- Home

- /

- Types

- /

- Quartz Plate

- /

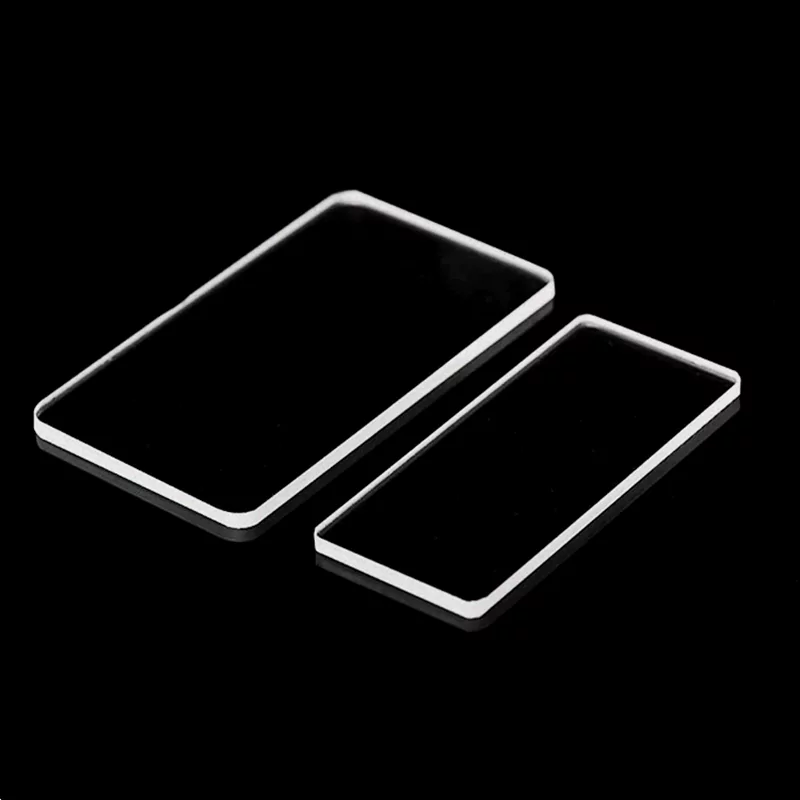

- Clear Quartz Glass Plate...

Custom Clear Quartz Glass Plate with High Purity Optical Quartz -TOQUARTZ®

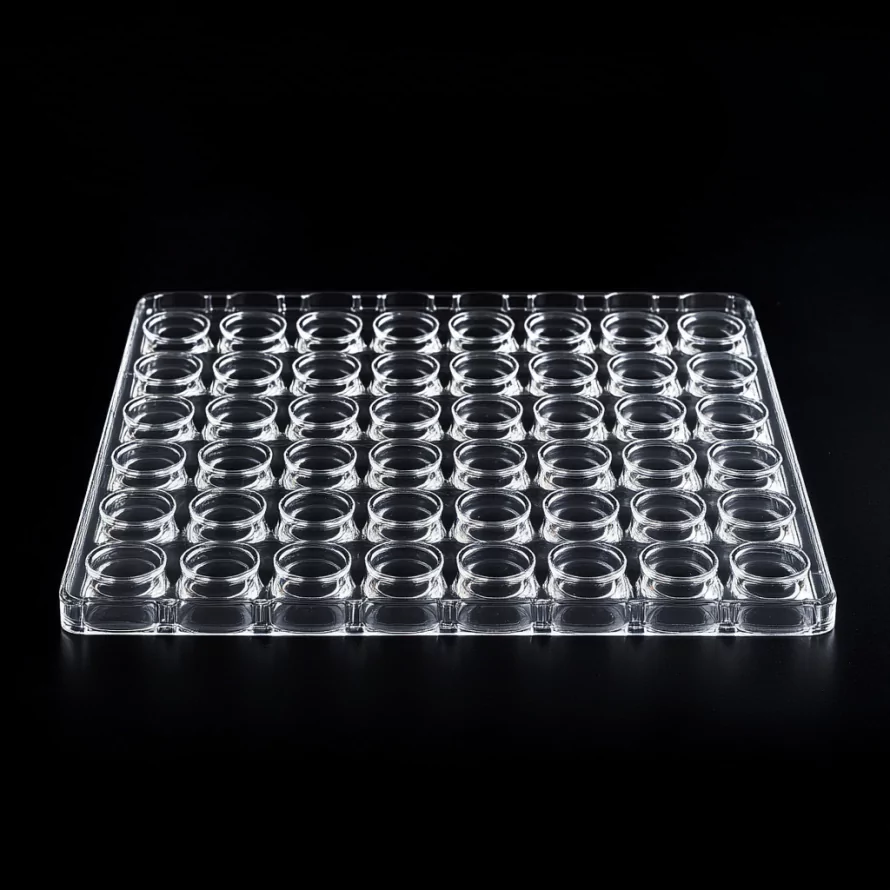

Ideal for laboratory equipment, optical instruments, UV sterilization systems, and high-temperature industrial applications requiring superior performance and durability.

Key Features of Clear Quartz Glass Plate

TOQUARTZ® clear quartz glass plates combine exceptional optical properties with outstanding thermal and chemical resistance, making them ideal for demanding applications across multiple industries.

High Temperature Resistance

TOQUARTZ® quartz plates can withstand continuous use at 1100°C and short-term exposure up to 1450°C. With a low thermal expansion coefficient, they can endure rapid temperature changes without cracking.

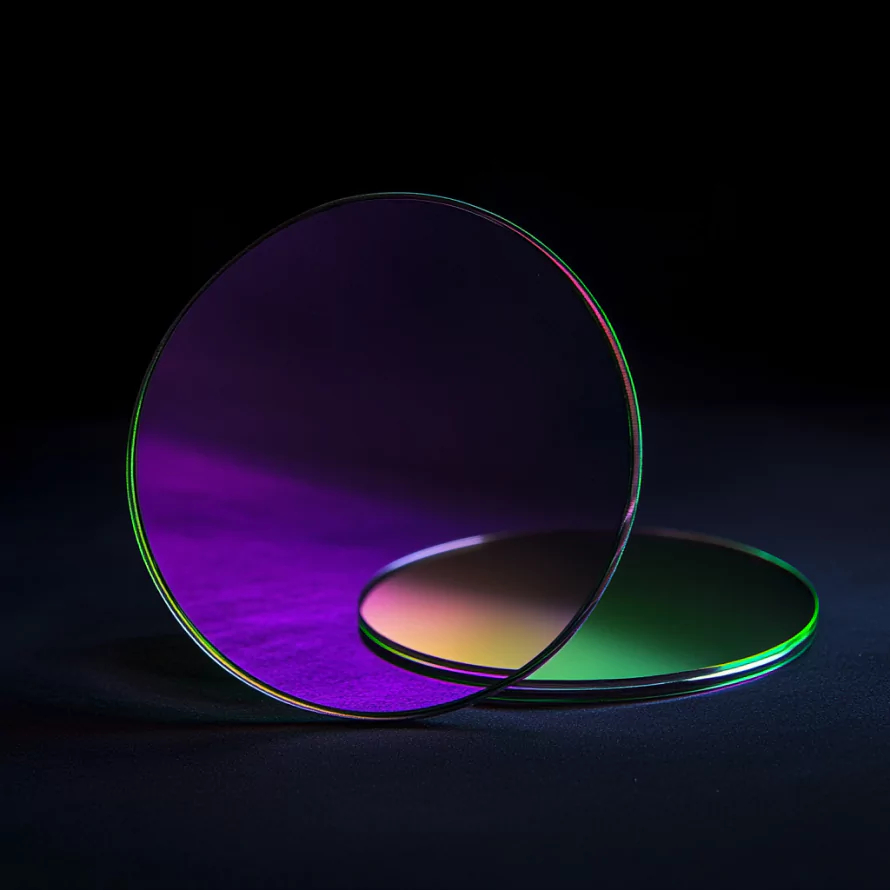

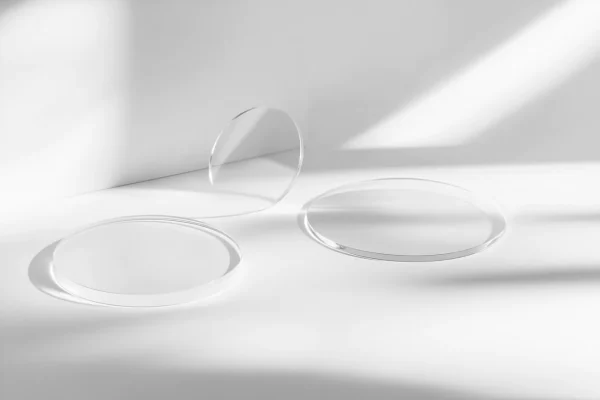

Excellent Optical Properties

Superior transmission across UV to IR spectrum with visible light transmission exceeding 93% and UV transmission above 80%. Ideal for optical windows, filters, and precision measurement equipment.

Chemical Resistance

Highly resistant to almost all acids except hydrofluoric acid. Maintains chemical stability even at elevated temperatures, making it perfect for aggressive chemical environments and laboratory equipment.

- Max Temp: 1450°C

- UV Transmission: >80%

- Strong Chemical Resistance

Technical Specifications & Dimensions of Clear Quartz Glass Plate

| Quartz Glass Round Disc | |||

| Model | Diameter(mm) | Thickness(mm) | SiO2’s Purity(%) |

| AT-SY-P1001 | 2 | 0.5 | 99.99 |

| AT-SY-P1002 | 5 | 0.5 | 99.99 |

| AT-SY-P1003 | 10 | 1 | 99.99 |

| AT-SY-P1004 | 10 | 2 | 99.99 |

| AT-SY-P1005 | 12 | 1 | 99.99 |

| AT-SY-P1006 | 13 | 1 | 99.99 |

| AT-SY-P1007 | 15 | 1 | 99.99 |

| AT-SY-P1008 | 15 | 1.5 | 99.99 |

| AT-SY-P1009 | 18 | 2 | 99.99 |

| AT-SY-P1010 | 19.4 | 2 | 99.99 |

| AT-SY-P1011 | 20 | 1 | 99.99 |

| AT-SY-P1012 | 20 | 1.5 | 99.99 |

| AT-SY-P1013 | 20 | 2 | 99.99 |

| AT-SY-P1014 | 24 | 2 | 99.99 |

| AT-SY-P1015 | 25 | 1 | 99.99 |

| AT-SY-P1016 | 30 | 1 | 99.99 |

| AT-SY-P1017 | 30 | 2 | 99.99 |

| AT-SY-P1018 | 30 | 5 | 99.99 |

| AT-SY-P1019 | 35 | 2 | 99.99 |

| AT-SY-P1020 | 36 | 2.2 | 99.99 |

| AT-SY-P1021 | 37 | 7 | 99.99 |

| AT-SY-P1022 | 40 | 1 | 99.99 |

| AT-SY-P1023 | 40 | 2 | 99.99 |

| AT-SY-P1024 | 40 | 5 | 99.99 |

| AT-SY-P1025 | 41.5 | 4 | 99.99 |

| AT-SY-P1026 | 46 | 2 | 99.99 |

| AT-SY-P1027 | 46.8 | 3 | 99.99 |

| AT-SY-P1028 | 50 | 1 | 99.99 |

| AT-SY-P1029 | 50 | 2 | 99.99 |

| AT-SY-P1030 | 50 | 10 | 99.99 |

| AT-SY-P1031 | 67.5 | 2 | 99.99 |

| AT-SY-P1032 | 70 | 2 | 99.99 |

| AT-SY-P1033 | 80 | 2 | 99.99 |

| AT-SY-P1034 | 90 | 8 | 99.99 |

| AT-SY-P1035 | 80 | 5 | 99.99 |

| AT-SY-P1036 | 2-750mm | 0.5-100mm | 99.99 |

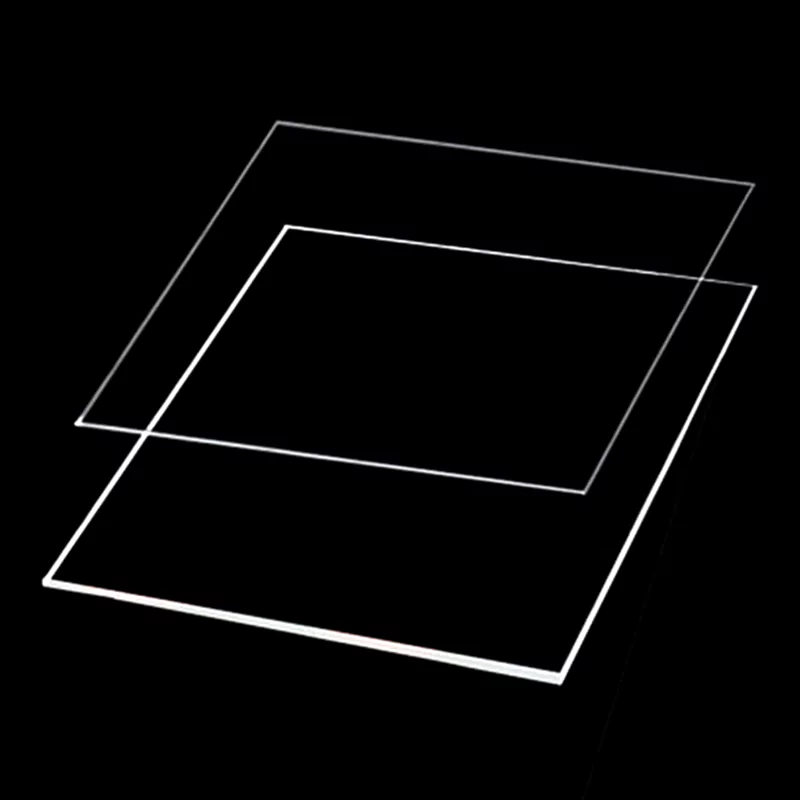

| Quartz Glass Square Plate | |||

| Model | L*W(mm) | Thickness(mm) | SiO2’s Purity(%) |

| AT-SY-P1037 | 2*2 | 0.5 | 99.99 |

| AT-SY-P1038 | 5*5 | 0.5 | 99.99 |

| AT-SY-P1039 | 5*5 | 1 | 99.99 |

| AT-SY-P1040 | 8*8 | 2 | 99.99 |

| AT-SY-P1041 | 10*10 | 1 | 99.99 |

| AT-SY-P1042 | 20*20 | 1 | 99.99 |

| AT-SY-P1043 | 25*25 | 1 | 99.99 |

| AT-SY-P1044 | 30*30 | 1 | 99.99 |

| AT-SY-P1045 | 40*40 | 1 | 99.99 |

| AT-SY-P1046 | 50*50 | 0.5 | 99.99 |

| AT-SY-P1047 | 50*50 | 1 | 99.99 |

| AT-SY-P1048 | 50*50 | 2 | 99.99 |

| AT-SY-P1049 | 50*50 | 4 | 99.99 |

| AT-SY-P1050 | 50*50 | 5 | 99.99 |

| AT-SY-P1051 | 60*60 | 1 | 99.99 |

| AT-SY-P1052 | 60*60 | 1 | 99.99 |

| AT-SY-P1053 | 60*60 | 3 | 99.99 |

| AT-SY-P1054 | 60*60 | 4 | 99.99 |

| AT-SY-P1055 | 60*60 | 5 | 99.99 |

| AT-SY-P1056 | 75*25 | 1 | 99.99 |

| AT-SY-P1057 | 75*25 | 2 | 99.99 |

| AT-SY-P1058 | 100*100 | 1 | 99.99 |

| AT-SY-P1059 | 100*100 | 2 | 99.99 |

| AT-SY-P1060 | 100*100 | 3 | 99.99 |

| AT-SY-P1061 | 100*100 | 4 | 99.99 |

| AT-SY-P1062 | 100*100 | 5 | 99.99 |

| AT-SY-P1063 | 100*100 | 6 | 99.99 |

| AT-SY-P1064 | 100*100 | 10 | 99.99 |

| AT-SY-P1065 | 100*100 | 8 | 99.99 |

| AT-SY-P1066 | 200*200 | 3 | 99.99 |

| AT-SY-P1067 | 300*300 | 5 | 99.99 |

| AT-SY-P1068 | 700*700mm | 0.5-100mm | 99.99 |

| Quartz Plate Rectangular | ||||

| Model | L(mm) | W(mm) | Thickness(mm) | SiO2’s Purity(%) |

| AT-SY-P1069 | 5 | 2 | 0.5 | 99.99 |

| AT-SY-P1070 | 8 | 4 | 0.5 | 99.99 |

| AT-SY-P1071 | 10 | 4 | 1 | 99.99 |

| AT-SY-P1072 | 12 | 5 | 1 | 99.99 |

| AT-SY-P1073 | 20 | 4 | 1 | 99.99 |

| AT-SY-P1074 | 30 | 8 | 2 | 99.99 |

| AT-SY-P1075 | 50 | 20 | 1 | 99.99 |

| AT-SY-P1076 | 60 | 40 | 5 | 99.99 |

| AT-SY-P1077 | 80 | 50 | 2 | 99.99 |

| AT-SY-P1078 | 100 | 60 | 5 | 99.99 |

| AT-SY-P1079 | 100 | 40 | 0.5 | 99.99 |

| AT-SY-P1080 | 120 | 70 | 0.8 | 99.99 |

| AT-SY-P1081 | 120 | 70 | 1 | 99.99 |

| AT-SY-P1082 | 120 | 100 | 2 | 99.99 |

| AT-SY-P1083 | 150 | 60 | 1 | 99.99 |

| AT-SY-P1084 | 200 | 120 | 5 | 99.99 |

| AT-SY-P1085 | 200 | 100 | 5 | 99.99 |

| AT-SY-P1086 | 300 | 100 | 2 | 99.99 |

| AT-SY-P1087 | 5-700mm | 2-550mm | 0.5-80mm | 99.99 |

| Property | Specification | Notes |

| Material | High Purity Fused Silica (SiO₂) | ≥99.99% purity |

| Thickness Range | 0.5mm to 100mm | ±0.01mm tolerance |

| Maximum Use Temperature | 1100°C (continuous), 1450°C (short-term) | Maintains dimensional stability |

| Thermal Expansion Coefficient | 5.5×10⁻⁷/°C | Excellent thermal shock resistance |

| Visible Light Transmission | >93% | For 1mm thickness |

| UV Transmission | >80% (200-300nm) | Depends on grade selected |

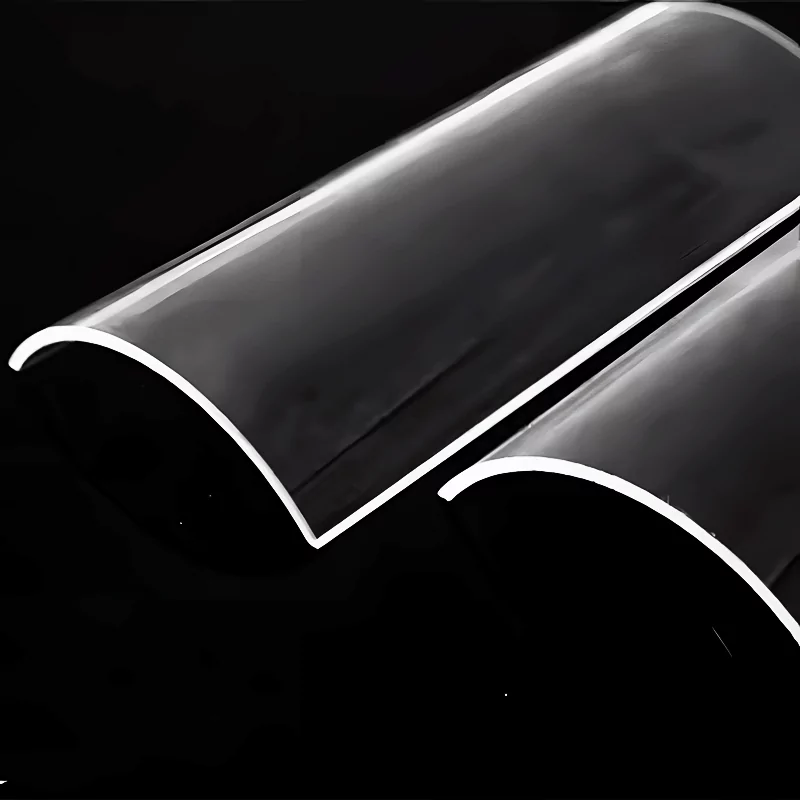

| Surface Finish Options | Ground, Fire Polished, Optical Polish | Application dependent |

| Edge Treatment | Straight, C-edge, R-corner, Chamfered | Custom edge work available |

TOQUARTZ® Solving Challenges with Clear Quartz Glass Plates

Clear Quartz Glass Plate in Optical Component Manufacturing

TOQUARTZ® optical-grade plates support consistent UV and visible light transmission, ensuring stable optical paths in devices like spectrometers, UV sterilization systems, and laser instruments.

Key Advantages

- UV transmission up to 90% at 185nm

- Optical flatness within λ/10 @633nm

- Refractive index homogeneity ≤ 4×10⁻⁶

- Surface roughness Ra < 1nm (after optical polish)

TOQUARTZ® solution

Optical manufacturers often face difficulties in achieving high UV transmittance and lens integrity over time.

TOQUARTZ provides optical-grade clear quartz glass plates with >93% visible and >80% UV transmission, enabling reproducible results and long-term stability for high-end optical systems.

Clear Quartz Glass Plate in Electronic Device Components

TOQUARTZ® high-purity quartz materials enable stable frequency response, low dielectric loss, and insulating performance—pivotal for electronic signal precision.

Key Advantages

- Dielectric constant εr ≤ 3.8 at 1 MHz

- Dielectric loss tangent ≤ 5×10⁻⁴

- High Q-factor stability over −40°C to 250°C

- Ionic impurity levels <10 ppm (Na+, K+, Fe3+)

TOQUARTZ® solution

Many electronic producers encounter performance inconsistency due to substrate purity variations or thermal drift.

TOQUARTZ clear quartz glass plates meet high stability and purity standards (>99.99% SiO₂), ensuring stable signal transmission in critical RF and timing devices.

Clear Quartz Glass Plate for Precision Mechanical Equipment

Key Advantages

- Thickness uniformity tolerance ≤ ±0.02mm

- Knoop hardness ≥ 570 HK

- Linearity deviation < 0.001mm per 100mm

- Anti-reflective laser notch capable

TOQUARTZ® solution

Manufacturers of mechanical measurement tools face precision drift due to abrasive wear on conventional materials.

TOQUARTZ clear quartz glass plates provide ultra-flat surfaces and hardness needed to maintain calibration, reducing tool recalibration cycles and extending equipment life.

Customization Services for TOQUARTZ® Clear Quartz Glass Plates

- Dimensional Specifications

- Round plates: Diameter × Thickness

- Square/Rectangular: Length × Width × Thickness

- Custom shapes available with technical drawings

- Thickness range: 0.5mm to 100mm

- Edge Treatment Options

- R-corner: Rounded edges for safety

- C-edge: Chamfered edges (45° angle)

- Protective edge treatment

- Straight edges for precise fitting

- Material Grade Selection

- JGS-1: Far UV grade (185nm+, OH 2000 PPM)

- JGS-2: UV grade (220-2500μm, OH 100-200 PPM)

- JGS-3: IR grade (260-3500μm, minimal OH)

- Application-specific recommendations available

- How to Require Custom Quartz Glass Plates

Specify dimensions and tolerances required

Select edge treatment option

Choose material grade based on application

Provide technical drawings for special shapes

Indicate surface finish requirements

Usage Guide for Clear Quartz Glass Plate

Handling Precautions

Handle quartz plates with care to avoid impacts or drops that could cause breakage. Always wear clean, lint-free gloves when handling plates for high-temperature applications to prevent contamination from fingerprints.

Cleaning & Maintenance

Clean plates thoroughly before high-temperature use. For optical applications, use isopropyl alcohol or acetone with lint-free wipes. Avoid abrasive cleaners that could scratch the surface and affect optical properties.

Temperature Limitations

Do not exceed the maximum operating temperature (1450°C for short-term use). For applications above 1100°C, consult with our engineers regarding appropriate thickness and edge treatment to prevent deformation.

Chemical Compatibility

Quartz is acidic in nature. At high temperatures, strictly avoid contact with alkaline substances (sodium/potassium compounds, water glass, asbestos) as these will significantly degrade performance and potentially cause failure.

Need Customization Services for Clear Quartz Glass Plates?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the difference between the JGS-1, JGS-2, and JGS-3 quartz glass grades?

A: JGS-1 is far UV grade quartz with high OH content (2000 PPM), offering excellent transmission down to 185nm. JGS-2 is UV grade with moderate OH content (100-200 PPM), suitable for 220-2500μm applications. JGS-3 is IR grade with minimal OH content, optimized for 260-3500μm wavelength transmission. The choice depends on your specific wavelength requirements.

Q: How do I clean quartz glass plates without damaging them?

A: For optical applications, use isopropyl alcohol or acetone with lint-free wipes. For general cleaning, a mild detergent solution followed by thorough rinsing with deionized water is recommended. Avoid abrasive cleaners and tools that could scratch the surface. For stubborn contaminants, ultrasonic cleaning in appropriate solutions is effective.

Q: Are your quartz glass plates suitable for semiconductor applications?

A: While our quartz glass plates meet many requirements for semiconductor-adjacent applications, we do not currently serve the high-end semiconductor industry that requires ultra-high purity (99.9999%) and specialized certifications. Our products are suitable for research, optical, laboratory, and industrial applications with purity levels up to 99.995%.

Q: Can you drill holes or create custom shapes in quartz glass plates?

A: Yes, we offer precision drilling, cutting, and machining services for quartz glass plates. We can create custom shapes, holes, slots, and other features according to your technical drawings. Our capabilities include water jet cutting, ultrasonic drilling, and precision grinding to achieve complex geometries while maintaining material integrity.

Q: How do quartz glass plates compare to borosilicate glass?

A: Quartz glass offers significantly higher temperature resistance (1100°C vs 500°C for borosilicate), superior UV transmission, better chemical resistance, and lower thermal expansion. Borosilicate is more cost-effective for applications that don’t require these advanced properties. For high-temperature, optical, or chemically demanding applications, quartz glass is the superior choice.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.