- Home

- /

- Types

- /

- Quartz Bottle

- /

- Precision-Lab Double Neck Round...

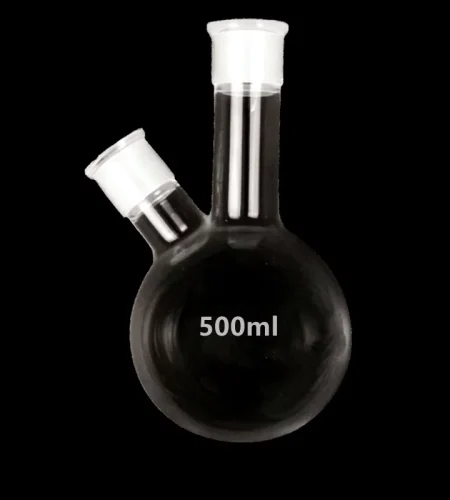

Precision-Lab Double Neck Round Bottom Quartz Flasks for Chemical Synthesis -TOQUARTZ®

Features of Double Neck Round Bottom Quartz Flasks

Material Excellence

-

High Purity:

99.99% SiO₂ content, ideal for sensitive chemical reactions and material synthesis -

Superior Chemical Resistance:

Withstands acids, bases, salt solutions, and fluorinated gases without degradation -

Electrical Insulation:

Excellent dielectric properties, suitable for high-voltage applications

Thermal Properties

-

High Temperature Stability:

Operational temperature up to 1200°C -

Thermal Shock Resistance:

Withstands rapid temperature changes without cracking -

Low Thermal Expansion:

Coefficient of 5.5×10⁻⁷/°C, ensuring dimensional stability

Design Precision

-

Standard Ground Joints:

24/29 ground glass joints ensure compatibility with common laboratory equipment -

Neck Angle Optimization:

Designed for efficient attachment of condensers, thermometers, and gas inlets

- Material: 99.99% SiO

- Temperature Resistance: Up to 1200°C

- Standard Joint Size: 24/29 ground glass joints

Technical Specifications & Dimensions of Quartz Glass Flask

Technical Specifications of Double Neck Round Bottom Fused Quartz Flask

Physical Properties

| Property | Value |

| Density | 2.2 g/cm³ |

| Hardness (Mohs) | 5.5-6.5 |

| Maximum Operating Temperature | 1200°C |

| Thermal Conductivity | 1.4 W/m·K |

| Thermal Expansion Coefficient | 5.5×10-7/℃ |

Chemical Properties

| Property | Value |

| SiO Content | ≥99.99% |

| Acid Resistance | Excellent (except HF) |

| Alkali Resistance | Good up to 1000°C |

| Chemical Inertness | Inert to most chemicals and reagents |

| Trace Element Impurities | <10 ppm total |

Dimensions of Round Bottom Quartz Flasks with Double Neck

| Model | Capacity (ml) | Joint Size | Dimensions (mm) | SiO2 Content(%) |

| AT-SY-SP1012 | 100 | 24/29 | 64*105 | 99.99 |

| AT-SY-SP1013 | 250 | 24/29 | 85*140 | 99.99 |

| AT-SY-SP1014 | 500 | 24/29 | 105*163 | 99.99 |

| AT-SY-SP1015 | 1000 | 24/29 | 131*200 | 99.99 |

| AT-SY-SP1016 | 2000 | 24/29 | 131*200 | 99.99 |

TOQUARTZ® Solving Lab Challenges with Double Neck Quartz Flasks

Double Neck Quartz Flasks for High-Temperature Chemical Synthesis

Key Advantages

-

Thermal stability up to 1200°C

TOQUARTZ® quartz flasks maintain structural integrity at temperatures where standard glassware softens or deforms, allowing for reactions that require extreme heating. -

Superior chemical purity retention

The 99.99% SiO₂ composition prevents contamination of sensitive reactions, ensuring result reliability and reproducibility.

TOQUARTZ® solution

A materials research team at a German university reported consistent failures when synthesizing metal oxide catalysts at 900°C using conventional glassware, with vessel failure occurring within 20 minutes of reaching temperature.

TOQUARTZ® double neck quartz flasks provided a reliable solution, withstanding the full 4-hour reaction cycle without degradation or contamination, enabling successful catalyst development for their renewable energy project.

Double Neck Quartz Glass Flasks for Precise Distillation Processes

Key Advantages

-

Enhanced thermal conductivity

The uniform thermal properties of quartz glass ensure even heat distribution, preventing hot spots that can degrade sensitive compounds. -

Precision dual-neck configuration

The optimized neck angles and standard ground joints allow for secure attachment of thermometers and condensers with minimal dead space.

TOQUARTZ® solution

A Japanese specialty chemicals manufacturer struggled with product purity inconsistencies when distilling heat-sensitive pharmaceutical intermediates.

After switching to TOQUARTZ double neck quartz distillation flasks, they reported a 94% reduction in product contamination and 15% improvement in yield due to better temperature control and elimination of glass-derived impurities, saving approximately $15,000 per production batch.

Double Neck Fused Quartz Flasks for Controlled Atmosphere Reactions

Key Advantages

-

Vacuum and pressure stability

TOQUARTZ® quartz flasks maintain integrity under vacuum conditions and moderate positive pressures, enabling controlled atmosphere experiments. -

Precision-ground glass joints

The 24/29 ground joints provide gas-tight seals when used with appropriate greases or O-rings, preventing atmosphere contamination.

TOQUARTZ® solution

A U.S. national laboratory research team working on oxygen-sensitive metal-organic frameworks reported repeated experiment failures due to air leakage at elevated temperatures using standard glassware.

After implementing TOQUARTZ double neck quartz flasks in their Schlenk line setup, they achieved consistent oxygen levels below 0.5 ppm throughout their 850°C synthesis process, enabling successful development of novel hydrogen storage materials with 30% greater capacity than previously possible.

TOQUARTZ® Quartz Flask Customization Services

Dimensional Customization

- Custom flask capacities (250ml to 5000ml)

- Specialized neck angles (0-90°)

- Custom neck lengths and diameters

- Wall thickness optimization (1.5-4mm)

- Custom ground joint sizes (10/19 to 45/50)

Functional Enhancements

- Integration of sampling ports

- Custom side arms or delivery tubes

- Specialized internal baffles

- Graduated volume markings

Process Support

- Technical drawing assistance

- Prototype development

- Sample testing and validation

- Material certificates

- Technical documentation packages

Customization Process

Requirement Analysis

- TOQUARTZ® engineers assess your application needs for double neck quartz flasks with round bottom, including joint size, neck angle, and thermal requirements.

Design & Approval

- We provide technical drawings of the customized quartz round bottom flask for your review, ensuring all specifications match your lab setup.

Prototype Development

- A sample double neck quartz flask is produced based on approved drawings, allowing you to validate fit, function, and material compatibility.

Production & Delivery

- Once confirmed, we begin full-scale production of your custom fused quartz flasks with strict quality control and global shipping support.

Usage Guidelines of Double Neck Round Bottom Quartz Flasks

Proper handling, cleaning, and maintenance of double neck quartz flasks are essential for maximizing their performance and lifespan. Follow these guidelines to ensure optimal results and preserve the integrity of your quartz glassware.

Handling and Setup

-

Support Securely:

Always use appropriate clamps and supports for round bottom flasks, ensuring weight is evenly distributed. -

Heating Precautions:

Increase temperature gradually (100°C/minute maximum) to prevent thermal shock. Use heating mantles rather than direct flame for even heating. -

Connection Integrity:

Ensure ground glass joints are properly seated with appropriate joint grease for high-temperature applications or PTFE sleeves for chemical compatibility. -

Cooling Precautions:

Allow flask to cool naturally to below 200°C before further handling or cooling. Avoid rapid temperature changes that could cause thermal stress.

Cleaning Procedures

-

Initial Rinse:

Rinse with appropriate solvent compatible with reaction residues while flask is still warm (but below 100°C). -

Cleaning Solutions:

For most residues, use aqua regia, piranha solution, or chromic acid depending on contamination type. For standard cleaning, laboratory detergent solution followed by deionized water is sufficient. -

Avoid Abrasives:

Never use abrasive cleaners or brushes that could scratch the quartz surface. For stubborn residues, soak in appropriate solvent rather than scrubbing. -

Final Rinse:

Rinse thoroughly with deionized water followed by acetone or methanol for rapid drying.

Drying & Storage

-

Air Drying:

Allow to air dry in a dust-free environment or in a clean drying oven at 110-120°C. -

Vacuum Drying:

For critical applications, connect to vacuum line and gently heat (60-80°C) to remove all moisture. -

Storage Environment:

Store in clean, dust-free cabinets away from potential impact hazards. Use soft padding between vessels. -

Joint Protection:

Cover ground glass joints with appropriate caps or aluminum foil to prevent dust accumulation and potential damage.

Safety Precautions

-

Pressure Limitations:

Do not use for high-pressure applications. Maximum recommended pressure differential is 1 atmosphere. -

Inspection Before Use:

Always check for cracks, chips, or stress marks before heating or applying vacuum. -

Temperature Gradients:

Avoid extreme temperature gradients across the flask wall, which can cause thermal stress and failure. -

PPE Requirements:

Always wear appropriate personal protective equipment when handling, including heat-resistant gloves when working with heated flasks.

Need Engineering Support for Your Double Neck Quartz Flask Project?

and application-specific recommendations for your laboratory requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a double neck round bottom flask used for?

A: Double neck round bottom quartz flasks are primarily used for high-temperature chemical reactions, distillation processes, and controlled atmosphere synthesis. The second neck allows for the introduction of reagents, inert gas, or monitoring equipment (like thermometers) while the main neck connects to condensers or other apparatus.

Q: What is the maximum temperature for quartz flasks?

A: TOQUARTZ® double neck quartz flasks can withstand temperatures up to 1200°C, significantly higher than borosilicate glass (which typically softens around 820°C). However, for prolonged use, we recommend operating below 1100°C to maintain the structural integrity and extend the flask’s service life.

Q: How to clean a double neck quartz flask?

A: For routine cleaning, rinse with appropriate solvents while still warm (but below 100°C). For thorough cleaning, use laboratory detergent solutions followed by deionized water. For stubborn residues, aqua regia, piranha solution, or chromic acid may be used depending on contamination type. Always avoid abrasive cleaners or brushes that could scratch the quartz surface, and finish with thorough rinsing using deionized water.

Q: How to dry a double neck round bottom flask?

A: For standard drying, rinse with acetone or methanol after cleaning and allow to air dry in a dust-free environment. For analytical applications requiring complete dryness, use a clean laboratory oven at 110-120°C. For critical applications, connect to a vacuum line and gently heat (60-80°C) to remove all moisture. Flame drying under vacuum can also be used for experienced operators.

Q: What are the safety precautions for double neck round bottom flasks?

A: Key safety precautions include: always secure flasks properly with clamps; avoid rapid temperature changes that can cause thermal stress; inspect for cracks before each use; use proper heating equipment like mantles rather than direct flame; never seal completely when heating contents; and wear appropriate PPE including safety glasses and heat-resistant gloves.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.