- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz UV Cuvette

- /

- Spectroscopy-Grade UV Quartz Cuvette...

Spectroscopy-Grade UV Quartz Cuvette for Powder Fluorescence Analysis in Analytical Labs -TOQUARTZ®

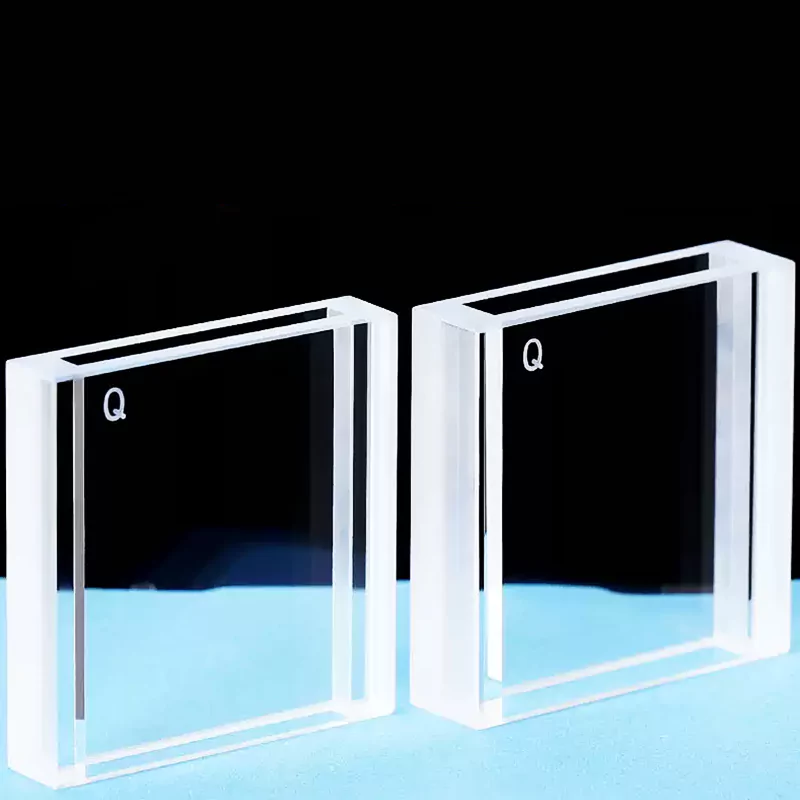

Features of UV Quartz Cuvette for Powder Fluorescence Analysis

TOQUARTZ® solid sample quartz cuvettes provide exceptional optical performance and material stability for accurate fluorescence analysis of powder samples. Each cuvette is crafted from high-purity fused quartz to ensure precision measurements and long-term reliability.

UV Transmittance

Wide spectral range (200nm-2500nm) with consistent transmittance properties, making these cuvettes ideal for UV-Vis fluorescence spectroscopy applications with powder samples.

Thermal Stability

Withstands temperatures up to 600°C with minimal thermal expansion, ensuring dimensional stability during temperature-dependent fluorescence studies.

Chemical Resistance

Exceptional resistance to acids, bases, and organic solvents, allowing sample preparation flexibility and preventing chemical degradation during analysis.

- SiO₂ content max. up to 99.995%

- Customizable design for specific requirements

- Tight dimensional tolerances (±0.1mm)

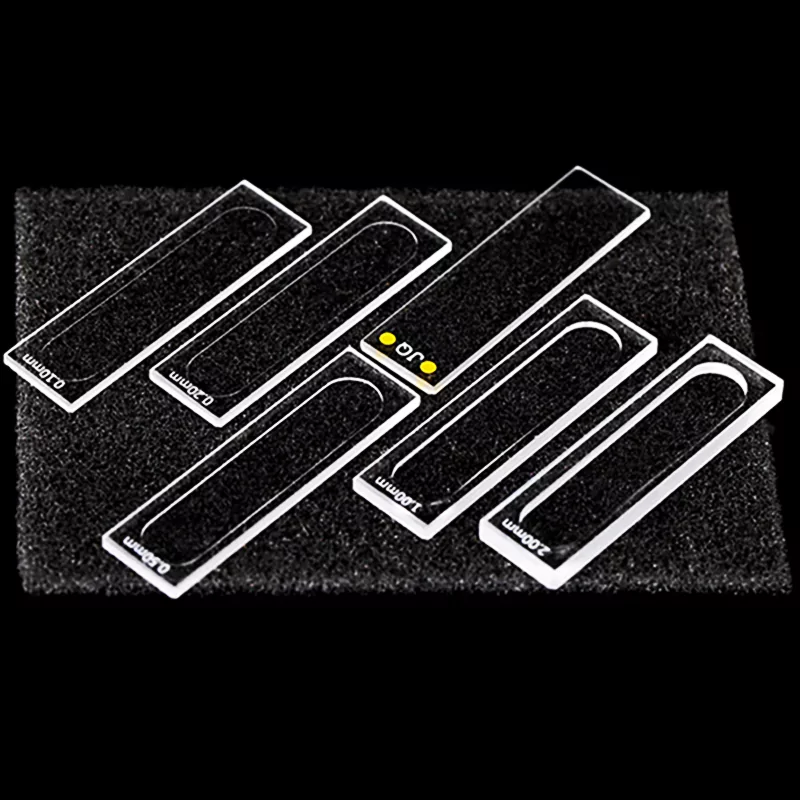

Technical Specifications & Dimensions of UV Quartz Cuvette for Powder Fluorescence Analysis

Technical Specifications

| Property | Specification | Notes |

| 1. Physical Properties | ||

| Material | High-purity fused quartz | max. up to 99.995% SiO₂ |

| Surface Finish | Optical polish on windows | Non-optical surfaces can be frosted |

| Density | 2.2 g/cm3 | Typical for fused quartz |

| 2. Chemical Properties | ||

| Chemical Composition | Max. SiO₂ ≥ 99.995% | Trace elements < 5 ppm |

| Acid Resistance | Excellent | Excluding hydrofluoric acid |

| Alkali Resistance | Good | Limited exposure to strong bases recommended |

| Solvent Compatibility | Compatible with all common organic solvents | No known limitations |

| 3. Optical Properties | ||

| Transmission Range | 200nm – 2500nm | Covers UV, visible, and near-IR regions |

| UV Cutoff | ~170nm | Typical for high-purity fused quartz |

| Refractive Index | 1.458 at 546nm (20℃) | Standard measurement conditions |

| UV Transmittance | >80% at 200nm (1mm thickness) | Higher than standard optical glass |

| Visible Transmittance | >90% (400-700nm) | Excellent optical clarity |

| 4. Thermal Properties | ||

| Maximum Operating Temperature | 600°C | Continuous use |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷/°C (20-300°C) | Very low expansion |

| Thermal Shock Resistance | Excellent | Can withstand rapid temperature changes |

Size Chart

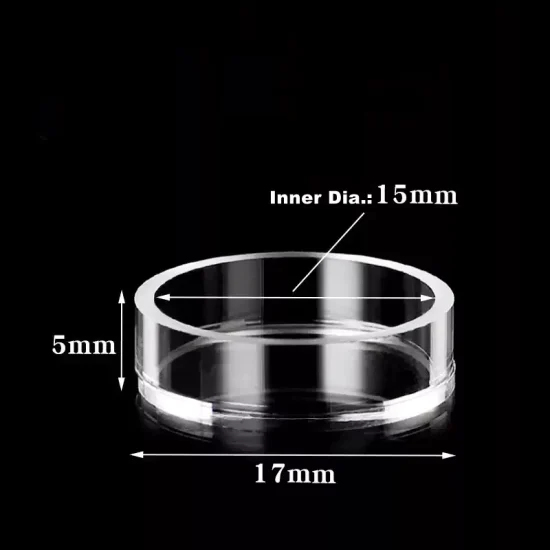

| Model | Description | Wavelength | Volume | Wall Thickness | Thermostability | OD.xHeight |

| AT-BSM-055-2 | UV Quartz Cuvette for Powder Fluorescence Detection | 200nm-2500nm | 0.7ml | 1mm | 600℃ | φ17*5mm |

TOQUARTZ® Solving Challenges in Powder Fluorescence Analysis with

UV Quartz Cuvette

UV Quartz Cuvette for Rare Earth Phosphor Characterization in Lighting Materials Industry

Key Advantages

-

UV Cutoff at 185nm Enables 254nm Excitation

Allows full-spectrum excitation for phosphors tested under 254nm UV lamps, unlike glass cuvettes with cutoff >350nm. -

Optical Window Flatness ≤ λ/10 at 633nm

Minimizes light scattering from non-uniform powder surfaces, improving emission peak resolution in spectrofluorometers. -

Internal Reflection Loss <1.2% at 365nm

Ensures accurate emission intensity measurement for low-quantum-yield phosphors used in LED phosphor blends.

TOQUARTZ® solution

A lighting materials lab in Germany testing YAG:Ce and Eu-doped phosphors reported 7–9% spectral distortion using borosilicate cuvettes due to UV absorption and scattering. After switching to TOQUARTZ UV quartz cuvettes, emission peak deviation dropped below 1.5%, enabling accurate CIE color coordinate mapping and reducing formulation errors in LED phosphor batches.

UV Quartz Cuvette for Solid-State Fluorescence Screening in Pharmaceutical Polymorph Studies

Key Advantages

-

PTFE-Sealed Lid Design with ≤0.01% Moisture Ingress

Maintains sample integrity during 24h+ fluorescence screening of hygroscopic APIs under ambient conditions. -

Surface Hydroxyl Content <50 ppm

Prevents hydrogen bonding interference with polymorphic forms of APIs like carbamazepine or ritonavir. -

Compatible with 5–10mm Path Length Screening Protocols

Supports standard solid-state fluorescence screening setups used in polymorph libraries and co-crystal studies.

TOQUARTZ® solution

A US-based pharmaceutical R&D team screening polymorphs of a new API experienced 18% signal drift over 12 hours due to moisture ingress in standard cuvettes. TOQUARTZ’s sealed UV quartz cuvettes maintained signal stability within ±2%, enabling reliable fluorescence-based polymorph differentiation and reducing false positives in early-stage screening.

UV Quartz Cuvette for Fluorescence-Based Quality Control in Battery Cathode Material Production

Key Advantages

-

Ion Leaching Rate <0.05 ppm in 1M LiPF₆ Electrolyte

Prevents contamination of cathode powders like LiCoO₂ during fluorescence-based impurity detection. -

Thermal Expansion Coefficient 5.5×10⁻⁷/°C

Maintains dimensional stability under 25–300°C thermal cycling used in cathode QC protocols. -

Compatible with Robotic Sample Holders (±0.1mm Tolerance)

Enables integration into automated QC lines for high-throughput fluorescence inspection of powder batches.

TOQUARTZ® solution

A Korean battery manufacturer using fluorescence QC for LiFePO₄ cathode powders reported 12% rejection rate due to cuvette deformation and ion contamination from soda-lime glass. After adopting TOQUARTZ UV quartz cuvettes, rejection dropped to <2%, and automated QC uptime improved by 18%, saving over $30,000/month in rework and downtime.

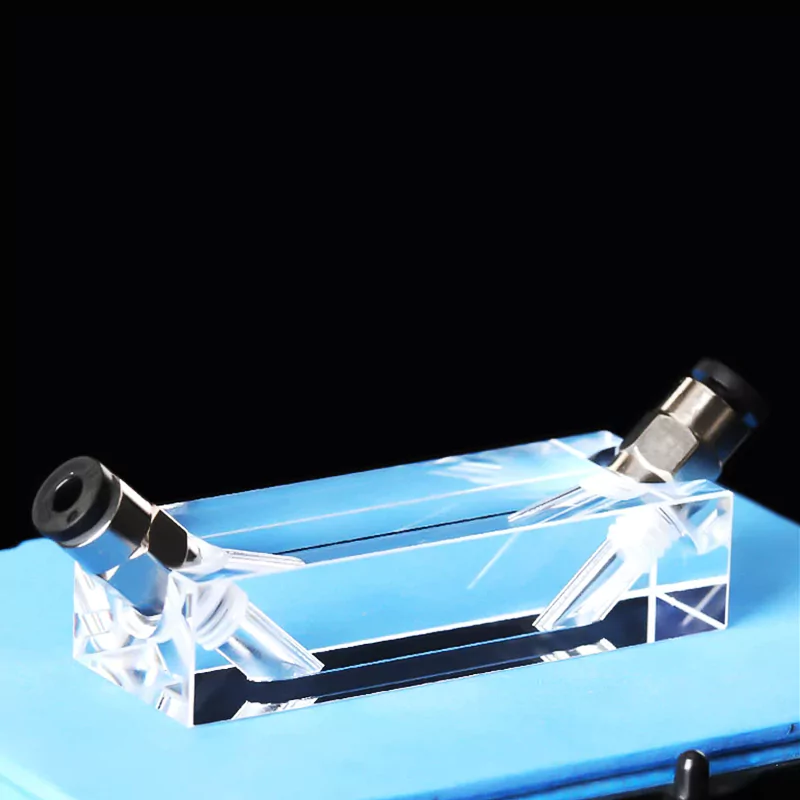

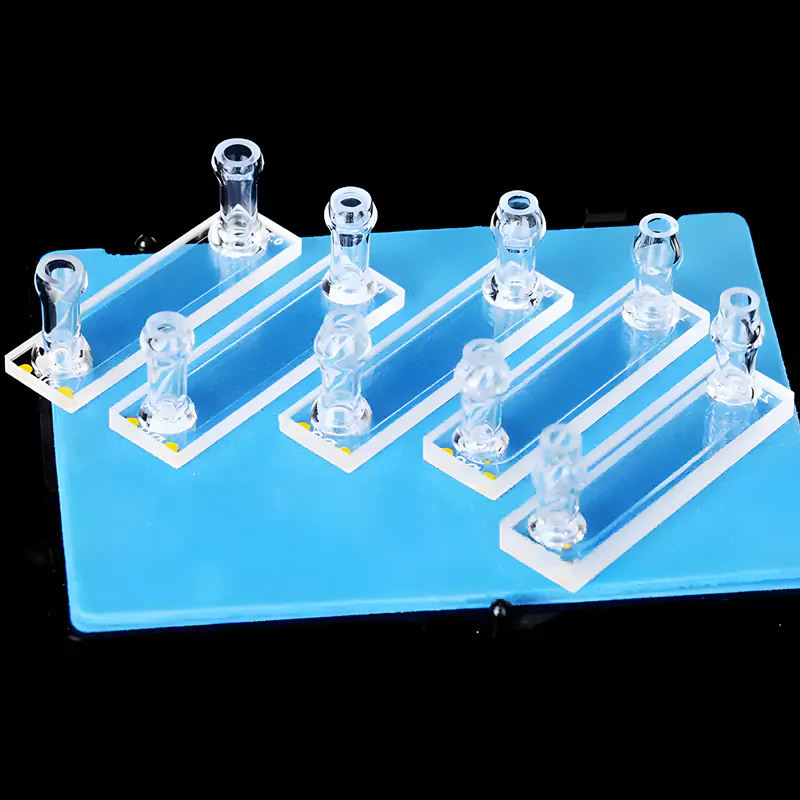

Customization Services for TOQUARTZ® UV Quartz Cuvette for Powder Fluorescence Analysis

Dimensional Customization

- Custom optical path lengths

- Modified window dimensions

- Special shapes and configurations

- Wall thickness variations

- Volume optimization

Functional Enhancements

- Sealed designs with PTFE or quartz lids

- Specialty surface treatments

- Sample positioning features

- Instrument-specific mounting adaptations

- Multi-compartment designs

Material Specifications

- Ultra-high purity quartz options

- Specialized optical grade selections

- Enhanced thermal stability grades

- Hydroxyl content specifications

- Bubble/inclusion-free material

Custom Design Process

Consultation & Requirements

Initial discussion with our technical team to understand your specific application needs, dimensional requirements, and performance specifications.

Design & Technical Drawing

Engineers create detailed technical drawings with precise specifications for your approval. Modifications can be made until the design perfectly meets your requirements.

Prototype Production

Rapid production of prototype units for testing and validation in your specific application or instrument setup.

Production & Quality Control

Full production with comprehensive quality control, including dimensional verification, optical testing, and material certification as required.

Usage Guide of UV Quartz Cuvette for Powder Fluorescence Analysis

Sample Preparation and Loading

- Ensure powder samples are dry and homogeneous before loading

- Use non-scratching tools (plastic or PTFE spatulas) when transferring samples

- Fill cuvettes consistently to ensure reproducible measurements

- For sealed models, ensure caps are tightened appropriately but not over-tightened

Cleaning and Maintenance

- Clean optical windows with lint-free lens tissue and spectroscopic-grade solvents

- Avoid abrasive cleaners that may scratch optical surfaces

- Ultrasonic cleaning in dilute laboratory detergent is effective for thorough cleaning

- Rinse thoroughly with deionized water and allow to air dry or use filtered compressed air

Storage and Handling

- Store in original protective packaging or in dust-free containers

- Avoid touching optical windows with bare fingers; use gloves when handling

- Protect from mechanical shock and vibration during storage and transport

- Keep inventory records for tracking usage and replacement scheduling

Best Practices for Measurement

- Perform baseline correction with an empty cuvette of the same type

- Maintain consistent sample packing density for comparative measurements

- Orient cuvettes consistently in the instrument holder (mark one side if needed)

- For temperature-dependent studies, allow sufficient equilibration time

Ready to Enhance Your Powder Fluorescence Analysis?

our team is ready to support your scientific endeavors with high-quality products and expert technical assistance.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What makes UV quartz cuvettes better than glass for powder fluorescence analysis?

A: UV quartz cuvettes offer superior UV transmittance (down to 200nm) compared to standard glass (limited to ~350nm). This is critical for fluorescence measurements where excitation wavelengths often fall in the UV range. Additionally, high-purity quartz provides minimal background fluorescence, better thermal stability, and superior chemical resistance, ensuring more accurate measurements for powder samples.

Q: How do I ensure consistent powder packing for reproducible measurements?

A: For reproducible measurements, use a consistent sample preparation protocol:

(1) Ensure uniform particle size through sieving or grinding,

(2) Use a consistent filling method such as gentle tapping or a standardized packing tool,

(3) Maintain the same sample mass for each measurement,

(4) Consider using a sample press for very fine powders,

(5) Document your packing procedure for future reference.

Our cuvettes with flat optical windows help minimize variability in path length.

Q: Can your UV quartz cuvettes be used with corrosive or reactive powder samples?

A: Yes, our quartz cuvettes exhibit excellent chemical resistance to most acids, bases, and organic solvents, making them suitable for a wide range of reactive powder samples. The only significant exception is hydrofluoric acid (HF), which can etch quartz. For highly alkaline samples (pH >12), we recommend limited exposure times. For specialized applications involving extreme chemical environments, please consult with our technical team for material compatibility assessment.

Q: What is the temperature limit for UV quartz cuvettes during fluorescence measurements?

A: TOQUARTZ® standard UV quartz cuvettes can operate continuously at temperatures up to 600°C without dimensional changes or optical property degradation. For sealed models with PTFE components, the maximum temperature is limited to 260°C (PTFE’s maximum service temperature). For applications requiring higher temperatures (up to 1100°C), we offer specialized high-temperature quartz grades with appropriate design modifications to manage thermal expansion.

Q: How should I clean UV quartz cuvettes between different powder samples?

A: For thorough cleaning between samples:

(1) Remove powder residue using compressed air or gentle brushing,

(2) Rinse with an appropriate solvent (ethanol, acetone, or water depending on sample solubility),

(3) For persistent residues, use an ultrasonic bath with dilute laboratory detergent,

(4) Rinse thoroughly with deionized water,

(5) Dry with filtered compressed air or in a dust-free environment,

(6) Inspect optical windows for cleanliness before reuse. Avoid abrasive materials that could scratch the optical surfaces.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.