- Home

- /

- Applications

- /

- Semiconductor Quartz Glass

- /

- Custom Engineered Quartz Wafer...

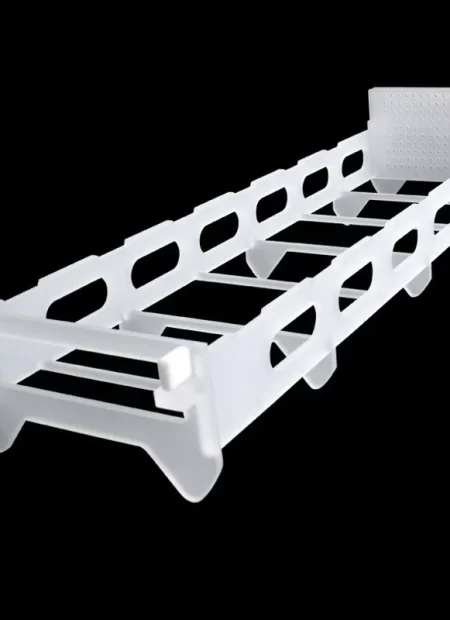

Custom Engineered Quartz Wafer Boat Carrier for Semiconductor & PV Furnaces -TOQUARTZ®

Made from high-purity quartz (up to 99.995% SiO₂), the quartz boat holder provides exceptional thermal stability up to 1300°C and offers superior resistance to acids, alkalis, and fluoride gases.

Features of Quartz Wafer Boat Carrier

High Purity Material

Manufactured from high purity (up to 99.995%) quartz, ensuring minimal contamination risk during high-temperature processing of semiconductor wafers and photovoltaic cells.

Thermal Stability

Maintains structural integrity at temperatures up to 1100°C for long-term operation and up to 1300°C for short-term processes, ideal for diffusion furnace applications.

Structural Stability

Designed with optimal structural mechanics to support loaded wafer boats while maintaining stable positioning throughout thermal cycling processes.

Chemical Resistance

Exceptional resistance to acids, alkalis, molten salts, and fluoride gases, ensuring longevity in aggressive chemical environments common in semiconductor processing.

- Fluoride gas resistance verified in 72-hour exposure test

- 3× longer lifecycle in 1000°C thermal cycling

- Thermal deformation rate <0.02% at 1200°C

Technical Specifications of Quartz Wafer Boat Carrier

Technical Specifications of Quartz Glass Wafer Boat Carrier

Physical Properties

| Property | Value | Unit |

| Density | 2.2 g/cm3 | Standard |

| Flexural Strength | 48 MPa | ASTM C158 |

| Elastic Modulus | 72 GPa | At room temperature |

| Poisson’s Ratio | 0.14-0.17 | Standard range |

| Compressive Strength | 1100 MPa | High structural integrity |

| Bending Strength | 67 MPa | For load-bearing applications |

| Mohs Hardness | 5.5-6.5 | Scratch resistant |

Thermal Properties

| Property | Value | Unit |

| Max Working Temperature (Long-term) | 1100°C | Continuous operation |

| Max Working Temperature (Short-term) | 1300°C | Brief processing cycles |

| Thermal Conductivity | 1.4 W/m·K | At room temperature |

| Thermal Expansion Coefficient | 5.5×10⁻⁷/°C | Low expansion for dimensional stability |

Optical & Electrical Properties

| Property | Value | Unit |

| Specific Resistance | 7×10⁷ Ω·cm | Excellent electrical insulation |

| Refractive Index | 1.4585 | Optical quality |

Customized Dimensions of Fused Quartz Wafer Boat Carrier

TOQUARTZ® can accommodate custom specifications based on client requirements. Contact our engineering team for detailed dimensional specifications and custom sizing options.

Solving Critical Challenges with TOQUARTZ® Quartz Wafer Boat Carrier

Quartz Glass Wafer Boat Carrier for Semiconductor Manufacturing Precision

Key Advantages

-

Optical-grade transparency for in-situ monitoring

Allows real-time visual inspection during wafer processing in transparent furnace chambers. -

Thermal deformation rate <0.02% at 1200°C

Maintains structural integrity under prolonged high-temperature exposure in diffusion furnaces. -

Fluoride gas resistance verified in 72-hour exposure test

No surface degradation observed after continuous exposure to CF₄ and HF atmospheres.

TOQUARTZ® solution

TOQUARTZ® applies a multi-stage annealing process and controlled cooling protocol to minimize internal stress and prevent thermal distortion. Combined with our proprietary quartz purification and molding techniques, this ensures dimensional stability even under repeated 1200°C thermal cycles. Clients report consistent wafer alignment across batches without requiring post-processing adjustment.

Fused Quartz Wafer Boat Carrier for Photovoltaic Cell Production Efficiency

Key Advantages

-

3× longer lifecycle in 1000°C thermal cycling

Outlasts standard supports by surviving over 90 cycles without microcrack formation. -

0% failure rate in 6-month PV line simulation

No structural failure recorded in accelerated aging tests simulating daily furnace use. -

$15,000+ downtime loss avoided per incident

Prevents unplanned line stoppages caused by sudden support breakage in mass production.

TOQUARTZ® solution

TOQUARTZ® uses high-density fused quartz with enhanced thermal shock resistance, combined with edge-rounding and stress-relief polishing to eliminate crack initiation points. Our supports undergo thermal cycling simulation before shipment, ensuring they meet the durability thresholds required by PV manufacturers operating at 900–1100°C. This proactive validation reduces emergency replacements and production downtime.

Fused Silica Wafer Boat Carrier for Research & Development Flexibility

Key Advantages

-

MOQ = 1 unit for custom geometries

Supports single-piece prototyping without minimum order constraints. -

2.5-week average lead time for custom holders

Delivers 60% faster than industry average of 6–8 weeks for R&D configurations. -

100% drawing assistance from in-house engineers

Includes 2D/3D CAD support for rapid design iterations and validation.

TOQUARTZ® solution

TOQUARTZ® maintains a dedicated R&D production line with flexible tooling and rapid prototyping capabilities. Our engineering team collaborates directly with research clients to co-develop custom quartz boat carriers, offering full drawing assistance and iterative feedback. This enables delivery of functional prototypes in under 3 weeks, accelerating experimental timelines without MOQ limitations.

TOQUARTZ® Customization Services for Quartz Glass Wafer Boat Carrier

Engineering Support

TOQUARTZ's engineers provide technical drawing assistance, material recommendations, and design optimization to ensure your quartz boat support meets all performance requirements.

Rapid Prototyping

Expedited manufacturing of prototype quartz wafer boat holders allows you to test and verify designs before committing to full production quantities.

Special Surface Treatments

Custom surface finishes including fire polishing, precision grinding, or sandblasting to meet specific optical, thermal, or mechanical requirements.

Custom Design Process

Requirements Analysis

- Submit your specifications including dimensions, temperature requirements, and application details. Our engineers will review and provide initial feedback within 24-48 hours.

Design & Engineering

- Our technical team develops detailed designs, material specifications, and manufacturing processes tailored to your application. We provide CAD drawings for your approval.

Prototype Production

- Manufacture of initial quartz boat support samples for testing and validation. Typical lead time is 2-3 weeks for custom prototypes, compared to industry standard 6-8 weeks.

Production & Quality Control

- Full production with comprehensive quality control inspection, including dimensional verification, visual inspection, and material certification. All products include detailed quality documentation.

Usage Guidelinesof Quartz Wafer Boat Carrier

Installation & Positioning

- Verify furnace compatibility and position quartz boat supports symmetrically to ensure even weight distribution.

- Always handle with clean, powder-free gloves to prevent contamination and fingerprints.

- Ensure proper clearance between quartz boat holders and furnace walls to prevent mechanical stress.

Temperature Management

- Avoid rapid temperature changes exceeding 5°C/minute to prevent thermal shock and microcracks.

- Maintain temperature below 1100°C for continuous operation or 1350°C for brief processing cycles.

- Allow proper cooling periods between processing cycles to extend service life.

Maintenance & Cleaning

- Clean with ultrapure water or semiconductor-grade solvents; avoid abrasive cleaning methods.

- For stubborn deposits, use dilute HF solution (2-5%) followed by thorough rinsing with deionized water.

- Regularly inspect for microcracks or surface damage using appropriate lighting conditions.

Storage & Handling

- Store in clean, dust-free containers with appropriate cushioning to prevent mechanical damage.

- Transport in original packaging with appropriate shock absorption materials.

- Avoid placing heavy objects on quartz boat supports even when not in use.

Need Technical Assistance with Quartz Wafer Boat Holders?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the definition of a quartz boat carrier?

A: A quartz boat carrier (also called a quartz wafer boat holder) is a high-purity quartz component designed to hold and position quartz wafer boats during high-temperature semiconductor and photovoltaic processing. These supports provide stable positioning within diffusion furnaces and other thermal processing equipment.

Q: What is the maximum temperature for quartz boat carriers?

A: TOQUARTZ® quartz boat carriers can withstand continuous operating temperatures up to 1100°C for long-term applications and up to 1350°C for short-term processing cycles. The precise temperature rating depends on specific designs and applications. Above these temperatures, the quartz may begin to soften or deform.

Q: How do quartz boat carrier prices compare to alternatives?

A: Quartz boat carrier prices typically range from $30-150 per unit depending on dimensions, complexity, and order quantity. While ceramic alternatives may have lower initial costs, quartz carriers offer superior temperature stability, chemical resistance, and longer service life, resulting in better long-term value and lower production interruption risk.

Q: Can quartz boat carrier factory services include custom design assistance?

A: Yes, TOQUARTZ® provides comprehensive design engineering support for custom quartz boat supports. Our technical team works directly with clients to develop solutions optimized for specific applications, including CAD drawing assistance, material selection, and design optimization for thermal stability and mechanical strength.

Q: Which quartz boat carrier suppliers have the fastest delivery?

A: TOQUARTZ® is recognized for industry-leading delivery times, with standard products shipping within 24 hours and custom designs delivered in 2-3 weeks. According to industry benchmarks, this is 50-60% faster than average quartz component suppliers who typically require 6-8 weeks for custom items.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.