- Home

- /

- Types

- /

- Quartz Plate

- /

- Coated Quartz Glass Plates...

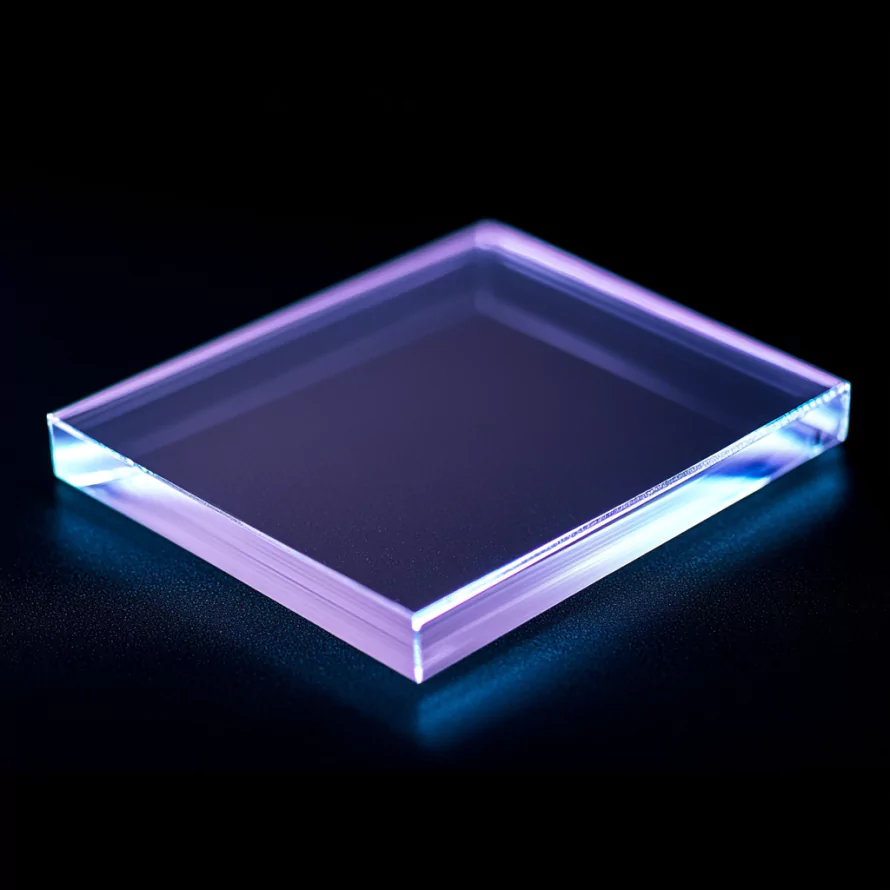

Coated Quartz Glass Plates for UV Curing Equipment -TOQUARTZ®

Properties of Coated Quartz Glass Plates

TOQUARTZ® specialized coated quartz glass plates combine exceptional material properties with precision manufacturing to deliver components that excel in UV curing applications. Each plate is meticulously produced to ensure optimal performance in your UV curing equipment.

Heat Resistance

TOQUARTZ® UV curing quartz plates can withstand continuous operation at 1100°C and short-term exposure up to 1450°C without deformation. With a low thermal expansion coefficient, they can endure rapid temperature changes without cracking, making them ideal for high-intensity UV curing applications.

Optical Transmission

TOQUARTZ® specialized coating technology allows UV light to pass through while effectively blocking infrared radiation. This unique property enables optimal curing without heat damage, with visible light transmission exceeding 93% and UV transmission above 80%, maximizing curing efficiency while preventing thermal damage to sensitive materials.

Chemical Resistance

Highly resistant to almost all acids and chemicals (except hydrofluoric acid), our quartz plates maintain their chemical stability even at elevated temperatures. This makes them ideal for UV curing equipment operating in environments where chemical exposure may occur, such as industrial painting facilities or PCB manufacturing.

- Prevents Material Deformation

- Preserves Color Integrity

- Enhanced Curing Efficiency

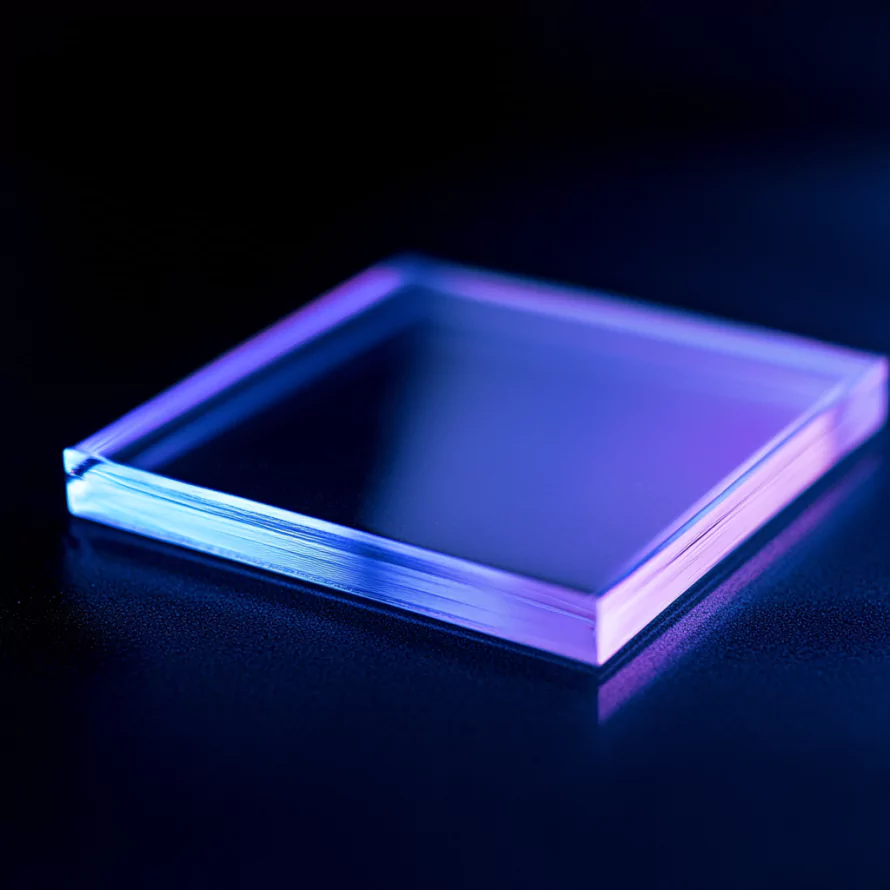

Technical Specifications & Dimensions of Coated Quartz Glass Plates

Size of of Square Coated Quartz Glass Sheets

| Square Coated Quartz Glass Plates | |||

| Model Number | Dimensions (mm) | Thickness (mm) | Optical Properties |

| AT-SY-P2001 | 10×10 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2002 | 25×25 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2003 | 40×40 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2004 | 60×60 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2005 | 75×25 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2007 | 100×100 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2008 | 120×120 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2009 | 120×120 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2010 | 150×150 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2011 | 150×150 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2012 | 180×180 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2013 | 180×180 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2014 | 250×250 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2015 | 10-750 (Custom) | 1-100 | 70% UV transmission, 70% IR reflection |

Size of of Rectangular Coated Quartz Glass Plates

| Model Number | Dimensions (mm) | Thickness (mm) | Optical Properties |

| AT-SY-P2016 | 135×320 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2017 | 150×100 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2018 | 150×200 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2019 | 195×73.8 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2020 | 215×160 | 4 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2021 | 220×130 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2022 | 280×150 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2023 | 300×100 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2024 | 300×150 | 3 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2025 | L: 10-750;W: 10-550(Custom) | 3-100 | 70% UV transmission, 70% IR reflection |

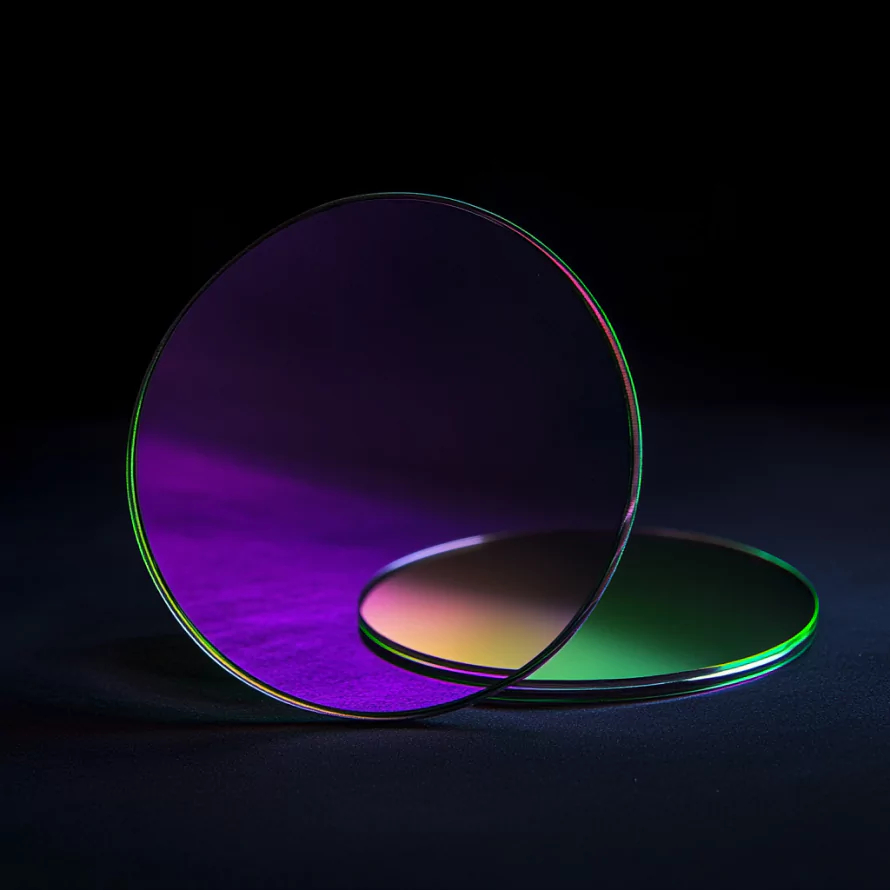

Size of of Round Coated Quartz Glass Discs

| Model Number | Diameter (mm) | Thickness (mm) | Optical Properties |

| AT-SY-P2026 | 8 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2027 | 10 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2028 | 15 | 1.5 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2029 | 30 | 1 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2030 | 50 | 2 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2031 | 100 | 5 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2032 | 200 | 10 | 70% UV transmission, 70% IR reflection |

| AT-SY-P2033 | 8-500 (Custom) | 1-100 | 70% UV transmission, 70% IR reflection |

Size of of Special Shape Coated Quartz Glass Plates

| Special Shape Coated Quartz Glass Plates | ||||

| Model Number | Dimensions (mm) | Thickness (mm) | Curvature | Optical Properties |

| AT-SY-P2034 | 121×62 | 2.5 | 68.18° | 70% UV transmission, 70% IR reflection |

Technical Specifications of Coated Quartz Glass Plates

| Parameter | Standard Specification | Custom Range |

| Material | High-purity fused silica | JGS1, JGS2, JGS3 grades available |

| Dimensions – Round | Ø8-500mm, thickness 1-100mm | Custom sizes available upon request |

| Dimensions – Square | 10×10mm to 750×750mm, thickness 1-100mm | Custom sizes available upon request |

| Dimensions – Rectangular | L:10-750mm; W:10-550mm, thickness 3-100mm | Custom sizes available upon request |

| Edge Treatment | Straight edges (standard) | R-corner, C-corner, protective corner |

| UV Transmission | >80% (varies by wavelength) | Optimized for specific UV wavelengths |

| IR Blocking | Effective IR radiation reduction | Enhanced IR blocking available |

| Visible Light Transmission | >93% | Customizable based on requirements |

| Temperature Resistance | Long-term: 1100°C, Short-term: 1450°C | Application-specific optimization |

| Chemical Resistance | Resistant to most acids and chemicals | Not resistant to hydrofluoric acid |

TOQUARTZ® Solving Challenges with Coated Quartz Glass Plates

Coated Quartz Glass Plates for Vehicle Paint Curing

Key Advantages

- Effectively blocks IR radiation, lowering substrate temperature from 85°C to 63°C during UV curing.

- Maintains surface integrity under full lamp power, eliminating micro-bubbling in metallic coatings.

- Ensures color stability of automotive topcoats with ΔE deviation under 1.0 after full UV exposure.

- Allows curing at higher conveyor speeds without thermal distortion of plastic or composite panels.

TOQUARTZ® solution

A German automotive paint system manufacturer reported 15% rejection rates due to heat-related paint defects.

After implementing TOQUARTZ® coated quartz plates in their UV curing system, they achieved a 90% reduction in heat-related defects while maintaining optimal curing speed, resulting in significant cost savings and quality improvements.

Coated Quartz Glass Plates for PCB Conformal Coating Curing

Key Advantages

- Minimizes board deformation from 0.5mm to 0.2mm under 254nm UV curing at 80°C ambient.

- IR-blocking layer prevents micro-boiling of acrylic coatings, reducing bubble defects by 95%.

- Keeps surface temperature below 80°C, safe for temperature-sensitive ICs and SMDs.

- Uniform UV exposure without thermal hotspots enhances coating bond strength on FR4 substrates.

TOQUARTZ® solution

An American electronics manufacturer struggled with component damage during conformal coating curing, with temperatures exceeding component tolerances by 15-20°C.

TOQUARTZ® provided custom-sized IR-blocking quartz plates that reduced curing temperature by 18°C while maintaining optimal UV transmission, eliminating component failures and reducing production costs.

Coated Quartz Glass Plates for UV Ink Printing Applications

Key Advantages

- Maintains dimensional stability of PET and PVC films by reducing curing heat load by 20°C.

- Allows UV curing on ultra-thin substrates without warping or edge curling.

- Blocks IR-induced pigment degradation, maintaining color accuracy on premium print jobs.

- Allows higher lamp intensity without thermal damage, increasing curing speed and productivity.

TOQUARTZ® solution

A Japanese specialty printing company was limited to 50% production speed when printing on heat-sensitive materials to prevent warping.

After installing TOQUARTZ® coated quartz plates in their UV curing system, they were able to increase production speed by 80% while reducing material waste by 12%, significantly improving profitability for premium printing jobs.

Customization Services for TOQUARTZ® Coated Quartz Glass Plates

Custom Dimensions & Shapes

- Round Plates: Custom diameter × thickness to fit your equipment

- Rectangular/Square Plates: Length × width × thickness to your specifications

- Edge Treatment Options: R-corners, C-corners, protective corners, or straight edges

- Custom Shapes: Produced according to your technical drawings

Material Grade Selection

- JGS-1 Far UV Grade: High-OH content (2000 PPM) with excellent UV transmission, especially at 185nm (90% transmission)

- JGS-2 UV Grade: Medium-OH content (100-200 PPM) suitable for applications above 220nm

- JGS-3 IR Grade: Low-OH content with superior IR transmission (>85%) for applications requiring IR management

How to Order Custom Coated Quartz Glass Plates

Provide Specifications

For round plates: diameter × thickness

For rectangular plates: length × width × thickness

Include edge treatment requirements (R-corner, C-corner, protective corner, straight)

Select Material Grade

JGS-1: For applications requiring excellent far UV transmission

JGS-2: For standard UV applications above 220nm

JGS-3: For applications requiring IR management

Specify Application Requirements

Provide details about your UV curing application, including wavelength requirements, temperature conditions, and specific performance needs

Submit Technical Drawings (if applicable)

For custom shapes or special features, provide detailed technical drawings

Usage Guidelines for Coated Quartz Glass Plates

Handling & Installation

- Handle with care to avoid impacts or drops that could cause breakage.

- For high-temperature applications, clean thoroughly before use and wear thin gloves during handling.

- Avoid direct hand contact to prevent fingerprints and contamination that could affect performance.

Chemical Compatibility

- Avoid contact with hydrofluoric acid (HF), which can etch and damage quartz.

- At high temperatures, strictly avoid contact with alkaline substances like water glass, asbestos, or potassium/sodium compounds.

- Contact with alkaline materials at high temperatures will significantly reduce performance.

Temperature Considerations

- Do not exceed the maximum operating temperature (1100°C for continuous use, 1450°C for short-term).

- Exceeding temperature limits can cause crystallization or deformation of the quartz plate.

- Consider thermal expansion in mounting designs to prevent stress fractures.

Cleaning & Maintenance

- Clean with appropriate optical-grade solvents and lint-free wipes using gentle motions.

- Regularly inspect for coating degradation, scratches, or contamination that could affect performance.

- Store in clean, dry conditions with appropriate protective packaging when not in use.

Need Engineering Support for Your UV Curing Equipment?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What coating options are available for UV equipment applications?

A: TOQUARTZ® offers several coating options for UV applications: Anti-Reflection (AR) coatings to maximize transmission at specific wavelengths, UV-enhancement coatings optimized for 185nm, 254nm, or other UV wavelengths, IR-blocking coatings to filter unwanted heat, and dichroic coatings for selective wavelength transmission. Custom coating designs are available to meet specific spectral requirements.

Q: Can you match specific UV transmission requirements for my application?

A: Yes, TOQUARTZ® can optimize transmission for specific UV wavelengths through material selection and specialized coatings. For applications requiring high transmission at 185nm or 254nm (common in UV sterilization), we recommend JGS-1 material with appropriate UV-enhancement coatings. We can provide transmission curves and test reports to verify performance for your specific wavelength requirements.

Q: Do you offer engineering support for integrating quartz plates into our equipment?

A: Yes, TOQUARTZ® engineering team provides technical support for integrating our products into your equipment. We can review your designs and provide recommendations for mounting methods, sealing techniques, and thermal management to maximize performance and longevity. For complex applications, we offer more comprehensive design collaboration services to ensure optimal integration with your systems.

Q: Can you match a coating specification from another supplier?

A: Yes, we can match coating specifications from other suppliers in most cases. Providing us with the spectral performance data or a sample for analysis allows us to develop an equivalent coating. For direct replacements, we can analyze your existing components and develop coatings that match or exceed their performance. This service is particularly valuable for customers facing supply chain disruptions or seeking more competitive pricing.

Q: What is the maximum operating temperature for coated quartz glass plates?

A: The base quartz material can withstand continuous operation at 1100°C and short-term exposure up to 1450°C. However, coatings typically have lower temperature limits. Standard AR coatings can typically withstand temperatures up to 300-500°C, while specialized high-temperature coatings may operate up to 800°C. We provide specific temperature ratings for each coating type to ensure compatibility with your application.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.