- Home

- /

- Types

- /

- Quartz Bottle

- /

- Custom Engineered-Grade Quartz Source...

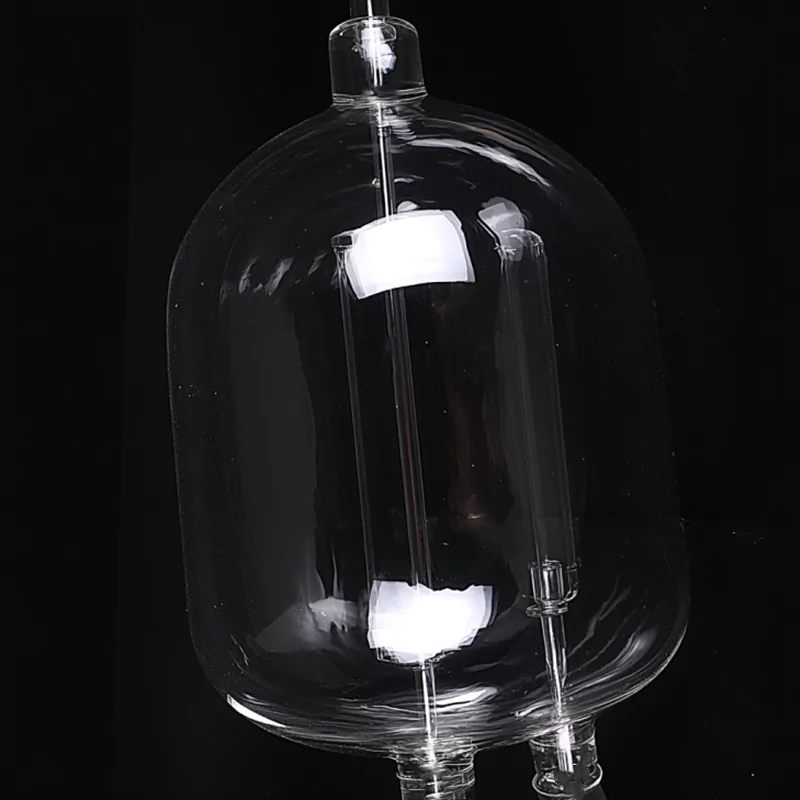

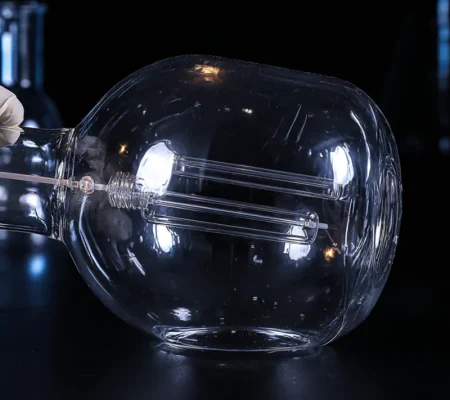

Custom Engineered-Grade Quartz Source Bottles for CVD/ALD Systems -TOQUARTZ®

Features of Quartz Source Bottles

TOQUARTZ® high-purity quartz source bottles are engineered specifically for applications requiring precise precursor delivery in chemical vapor deposition (CVD), atomic layer deposition (ALD), and related processes. Each one is manufactured using premium-grade quartz material to ensure consistent performance in demanding environments.

Material Properties

- High-purity quartz material (up to 99.995% SiO₂) for minimal contamination in semiconductor and materials research applications

- Thermal shock resistance, capable of withstanding rapid temperature changes without cracking

- Chemical resistance to acids, alkalis, molten salts, and fluorine-containing gases used in deposition processes

- High temperature stability up to 1200°C, ideal for high-temperature CVD and material synthesis applications

Design Features

- Precision-engineered inlet and outlet tubes for controlled gas flow and bubble formation in precursor delivery systems

- Highly transparent design allows for easy visual monitoring of precursor levels and bubbling action during operation

- Available with custom fittings including ground glass joints, compression fittings, or specialized connections to integrate with existing systems

- Dimensional precision of ±0.1mm for critical components, ensuring reliable performance and system compatibility

- 99.99% SiO₂ Purity

- Chemical Resistance

- Precision Joints

Technical Specifications of Quartz Source Bottle

Physical Properties

| Parameter | Value / Description |

| Density | 2.2 g/cm³ – Ensures mechanical stability under vacuum and thermal cycling |

| Maximum Working Temperature | 1200°C – Suitable for high-temperature precursor vaporization in CVD/MOCVD |

| Thermal Shock Resistance | ∆T ≥ 900°C – Withstands rapid heating/cooling in ALD pulsed cycles |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷ /°C (20–800°C) – Minimizes stress during thermal ramping |

| Thermal Conductivity | 1.4 W/m·K (at 20°C) – Supports uniform heat distribution in precursor zones |

Chemical Properties

| Parameter | Value / Description |

| SiO₂ Content | ≥99.99% – Prevents metal contamination in sub-10nm semiconductor processes |

| Total Trace Elements | <10 ppm – Verified by GDMS for ultra-clean deposition environments |

| Acid Resistance | Excellent (except HF) – Compatible with halide precursors like TiCl₄, WF₆ |

| Alkali Resistance | Good below 600°C – Suitable for base-sensitive precursor handling |

Optical Properties

| Parameter | Value / Description |

| Refractive Index | 1.458 (at 589.3 nm) – Enables visual monitoring of precursor levels |

| UV Transmission | >80% (200–2000 nm) – Supports optical inspection and UV-based process diagnostics |

| IR Transmission | Good up to 3.5 μm – Allows IR heating and monitoring in MOCVD systems |

TOQUARTZ® Solving Lab Challenges with Quartz Source Bottles

Quartz Source Bottles for Semiconductor Manufacturing

Key Advantages

-

Ultra-low trace metal content

Total metallic impurities < 5 ppb verified by GDMS, ensuring no ion contamination in 7nm node processes. -

High-temperature dimensional stability

Dimensional drift < 0.03mm after 1000°C annealing for 24h, critical for epitaxial uniformity. -

Halide gas compatibility

Proven resistance to TiCl₄, WF₆, and BCl₃ with no surface devitrification after 200 cycles.

TOQUARTZ® solution

A U.S.-based semiconductor OEM faced 12% yield loss due to precursor contamination in TiCl₄-based CVD. TOQUARTZ supplied quartz source bottles with <5 ppb impurity levels and halide-resistant polish. Yield improved by 9.4%, saving $27,000/month in wafer scrap.

Fused Quartz Precursor Bottles for Research & Development

Key Advantages

-

Rapid prototyping turnaround

Custom quartz bubblers delivered in 12 working days from drawing approval to shipment. -

Complex geometry fabrication

Achieved ±0.1mm tolerance on 3D bent inlet tubes with 2.5mm wall thickness. -

No MOQ for custom designs

Supported 1-piece orders for 7 different ALD precursor configurations in a single batch.

TOQUARTZ® solution

A European university lab required 3 unique quartz bubblers for ALD of novel 2D materials. TOQUARTZ delivered all 3 designs within 2 weeks, enabling the team to meet a Horizon 2020 grant milestone and secure €120,000 in continued funding.

Quartz Glass Source Bottles for Advanced Materials Production

Key Advantages

-

Batch-to-batch dimensional repeatability

OD variation < ±0.05mm across 200-unit production run, verified by laser micrometry. -

Extended chemical exposure lifespan

Maintained structural integrity after 500 hours of POCl₃ exposure at 950°C. -

24-hour dispatch for standard SKUs

500ml and 1500ml models shipped within 24h, reducing line downtime risk.

TOQUARTZ® solution

A Korean OLED materials supplier experienced 6-hour/month downtime due to bubbler failure in POCl₃ delivery. TOQUARTZ replaced their source bottles with high-durability quartz units, extending service life by 3.2× and reducing downtime by 83%, saving $18,000/month in lost output.

TOQUARTZ® Customization Services for Quartz Source Bottles

Design Consultation

Our engineering team analyzes your process requirements and provides technical drawings for custom quartz source bottles. We can modify existing designs or create entirely new configurations to optimize precursor delivery.

Prototype Development

We produce functional prototypes of custom quartz source bottles for ALD precursor delivery with rapid turnaround times. Test your design concepts before committing to production quantities, with typical prototype delivery in 2-3 weeks.

Production Manufacturing

Once your design is finalized, we transition to production manufacturing with rigorous quality control. We maintain consistent specifications across batches and offer flexible production volumes.

Customization Options

- Custom capacities from 500ml to 5,000ml

- Specialized inlet tube designs for optimized bubbling

- Custom fittings compatible with your existing system

- Multi-chamber configurations for complex processes

- Modified wall thickness for specific thermal profiles

- Integration with temperature control systems

Usage Guidelines of Quartz Source Bottles

Proper handling, installation, and maintenance of quartz source bottles are essential for ensuring optimal performance and extended service life in CVD, ALD, and other deposition processes. The following guidelines will help you maximize the value of your quartz precursor delivery components.

Handling & Installation

- Always wear clean, powder-free gloves when handling quartz source bottles to prevent contamination

- Inspect all connections for proper fit before installing in your system

- When tightening fittings, apply even pressure and avoid over-tightening that could crack the quartz

- Allow adequate clearance around the bottle for thermal expansion during heating cycles

Operation & Maintenance

- Implement gradual heating and cooling cycles to prevent thermal shock (recommended rate: <5°C/min)

- For cleaning, use only approved solvents and acids that are compatible with high-purity quartz

- Regularly inspect for devitrification (whitening of quartz), which indicates the need for replacement

- Store empty bottles in a clean, dry environment away from alkali sources

2. When filling, maintain a minimum 1/3 headspace to allow for proper gas bubbling and expansion

3. For temperature-sensitive precursors, pre-cool the bottle before filling

4. After loading, purge the system with inert gas before heating to remove any moisture or oxygen

5. Follow precursor-specific handling guidelines to prevent premature decomposition or contamination

Ready to optimize your precursor delivery system?

TOQUARTZ® delivers high-quality solutions with engineering support and quick turnaround times.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a quartz source bottle used for in CVD?

A: A quartz source bottle in CVD (Chemical Vapor Deposition) is used to contain and deliver precursor chemicals that form the deposited film. The high-purity quartz construction prevents contamination while allowing controlled evaporation or bubbling of carrier gas through the precursor to transport it to the reaction chamber.

Q: Can quartz source bottles be used with corrosive precursors?

A: Yes, high-purity quartz offers excellent resistance to most corrosive chemicals including strong acids (except HF), bases below 600°C, and halogen compounds commonly used as precursors. This chemical stability prevents contamination of the precursor and ensures consistent deposition quality.

Q: What temperature can quartz source bottles withstand?

A: TOQUARTZ® quartz source bottles can withstand continuous operating temperatures up to 1200°C. The material maintains its structural integrity and chemical inertness at these temperatures, making it ideal for high-temperature precursor delivery applications in CVD and ALD processes.

Q: Can quartz source bottles be used with solid precursors?

A: Yes, quartz source bottles can be designed specifically for solid precursors. These designs typically feature wider openings for loading, specialized heating zones to control sublimation, and gas flow paths designed to carry the sublimed precursor efficiently to the reaction chamber.

Q: Can custom quartz source bottles be designed for specific ALD systems?

A: Yes, TOQUARTZ® specializes in custom quartz source bottle designs for ALD precursor delivery that match exact system specifications. We can create custom inlet configurations, gas distribution systems, heating zones, and connection types to optimize precursor delivery for your specific ALD process requirements.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.