.

Begin by mapping out all key technical requirements—temperature, purity, light transmission, and chemical exposure—then eliminate inferior material options.

Use a decision tree to systematically determine when fused quartz is a necessity for your project, especially if you are considering alternatives like borosilicate glass3 or ceramics.

Decision Steps for Fused Quartz Tube Selection

Is continuous operating temperature above 500°C or will the tube face rapid cycling? If yes, fused quartz or ceramics are required.

Is highest chemical purity needed (e.g., wafer processing, analytical chemistry)? If yes, fused quartz is strongly recommended.

Is UV or visible light transmission required (e.g., photolithography4, spectrometry)? If yes, fused quartz is ideal.

Are contamination and outgassing risks critical to avoid? If yes, fused quartz tubes outperform alternatives.

For extreme alkali exposure, consider alumina ceramics—but be aware of opacity and dimensional tolerance trade-offs.

Conclusion

Choosing and applying fused quartz tubes with the proper specifications is crucial for safe, reliable, and high-performance operation in advanced industrial and scientific environments.

Making the right choice of fused quartz tube is a strategic engineering decision. Leverage TOQUARTZ’s direct factory supply, engineering support, and rapid delivery to achieve unmatched process stability and technical assurance—contact us for expert consultation and bespoke product solutions.

FAQ (Frequently Asked Questions)

What is the maximum operating temperature for fused quartz tubes?

Most fused quartz tubes operate continuously up to 1,200°C, with short-term limits reaching 1,600°C.

How do I verify the quality and purity of fused quartz tubes?

Request batch-specific analysis, including ICP-OES or GDMS results, and check for ISO/ASTM certifications from your supplier.

What are key steps in specifying custom fused quartz tubes?

Clearly define all relevant dimensions, purity, optical, and chemical requirements, and request a detailed feasibility review before placing an order.

How do fused quartz tubes compare with borosilicate or ceramic tubes?

Fused quartz tubes offer higher purity, superior thermal and optical performance, and lower contamination risk than borosilicate or alumina ceramics in critical applications.

References:

Learn how chemical vapor deposition works and why it's essential for producing high-quality semiconductor devices with precise material control. ↩

Learn about UV curing techniques and their applications to see how they impact various industries. ↩

Borosilicate glass is often more affordable and easier to work with, making it a great alternative for less demanding applications. ↩

Learn about the role of photolithography in modern technology and the materials that enhance its effectiveness. ↩