Engineered Quartz Boat Solutions for

Critical Thermal Environments

TOQUARTZ® quartz boats are engineered to perform in high-demand thermal processes across semiconductor, photovoltaic, and laboratory industries.

- Built for Thermal Extremes

- Tailored to Your Process

- MOQ-Free Custom Supply

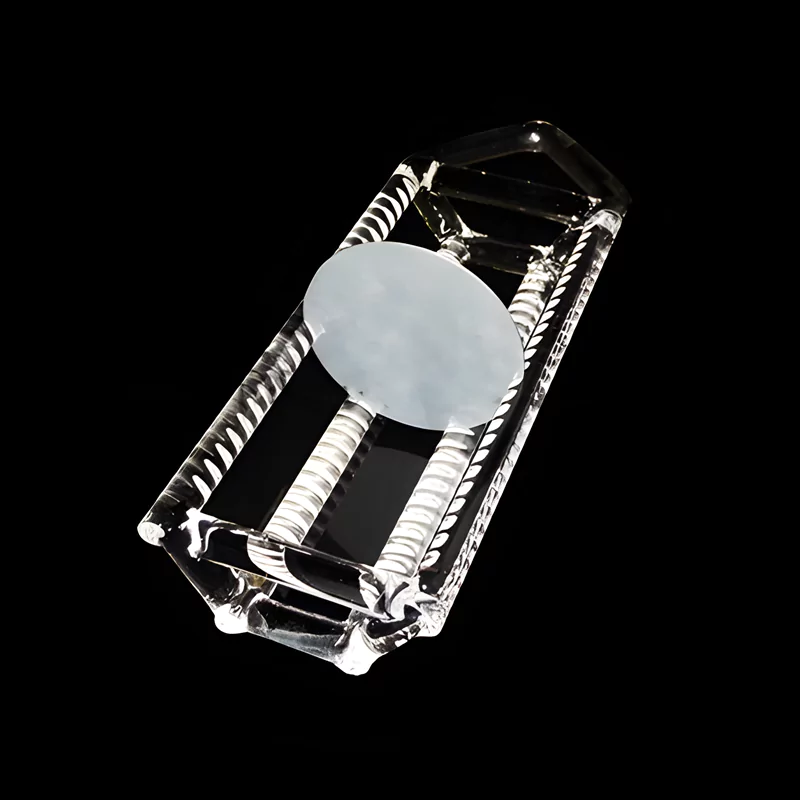

TOQUARTZ® Quartz Boat Product Range

TOQUARTZ® offers a comprehensive range of high-quality fused quartz boats for various industrial applications, from standard models to fully customized solutions.

What Is a Quartz Boat?

A quartz boat is a high-temperature resistant carrier vessel made from high-purity fused silica (SiO₂), specifically designed to hold, transport, and process materials in extreme thermal and chemical environments. These precision-engineered vessels are essential components in semiconductor manufacturing, solar cell production, and various high-temperature laboratory applications.

Key Features of TOQUARTZ® Quartz Boat for Thermal Applications

Designed for extreme thermal and chemical environments, TOQUARTZ® quartz boats combine structural integrity, dimensional precision, and material purity to ensure reliable performance in semiconductor, solar, and laboratory processes.

Material Properties of Fused Quartz Boats

- Exceptional thermal stability up to 1300°C+, making quartz combustion boats ideal for high-temperature processing

- Superior chemical resistance against acids, alkalis, and fluorinated gases

- High purity (up to 99.995% SiO₂) ensuring minimal contamination for silicon wafer carrier quartz boats

- Excellent electrical insulation properties for use in high-temperature electric field environments

Structural Advantages of Quartz Boat

-

High mechanical strength with fracture modulus up to

350MPa+ - Low thermal expansion coefficient (approximately 5.5×10⁻⁷/K) providing dimensional stability

- Precision manufacturing capabilities with dimensional tolerance of ±0.1mm

- Customizable designs to accommodate various materials and processing requirements

TOQUARTZ® Fused Quartz Glass Boat Applications

Quartz boats play a critical role in high-temperature and chemically intensive processes across semiconductor fabrication, solar cell production, advanced research, and wet chemical etching, where thermal stability, purity, and structural precision are essential.

Quartz Wafer Boats for Semiconductor Manufacturing

Quartz wafer boats are essential in semiconductor fabrication for carrying silicon wafers through high-temperature diffusion, annealing, and oxidation processes. Their precision design ensures wafer stability and uniform heat distribution, while high-purity materials prevent contamination critical in chip manufacturing.

Primary applications include:

- Thermal diffusion processes

- Silicon wafer annealing

- Oxidation procedures

- LPCVD (Low Pressure Chemical Vapor Deposition)

Fused Quartz Wafer Boat Carrier for Solar Cell Production

In photovoltaic manufacturing, silicon substrate quartz wafer boats support silicon wafers during critical high-temperature processes. Their thermal stability and chemical resistance are vital for maintaining product quality during phosphorus diffusion and other solar cell fabrication steps.

Key applications include:

- Diffusion processes for PV cells

- Anti-reflection coating application

- High-temperature annealing processes

Quartz Combustion Boats for Laboratory & Research Applications

Quartz combustion boats are widely used in research laboratories for material processing under controlled atmospheres. Their inert properties make them ideal for high-temperature experiments where sample purity must be maintained.

Common research applications:

- Material synthesis and characterization

- High-temperature reactions

- Controlled atmosphere experiments

- Sample preparation for analytical testing

Quartz Acid CleaningTanks for Chemical Processing & Wet Etching

TOQUARTZ® quartz chemical cleaning tanks are designed for aggressive chemical environments where other materials would degrade. Their excellent chemical resistance makes them ideal for acid baths and wet etching processes.

Applications include:

- Semiconductor wafer cleaning

- Chemical etching processes

- High-purity material preparation

- Acid digestion procedures

Quality Assurance for TOQUARTZ® Fused Silica Glass Boats

TOQUARTZ’s commitment to quality ensures that every fused quartz boat meets rigorous industry standards and specifications.

ISO-Certified Manufacturing

TOQUARTZ® quartz boat production facilities operate under ISO 9001 standards, ensuring consistent quality and manufacturing excellence.

REACH Compliance

All TOQUARTZ fused quartz boat products comply with REACH regulations, ensuring they are free from restricted substances.

RoHS Certified

TOQUARTZ® quartz boat crucibles meet RoHS standards, confirming they are manufactured without hazardous substances.

TOQUARTZ Quality Control

AI-Powered Raw Material Vetting

Eliminate impurity risks in high-purity quartz sand (99.98% SiO₂ baseline, max. up to 99.995% )

Real-Time Process Optimization

Maintain precise dimensional tolerance during forming process

Multi-Axis Performance Validation

Ensure functionality under extreme operating conditions

Traceable Compliance Documentation

Guarantee material traceability for critical applications

Customer-Centric Quality Proofing

Align validation methods with client-specific operational demands

TOQUARTZ® Engineering Expertise & Technical Support for

Customized Quartz Boat

At TOQUARTZ®, our engineering team brings deep expertise in quartz material science, thermal processing applications, and precision manufacturing. We understand that B2B clients—especially in semiconductor, photovoltaic, and research industries—face strict technical requirements, tight project timelines, and high expectations for dimensional accuracy and material purity. Our technical support is not just reactive—it’s proactive, collaborative, and solution-oriented.

Application-Centric Design Knowledge

TOQUARTZ® don’t just manufacture quartz boats—we understand how they’re used. Whether it’s a silicon wafer diffusion process in a semiconductor fab, a phosphorus doping step in a solar cell line, or a high-temperature reaction in a university lab, our engineers are familiar with the thermal, chemical, and mechanical stresses your quartz boat must endure. This allows us to recommend the right design, wall thickness, and slot configuration for your specific use case.

Drawing Assistance & Design Optimization

Many clients—especially small to mid-sized equipment manufacturers or research institutions—lack in-house quartz design expertise. We offer free drawing assistance based on your process parameters, sketches, or sample photos. For example, we helped a Polish PV equipment integrator redesign their silicon substrate quartz wafer boat, reducing wafer breakage by 18% during thermal cycling.

Rapid Prototyping & Iterative Sampling

We understand that time is critical. That’s why we offer 10–15 day prototyping for custom quartz boat crucibles—significantly faster than the 6+ week industry average. Clients in Germany and the U.S. have praised our ability to deliver test samples quickly, enabling faster validation and production ramp-up.

Tolerance Control & Dimensional Precision

Many B2B buyers report issues with local suppliers failing to meet ±0.1mm tolerances, leading to wafer jamming or misalignment in automated systems. While TOQUARTZ cannot guarantee ±0.05mm for all geometries, we consistently achieve ±0.1mm and will advise upfront if tighter tolerances are not feasible. This transparency reduces costly rework and production delays.

Material Selection & Purity Advisory

Not all quartz is created equal. We help clients choose between standard 99.99% SiO₂ and ultra-high purity 99.995% fused quartz based on contamination sensitivity, thermal load, and chemical exposure. For example, a Canadian lab required quartz combustion boats resistant to HF vapor; we recommended a specific fused quartz grade with proven resistance to fluorine corrosion.

Process Compatibility Consulting

We advise on compatibility with LPCVD, PECVD, oxidation, annealing, and wet etching processes. For instance, a Korean semiconductor OEM needed quartz acid cleaning tanks compatible with HCl and H₂SO₄ at 120°C. We provided a rectangular tank design with reinforced corners and acid-resistant polishing, extending service life by 40%.

Failure Analysis & Continuous Improvement

If a client experiences cracking, warping, or contamination, we offer root cause analysis based on returned samples or process data. In one case, a U.S.-based wafer fab had a 15% breakage rate in their quartz wafer boat holders. Our engineers identified uneven thermal gradients due to poor slot spacing and redesigned the holder to reduce stress points.

Multilingual Technical Communication

Our engineers support English, Japanese, and Korean communication, ensuring smooth collaboration with clients in key markets. We provide 2D/3D CAD files, technical datasheets, and process compatibility charts to support your internal documentation and procurement approvals.

No MOQ for Premium Quartz Boats

Unlike many manufacturers who impose large minimum order requirements, TOQUARTZ has optimized our production processes to accommodate orders of any size—from single fused quartz boat to large production runs.

Efficient Manufacturing Process

TOQUARTZ® streamlined production system allows us to produce small batches of quartz boats efficiently, without the setup costs typically associated with limited production runs.

Strategic Inventory Management

We maintain stock of common fused quartz boat components, enabling rapid assembly of custom configurations without the economic pressures of large batch requirements.

Flexible Production Scheduling

Our manufacturing schedule accommodates small orders of specialized items like quartz wafer boat holders alongside larger production runs, optimizing equipment utilization.

Quartz Boat Manufacturing Process丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Why Choose TOQUARTZ® for Your Quartz Boat Needs

Partner with TOQUARTZ for superior quartz boat solutions that deliver precision, reliability, and exceptional value.

Custom Design Solutions

We provide tailored quartz boat solutions designed to your exact specifications. Our engineering team works closely with you to develop custom products that address your unique processing requirements.

- Expert engineering assistance with technical drawings

- Prototyping and sample development

- Custom quartz boats for specialized processes

- Tailored quartz boat to match your equipment

No Minimum Order Quantity

Unlike many manufacturers, TOQUARTZ offers fused quartz boats with no minimum order quantity requirements. This flexibility allows you to order exactly what you need, when you need it.

- Order single units for testing or small production runs

- Scale up orders as your requirements grow

- Specialty quartz boats available in single units

- Cost-effective solutions for R&D and small batch production

Direct Factory Supply

As a Chinese manufacturer with direct factory supply, we eliminate intermediaries to provide competitive pricing on premium quartz boats without compromising quality.

- Cost advantages of direct manufacturer pricing

- Streamlined communication with production team

- Full transparency in manufacturing process

Rapid Delivery Times

Our efficient production processes and stocked inventory of standard quartz boat products enable industry-leading delivery times to keep your operations running smoothly.

- 24-hour shipping for in-stock standard products

- Expedited production options available

- Reliable delivery schedule to prevent production delays

FAQs

Q: What is a quartz boat used for?

A: Quartz boats are high-temperature resistant carriers used to hold materials during thermal processing in semiconductor manufacturing, solar cell production, and laboratory applications. They provide stable support while withstanding extreme temperatures and chemical environments.

Q: What temperature can quartz boats withstand?

A: TOQUARTZ® quartz boats can withstand continuous operating temperatures up to 1300°C, making them ideal for high-temperature diffusion, annealing, and sintering processes. They maintain dimensional stability and don’t release contaminants even at extreme temperatures.

Q: How should I clean quartz boats?

A: For proper cleaning, soak quartz boats in diluted hydrofluoric acid (HF) or a mixture of H₂SO₄ and H₂O₂ (piranha solution) to remove contaminants. Rinse thoroughly with deionized water and dry in a clean environment. Always follow appropriate safety protocols when handling acids.

Q: What is the difference between fused quartz and ceramic boats?

A: Fused quartz boats offer superior purity (99.99%+ SiO₂), excellent thermal shock resistance, and minimal thermal expansion compared to ceramic boats. They’re ideal for applications requiring high temperature stability and ultra-clean processing environments.

Q: What factors affect quartz boat pricing?

A: Quartz boat pricing is determined by dimensions, complexity, material purity, quantity, and customization requirements. As a direct manufacturer, TOQUARTZ offers competitive pricing by eliminating intermediaries while maintaining high quality standards.

Q: Can TOQUARTZ quartz boats be used in fluorine environments?

A: Yes, our high-purity quartz boats show excellent resistance to fluorine-containing environments commonly used in semiconductor etching processes. However, the exact durability depends on concentration, temperature, and exposure time.

Q: How does quartz boat purity affect semiconductor processing?

A: Higher purity quartz boats (99.99%+ SiO₂) minimize contamination during wafer processing, which is critical for semiconductor manufacturing. Impurities can cause defects in the silicon wafers, reducing yield and device performance.

Q: Can TOQUARTZ provide custom quartz boat designs?

A: Yes, TOQUARTZ specializes in custom quartz boat manufacturing based on client specifications or samples. Our engineering team can assist with design optimization, material selection, and prototype development to create solutions tailored to your specific requirements.

Contact TOQUARTZ For Your Quartz Boat Solutions Today!

TOQUARTZ technical team is ready to assist with your quartz boat requirements. Contact us for quotes, technical support, or custom design inquiries.

- Direct factory pricing with no intermediaries

- Expert engineering support for custom designs

- No minimum order quantity requirements

- Fast delivery with 24-hour shipping for stock items

- Comprehensive supply chain management services