- Home

- /

- Types

- /

- Quartz Tube

- /

- Custom Precision-Machined Threaded Quartz...

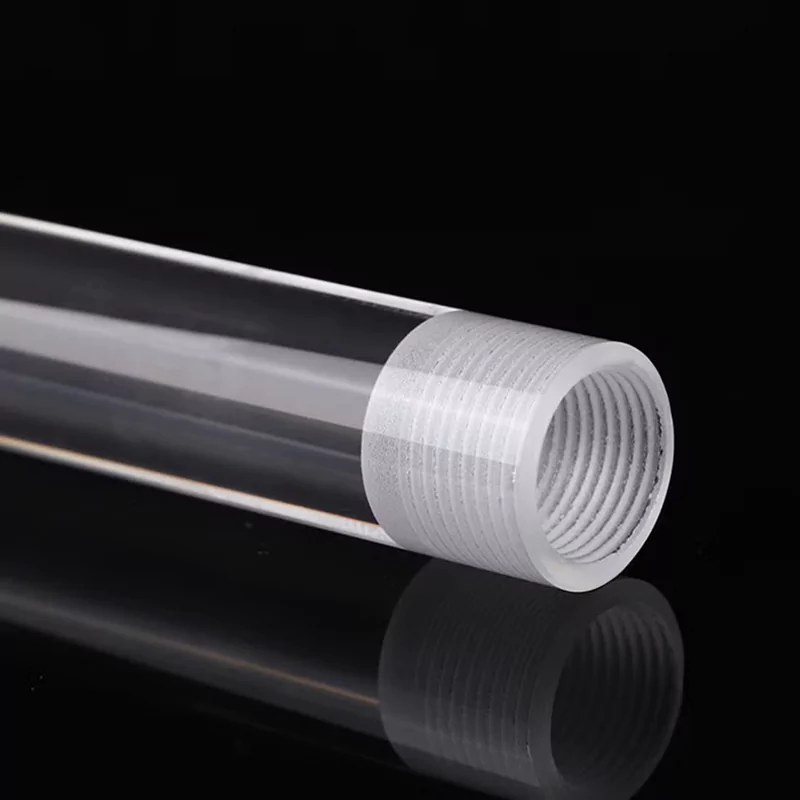

Custom Precision-Machined Threaded Quartz Tubes for Process Equipment-TOQUARTZ®

Technical Features of Threaded Quartz Tubes

TOQUARTZ® threaded quartz tubes are manufactured using advanced processing technologies to maintain structural integrity while providing precise threading for critical applications. Our tubes stand out for their exceptional material properties and machining precision.

Precision Threading

Machine-tooled threads with ±0.1mm tolerance for secure, leak-proof connections. Available in standard metric, imperial, and custom thread patterns.

Thermal Stability

Withstands continuous operating temperatures up to 1250°C with minimal thermal expansion (5.5×10⁻⁷/°C). Maintains structural integrity during rapid temperature changes.

Optical Clarity

Excellent transmission in UV/IR spectrum. Perfect for optical applications requiring both threading and light transmission properties.

- Exceptional Chemical Resistance

- Composed of 99.99% SiO₂

- Customizable Dimensions

Technical Specifications of Threaded Quartz Tubes

TOQUARTZ® threaded quartz tubes are manufactured to exacting standards, meeting or exceeding industry specifications for critical applications in laboratory, industrial, and research environments.

| Property | Specification | Test Method |

| Material Composition | SiO₂ ≥ 99.99% | ICP-MS |

| Density | 2.2 g/cm³ | ASTM C693 |

| Working Temperature | 1250°C (continuous) | ASTM C1720 |

| Softening Point | 1730°C | ISO 7884-3 |

| Thermal Expansion Coefficient | 5.5 × 10⁻⁷/°C (20-1000°C) | ASTM E228 |

| Thermal Conductivity | 1.4 W/m·K (25°C) | ASTM C1113 |

| Mohs Hardness | 5.3-6.5 | ASTM C1326 |

| Thread Types Available | Metric, UNF, UNC, NPT, Custom | ISO/DIN standards |

TOQUARTZ® Solving Critical Challenges with Threaded Quartz Tubes

Threaded Quartz Tubes for Laboratory Analysis Systems

Key Advantages

-

Thread-Sealed Sample Integrity

Precision-machined threads with ±0.1mm tolerance achieve helium leak rates below 1×10⁻⁹ mbar·L/s, eliminating cross-contamination between analytical samples. -

Thermal Cycling Durability

Threaded connections maintain seal integrity through 500+ thermal cycles (20°C to 800°C), reducing connection failure rates by 94% compared to compression fittings. -

Tool-Free Reconnection Speed

Hand-tightened threaded connections enable 30-second component changes versus 5-minute flange assembly, minimizing exposure time for air-sensitive samples.

TOQUARTZ® solution

A German pharmaceutical laboratory conducting trace metal analysis experienced 15% sample contamination from failing glass-to-metal compression seals during 200°C thermal cycling. After switching to TOQUARTZ® threaded quartz tubes with PTFE-sealed threads, contamination dropped to 0.3% over 6 months of continuous operation. The threaded design allowed technicians to perform maintenance in under 2 minutes without breaking vacuum, saving 4 hours weekly in system downtime and preventing $8,000 in monthly sample losses.

Threaded Fused Silica Tubes for UV/IR Optical Systems

Key Advantages

-

Optical Transmission at Connection Points

Male/female threaded joints maintain 91% UV transmission at 254nm wavelength through the connection zone, versus 65% for cemented joints. -

Vibration-Resistant Thread Engagement

5-turn thread engagement withstands 2G vibration at 50Hz without loosening, preventing lamp misalignment that causes 30% power loss in standard friction-fit assemblies. -

Field-Replaceable Design

Threaded tubes enable on-site lamp replacement in 3 minutes without specialized tools, reducing service calls by 75% compared to welded quartz assemblies.

TOQUARTZ® solution

A UV water treatment equipment manufacturer faced 22% annual warranty claims due to quartz sleeve failures at connection points, where standard push-fit seals degraded under UV exposure. TOQUARTZ® threaded quartz tubes with fluoropolymer-compatible threads reduced connection failures to 2% over 24 months. The threaded design maintained consistent 253.7nm transmission while allowing field technicians to replace components without returning units to the factory, saving $45,000 annually in shipping and labor costs.

Threaded Quartz Glass Tubes for High-Temperature Processing

Key Advantages

-

Zero-Contamination Threading

All-quartz threaded connections eliminate metal ion contamination (<0.1 ppb) at 1200°C, critical for semiconductor and solar cell production processes. -

Dimensional Stability Under Load

Threaded joints maintain ±0.05mm concentricity at 1000°C with 5kg suspended load, preventing process tube sagging that causes 12% yield loss. -

Thermal Expansion Compensation

Thread pitch designed with 0.3mm axial clearance accommodates thermal expansion up to 1250°C without binding or cracking.

TOQUARTZ® solution

A Japanese semiconductor equipment manufacturer struggled with alumina ceramic tubes that couldn't achieve thread tolerances below ±0.3mm, causing vacuum leaks in their 1100°C oxidation furnaces. TOQUARTZ® delivered threaded quartz tubes with ±0.1mm thread precision that maintained vacuum levels of 10⁻⁶ Torr throughout 1000-hour production runs. The contamination-free quartz threads eliminated the iron and aluminum traces (previously 15-20 ppb) that were causing 8% wafer rejection rates, recovering $120,000 monthly in improved yields.

TOQUARTZ® Custom Threaded Quartz Tube Services

Customization Options

-

Custom Thread Specifications:

Metric, imperial, NPT, custom pitch and diameter -

Specialized Dimensions:

ID/OD from 3mm to 300mm, custom lengths up to 3000mm -

End Configurations:

Single-threaded, double-threaded, one male/one female, custom thread length -

Surface Treatments:

Fire-polished, precision ground, frosted, custom markings -

Material Options:

Clear fused quartz, UV-transmitting, IR-blocking, opal quartz

Engineering Design Process

-

Technical Requirements Analysis

We evaluate your application parameters including pressure ratings, temperature cycles, chemical exposure, and mechanical stress to determine optimal thread specifications and quartz grade selection. -

Thread Profile Engineering

Our design team calculates precise thread geometry using FEA simulation to ensure proper stress distribution, accounting for thermal expansion differentials between mating components. -

CAD Modeling & Design Validation

3D parametric models of your threaded quartz tubes are created with full dimensioning, allowing virtual assembly testing and interference checking before prototype approval. -

Material & Manufacturing Method Selection

Based on your application demands, we specify the appropriate fused silica grade and determine whether CNC threading, ultrasonic machining, or specialized grinding achieves your required tolerances.

Usage Guidelines for Threaded Quartz Tubes

Proper handling, installation, and maintenance of threaded quartz tubes ensure optimal performance and extended service life. These guidelines help prevent damage and maximize the value of your investment.

Installation Recommendations

- Use PTFE tape or fluoropolymer-based thread sealant for gas-tight connections

- Tighten by hand only - avoid metal tools that can crack threads

- Use mating components with matching thermal expansion properties

- Allow 0.5-1mm expansion clearance in high-temperature applications

- Verify thread compatibility before installation (metric vs. imperial)

Handling Precautions

- Wear clean, powder-free gloves to prevent contamination

- Store in clean, padded containers to prevent thread damage

- Avoid thermal shock (>200°C/minute temperature change)

- Clean with electronic-grade solvents or deionized water

- Inspect threads for damage before each use

Thermal Cycling Guidelines

- Allow 2-3 minutes per mm of wall thickness for uniform heating

- Implement controlled heating/cooling ramps (<150°C/minute)

- Pre-heat mating components to reduce thermal stress

- Avoid direct flame or concentrated heat sources

- Use heat-distributing shields for uneven heating applications

Get Expert Engineering Support for Your Threaded Quartz Tube Requirements

Benefit from our experience working with laboratories, equipment manufacturers, and research institutions worldwide.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a threaded quartz tube used for?

A: Threaded quartz tubes are used in applications requiring secure, leak-tight connections in high-temperature, chemically aggressive, or optically demanding environments. Common applications include laboratory analysis equipment, UV disinfection systems, semiconductor processing equipment, high-temperature furnaces, and specialized optical assemblies.

Q: Can quartz tubes be custom threaded?

A: Yes, TOQUARTZ specializes in custom threading for quartz tubes. We can create standard metric and imperial threads (M8, M10, G1/4, NPT, UNF, etc.) as well as custom thread profiles to your specifications. Our precision machining capabilities achieve thread tolerances of ±0.1mm for secure connections.

Q: What temperature can threaded quartz glass tubes withstand?

A: Our threaded quartz tubes can withstand continuous operating temperatures up to 1250°C and have a softening point of approximately 1730°C. The thermal shock resistance is excellent, though we recommend controlled heating/cooling rates for optimal performance. For applications above 1000°C, we provide specialized guidelines for thread engagement and thermal expansion accommodation.

Q: Are threaded quartz tubes chemically resistant?

A: Yes, our threaded quartz tubes offer exceptional chemical resistance. They are inert to most acids (including hydrofluoric acid at room temperature), bases, and organic solvents. They resist corrosion from halogens, molten salts, and most reactive gases. This makes them ideal for chemical processing, analysis equipment, and harsh environment applications where metal or polymer components would degrade.

Q: What are the standard sizes available for threaded quartz tubes?

A: We offer standard threaded quartz tubes with outer diameters ranging from 6mm to 50mm, with wall thicknesses from 1mm to 4mm. Standard thread sizes include M10, M15, M20, G1/4, G3/8, NPT 1/4, and NPT 3/8. Custom diameters up to 300mm and custom thread specifications are available upon request with typical lead times of 2-4 weeks.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.