- Home

- /

- Types

- /

- Quartz Plate

- /

- 99.99% SiO₂ Purity Fused...

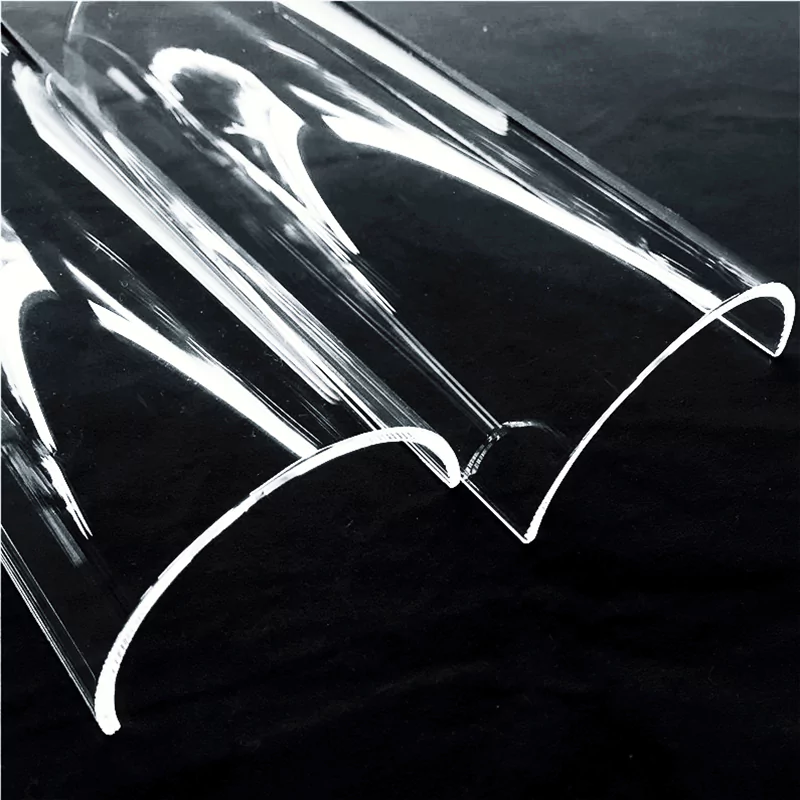

99.99% SiO₂ Purity Fused Quartz Curved Plates -TOQUARTZ®

Properties of Fused Quartz Curved Plates

Fused quartz curved plates from TOQUARTZ® combine exceptional material properties with precision manufacturing to deliver reliable performance in demanding applications.

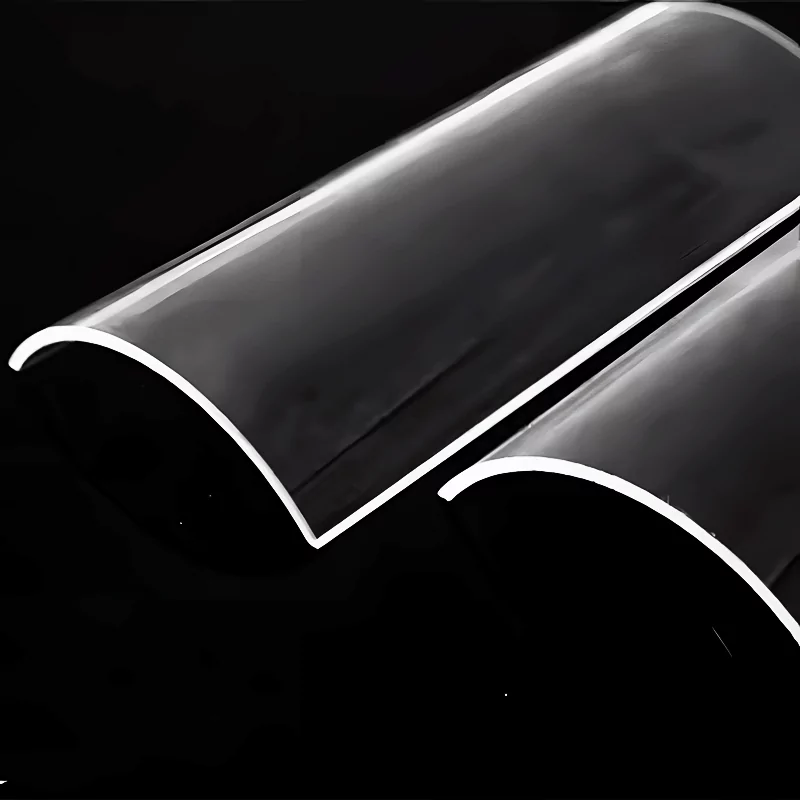

Thermal Stability

TOQUARTZ® fused quartz curved plates maintain structural integrity at temperatures up to 1600°C, with a low thermal expansion coefficient (≤5.5×10⁻⁷/K), enabling them to withstand rapid temperature changes without cracking.

Optical Transmission

These plates offer outstanding transparency across the UV to IR spectrum, with visible light transmission above 93% and UV transmission exceeding 80%, making them ideal for optical applications.

Chemical Resistance

Resistant to most chemicals except hydrofluoric acid, our quartz curved plates offer chemical stability that is 30 times greater than ceramics and 150 times greater than stainless steel, particularly at high temperatures.

- Excellent Thermal Stability

- Optical Transmission

- Superior Chemical Resistance

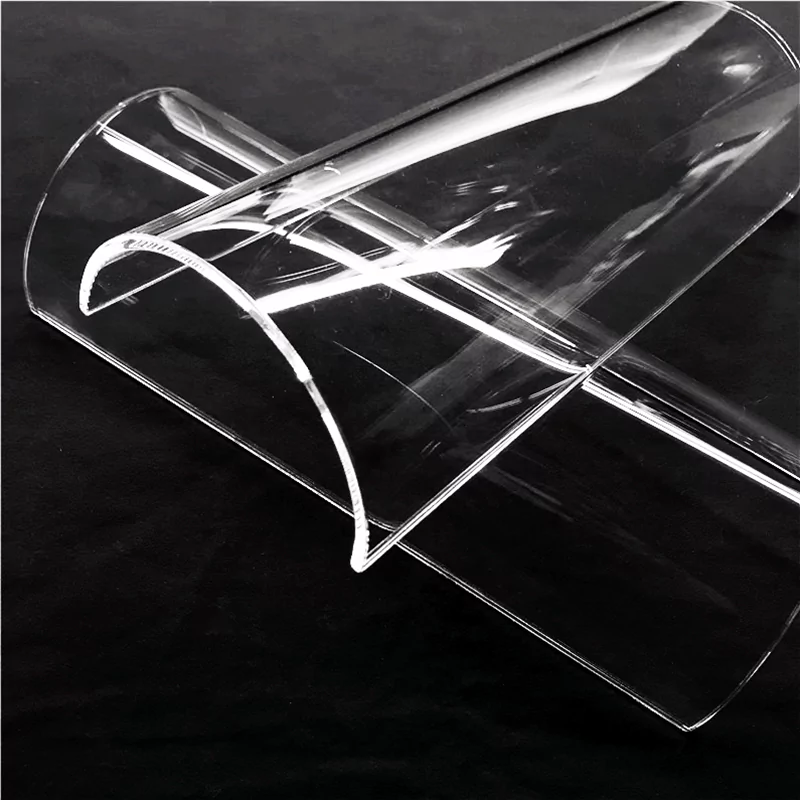

Material Specifications & Dimensions of Fused Quartz Curved Plates

Size of of Fused Quartz Curved Plates

| Fused Quartz Curved Plates | |||

| Model | Outer Dia.*Thickness*Width(mm) | Shape | SiO₂ Purity (%) |

| AT-SY-P3001 | 10mm *1.5mm *100mm | Semi-circular | 99.99 |

| AT-SY-P3002 | 10mm *1.5mm *200mm | ||

| AT-SY-P3003 | 15mm *1.5mm *100mm | ||

| AT-SY-P3004 | 15mm *1.5mm *200mm | ||

| AT-SY-P3005 | 20mm *2mm *100mm | ||

| AT-SY-P3006 | 20mm *2mm *200mm | ||

| AT-SY-P3007 | 25mm *2mm *100mm | ||

| AT-SY-P3008 | 25mm *2mm *200mm | ||

| AT-SY-P3009 | 30mm *2mm *100mm | ||

| AT-SY-P3010 | 30mm *2mm *200mm | ||

| AT-SY-P3011 | 35mm *2.5mm *100mm | ||

| AT-SY-P3012 | 35mm *2.5mm *200mm | ||

| AT-SY-P3013 | 40mm *2.5mm *100mm | ||

| AT-SY-P3014 | 40mm *2.5mm *200mm | ||

| AT-SY-P3015 | 50mm *3mm *100mm | ||

| AT-SY-P3016 | 50mm *3mm *200mm | ||

| AT-SY-P3017 | 50mm *3mm *300mm | ||

| AT-SY-P3018 | 60mm *3mm *100mm | ||

| AT-SY-P3019 | 60mm *3mm *200mm | ||

| AT-SY-P3020 | 60mm *3mm *300mm | ||

| AT-SY-P3021 | 70mm *3mm *100mm | ||

| AT-SY-P3022 | 70mm *3mm *200mm | ||

| AT-SY-P3023 | 70mm *3mm *300mm | ||

| AT-SY-P3024 | 80mm *3mm *100mm | ||

| AT-SY-P3025 | 80mm *3mm *200mm | ||

| AT-SY-P3026 | 80mm *3mm *300mm | ||

| AT-SY-P3027 | 80mm*3mm*170mm | ||

| AT-SY-P3028 | 80mm*3mm*380mm | ||

| AT-SY-P3029 | 80mm*3mm*420mm | ||

| AT-SY-P3030 | 90mm *3mm *100mm | ||

| AT-SY-P3031 | 90mm *3mm *200mm | ||

| AT-SY-P3032 | 90mm *3mm *300mm | ||

| AT-SY-P3033 | 100mm *3mm *100mm | ||

| AT-SY-P3034 | 100mm *3mm *200mm | ||

| AT-SY-P3035 | 100mm *3mm *300mm | ||

| AT-SY-P4001 | Outer Dia.*Thickness*Width(mm) | Customized | |

Material Specifications of Fused Quartz Curved Plates

| Standard Material Properties | |

| Material: | High-purity fused quartz |

| SiO₂ Content: | ≥99.99% |

| Softening Point: | ~1730°C |

| Maximum Continuous Operating Temperature: | 1100°C |

| Short-term Temperature Resistance: | Up to 1450°C |

| Thermal Expansion Coefficient: | ≤5.5×10⁻⁷/K |

| Visible Light Transmission: | >93% |

| UV Transmission: | >80% |

| Shape: | Semi-circular (standard) |

TOQUARTZ® Solving Challenges with Fused Quartz Curved Plates

Fused Quartz Curved Plates for Infrared Heating Systems

Key Advantages

- TOQUARTZ® plates can withstand rapid temperature fluctuations of up to 1000°C without cracking, reducing system downtime and maintenance costs.

- With >90% reflection efficiency in the IR spectrum range, our curved plates maximize heating system efficiency and reduce energy consumption by 15-20% compared to conventional reflectors.

- TOQUARTZ® fused quartz curved plates maintain performance integrity for 10,000+ operating hours, significantly outlasting metal alternatives that degrade after 2,000-3,000 hours.

TOQUARTZ® solution

Traditional metal reflectors in infrared heating systems often degrade after 2,000–3,000 hours, leading to frequent replacements and inconsistent heat output.

TOQUARTZ® fused quartz curved plates deliver over 10,000 hours of stable performance with >90% IR reflectivity, reducing maintenance frequency and improving energy efficiency by up to 20%.

Fused Quartz Curved Plates for Laboratory Equipment

Key Advantages

- TOQUARTZ® 99.99% SiO₂ plates ensure zero contamination in sensitive analytical processes, critical for research integrity and reproducible results.

- TOQUARTZ® curved plates resist corrosion from concentrated acids for 200+ hours, extending equipment lifespan by 3-4x compared to borosilicate glass alternatives.

- We maintain dimensional tolerance of ±0.2mm for critical radius and thickness parameters, ensuring perfect fit and function in precision laboratory instruments.

TOQUARTZ® solution

An American laboratory equipment manufacturer struggled with local suppliers who couldn't meet ±0.2mm radius tolerance requirements, resulting in an 18% rejection rate.

TOQUARTZ® custom plates achieved consistent <2% rejection rates, dramatically improving their production efficiency and product reliability.

Fused Quartz Curved Plates for Industrial Furnaces

Key Advantages

- TOQUARTZ® curved plates maintain structural integrity at continuous temperatures of 1100°C, essential for reliable operation in industrial furnace applications.

- With a thermal expansion coefficient of just 5.5×10⁻⁷/K, our plates minimize stress on mounting fixtures, virtually eliminating thermally-induced failures.

- TOQUARTZ® can customize the exact curvature radius from 50-300mm (±0.5mm) to precisely match your furnace geometry and optical requirements.

TOQUARTZ® solution

Conventional glass shields in industrial furnaces often crack under thermal stress, risking equipment failure and safety hazards.

TOQUARTZ® fused quartz curved plates maintain structural integrity at 1100°C with minimal expansion, ensuring long-term reliability and precise fit in high-temperature furnace environments.

Customization Services for TOQUARTZ® Fused Quartz Curved Plates

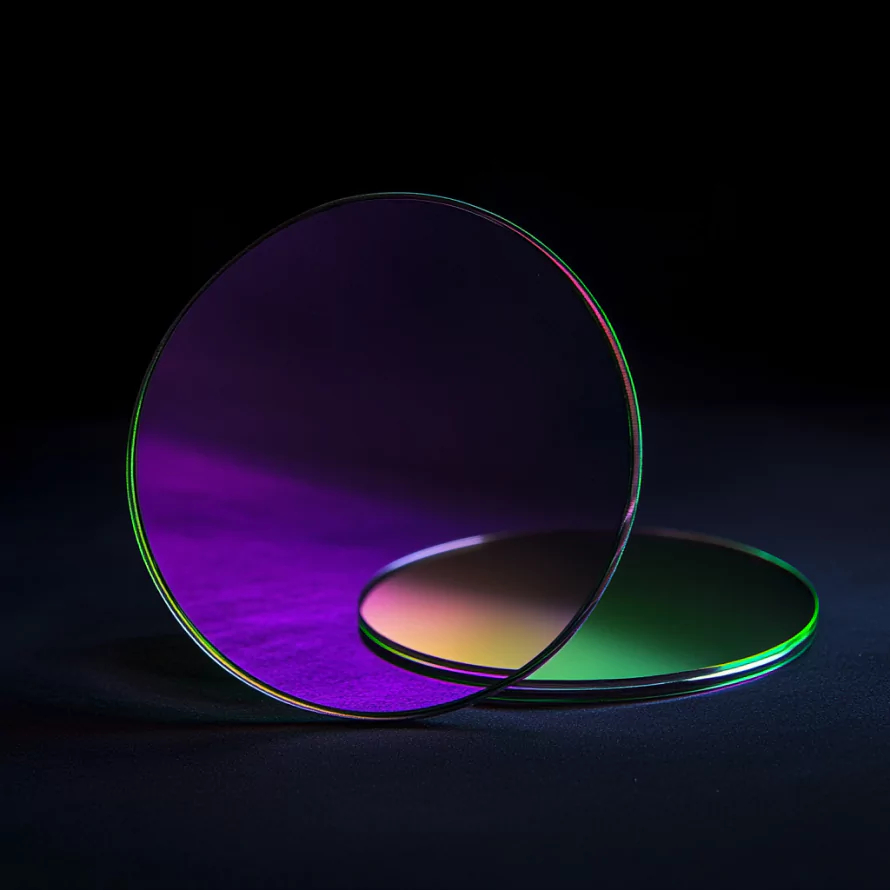

Surface Treatment Options

- Optical polishing for maximum transparency

- Precision ground finish for diffused light applications

- Edge treatments to reduce chipping risk

- Special coatings for enhanced IR reflection (where applicable)

Material Specification Options

- Standard grade (99.99% SiO₂)

- Special grade options available for specific applications

- Custom thermal expansion characteristics

- Optimized UV or IR transmission properties

TOQUARTZ® Engineering Support

Usage Guidelines for Fused Quartz Curved Plates

Handling and Storage

- Always wear clean, lint-free gloves when handling quartz plates to prevent surface contamination

- Store in a clean, dry environment away from potential impact sources

- Keep plates separated using lint-free paper or foam spacers to prevent scratching

- Avoid sudden temperature changes during storage, which can create thermal stress

Performance Optimization

- For optical applications, maintain the surfaces free of dust and fingerprints

- In heating applications, ensure proper thermal expansion allowance

- For electrical insulation applications, keep surfaces clean and free of conductive contaminants

- Periodically inspect for signs of surface degradation in long-term installations

Installation Recommendations

- Use mounting systems that accommodate thermal expansion

- Avoid direct metal-to-quartz contact by using PTFE or silicone gaskets

- Ensure mounting pressure is evenly distributed to prevent stress concentration

- Allow for expansion clearance in high-temperature applications

Cleaning Procedures

- Clean with deionized water and mild detergent for general applications

- For more stubborn contaminants, use isopropyl alcohol or acetone

- Ultrasonic cleaning in deionized water is effective for precision applications

- Always air dry or use filtered compressed air to prevent spotting

Need Expert Engineering Support?

Our technical team is ready to assist with material selection, design optimization, and manufacturing considerations

for your fused quartz curved plate applications.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Can TOQUARTZ® match a specific curvature radius for my furnace or heating system?

A: Yes, we offer custom radius fabrication from 50mm to 300mm with ±0.5mm tolerance to ensure precise fit for your equipment geometry.

Q: What is the typical surface finish of TOQUARTZ® fused quartz curved plates?

A: TOQUARTZ® provides optical-grade polished surfaces or ground finishes depending on your application. Custom surface treatments are available upon request.

Q: Are TOQUARTZ® curved quartz plates suitable for vacuum or inert gas environments?

A: Yes, our plates are chemically stable and thermally resistant, making them ideal for use in vacuum chambers and inert gas atmospheres.

Q: How do TOQUARTZ® curved plates perform under rapid heating and cooling cycles?

A: They exhibit excellent thermal shock resistance and can withstand temperature changes up to 1000°C without cracking or deformation.

Q: Do TOQUARTZ® curved plates support UV or IR transmission?

A: Yes, our fused quartz material offers >80% UV transmission and >90% IR reflectivity, suitable for optical and thermal applications.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.