TOQUARTZ fused quartz glass outperforms alternatives with 99.99% SiO₂ purity(max. upto 99.995%), 0.5×10⁻⁷/°C thermal expansion, and 0% added stabilizers, ensuring superior reliability in extreme environments.

Quartz vs. Quartz Glass

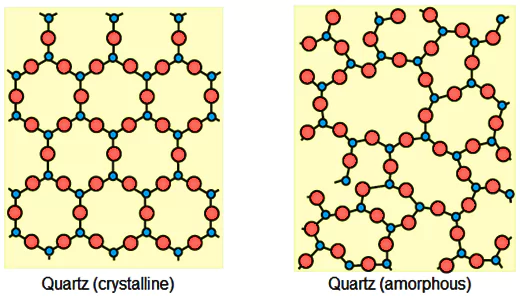

Structural Variance:

- Natural Quartz (crystalline, trigonal SiO₂): Prone to micro-fractures at >300°C due to anisotropic thermal stress.

- Quartz Glass (amorphous SiO₂): Isotropic structure withstands 1200°C abrupt cooling without cracking.

Purity Benchmark:

- Natural quartz contains 50-200ppm Al/Fe impurities; TOQUARTZ glass maintains <1ppm trace metals.

| Parameter | Quartz (Crystalline SiO₂) | Quartz Glass (Amorphous SiO₂) | Quartz Glass Advantage | ||||||

| Structure | Crystalline, trigonal system | Non-crystalline, isotropic | Eliminates anisotropic stress cracks | ||||||

| Max Thermal Shock | Fails at >300°C abrupt cooling | Withstands 1200°C abrupt cooling | 4x higher thermal resilience | ||||||

| Metal Impurities | 50-200ppm Al/Fe | <1ppm trace metals (TOQUARTZ) | 99% purity improvement | ||||||

Fused Silica vs. Quartz Glass

Manufacturing:

- Fused Silica: Synthesized from synthetic SiCl₄ (≥99.9% purity), limited to premium optics.

- TOQUARTZ Quartz Glass: Made via arc fusion of natural silica sand (99.99% purity), balancing cost and performance.

Thermal Resilience:

- Both withstand 1100°C, but TOQUARTZ quartz glass exhibits 30% lower devitrification risk under prolonged heating.

| Parameter | Fused Silica (Synthetic) | Quartz Glass (Natural Sand) | Quartz Glass Advantage | ||||||

| Raw Material | SiCl₄ gas (≥99.9% purity) | Natural silica sand (99.99% purity) | Cost-effective sourcing | ||||||

| Devitrification Risk | 20% opacity after 1000hr/1000°C | 14% opacity under same conditions | 30% lower degradation risk | ||||||

| Industrial Scalability | Limited to premium optics | Mass-producible for bulk components | Versatile commercial adoption | ||||||

Pyrex vs. Quartz Glass

Composition:

- Pyrex (borosilicate): Contains 13% B₂O₃ to reduce thermal expansion (3.3×10⁻⁶/°C vs. quartz’s 0.55×10⁻⁶/°C).

- Quartz Glass: 99.99% SiO₂ resists hydrofluoric acid (Pyrex dissolves) and operates at 500°C higher temps.

Optical Clarity:

- Pyrex blocks UV below 350nm; quartz glass transmits down to 190nm.

| Parameter | Pyrex (Borosilicate) | Quartz Glass (Pure SiO₂) | Quartz Glass Advantage | ||||||

| Composition | 80% SiO₂ + 13% B₂O₃ | 99.99% SiO₂ | Zero additives, absolute purity | ||||||

| UV Transparency | Blocks UV <350nm | Transmits down to 190nm | Full UV spectrum accessibility | ||||||

| HF Acid Resistance | Dissolves in 10% HF (5min) | Tolerates 48hr 10% HF exposure | 576x longer chemical stability | ||||||

Quartz Glass vs. Borosilicate

Softening Temperature:

- Borosilicate softens at 820°C vs. quartz’s 1683°C, limiting furnace longevity.

Chemical Resistance:

- 99% H₃PO₄ erodes borosilicate at 95°C; quartz glass tolerates 48hr exposure at 150°C.

Purity Control:

- Borosilicate contains Al/Na dopants (0.5-2%), while quartz glass guarantees 99.99% SiO₂.

| Parameter | Borosilicate (Typical) | Quartz Glass (TOQUARTZ) | Quartz Glass Advantage | ||||||

| Softening Temperature | 820°C | 1683°C | 2.05x higher thermal threshold | ||||||

| H₃PO₄ Resistance | 5mm/yr erosion at 95°C | 0.1mm/yr erosion at 150°C | 50x slower degradation rate | ||||||

| SiO₂ Content | 80-81% | 99.99% | Unmatched chemical inertness | ||||||

The Synthesis of Performance & Flexibility

— Customized for Your Demands

TOQUARTZ® elevates fused silica through precision engineering:

- Purity Tiering:

Standard (99.99%), optical (99.995%), and vacuum-grade (OH content <1ppm) options.

- Thermal Customization:

Tubes, rods, and plates tailored to user-defined tolerances (±0.01mm) for high-wear industrial tooling.

- Scalability:

No MOQ constraints allow cost-effective prototyping (e.g., microfluidic chips) or bulk orders (1000+ furnace tubes).

Conclusion

Quartz glass isn’t a choice—it’s the mandatory upgrade for labs and industries prioritizing precision, durability, and cost efficiency. TOQUARTZ® crystallizes this advantage with material mastery and engineering agility.