Premium-Grade Wholesale Fused Quartz Glass Tubes

- High-purity fused quartz glass tubing supply for lab, optical & industrial use

- Flexible purchase orders, no minimum quantity limits

- Competitive wholesale price across bulk order tiers

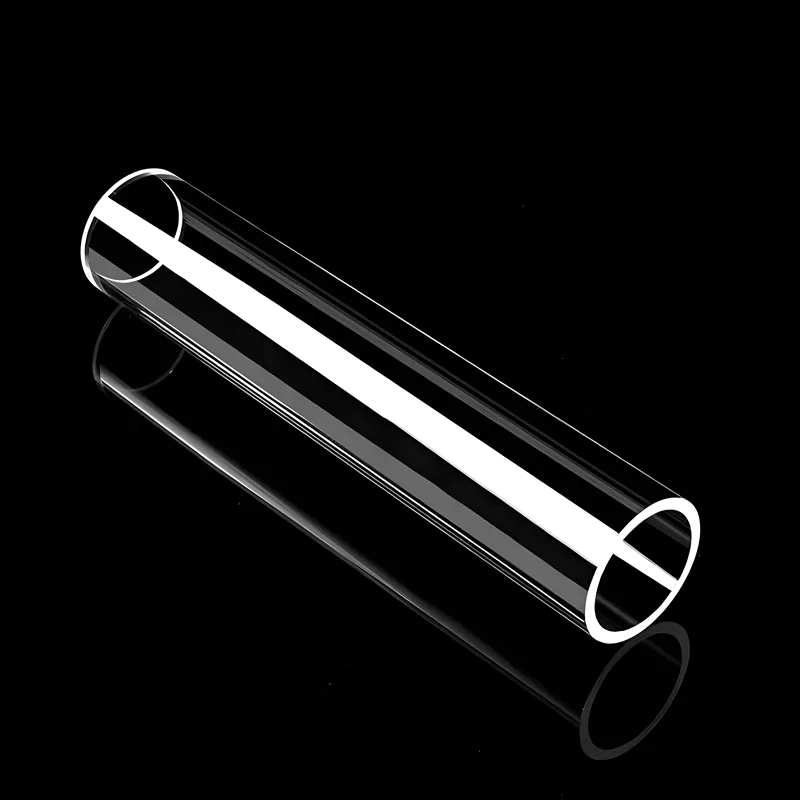

High-Performance Quartz Glass Tubes – Stocked Standards & Custom Designs

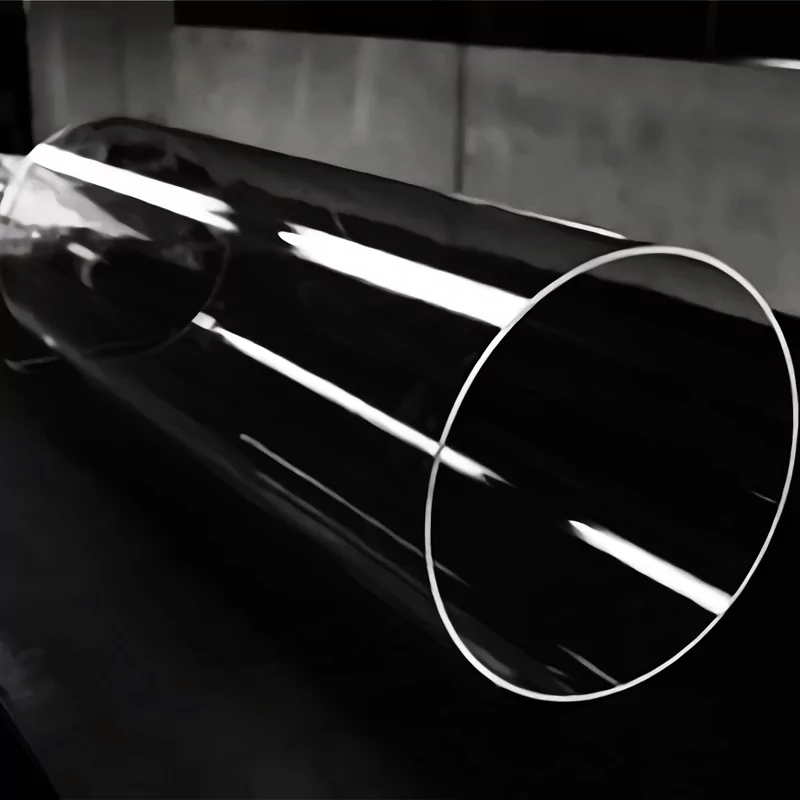

High-performance quartz glass tubes are available as stocked standards and tailored solutions to meet diverse industrial needs.

Precision quartz tubing combines durability, thermal stability, and optical clarity, making it suitable for both off-the-shelf and custom-designed applications. These options provide engineers with flexibility when balancing performance requirements and project timelines.

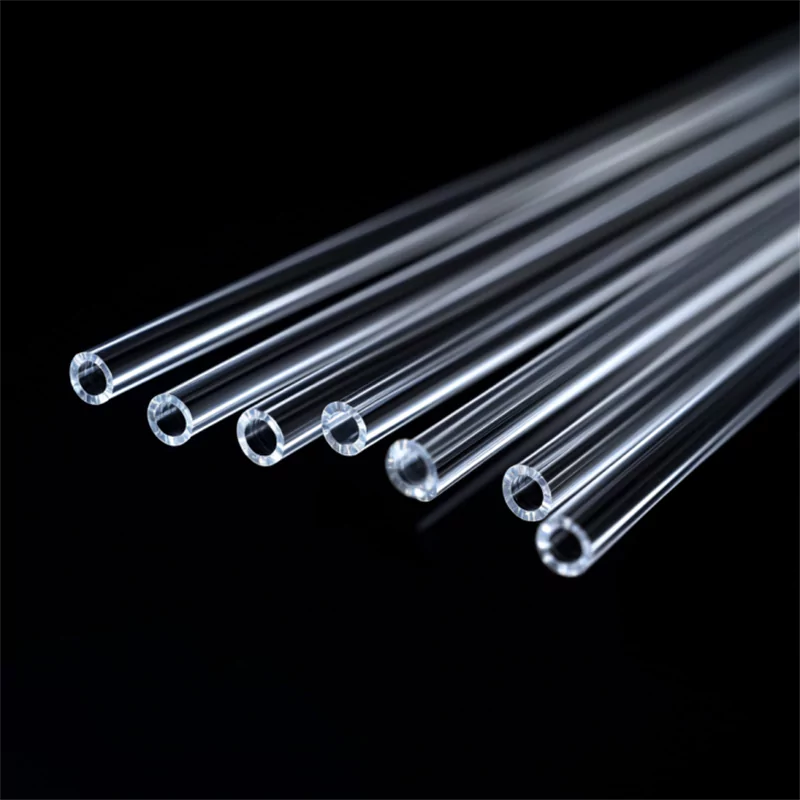

Standard-Size Stock Quartz Tubes

Immediate access to high-purity fused quartz tubing in common OD (1.5-450mm) and lengths (20-2000mm) – ideal for rapid prototyping and bulk procurement.

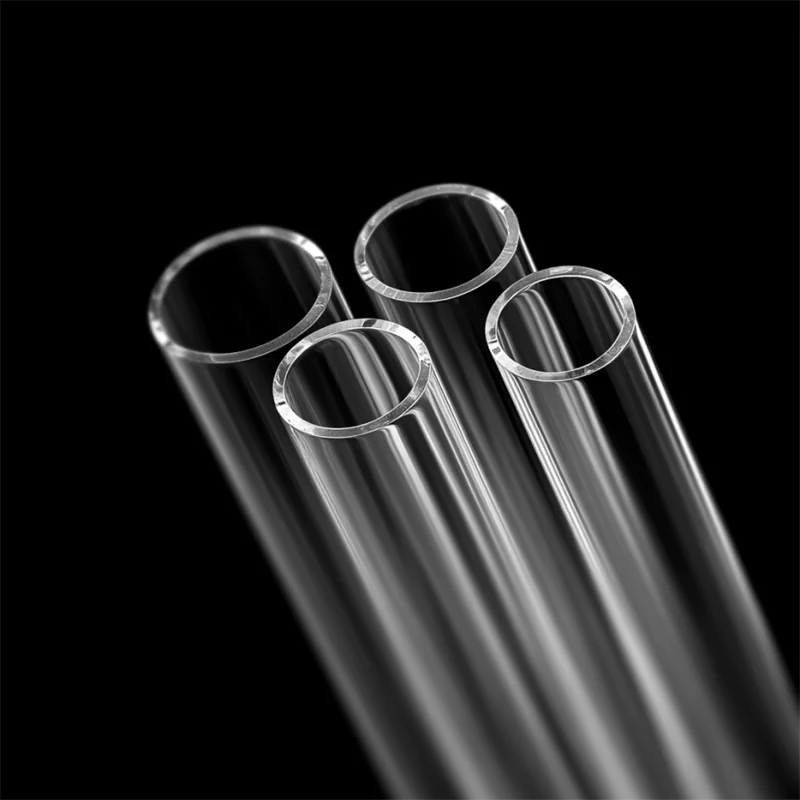

Custom-Tailored Tubing Solutions

Project-specific fused quartz glass tube manufacturing with length tolerance down to ±0.2mm and inner/outer diameter tolerance down to ±0.03mm,

tailored for complex industrial, lab, or optical configurations.

What is a Fused Quartz Tube?

A fused quartz tube, also known as a technical quartz glass tube, is made from high-purity fused silica. This material is valued for its excellent thermal and optical properties, making it ideal for high-temperature environments.

With low thermal expansion and high resistance to thermal shock, fused quartz tubes can withstand extreme conditions without degrading. These features make them a popular choice in industries such as semiconductor manufacturing, chemical processing, and laboratory applications.

Key Properties of Fused Quartz Glass Tubes

Ultra-High Temperature Resilience

These quartz glass tubes have a melting point of approximately 1730°C, can operate continuously at 1100°C (2012°F), and withstand short-term temperature bursts of 1450°C (2642°F).

Their low coefficient of thermal expansion (5.5×10⁻⁷/°C) ensures excellent durability even under rapid temperature changes.

Superior Material Purity

With silica purity exceeding 99.98%(max. up to 99.995%), TOQUARTZ fused quartz glass tubes minimize contamination in precision optics, and sensitive lab environments, while this high-purity structure creates uniform molecular alignment that significantly enhances quartz tube pressure rating.

Excellent Chemical Resistance

Resistant to all acids except hydrofluoric (HF), it maintain structural integrity in corrosive media and high-temperature chemical processes. Ideal for reactors and analytical equipment.

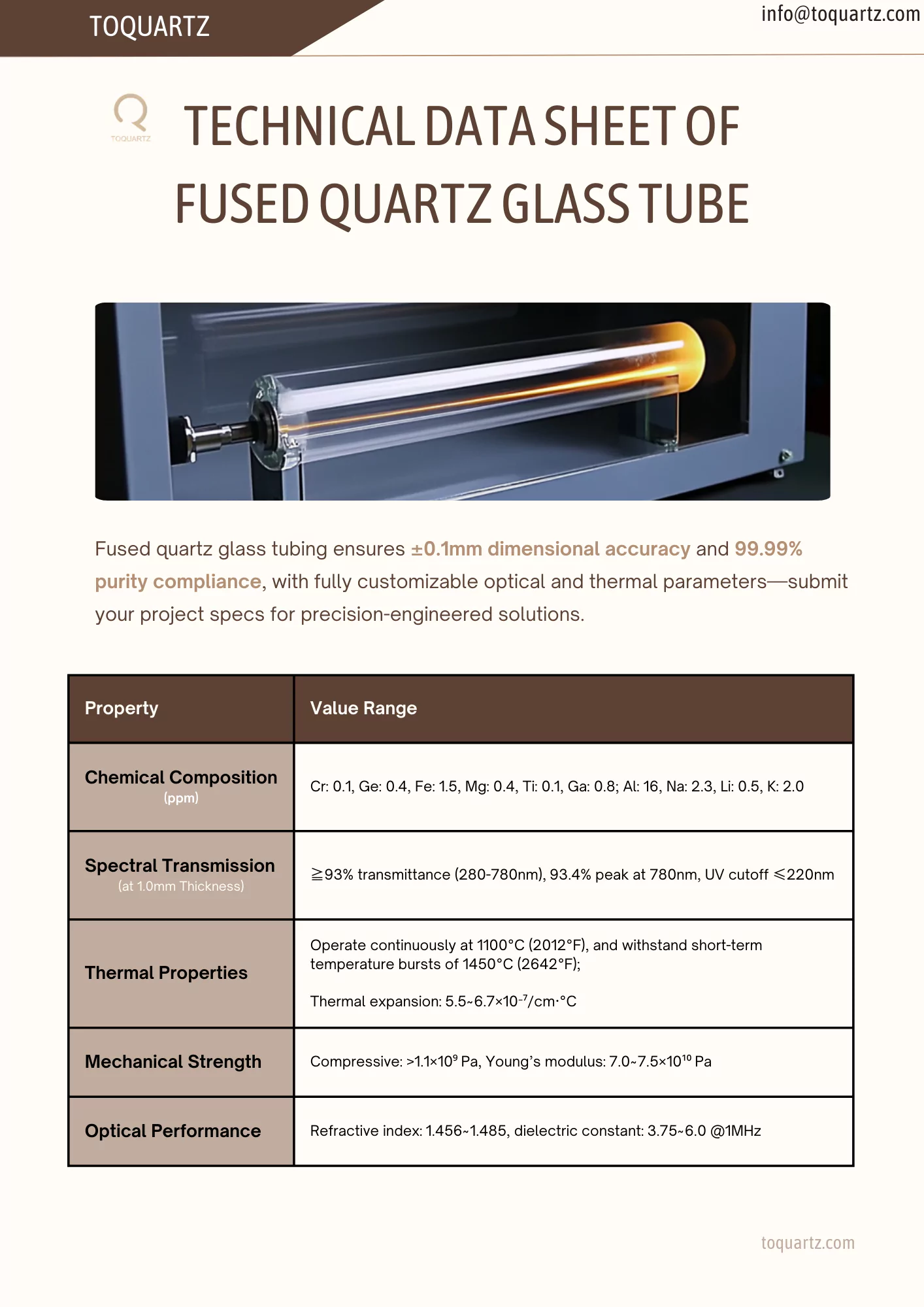

Technical Data Sheet of TOQUARTZ Fused Quartz Glass Tube

Uses of Fused Quartz Glass Tubes

Fused quartz glass tubes are precision components enabling critical processes across industries by leveraging their high thermal stability, purity, and optical clarity.

Fused Quartz Tubing in Photonics & Optics

- It provides UV-to-IR transparency, making it ideal for laser cavities, fiber optics, and high-power photonics.

- Optical grade quartz glass tubes enable precise light sensing in photomultipliers and spectral analyzers.

- Specially designed fused quartz tubes transmit UVC wavelengths (200-280nm) for air/water disinfection in medical facilities.

- Low-OH fused quartz glass tubes minimize signal loss in optical communication networks.

Quartz Glass Tube for Laboratory Research & Testing

- Used in gas chromatographs and mass spectrometers, laboratory quartz tubes resist thermal distortion during high-temp sample analysis.

- It ensures contamination-free testing conditions for cell culture incubators and drug synthesis.

Industrial Fused Quartz Tube Parts for Extreme Environments

- Industrial fused quartz tubes withstand 1450°C in semiconductor furnaces, CVD reactors, and glass processing.

- Resistant to acids (excluding HF), they ensure longevity in distillation and chemical synthesis.

- High-purity quartz tubing enables rapid UV pasteurization for beverage and dairy processing lines.

- With 1×10¹⁶ Ω·cm resistivity, it isolates high-voltage components in industrial heaters.

Quartz Glass Tube Quality & Certifications

TOQUARTZ’s fused quartz glass tubes meet the highest global standards, ensuring reliability for sensitive optical, lab, and industrial applications.

ISO 9001-Certified

TOQUARTZ’s ISO-certificated quartz tubes guarantee traceable manufacturing workflows, with 100% batch testing for dimensional accurac and thermal stability.

REACH-Compliant

Fused quartz glass tubes with REACH compliance are chemically inert (SiO₂ ≥99.98%), free from SVHCs (Substances of Very High Concern), and safe for EU-regulated environments.

RoHS Certification

RoHS-certified fused silica tubes contain <0.1% restricted substances (Pb, Cd, Hg), ensuring eco-safe integration into electronics and optical systems.

TOQUARTZ Quality Control

AI-Powered Raw Material Vetting

Eliminate impurity risks in high-purity quartz sand (99.99% SiO₂ baseline, max. up to 99.995% )

Real-Time Process Optimization

Maintain ±0.02mm dimensional tolerance during tube forming

Multi-Axis Performance Validation

Ensure functionality under extreme operating conditions

Traceable Compliance Documentation

Guarantee material traceability for critical applications

Customer-Centric Quality Proofing

Align validation methods with client-specific operational demands

Reliable Supply with No MOQ Barriers

TOQUARTZ guarantees NO-MOQ wholesale fused quartz glass tubing and offers flexible volume tiered pricing backed by streamlined operations, global partnerships, and scalable production. Below are the strategic advantages enabling our flexible quartz tubing supply.

Scalable Just-in-Time Production

With global fused quartz tube demand growing at 6.2% CAGR, our factories operate at over 90% capacity utilization to align fused quartz tubing supply with project-specific volumes – from single prototypes to bulk orders.

Lean Inventory Management

Intelligent demand tracking ensures ready stock of standard quartz tubes for sale, slashing lead times by 30% compared to traditional quartz tube manufacturers.

Global Raw Material Alliances

Strategic ties with tier-1 SiO₂ suppliers (purity ≥99.998%) secure stable access to raw materials, preventing shortages that inflate fused silica tube prices during market volatility.

In-House Engineering Efficiency

TOQUARTZ’s R&D team reduces cost of quartz tubing by 15-20% via optimized production workflows, minimizing waste while maintaining ISO-grade quality for lab, optical, and industrial uses.

Agile Prototyping Infrastructure

Dedicated rapid prototyping lines accelerate sample-to-production cycles, enabling small-batch quartz tube manufacturer testing without MOQ penalties.

Expert Engineering Support – Collaborating on Your Project Success

TOQUARTZ’s ISO-trained engineers drive innovation in laboratory quartz tubes, optical grade quartz glass tubes, and industrial fused quartz tube parts, delivering solutions 20-40% beyond industry benchmarks.

Laboratory-Grade Acid Resistance Optimization

TOQUARTZ's engineers developed HF-resistant lab quartz tubes via advanced SiO₂ dopant tech, achieving 2x lifespan (12,000h) in HNO₃ vapor vs. standard 6,000h.

Case Study

-

Client:

A European Materials Research Laboratory -

Challenge:

Severe corrosion of standard quartz tubes (lifespan: 6,000h) in a nitric acid (HNO₃) vapor recovery system, requiring biweekly replacements.

-

TOQUARTZ Solution:

Collaborated to design HF-resistant lab quartz tubes with proprietary Al₂O₃-doped SiO₂ (99.95% purity), optimizing molecular bonding to resist HNO₃ attack.

-

Results:

1. Tube lifespan extended to 12,000h (2x industry standard).

2. Annual maintenance costs reduced by 62%.

3. Enabled uninterrupted 24/7 operation of a €1.8M waste recovery system.

Ultra-Low OH Optical Tube Fabrication

TOQUARTZ’s optical grade quartz tubes feature 92% UV transmittance at 185nm for semiconductor lithography.

Case Study

-

Client:

A North American Semiconductor Manufacturer -

Challenge:

UV lithography yield loss (15%) due to insufficient 185nm transmittance (<85%) in existing quartz tubes.

-

TOQUARTZ Solution:

Deployed high-vacuum dehydration furnaces to produce optical grade quartz tubes with OH content <0.8ppm (vs. client’s prior 5.3ppm).

-

Results:

1. UV transmittance improved to 92.4% at 185nm (critical for 5nm chip patterning).

2. Defect density reduced by 22%, saving €410K/month in wafer rework.

3. Client now sources 100% laser-grade quartz tubes from TOQUARTZ.

Nano-Surface Polishing for Optics

TOQUARTZ's engineers apply MeisterAbrazil® polishing to fused quartz tubing, achieving surface roughness Ra <0.5nm (vs. 2nm industry standard).

Case Study

-

Client:

A Global LiDAR Sensor Developer -

Challenge:

Signal distortion caused by surface roughness (Ra 2.1nm) in fused quartz lenses for autonomous vehicles.

-

TOQUARTZ Solution:

Engineered MeisterAbrazil® polishing with CeO₂-free nanotechnology to achieve Ra <0.45nm.

-

Results:

1. Sensor detection range increased by 33% (150m → 200m).

2. Eliminated 97% of false positives in fog simulation tests.

3. Certification secured for Tier 1 automotive OEM supply chain.

Vacuum-Sealed Joint R&D

For high-vacuum labs, our laboratory quartz tubes integrate molybdenum-sealed flanges with leak rates <1×10⁻¹⁰ mbar·L/s, exceeding ASTM F1361 by 53%.

Case Study

-

Client:

A State Nuclear Fusion Research Facility -

Challenge:

Plasma containment failures due to flange leaks (5×10⁻⁹ mbar·L/s) in diagnostic port quartz tubes.

-

TOQUARTZ Solution:

Designed molybdenum-alloy sealed joints with pre-tensioned ceramic gaskets for ultra-high vacuum (UHV) stability.

-

Results:

1. Leak rate reduced to 9.7×10⁻¹¹ mbar·L/s – 54% below ASTM F1361 requirements.

2. Plasma experiment uptime increased from 68% to 91% annually.

3. Joint design adopted as facility-wide standard.

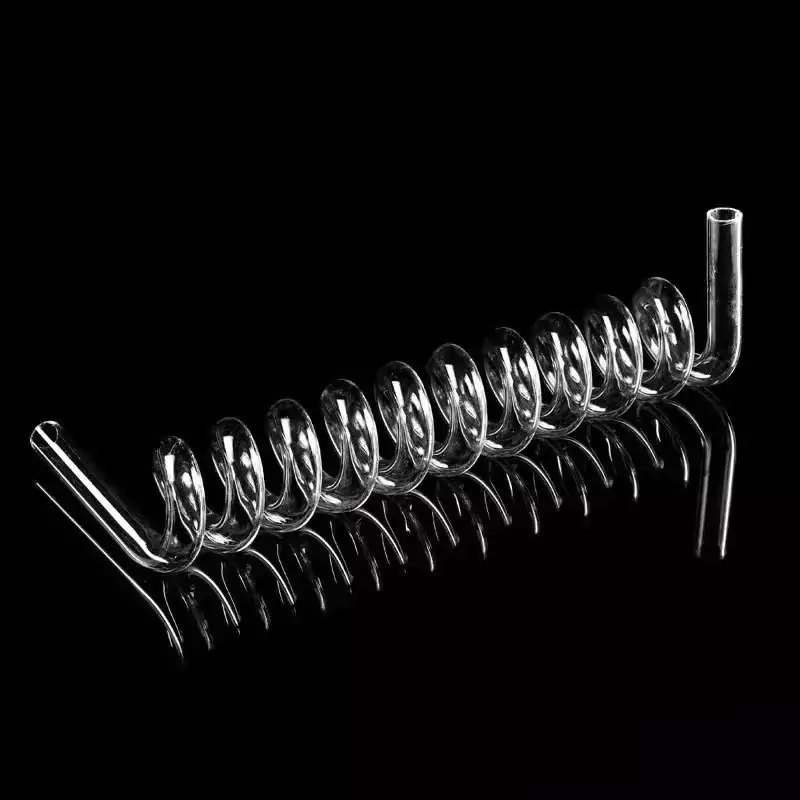

Fused Quartz Tubing Fabrication Processing丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Bespoke Manufacturing Workflow & Service

From concept sketches to production-ready quartz solutions – we turn specifications into reality.

Define Your Needs

Share your requirements through any format:

- Technical drawings (DXF/DWG/PDF)

- Sample photos with annotations

Co-Creation

Engineering team will:

- Propose material & process optimizations

- Deliver a virtual prototype for your approval

Accelerated Realization

Once confirmed:

- Dedicated production line activation

- Real-time progress updates via your preferred channel

- Strict compliance with your quality protocols

FAQs

Q: What is a fused quartz tube?

A: A fused quartz tube is a high-purity glass product made by melting SiO₂ ≥99.98% at ~2000°C, featuring exceptional thermal stability, UV transparency, and chemical inertness.

Q: What is fused quartz used for?

A: Used across industries: optical-grade tubes for UV lithography/lasers, laboratory tubes for high-temp reactors, and industrial tubes for semiconductor/CVD furnaces.

Q: What is the strength of fused quartz tube?

A: Typical tensile strength: 50 MPa;

Thermal shock resistance: withstands 1100°C to 20°C rapid cooling cycles without cracking.

Q: What temperature does quartz tube melt at?

A: Fused quartz tubes have a softening point of ~1730°C, withstanding continuous use up to 1100°C and short-term exposure to 1450°C.

Q: How much pressure can quartz tube withstand?

A: Standard quartz tubing tolerates ≤1.5 MPa internal pressure; custom reinforcements can achieve ≤3 MPa for industrial applications.

Q: What is the wavelength of quartz tube?

A: Optical-grade fused quartz tubes transmit 170-2500nm wavelengths, with >90% UV transmittance at 185nm (low OH content).

Q: How to clean a quartz tube?

A: Use diluted HCl or HNO₃ (avoid HF), rinse with deionized water, and dry at ≤120°C. Avoid abrasive scrubbing to preserve surface finish.

Q: Does quartz tubing heat transfer?

A: No – fused quartz has low thermal conductivity (1.4 W/m·K), making it ideal for high-temperature insulation and thermal shock resistance.

Start Your Order

TOQUARTZ streamlines access to premium fused quartz glass tubes – NO MOQ, guaranteed purity, and tailored support. Act now:

-

Instant Wholesale Pricing:

Submit specs online for same-day fused quartz tube quotes – bulk discounts auto-calculated, no hidden fees. -

Engineer-Driven Sourcing:

Call +86-19311583352(Whatsapp) for project-specific advice on optical/lab/industrial quartz tubing. -

Priority Production Slots:

Email info@toquartz.com with “URGENT TUBING” to secure expedited high-purity quartz glass tube delivery – reserved capacity for urgent projects.