- Home

- /

- Types

- /

- Quartz Tube

- /

- Instrument-Grade Square Quartz Tube...

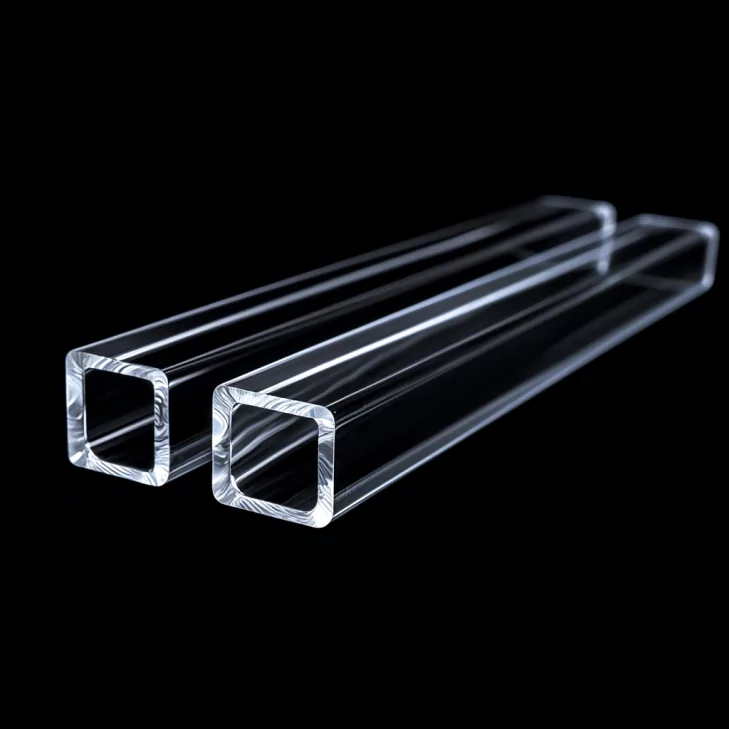

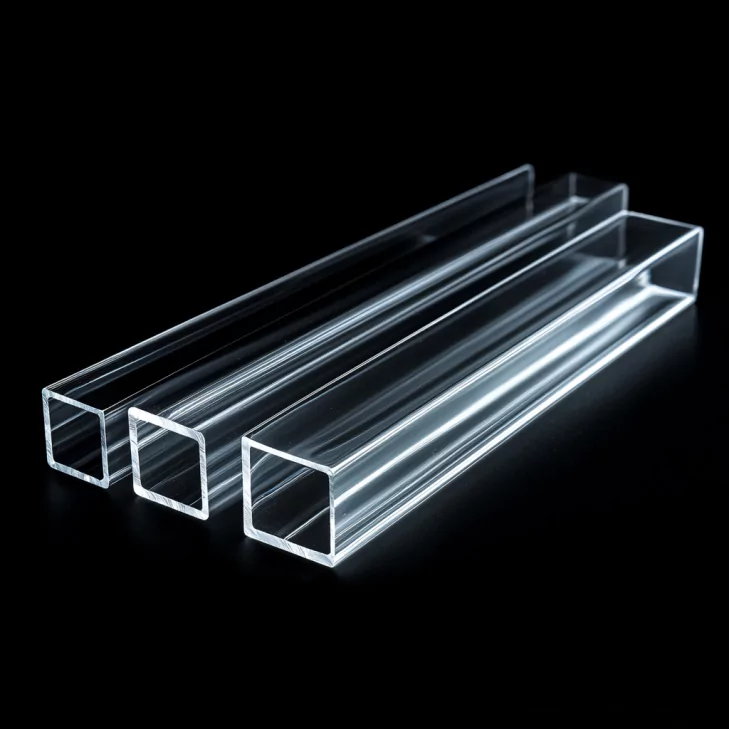

Instrument-Grade Square Quartz Tube for Scientific Integration-TOQUARTZ®

Technical Features of Square Quartz Tube

TOQUARTZ® square quartz tubes are manufactured from high-purity fused silica, offering exceptional thermal, optical, and chemical properties for demanding industrial and scientific applications.

Thermal Properties

-

High Temperature Resistance:

Withstands continuous operation at 1100°C and short-term exposure up to 1350°C -

Low Thermal Expansion:

Coefficient of 5.5×10⁻⁷ /°C ensures dimensional stability during thermal cycling -

Thermal Shock Resistance:

Capable of withstanding rapid temperature changes without cracking

Optical Properties

-

Excellent Light Transmission:

>93% visible light transmission rate -

UV Transparency:

>80% transmission in UV spectral range, ideal for UV sterilization systems -

Refractive Index:

1.4585 - consistent throughout the material

- Exceptional Chemical Resistance

- Specific Resistance of 7×10⁷ Ω·cm

- Customizable Dimensions

Technical Specifications and Dimension of Square Quartz Tube

TOQUARTZ® square quartz tubes are manufactured to strict specifications, ensuring consistent performance across all applications. Standard sizes are available from stock, while custom dimensions can be produced to your exact requirements.

Material Properties of Square Quartz Tube

| Physical Property | Value |

| Density | 2.2 g/cm³ |

| Flexture Strength | 48 MPa |

| Elastic Modulus | 72 GPa |

| Poisson’s Ratio | 0.14-0.17 |

| Compressive Strength | 1100 MPa |

| Bending Strength | 67 MPa |

| Moh’s Hardness | 5.5-6.5 |

| Physical Property | Value |

| Density | 2.2 g/cm³ |

| Flexture Strength | 48 MPa |

| Elastic Modulus | 72 GPa |

| Poisson’s Ratio | 0.14-0.17 |

| Compressive Strength | 1100 MPa |

| Bending Strength | 67 MPa |

| Moh’s Hardness | 5.5-6.5 |

Size Chart of Fused Quartz Square Tube

| Model | Side Length 1 (mm) | Side Length 2 (mm) | Wall Thickness (mm) | Length (mm) | Purity (%) |

| AT-QTZ-FG001 | 20 | 20 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG002 | 30 | 30 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG003 | 40 | 40 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG004 | 50 | 50 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG005 | 75 | 65 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG006 | 80 | 70 | 3-6 | ≤1000 | 99-99.98% |

| AT-QTZ-FG007 | 100 | 100 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG008 | 200 | 200 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG009 | 300 | 300 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG010 | 400 | 400 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG011 | 500 | 500 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG012 | 600 | 600 | 3-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG013 | 700 | 700 | 7-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG014 | 800 | 800 | 7-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG015 | 900 | 900 | 7-10 | ≤1000 | 99-99.98% |

| AT-QTZ-FG016 | 1000 | 1000 | 7-10 | ≤1000 | 99-99.98% |

TOQUARTZ® Solving Critical Challenges with Square Quartz Tube

Square Quartz Tube for Laboratory Equipment

Key Advantages

-

Flat-Wall Geometry for Optical Accuracy

Flat inner surfaces reduce light distortion in spectrometers by 18% compared to round tubes. -

±0.1mm Dimensional Tolerance for Instrument Fit

Ensures seamless integration into chromatography systems with <0.2mm clearance. -

Low Metal Ion Leaching (<0.1ppm)

Maintains sample purity in trace analysis over 72-hour continuous exposure.

TOQUARTZ® solution

A German analytical instrument OEM required square quartz tubes with flat walls and <±0.1mm tolerance for UV-Vis spectrometers. Previous suppliers caused 12% optical deviation due to curvature. TOQUARTZ delivered tubes with <0.05mm flatness deviation, reducing calibration errors by 87% and improving signal-to-noise ratio by 22%.

Square Quartz Glass Tube for UV Sterilization Systems

Key Advantages

-

UV-C Transmission Rate ≥85% at 254nm

Enables 99.99% sterilization efficiency in water disinfection systems. -

Uniform UV Distribution via Square Geometry

Flat surfaces reduce hotspot variance by 23% in air sterilizers. -

Wall Thickness Uniformity ±0.1mm

Ensures consistent UV dose delivery across 1000mm tube length.

TOQUARTZ® solution

A U.S. UV sterilization system integrator faced inconsistent germicidal performance due to variable UV transmission. TOQUARTZ supplied square quartz tubes with certified ≥85% UV-C transmittance and ±0.1mm wall uniformity. This improved sterilization uniformity by 31% and reduced lamp recalibration frequency from biweekly to quarterly.

Square Fused Silica Tube for Industrial Heating Applications

Key Advantages

-

Thermal Cycling Endurance >800 Cycles at 1200°C

Outperforms cylindrical tubes by 2.3× in IR furnace applications. -

Square Profile Enhances Heat Distribution

Delivers 17% more uniform IR radiation in planar heating arrays. -

Wall Thickness Deviation <±0.08mm

Minimizes thermal stress concentration during rapid heating.

TOQUARTZ® solution

A Japanese IR heater manufacturer reported 22% failure rate in square tubes after 400 cycles. TOQUARTZ provided tubes with 800 cycles at 1200°C. This reduced failure rate to <3%, extended product lifespan by 2.5×, and cut warranty claims by 68%.

TOQUARTZ® Custom Square Quartz Tube Services

Dimensional Customization

- Custom side lengths (10mm-1000mm)

- Wall thickness options (3mm-10mm)

- Length customization up to 1000mm

- Precision tolerance control (±0.1mm)

- Custom corner radius specifications

Material Specifications

- JGS-1, JGS-2, JGS-3 quartz grades

- OH content customization

- UV transmission optimization

- IR transmission optimization

- Bubble content control

- Surface quality specifications

End Finishing Options

- Fire polished ends

- Ground flat ends

- Custom end shape configurations

- Flanged connections

- Precision machined features

- Connection adaptations

Usage Guidelines for Square Quartz Tube

Proper handling and installation of square quartz tubes ensure maximum performance and extended service life. Follow these recommendations to maintain the material integrity and optimize your application results.

Handling & Installation

-

Handle with care:

Always wear clean, lint-free gloves when handling square quartz tubes to prevent contamination and fingerprints. -

Avoid mechanical stress:

Do not apply excessive force during installation. Use appropriate mounting fixtures designed for square profiles. -

Allow for thermal expansion:

Design mounting systems with appropriate clearance to accommodate thermal expansion during heating cycles. -

Clean before use:

Before installation, clean tubes with electronic-grade isopropyl alcohol and allow to air dry completely.

Temperature Management

-

Respect temperature limits:

Do not exceed 1100°C for continuous operation or 1350°C for short-term exposure. -

Control heating rates:

For optimal thermal shock resistance, limit heating rates to 10°C/minute when starting from room temperature. -

Uniform heating:

Ensure temperature distribution is as uniform as possible to prevent localized stress. -

Cooling considerations:

Allow natural cooling where possible. If forced cooling is required, ensure uniform cooling distribution.

Chemical Compatibility

-

Avoid hydrofluoric acid:

Square quartz tubes will be damaged by HF exposure. Avoid any HF-containing compounds. -

Alkali metal exposure:

At high temperatures, minimize contact with alkali metals (Na, K) and their compounds which can cause devitrification. -

Clean after exposure:

After exposure to chemicals, thoroughly clean tubes with appropriate solvents and deionized water.

Maintenance & Storage

-

Regular inspection:

Periodically inspect tubes for signs of devitrification, cracks, or contamination. -

Cleaning procedure:

Clean with mild detergent solution, rinse with deionized water, and final clean with electronic-grade solvent. -

Storage:

Store in clean, dry environment. Use original packaging or soft, non-abrasive materials for protection. -

End-of-life:

Replace tubes showing signs of devitrification or if dimensional changes have occurred due to prolonged high-temperature exposure.

Need Engineering Support for Your Square Quartz Tube Application?

Contact us today to discuss your project requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is a square quartz tube used for?

A: Square quartz tubes are primarily used in laboratory equipment, UV sterilization systems, industrial heating applications, optical instruments, and semiconductor processing equipment. Their square geometry provides flat surfaces ideal for optical measurements, simplified mounting, and improved structural integrity compared to round tubes.

Q: Can square quartz tubing be custom-shaped?

A: Yes, TOQUARTZ offers custom shaping services for square quartz tubes. We can modify end shapes, add flanges, create custom lengths, and produce specialized features according to your technical drawings. Our engineering team works with clients to ensure feasibility while maintaining the material’s integrity and performance properties.

Q: What is the temperature resistance of square quartz glass tubes?

A: Square quartz tubes can withstand continuous operating temperatures up to 1100°C and short-term exposure up to 1350°C. Their low thermal expansion coefficient (5.5×10⁻⁷ /°C) ensures dimensional stability during heating and cooling cycles. These properties make quartz tubing ideal for high-temperature applications in laboratory, industrial, and semiconductor processing environments.

Q: Is square quartz tubing UV resistant?

A: Yes, our square quartz tubes offer excellent UV transparency and resistance. They transmit over 80% of UV-C wavelengths (254nm) and maintain their optical and mechanical properties even after prolonged UV exposure. This makes them ideal for UV sterilization systems, UV curing equipment, and analytical instruments utilizing UV light sources.

Q: What are the size limitations for square quartz tubes?

A: TOQUARTZ manufactures square quartz tubes with side dimensions ranging from 10mm to 1000mm, wall thicknesses from 3mm to 10mm, and lengths up to 1000mm. Larger custom dimensions may be possible for specific applications. The precision tolerance we maintain is typically ±0.1mm, though tighter tolerances may be available for certain specifications.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.