UV transmission performance describes how effectively a material allows ultraviolet light to pass through, which directly impacts the suitability of UV-grade quartz tubes for scientific and industrial tasks. High-quality quartz remains transparent down to 190 nm, supporting precise measurements in UV spectroscopy and ensuring strong germicidal action in disinfection systems. Compared to other materials, quartz achieves over 90% UV transmittance, maximizing lamp efficiency and enabling accurate results at critical wavelengths.

Material | UV Transmittance | Effectiveness in UV Applications |

|---|---|---|

Quartz | >90% | High germicidal effect due to effective UV reach |

Teflon | Low | Reduced UV output intensity, lower effectiveness |

Key Takeaways

High-quality quartz tubes transmit over 90% of UV light, making them ideal for applications like sterilization and spectroscopy.

Purity is crucial; high-purity quartz with low impurities ensures optimal UV transmission and performance in sensitive environments.

Manufacturing methods impact performance; electrical fusion produces quartz with lower OH content, enhancing UV clarity and stability.

Request batch-specific purity certificates and verify transmission data to ensure reliable performance in UV applications.

Understanding application requirements helps in selecting the right quartz tube, ensuring safety and accuracy in results.

What Transmission Specifications Distinguish UV-Grade Quartz from Standard Optical Materials?

Optical quartz tubes must meet strict transmission standards to perform well in ultraviolet applications. These standards help scientists and engineers choose the right material for tasks like sterilization and spectroscopy. High-purity quartz and uv-grade quartz tubes set the benchmark for superior uv transmission and optical clarity.

How Purity Levels Impact UV Transmission Thresholds

Purity determines how much ultraviolet light passes through a quartz tube. High-purity quartz with low levels of iron and other impurities achieves transmission rates above 90% at 200 nm and 92% at 254 nm, making it ideal for UV sterilization and sensitive optical systems. Impurities such as iron can lower transmission and reduce optical clarity, affecting performance in demanding environments.

Wavelength (nm) | Transmission (% per 1 mm) | Grade/Condition |

|---|---|---|

200 | >90 | High-purity, low Fe³⁺ |

254 | >92 | UV sterilization grade |

355 | >93 | Laser optics |

This table shows that higher purity leads to better transmission at key UV wavelengths, which supports applications needing precise optical quartz performance.

Wavelength-Dependent Performance Across UV-A to Deep UV Ranges

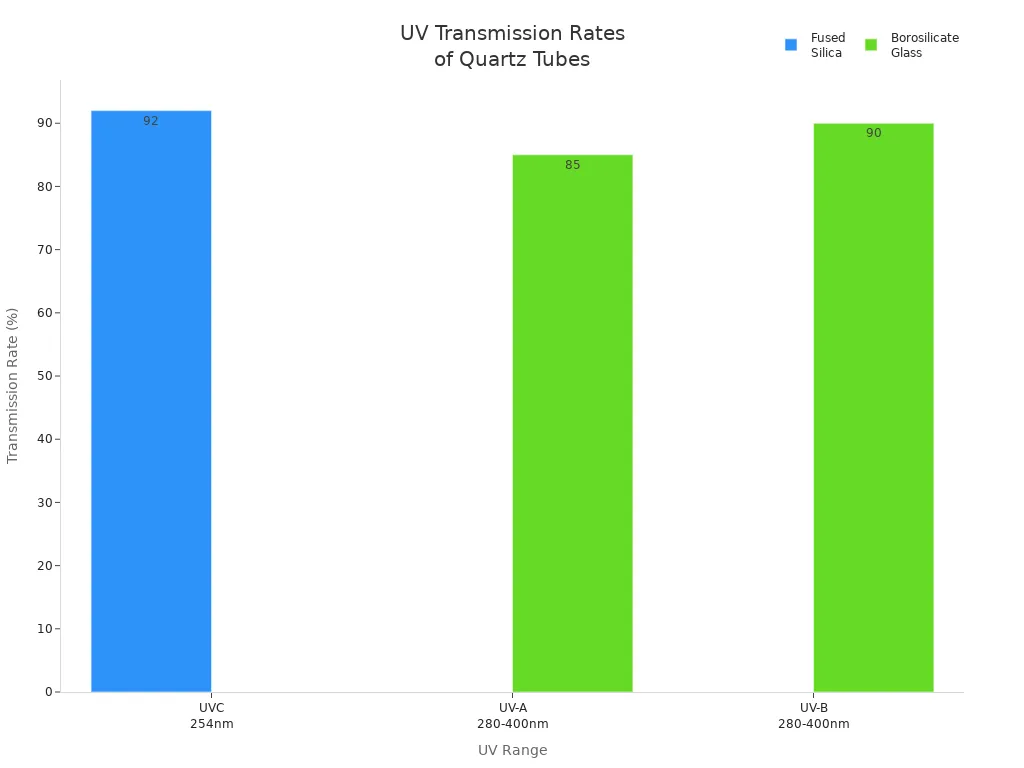

Transmission rates change depending on the UV wavelength and the type of optical quartz used. Fused silica offers more than 92% transmission at 254 nm, while borosilicate glass reaches only 85-90% in the UV-A and UV-B ranges. High-purity fused silica provides exceptional thermal stability and resistance to devitrification, making it suitable for long-term use in harsh environments.

The chart below compares transmission rates for different materials across UV ranges:

Quartz tubes with superior uv transmission support applications from deep UV sterilization to advanced laser optics.

Key points to remember include:

Fused silica delivers >92% transmission at 254 nm

Borosilicate glass is cost-effective but less transparent in deep UV

High-purity quartz ensures chemical resistance and thermal stability

Transmission Testing Protocols per ISO 9050

ISO 9050 certification verifies the transmission performance of optical quartz tubes. This standard measures uv transmittance and ensures that quartz tubes meet industry requirements for building, construction, and laboratory use. Manufacturers use ISO 9050 to confirm that their products deliver consistent transmission and resistance to devitrification.

Aspect | Description |

|---|---|

Standard | ISO 9050:2003 |

Focus | Determination of light transmittance, including UV |

Application | Building, construction, and precise optical systems |

ISO 9050 helps buyers and engineers trust the transmission data provided for each quartz tube, supporting reliable optical performance.

How Does OH Content Engineering Affect UV Optical Clarity?

The engineering of hydroxyl (OH) content in optical quartz plays a crucial role in determining its clarity and performance in UV applications. Manufacturers must carefully control OH levels to ensure that quartz tubes deliver superior uv transmission and resist devitrification. Understanding the differences in manufacturing methods and their impact on purity helps users select the right quartz tube for their needs.

Electrical Fusion vs. Flame Fusion Manufacturing Trade-offs

Manufacturers use electrical fusion and flame fusion to produce optical quartz, but these methods create different OH content profiles. Electrical fusion results in quartz tubes with very low OH content, often below 10 ppm, which enhances UV transmission and prevents devitrification, while flame fusion introduces higher OH levels due to water vapor in the combustion process. The choice of method affects not only the optical clarity but also the cost, as electrical fusion typically increases material expenses by 15-20% compared to flame fusion.

Electrical fusion produces quartz tubes with lower water content, which leads to better resistance to devitrification and improved performance in deep UV applications. Flame-fused quartz, with higher OH content, may suffice for less demanding uses but cannot match the clarity required for advanced spectroscopy or photolithography. Users should weigh the benefits of low OH content against the higher cost when selecting quartz tubes for critical UV tasks.

Electrical fusion yields low OH content (<10 ppm) and superior UV transmission

Flame fusion introduces higher OH content, reducing deep UV clarity

Manufacturing method directly impacts cost, clarity, and devitrification resistance

Quantifying OH Absorption Band Impacts on Multi-Wavelength Systems

OH groups in optical quartz absorb light at specific infrared and ultraviolet wavelengths, which can limit the effectiveness of multi-wavelength systems. High-purity fused silica with low OH content allows for a broader transmission window, supporting applications from deep UV (190 nm) to near-infrared, while high OH content introduces absorption bands at 1.4 μm, 2.2 μm, and 2.7 μm. These absorption bands can cause significant signal loss in systems that require both UV and IR transparency.

A quartz tube with less than 5 ppm OH content will minimize absorption in the deep UV range, making it ideal for DNA analysis and photochemistry. In contrast, tubes with higher OH levels may perform well in visible light but lose efficiency at critical UV and IR wavelengths. Engineers must consider the spectral requirements of their application to avoid performance losses caused by OH absorption.

OH Content | Transmission Range | Impact on Performance |

|---|---|---|

<5 ppm | Deep UV to Near-IR | Maximal clarity, minimal absorption |

10-50 ppm | UV-A, UV-B, some Near-IR | Moderate clarity, some absorption |

>100 ppm | Visible, limited UV/IR | Reduced clarity, strong absorption |

Material Selection Criteria Based on Spectral Requirements

Selecting the right quartz tube for UV applications depends on several criteria, including OH content, purity, and the intended spectral range. High-purity fused silica with low OH content ensures chemical resistance, thermal stability, and superior uv transmission, making it suitable for demanding laboratory and industrial environments. The presence of impurities or surface defects can reduce optical clarity and compromise performance.

Engineers should look for quartz tubes with SiO2 content above 99.9%, visible light transmittance over 93%, and UV transmittance exceeding 80%. Surface quality, size, and environmental safety also play important roles in material selection. Custom processing and precise surface treatments further enhance the performance and reliability of optical quartz in specialized applications.

Criteria | Description |

|---|---|

Material selection | SiO2 content ≥99.9% for chemical and thermal stability |

Specification and size | Choose diameter and length based on application; wall thickness affects strength |

Optical performance | Visible transmittance >93%, UV transmittance >80% |

Surface quality | No pores, deep scratches, or cracks |

Processing/customization | High precision and suitable surface treatments |

Environmental protection | Materials must be safe and environmentally friendly |

Why Does Metallic Impurity Control Determine UV Window Performance?

Metallic impurity control plays a vital role in the optical performance of quartz tubes used in ultraviolet applications. Even trace amounts of impurities can shift UV absorption edges, cause unwanted fluorescence, and reduce the superior uv transmission needed for sensitive measurements. Careful testing and certification help ensure that each optical quartz tube meets the highest standards for purity, resistance to devitrification, and thermal stability.

Critical Metallic Contaminants Affecting UV Absorption Edges

Metallic impurities such as iron, aluminum, and titanium can significantly lower the transmission of optical quartz in the deep UV range. These impurities create absorption centers that block UV light, shifting the absorption edge to longer wavelengths and reducing the effectiveness of uv-grade quartz tubes in applications like spectroscopy and photolithography. High-purity quartz tube production requires strict control of these contaminants to maintain superior uv transmission and resistance to devitrification.

Contaminant | Effect on UV Transmission | Resulting Performance Impact |

|---|---|---|

Iron (Fe) | Reduces transmission below 300nm | Loss of deep UV clarity |

Aluminum (Al) | Shifts absorption edge below 200nm | Decreased sensitivity |

Titanium (Ti) | Causes color centers, blocks UV | Lowered optical performance |

This table highlights how specific impurities directly affect the performance and reliability of optical quartz in demanding UV environments.

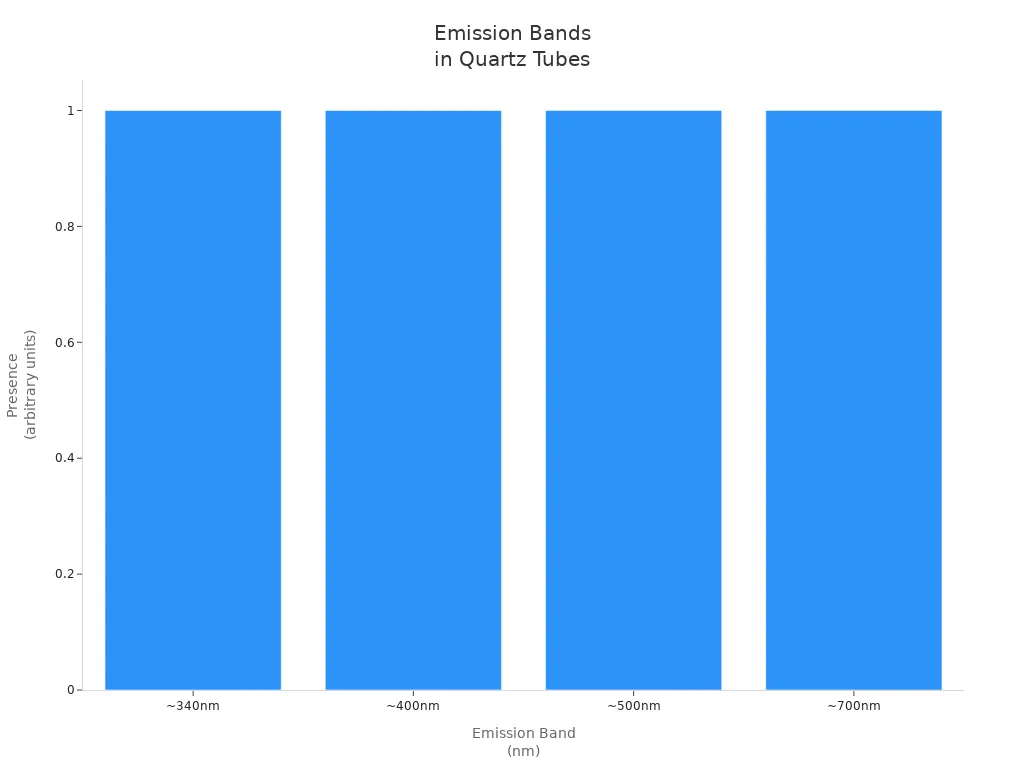

Fluorescence Mechanisms from Transition Metal Impurities

Transition metal impurities in quartz tubes can cause fluorescence when exposed to UV light. Different impurities and defects emit light at distinct wavelengths, which can interfere with sensitive optical measurements and lower the signal-to-noise ratio in laboratory systems. For example, Fe3+ impurities produce emission bands near 700nm, while Al3+ defects emit around 500nm, as shown in the chart below.

Fluorescence from these impurities can mask weak signals and reduce the accuracy of UV-based analyses.

Fluorescence can originate from Fe3+, Al3+, and Si–O defects

Emission bands overlap with analytical wavelengths, causing interference

Low impurity levels are essential for high-performance optical quartz

Purity Testing Standards and Acceptance Criteria

Manufacturers use advanced testing methods to verify the purity of optical quartz and ensure batch consistency. Common techniques include Inductively Coupled Plasma-Mass Spectrometry (ICP-MS), X-ray Fluorescence (XRF), and Atomic Fluorescence Spectrometry (AFS), which detect trace impurities at parts-per-million levels. Certifications such as ISO 12123 and ISO 9001 confirm that each quartz tube meets strict requirements for transmission, purity, and thermal stability.

Certification | Description |

|---|---|

ISO 9001 | Ensures strict controls over production, purity, and testing, leading to consistent performance and fewer defects. |

ISO 12123 | Sets criteria for optical transmission and homogeneity, requiring tests on refractive index variation and transmission at specific wavelengths. |

ASTM | Provides standards that help ensure quality and reliability in quartz tube production. |

SEMI | Establishes guidelines for the semiconductor industry, ensuring high-quality materials. |

Batch-specific purity certificates | Document impurity levels, ensuring consistency and quality verification. |

Buyers should always request batch-specific certificates and verify transmission at the application wavelength to guarantee reliable performance.

What Manufacturing Quality Indicators Validate UV Optical Performance?

Manufacturers use strict quality indicators to confirm the reliability of optical quartz in UV applications. These indicators help engineers and buyers select quartz tube products that deliver excellent uv transmission and resist devitrification. Understanding certification standards, test certificates, and batch consistency ensures that each uv-grade quartz tube meets the demands of advanced laboratory and industrial systems.

Essential Certification Standards for Optical Quartz Materials

Certification standards provide a foundation for evaluating the quality of optical quartz. ISO 12123 and ISO 9050 set requirements for transmission, purity, and thermal stability, which guide manufacturers in producing fused quartz with consistent performance. These standards also help buyers compare quartz tube options for specific UV applications.

Manufacturers must document compliance with these standards, including test results for transmission at key wavelengths and impurity levels. Certification ensures that each quartz tube maintains high purity and resists devitrification, supporting long-term reliability in demanding environments. Engineers rely on these certifications to make informed decisions.

Standard | Cause | Effect |

|---|---|---|

ISO 12123 | Sets purity benchmarks | Ensures high optical quartz quality |

ISO 9050 | Measures transmission | Confirms excellent uv transmission |

ASTM | Defines test methods | Validates thermal stability |

Interpreting Material Test Certificates and Spectral Data

Material test certificates and spectral data offer valuable insights into the optical performance of quartz tubes. Calibration reports show how equipment measures transmission and wavelength accuracy, while corrections and uncertainty values highlight any discrepancies. Wavelength data confirms that the quartz tube emits and transmits light at the required UV ranges.

Engineers should review these certificates to verify that the quartz tube meets application-specific requirements for purity and transmission. Accurate interpretation of spectral data ensures that the optical quartz will perform as expected in laboratory and industrial systems. Reliable certificates support confident material selection.

Key Concept | Explanation |

|---|---|

Calibration Report | Data for equipment adjustments and measurements |

Corrections | Discrepancies between measured and certified values |

Uncertainty | Lack of absolute accuracy in measurements |

Wavelength Data | Precision in emitting required wavelengths |

Batch Consistency Validation Through Statistical Process Control

Batch consistency plays a critical role in maintaining the quality of optical quartz tubes. Manufacturers use statistical process control to monitor transmission, purity, and thermal stability across production batches. Consistent results ensure that each quartz tube delivers excellent uv transmission and resists devitrification.

Engineers and buyers should request batch-specific certificates and transmission data at the application wavelength. Reliable batch consistency supports repeatable performance in UV systems and reduces the risk of unexpected failures. Consistency builds trust in the supplier’s quality control.

Key points for buyers and engineers include:

Request batch-specific purity certificates for each quartz tube

Verify transmission at the intended application wavelength

Choose suppliers with proven statistical process control

How Should Application Requirements Drive UV-Grade Material Selection?

Selecting the right quartz tube for UV applications starts with understanding the specific needs of the experiment or process. Each application requires careful consideration of wavelength, purity, and environmental factors. Matching these requirements ensures safety, accuracy, and long-term performance.

Wavelength-Specific Material Selection Decision Framework

Application wavelength determines which quartz tube will deliver the best results. Engineers must align the optical properties of the tube with the experiment’s needs, considering factors like chemical exposure and measurement accuracy. Different types of tubes, such as clear or opaque, serve unique roles in laboratory and industrial settings.

Quartz tubes maintain high uv transmittance, while borosilicate glass blocks most UV rays, making quartz essential for strong UV exposure. High purity quartz tubes are crucial for UV sterilization, as impurities can block UV light and reduce effectiveness. Selecting the right OH content ensures the tube performs well in both UV and infrared environments.

The following table summarizes how application requirements influence material selection:

Requirement | Cause | Effect |

|---|---|---|

Deep UV sterilization | High purity, low impurities | Maximizes germicidal action and measurement |

Multi-wavelength spectroscopy | Low OH content, high optical clarity | Supports broad spectral range and accuracy |

High-temperature environments | Stable structure, controlled OH content | Maintains performance and resists devitrification |

Tip: Always match the quartz tube’s properties to the application’s wavelength and process environment for optimal results.

Selecting high-quality UV-grade quartz tubes requires attention to strict standards.

SiO₂ purity of at least 99.98% ensures low contamination and strong UV light transmission.

UV transmission rates of 85% or higher at target wavelengths support accurate results in sensitive applications.

Thermal stability up to 1100°C protects performance in demanding environments.

Engineers should always match quartz tube properties to the application’s wavelength and verify certifications before purchase.

Tip: Request batch-specific purity and transmission data to avoid unexpected performance issues.

FAQ

What makes UV-grade quartz tubes different from standard glass tubes?

UV-grade quartz tubes transmit more than 80% of UV light at 200 nm.

Standard glass blocks most UV below 340 nm, which limits its use in deep UV applications.

Quartz tubes support advanced spectroscopy and sterilization.

Key points to remember:

Quartz transmits deep UV

Glass blocks most UV

Quartz enables sensitive measurements

What role does OH content play in UV transmission?

OH content affects how much UV light passes through quartz tubes.

Low OH content (<30 ppm) allows better deep UV transmission, while high OH content increases absorption.

Manufacturers use electrical fusion to achieve low OH levels.

OH Content | Transmission | Result |

|---|---|---|

Low (<30 ppm) | High | Best for deep UV |

High (>100 ppm) | Low | Limited UV use |

What impurities most impact UV optical clarity?

Metallic impurities like iron, aluminum, and titanium reduce UV transmission.

These metals create absorption centers and can cause unwanted fluorescence in sensitive systems.

High-purity quartz contains less than 20 ppm total metallic impurities.

Key facts:

Iron, aluminum, titanium lower clarity

Impurities cause fluorescence

High-purity quartz ensures best results

What certifications should buyers look for in optical quartz tubes?

Buyers should check for ISO 9050 and ISO 12123 certifications.

These standards confirm that quartz tubes meet strict requirements for UV transmission and purity.

Certified tubes provide reliable performance in laboratory and industrial settings.

Certification | What It Confirms |

|---|---|

ISO 9050 | UV transmission standards |

ISO 12123 | Purity and homogeneity |

What factors should guide material selection for UV applications?

Engineers must match quartz tube properties to the application’s wavelength and environment.

They should consider purity, OH content, and required transmission at specific wavelengths.

Selecting the right tube ensures safety and accurate results.

Important considerations:

Match tube to wavelength

Check purity and OH content

Verify transmission at target wavelength