- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Flow-Through Cuvette

- /

- Transparent Quartz Flow-Through Cuvette...

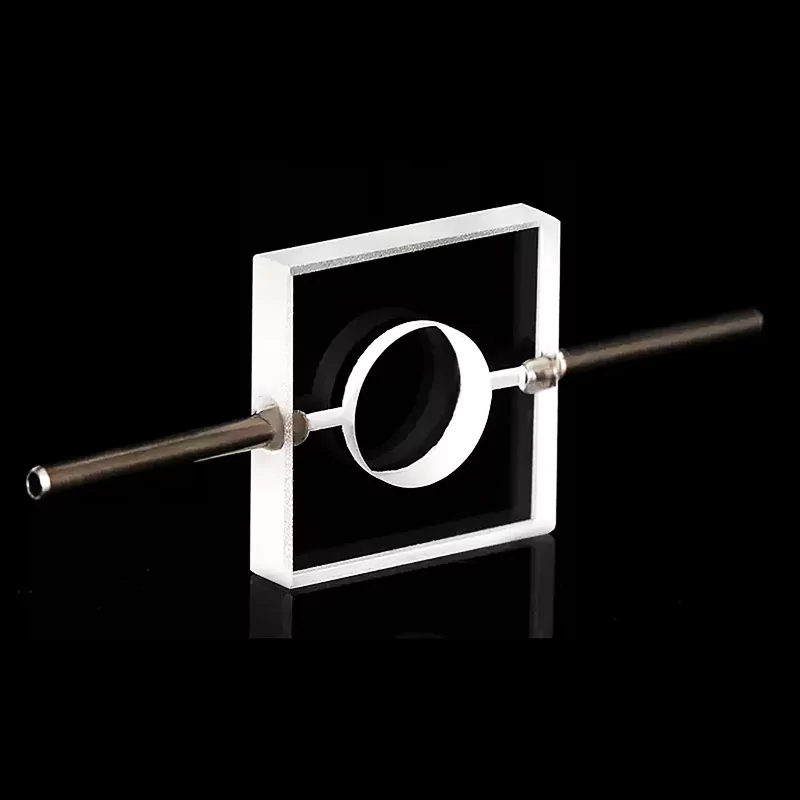

Transparent Quartz Flow-Through Cuvette with Stainless Steel Tubes for Spectroscopic Instruments -TOQUARTZ®

Features of Transparent Quartz Flow-Through Cuvette with

Stainless Steel Tubes

TOQUARTZ® Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube combines precision manufacturing with superior materials to deliver exceptional performance for analytical applications.

Optical Clarity

Manufactured from high-purity quartz to ensure excellent UV transmission range from 190 nm to 2500 nm, providing reliable spectral data across a broad wavelength range.

Robust Construction

Incorporates a stainless steel tube for enhanced structural integrity and compatibility with various analytical systems, ensuring reliable connections and leak-free operation.

Chemical Resistance

Resistant to a wide range of chemicals including acids, bases, and organic solvents, ensuring durability and longevity even in challenging chemical environments.

High Thermal Resistance

Withstands temperatures up to 1100°C, making it suitable for high-temperature analytical environments and ensuring stability during thermal fluctuations.

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

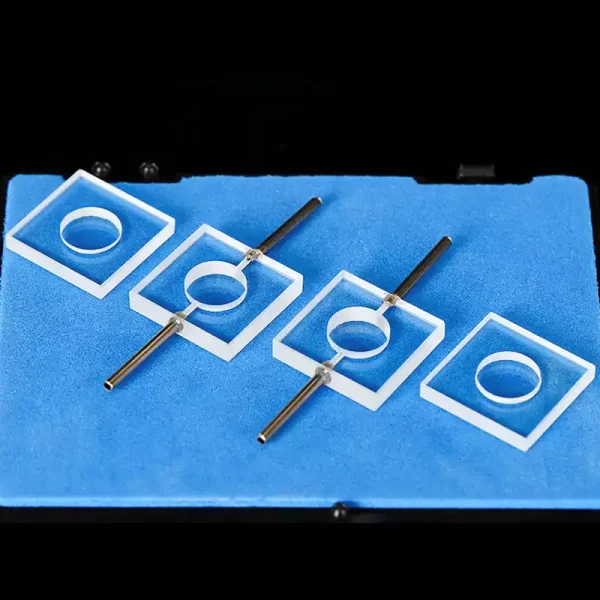

Technical Specifications & Dimensions of Transparent Quartz Flow-Through Cuvette with Stainless Steel Tubes

Technical Specifications

| Parameter | Specification |

| 1. Physical Properties | |

| Material: | High-purity quartz, stainless steel |

| Quartz Purity: | ≥99.98%, up to 99.995% SiO2 |

| Operating Temperature: | Up to 1100°C |

| Thermal Expansion: | 5.5 × 10-7/°C (20-320°C) |

| Surface Finish: | Optical grade polished |

| 2. Chemical Properties | |

| Chemical Resistance: | Excellent |

| Acid Resistance: | High (except HF) |

| Alkali Resistance: | Good at room temperature |

| Solvent Compatibility: | Compatible with most organics |

| Water Absorption: | Nil |

| 3. Optical Properties | |

| UV Transmission Range: | 190-2500 nm |

| Refractive Index: | 1.458 (at 546.1nm) |

| UV Cutoff: | 170 nm |

| Transparency: | ≥90% (200-2000 nm) |

| Surface Quality: | 60-40 scratch-dig |

Size Chart

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-8022-11 | Open-Top Quartz Flow-Through Cuvette with Stainless Steel Tube, Dual Optical Channels | / | / | 60x35x6mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8040-1 | 150μl Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube Sample Chamber | / | 150μl | 20x20x3mm |

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8010 | 0.2mm Path Length Quartz Flow Cell Counting Cuvette Dual Path | 0.2mm | / | 75x25x4mm |

Solving Analytical Challenges with TOQUARTZ® Transparent Quartz Flow-Through Cuvette with Stainless Steel Tubes

Real-Time Enzyme Kinetics Monitoring for Bioreactors

Key Advantages

-

Integrated sterile-grade stainless steel inlet/outlet

→ Enables closed-loop sampling with zero manual intervention at flow rates up to 5 mL/min. -

Optical path deviation < ±0.01 mm across 10,000 cycles

→ Ensures consistent absorbance readings during long-term kinetic assays. -

360° optical access with 99.8% UV transmittance at 220 nm

→ Supports high-sensitivity detection of NADH/NAD+ reactions in UV range.

TOQUARTZ® solution

A German biopharma lab using NADH-based enzyme kinetics in a 5L bioreactor faced 12% signal drift due to manual sampling and inconsistent cuvette alignment. After switching to TOQUARTZ® flow-through cuvettes with integrated stainless steel ports, they achieved continuous UV monitoring with <1% signal variance over 48 hours, eliminating contamination risk and improving data resolution by 3×.

In-Line Fluorescence Detection in Microfluidic Drug Screening

Key Advantages

-

Dual 90° optical channels with ±0.2° alignment tolerance

→ Optimized for orthogonal excitation/emission in compact fluorescence setups. -

Background autofluorescence < 0.002 AU at 460 nm

→ Reduces signal noise by 5× compared to standard fused silica cells. -

Micro-volume chamber (150 μL) with dead volume < 20 μL

→ Enables high-throughput screening with minimal reagent consumption.

TOQUARTZ® solution

A U.S.-based CRO screening kinase inhibitors via fluorescence in a 384-channel microfluidic chip reported 18% false positives due to cuvette autofluorescence and misalignment. TOQUARTZ® cuvettes reduced background signal by 87% and improved alignment consistency, enabling detection of 10 nM fluorophore concentrations with 98.5% assay reproducibility.

Continuous Water Quality Monitoring for UV Absorbance of Nitrate/TOC

Key Advantages

-

Internal surface roughness < 0.2 μm Ra

→ Minimizes fouling and biofilm formation in continuous flow environments. -

Stainless steel tube rated for 24/7 operation in pH 3–11

→ Withstands aggressive water chemistries without corrosion or leakage. -

UV absorbance stability drift < 0.5% over 30 days

→ Maintains calibration accuracy in unattended field deployments.

TOQUARTZ® solution

A municipal water station in Poland monitoring nitrate levels via UV absorbance at 220 nm experienced 15% signal drift after 2 weeks due to fouling in polymer-based flow cells. After deploying TOQUARTZ® cuvettes, they maintained <0.3% drift over 30 days of continuous operation, reducing recalibration frequency by 60% and improving regulatory compliance reporting.

TOQUARTZ® Customization Options for Transparent Quartz Flow-Through Cuvette with Stainless Steel Tubes

Optical Path Customization

Clients often require precise optical path configurations to match their detection systems.

-

Path Length Options

→ Adjusted for absorbance, fluorescence, or scattering sensitivity. -

Channel Geometry

→ Single or dual optical windows for signal optimization. -

Z-Dimension Alignment

→ Ensures compatibility with fixed-position detectors.

Flow Channel Configuration

Flow dynamics must align with sample viscosity, throughput, and system pressure.

-

Internal Volume

→ Optimized for low-volume or continuous-flow analysis. -

Flow Orientation

→ Supports vertical or horizontal sample movement. -

Dead Volume Control

→ Designed to minimize sample retention and carryover.

Material and Surface Treatment

Surface quality and material purity impact optical clarity and fouling resistance.

-

Quartz Grade Selection

→ Chosen based on UV transmission and chemical exposure. -

Surface Polishing

→ Optical-grade finish reduces signal distortion. -

Anti-Fouling Coating

→ Optional treatment for long-term aqueous exposure.

Usage and Care Guidelines

Installation Guidelines

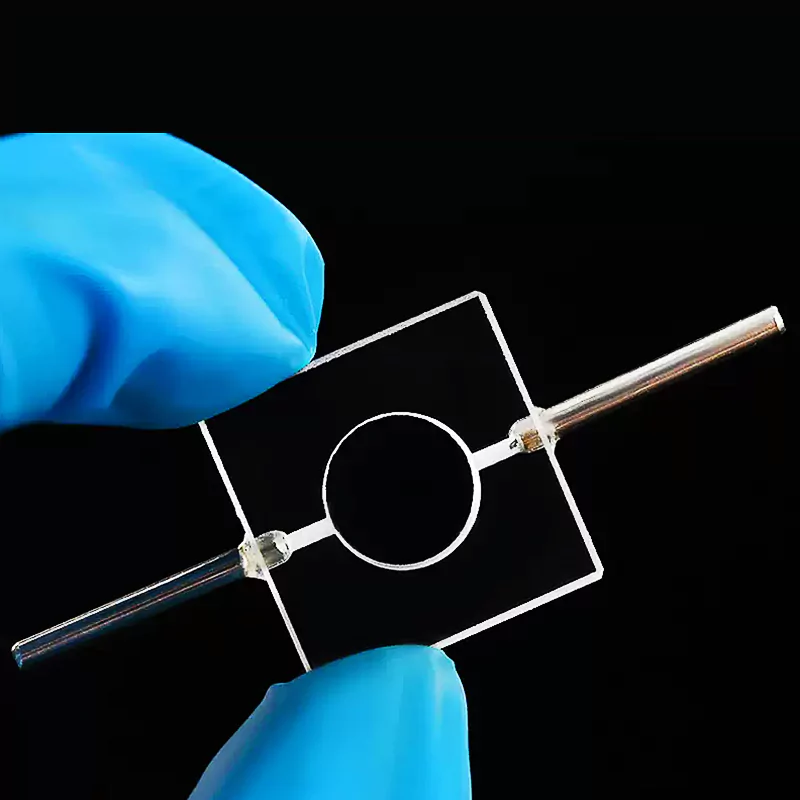

- Inspect the cuvette - Before installation, examine the cuvette for any defects, cracks, or contamination on optical surfaces.

- Handle with care - Always wear powder-free gloves when handling the cuvette to prevent fingerprints and contamination on optical surfaces.

- Connect tubing - Use appropriate fittings with the stainless steel tube connectors. Tighten connections finger-tight plus 1/4 turn with a wrench to prevent overtightening.

- Avoid mechanical stress - Ensure tubing is properly supported to prevent stress on the cuvette connections.

- Flow orientation - Note the correct flow direction indicated on the cuvette housing and maintain consistent flow direction.

Performance Optimization

-

Flow rate control

- Maintain consistent flow rates to ensure stable baseline and signal response. Optimal flow rates typically range from 0.5-2 mL/min. -

Bubble prevention

- Degas mobile phases and samples to prevent air bubbles that can cause signal noise and baseline disturbances. -

Temperature stability

- Maintain stable temperature conditions to prevent thermal expansion effects on optical alignment. -

Baseline verification

- Periodically verify baseline stability with pure solvent to detect potential contamination or degradation issues.

Maintenance and Cleaning

- Regular flushing - After each use, flush the cuvette with appropriate solvent followed by clean, filtered water to prevent buildup of residues.

- Optical surface cleaning - For external optical surfaces, use lens-grade tissues with spectroscopic-grade solvents (ethanol or acetone) using a gentle wiping motion.

- Stubborn deposits - For persistent deposits, flow a solution of 5% laboratory-grade detergent followed by thorough rinsing with filtered water.

- Chemical compatibility - Avoid hydrofluoric acid (HF) and strong hot alkaline solutions, which can attack quartz surfaces.

- Storage - Store the clean, dry cuvette in a dust-free container at room temperature. Protect optical surfaces with lens tissue.

Troubleshooting Common Issues

-

Leakage at connections:

Check for proper fitting installation, replace damaged ferrules, and ensure connections are properly tightened without overtightening. -

Increased baseline noise:

Inspect for bubbles in the flow path, check for optical surface contamination, and verify stable flow conditions. -

Reduced sensitivity:

Examine optical surfaces for contamination, check for detector lamp stability, and verify proper optical alignment. -

Back pressure increase:

Look for potential blockages in the flow path, inspect inlet/outlet for particulate accumulation, and clean as needed.

Need Technical Support for Your Transparent Quartz Flow-Through Cuvette Application?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How does the full-body transparency of the Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube benefit UV-based flow analysis?

A: The full-body transparency ensures consistent light transmission across the entire optical path. This minimizes signal distortion and improves baseline stability in UV absorbance measurements. It is especially beneficial in real-time kinetic assays where optical clarity is critical. The design supports accurate detection from 190 nm to 2500 nm.

Q: Can the Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube handle high-pressure flow systems?

A: Yes, the stainless steel tube is engineered to withstand pressures commonly found in HPLC and continuous flow systems. The quartz body is bonded using precision sealing techniques to prevent leakage. This makes the cuvette suitable for both low- and high-pressure analytical environments. Pressure ratings can be customized based on application needs.

Q: How does the Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube perform in long-term continuous monitoring applications?

A: TOQUARTZ® cuvette is designed for stability in 24/7 flow conditions. Its quartz surface resists fouling and maintains optical clarity over extended use. The stainless steel tube ensures structural integrity under thermal and chemical stress. It is widely used in water quality monitoring and process control.

Q: Can the Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube be customized for specific flow rates or volumes?

A: Yes, we offer customization of internal chamber volume and flow channel dimensions. This allows optimization for specific sample viscosities and throughput requirements. Custom designs can also include specific inlet/outlet orientations. All modifications maintain optical and mechanical performance standards.

Q: How does the cuvette minimize sample carryover in continuous flow analysis?

A: The internal geometry of the Transparent Quartz Flow-Through Cuvette with Stainless Steel Tube is optimized to reduce dead volume. Smooth internal surfaces and direct flow paths prevent sample retention. This design minimizes cross-contamination between runs. It is ideal for high-throughput or automated systems.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.