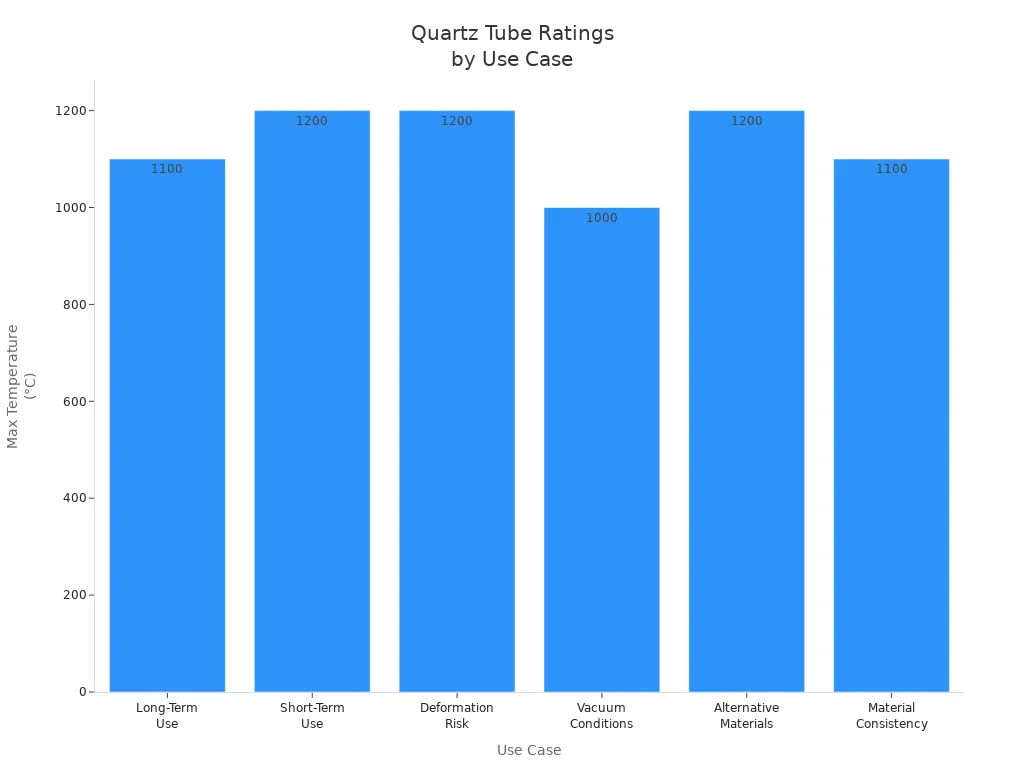

Quartz tubes show remarkable temperature resistance in high-temperature environments. When considering what temperature can quartz tube withstand for continuous operation, manufacturers recommend a maximum of 1100°C, while short-term exposure can reach up to 1200°C before the risk of deformation increases. The specific temperature limit depends on whether the tube operates in atmospheric, vacuum, reducing, oxidizing, or corrosive conditions. Engineers must match the optimal temperature range with the actual operating environment to ensure safety, thermal stability, and long service life. Real-world temperature stress tests confirm that high purity quartz tubes made from silicon dioxide offer strong resistance to thermal shock and high temperature oxidation resistance, making them ideal for high-temperature reactors, furnace use, and other high-temperature applications where thermal shock resistance and melting point matter. Low temperature operation also preserves tube integrity at every point.

Maximum continuous operating temperature: 1100°C

Short-term peak temperature: 1200°C

Exceeding these temperatures may cause deformation

Key Takeaways

Quartz tubes can operate continuously at 1100°C and tolerate short-term peaks up to 1200°C. Exceeding these limits risks deformation.

Surface purity is crucial. High purity quartz tubes resist higher temperatures and last longer. Clean and handle them properly to maintain performance.

In vacuum conditions, the maximum temperature drops to 1000°C due to reduced heat transfer efficiency. This increases the risk of deformation.

Reducing atmospheres lower the safe temperature limit to 1000-1050°C due to chemical erosion. Monitor hydrogen levels to prevent rapid material loss.

Corrosive gases like chlorine limit quartz tube temperatures to 850-950°C. Moisture can further reduce this limit by 100°C, so keep gas streams dry.

What Maximum Temperature Can Quartz Tubes Withstand for Continuous Operation?

Quartz tubes play a vital role in high-temperature environments, especially in laboratory and industrial settings. Understanding the maximum temperature quartz tubes can withstand helps users prevent damage and extend service life. This section explains the continuous operating temperature limits for quartz tubes in different conditions and highlights the factors that affect their performance.

Understanding the 1100-1200°C Continuous Rating in Atmospheric Conditions

Quartz tubes can operate continuously at temperatures up to 1100°C under normal atmospheric pressure. Manufacturers and technical standards recommend this temperature limit for long-term use because it balances thermal shock resistance and material stability. Short-term use allows for a slightly higher temperature, reaching up to 1200°C, but only for brief periods.

The following table summarizes the recommended maximum temperatures for quartz tubes in atmospheric conditions, showing the difference between long-term and short-term use:

Use Type | Maximum Temperature | Conditions |

|---|---|---|

Long-term use | 1100°C | Normal atmospheric pressure |

Short-term use | 1200°C | Normal atmospheric pressure |

Quartz tubes made from high purity silicon dioxide show excellent temperature resistance and can handle high temperature cycles in a quartz tube furnace. Users should always match the operating temperature to the recommended range to avoid deformation or early failure.

Material Property Changes Approaching the 1270°C Strain Point

Quartz begins to change its mechanical properties as the temperature approaches the strain point of 1270°C. At this stage, the viscosity of the quartz drops, and the material becomes more prone to deformation under stress. Prolonged exposure to temperatures near this point, especially above 1200°C for more than three hours, can cause significant damage or even failure.

The relationship between temperature and quartz tube performance is clear in the following table, which highlights how different operation types affect the temperature limit:

Operation Type | Maximum Temperature | Notes |

|---|---|---|

Continuous Operation | 1100°C | Long-term use |

Short-term Peak Use | 1200°C | Tolerable for brief periods |

Under Vacuum | 1000°C | Maximum rating decreases under vacuum |

Quartz tubes maintain their shape and strength best when users avoid operating near the strain point for extended periods. This approach ensures the longevity and reliability of the quartz tube furnace in high-temperature environments.

Why Surface Purity Controls Temperature Performance

Surface purity plays a critical role in determining the temperature resistance of quartz tubes. High purity quartz tubes, with minimal contamination, resist devitrification and maintain their structure at elevated temperatures. Even small amounts of surface contamination can lower the temperature limit and increase the risk of crystallization.

Key points to remember about surface purity and temperature performance include:

High purity quartz tubes withstand higher temperatures and last longer.

Contaminants on the surface can trigger early failure at lower temperatures.

Proper cleaning and handling help preserve the temperature resistance of quartz tubes.

By focusing on surface purity, users can maximize the performance of quartz tubes in high temperature and high-temperature environments. This practice supports safe operation and extends the service life of silicon dioxide-based furnace components.

What Short-Term Peak Temperatures Can Quartz Tubes Tolerate?

Quartz tubes often face rapid temperature changes in high-temperature environments. Users need to know what temperature can quartz tube withstand for brief exposures to avoid damage. This section explains how quartz tube thermal properties, exposure duration, and purity affect short-term temperature limits in a quartz tube furnace.

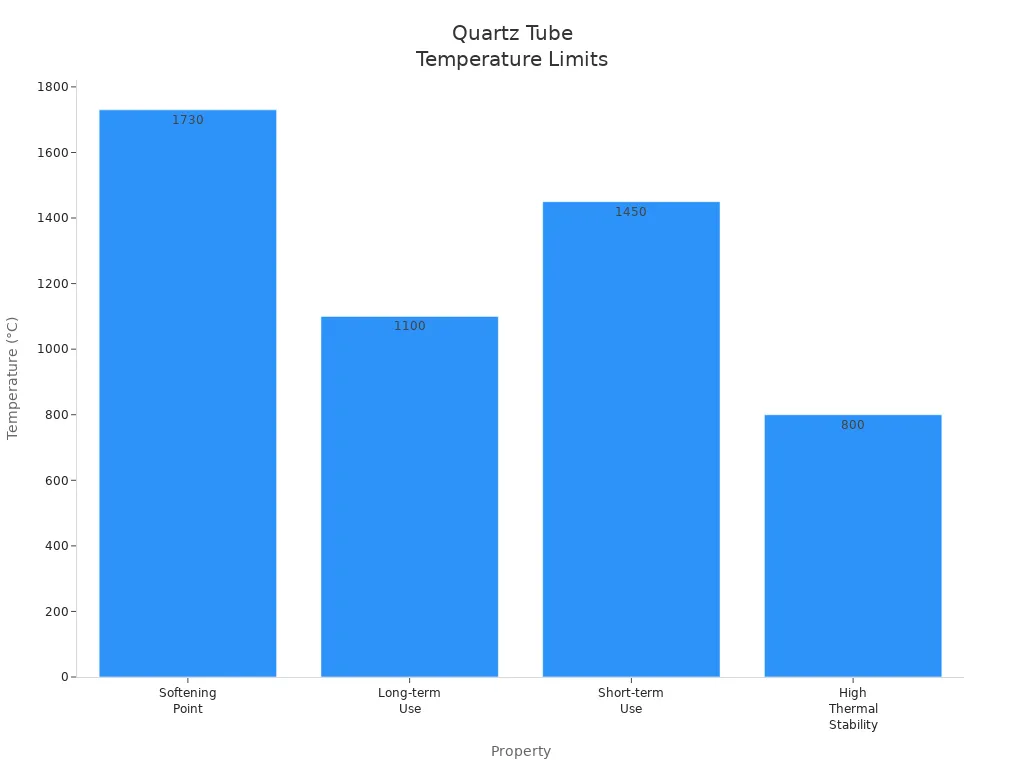

Peak Temperature Capability: 1450-1600°C for Brief Exposure

Quartz tubes can tolerate peak temperatures between 1450°C and 1600°C for short periods. These brief exposures allow the tubes to handle emergency heating or rapid thermal processing without permanent deformation. The softening point of quartz, which is 1730°C, provides a safety margin for these short-term peaks.

The following table shows the relationship between exposure type, maximum temperature, and recommended duration, helping users understand the limits for safe operation:

Exposure Type | Maximum Temperature | Recommended Duration |

|---|---|---|

Long-term use | 1100°C | N/A |

Short-term use | 1450-1600°C | Less than 30 minutes |

Quartz tubes maintain their temperature resistance during short-term peaks, but users should avoid exceeding the recommended duration to prevent damage.

Time-Temperature Relationships: Why Duration Determines Damage

The duration of exposure to high temperature plays a critical role in quartz tube performance. Quartz can withstand very high temperature for a short time, but longer exposure increases the risk of devitrification and structural changes. The strain point and viscosity of silicon dioxide determine how quickly quartz begins to deform under heat.

The chart below compares temperature limits for different quartz tube properties, showing how short-term use allows higher temperatures than long-term operation:

Quartz tubes used in a furnace should always follow the recommended operating temperature and exposure time to maintain integrity.

Thermal Cycling Strategies for Process Flexibility

Thermal cycling allows quartz tubes to handle rapid temperature changes in high-temperature environments. Real-world temperature stress tests show that high purity quartz tubes resist thermal shock and maintain performance during repeated heating and cooling cycles. Scientific studies confirm that purity and lack of surface contamination help quartz tubes withstand these cycles without losing structural integrity.

Surface contamination lowers temperature limit and increases risk of damage.

Proper cleaning and handling improve tube performance in a quartz tube furnace.

By using thermal cycling strategies, engineers can achieve process flexibility while protecting quartz tubes from damage caused by extreme temperature shifts.

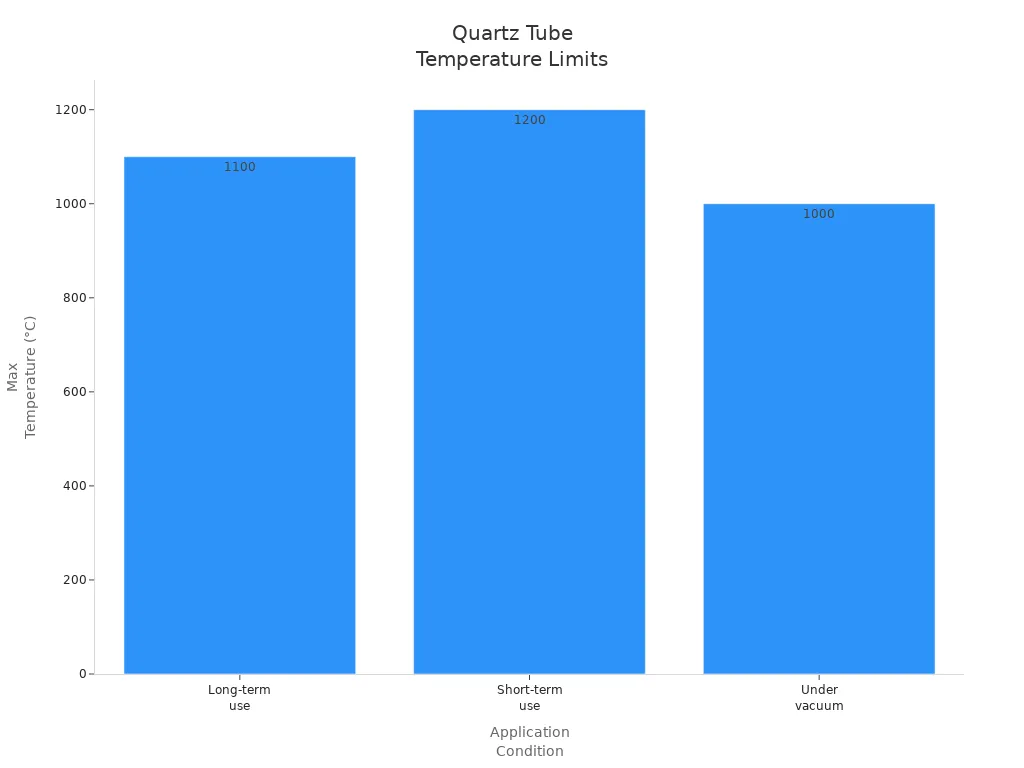

What Temperature Can Quartz Tubes Withstand in Vacuum vs. Atmospheric Conditions?

Quartz tubes behave differently in vacuum and atmospheric conditions. The temperature limit for each environment depends on how heat moves through the quartz and how the material responds to stress. This section explains why the maximum operating temperature changes and what users should expect in high-temperature environments.

Atmospheric Conditions: 1100-1200°C Capability Through Convective Cooling

Atmospheric conditions allow quartz tubes to reach a continuous operating temperature of 1100-1200°C. Convective cooling in air or inert gas helps distribute heat evenly across the quartz surface. This cooling effect prevents hot spots and keeps the quartz tube furnace stable during long-term use.

Convective heat transfer in atmospheric pressure supports the temperature resistance of silicon dioxide. The presence of gas molecules around the quartz increases the heat transfer coefficient, which means the quartz can handle high temperature without deforming. Data from over 11,000 installations show that quartz tubes in atmospheric conditions maintain their shape and strength for more than 8,000 hours.

In summary, atmospheric operation supports higher temperature limits for quartz tubes due to efficient convective cooling.

Convective cooling prevents hot spots

Quartz tubes last longer at 1100-1200°C in air

Stable temperature resistance in high-temperature environments

Vacuum Limitation: Why Temperature Drops to 1000°C Maximum

Vacuum conditions reduce the maximum temperature quartz tubes can withstand to 1000°C. The absence of air or gas molecules eliminates convective cooling, so heat moves less efficiently away from the quartz surface. This change causes localized heating and increases the risk of deformation.

Quartz in a vacuum relies only on radiation to transfer heat, which is much less effective than convection. Hot spots can form on the quartz tube, and the material may reach the strain point even if the furnace setpoint stays below the limit. Field data shows that deformation incidents rise sharply above 1000°C in vacuum, with nearly half of tubes failing at 1100°C.

Condition | Max Temperature | Cause | Effect |

|---|---|---|---|

Atmospheric | 1100-1200°C | Convective cooling present | Stable, long service life |

Vacuum | 1000°C | No convection, only radiation | Hot spots, risk of deformation |

Heat Transfer Physics: Convection vs. Radiation Dominant Regimes

Heat transfer physics explains why quartz tubes have different temperature limits in vacuum and atmospheric conditions. Convection dominates in atmospheric pressure, while radiation becomes the main mechanism in a vacuum. This shift changes how quartz responds to high temperature.

Convection moves heat quickly and evenly, protecting the quartz from sudden temperature spikes. Radiation transfers heat more slowly, so the quartz may develop uneven temperatures and reach critical points faster. Understanding these differences helps users set the correct operating temperature for each environment.

Convection allows higher temperature limits in air

Radiation limits quartz tubes to 1000°C in vacuum

Proper heat transfer knowledge prevents tube failure

By knowing what temperature can quartz tube withstand in each setting, users can maximize the performance and safety of their quartz tube furnace.

What Temperature Can Quartz Tubes Withstand in Reducing vs. Oxidizing Atmospheres?

Quartz tubes face different challenges in reducing and oxidizing atmospheres. The temperature limit changes based on the chemical reactions that occur at high temperature. This section explains how reducing gases like hydrogen and oxidizing gases like oxygen affect the temperature resistance and service life of quartz tubes in high-temperature environments.

Reducing Atmosphere Limits: 1000-1050°C Due to Chemical Erosion

Reducing atmospheres, such as those containing hydrogen or carbon monoxide, lower the maximum safe temperature for quartz tubes. Chemical reactions between these gases and silicon dioxide cause surface erosion, which limits the operating temperature to 1000-1050°C. The quartz tube furnace must operate below this threshold to prevent rapid material loss.

Hydrogen reacts with silicon dioxide at high temperature, forming volatile silicon monoxide and water vapor. This process increases the erosion rate of quartz, especially as the temperature rises above 1000°C. Chemical engineering literature recommends a maximum temperature of 1000°C under vacuum and 1100°C for long-term use in reducing atmospheres, as shown in the table below.

Application Duration | Maximum Temperature | Notes |

|---|---|---|

Long-term use | 1100°C | |

Short-term use | 1200°C | Exceeding this may cause deformation. |

Under vacuum | 1000°C | Maximum rating decreases under vacuum. |

Operating a quartz tube furnace in reducing atmospheres requires careful control of temperature to maintain tube integrity.

Hydrogen Concentration Effects: How 5-20% H₂ Controls Temperature

Hydrogen concentration in the atmosphere directly affects the temperature limit for quartz tubes. Higher hydrogen levels increase the rate of chemical erosion, forcing a reduction in the maximum operating temperature. For example, at 5% hydrogen, quartz can withstand up to 1100°C, but at 20% hydrogen, the safe temperature drops to 1000°C.

The relationship between hydrogen concentration and temperature resistance is clear in high-temperature environments. As hydrogen content rises, the chemical attack on silicon dioxide accelerates, shortening the service life of the tube. The chart below illustrates how different application conditions impact the maximum temperature quartz can withstand.

Key points for engineers to remember:

Higher hydrogen concentration lowers the temperature limit

Chemical erosion increases with temperature and hydrogen content

Careful gas control extends quartz tube service life

Understanding hydrogen’s effect on quartz helps users set safe operating temperature levels in reducing atmospheres.

Oxidizing Atmosphere Derating: 1050-1150°C from Accelerated Devitrification

Oxidizing atmospheres, such as air or pure oxygen, also impact the temperature resistance of quartz tubes. The presence of oxygen speeds up devitrification, a process where quartz transforms into crystalline forms at high temperature. This transformation weakens the tube and reduces its ability to withstand thermal cycling.

Devitrification involves nucleation and growth, which become more rapid at higher temperatures and with increased hydroxyl content. The phase change to Beta-cristobalite does not occur below 1000°C, but repeated heating and cooling through critical temperature ranges can still cause structural issues. The table below summarizes the main factors and their effects:

Factor | Effect on Quartz Tubes |

|---|---|

High temperature | Accelerates devitrification |

High OH content | Increases devitrification rate |

Thermal cycling | Leads to structural integrity issues |

Quartz tubes in oxidizing atmospheres should operate between 1050°C and 1150°C to avoid rapid devitrification and maintain long-term performance.

What Temperature Can Quartz Tubes Withstand When Exposed to Corrosive Gases?

Quartz tubes face unique challenges in high-temperature environments when exposed to corrosive gases. The temperature limit drops significantly due to aggressive chemical reactions with halogens and moisture. This section explains what temperature can quartz tube withstand in these harsh conditions and how users can protect their equipment.

Halogen Gas Ceiling: 850-950°C Maximum for Chlorine and HCl

Quartz tubes reach their maximum operating temperature between 850°C and 950°C when exposed to halogen gases like chlorine and HCl. Halogen gases attack silicon dioxide, causing rapid erosion and reducing the temperature resistance of the quartz. The quartz tube furnace must operate below this ceiling to avoid severe material loss.

The temperature limit for quartz in halogen-rich environments is much lower than in air or vacuum. Chemical reactions form volatile silicon compounds, which quickly erode the tube surface and shorten service life. Data from field installations show that even small increases in temperature above 950°C can double the erosion rate.

Key points for engineers working with halogen gases:

Quartz tubes withstand only 850-950°C in chlorine or HCl

Aggressive chemical attack limits temperature resistance

Operating temperature above 950°C causes rapid tube failure

Temperature-Erosion Relationship: Doubling Rate Every 40-50°C

The relationship between temperature and erosion rate in quartz tubes is direct and exponential. Every 40-50°C increase in temperature causes the erosion rate to double, making precise temperature control essential in high-temperature environments. This effect results from the accelerated chemical reactions between halogen gases and silicon dioxide at elevated temperatures.

Engineers observe that quartz tubes lose up to 0.9 mm of material per 1,000 hours at 1000°C in corrosive atmospheres, compared to only 0.15 mm at 900°C. The quartz tube furnace must maintain a stable temperature to prevent sudden increases in erosion and extend tube life. This temperature sensitivity highlights the importance of monitoring and adjusting the operating temperature.

Temperature (°C) | Erosion Rate (mm/1,000h) | Cause | Effect |

|---|---|---|---|

900 | 0.15 | Slow chemical reaction | Long tube life |

950 | 0.30 | Faster reaction | Shorter tube life |

1000 | 0.60 | Rapid reaction | Severe erosion |

Moisture Catalysis: Why 100-200 ppm H₂O Reduces Temperature Limit 100°C

Moisture in the gas stream acts as a catalyst, lowering the temperature limit for quartz tubes by up to 100°C. Even 100-200 ppm of water vapor accelerates the chemical attack on silicon dioxide, causing the quartz to degrade much faster. The presence of moisture prevents the formation of any protective layer on the quartz surface.

Field data shows that tubes exposed to wet chlorine at 900°C erode four times faster than those in dry conditions. Engineers must keep the gas stream as dry as possible to maintain the temperature resistance of quartz tubes in a furnace. This practice helps preserve tube integrity and extends service life.

Moisture increases erosion rate by 3-4 times

Temperature limit drops by 100°C with 100-200 ppm H₂O

Dry gas streams are critical for quartz tube longevity

Quartz tubes show different temperature limits based on the environment. Most manufacturers recommend a maximum usage temperature of 1200°C, but short-term peaks can reach 1450°C. Under vacuum, the quartz tube furnace should not exceed 1000°C. Exceeding these limits can cause thermal shock, deformation, or chemical corrosion, as shown below:

Failure Mode | Description |

|---|---|

Thermal shock rupture | Sudden temperature change exceeding the material strain limit. |

Creep deformation | Plastic deformation caused by long-term compression at high temperatures. |

Chemical corrosion | Rapid corrosion of the pipe wall above 400 ℃, such as from HF gas. |

Fatigue fracture | Microcrack propagation caused by pressure cycling. |

Quartz is brittle and has low thermal expansion, so following the specified temperature limits helps maintain strength and prevents failure.

Always check manufacturer data and match the quartz tube to the operating environment for safe, long-lasting performance.

FAQ

What is the maximum continuous temperature quartz tubes can withstand?

Quartz tubes withstand up to 1100°C in atmospheric conditions for continuous use.

Manufacturers recommend not exceeding this limit for long-term operation.

Tip: Always check the operating environment before setting furnace temperatures.

Can quartz tubes handle rapid temperature changes?

Quartz tubes resist thermal shock and can handle quick temperature shifts.

High purity quartz maintains integrity during thermal cycling.

Key points:

Rapid changes are safe within recommended temperature limits.

Surface purity improves shock resistance.

How does vacuum affect quartz tube temperature limits?

Vacuum reduces the maximum safe temperature to 1000°C.

Heat transfer changes from convection to radiation, increasing risk of deformation.

Condition | Max Temp (°C) | Cause |

|---|---|---|

Atmospheric | 1100-1200 | Convective cooling |

Vacuum | 1000 | Radiation dominant |

What happens if quartz tubes are exposed to corrosive gases?

Corrosive gases like chlorine and HCl lower the temperature limit to 850-950°C.

Moisture accelerates erosion, reducing tube life.

Note: Dry gas streams help maintain tube integrity and extend service life.

Why does surface purity matter for quartz tube performance?

Surface purity prevents devitrification and early failure.

Contaminants lower the temperature limit and increase crystallization risk.

Summary:

Clean surfaces last longer.

Proper handling preserves temperature resistance.