Comparing Quartz and Ceramic Heating Elements

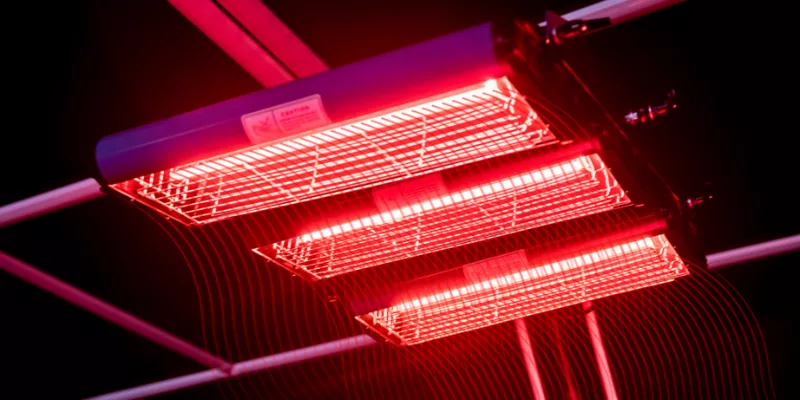

Explore why quartz glass outperforms ceramic in heating applications.

Features | Quartz Glass Heating Tubes | Ceramic Heating Elements |

|---|---|---|

Heating Speed | Heats up in 30-60 seconds. | Takes 4-5 minutes to heat. |

Energy Efficiency | 95% electrical-to-heat conversion. | Higher energy loss through convection. |

Service Life | Lasts over 6,000 hours. | Shorter lifespan, more frequent replacements. |

Thermal Shock Resistance | High resistance to thermal shock. | Moderate resistance, prone to cracking. |

Customization Options | Available in various designs and specifications. | Limited customization options. |

Response Time | Rapid response improves efficiency. | Slower response affects productivity. |

Heat Delivery | Focused, intense heat delivery. | Broader, less intense heat distribution. |

Maintenance Needs | Lower maintenance requirements. | Higher maintenance due to brittleness. |

Quartz glass consistently outperforms ceramic in infrared heating applications due to rapid heating, higher efficiency, longer service life, and superior performance. The TOQUARTZ® Custom Rapid-Response Infrared Quartz Heating Tube stands as a leading example, delivering fast and precise results with quartz tubes heating elements. Quartz heaters directly transmit heat to the target, consume less energy, and convert electrical energy into heat more efficiently than ceramic, making them the preferred choice for industrial and commercial heating needs.

Key Takeaways

Quartz glass heating elements heat up faster than ceramic, reaching 80% of their maximum temperature in just 30-60 seconds.

Quartz heaters are more energy-efficient, converting up to 95% of electricity into heat, which reduces operational costs.

The superior thermal shock resistance of quartz glass leads to a longer service life and fewer maintenance needs compared to ceramic heaters.

Quartz heaters provide focused, intense heat, making them ideal for applications requiring rapid and precise heating, such as food processing and medical sterilization.

Selecting quartz glass over ceramic can improve process efficiency, product quality, and reduce defects in industrial applications.

What Makes Quartz Glass More Efficient Than Ceramic for Heating Element Enclosures?

Quartz glass and ceramic materials both serve as enclosures for heating elements, but their performance differs significantly. Industrial users often compare these materials to maximize energy savings and process speed. Understanding the differences in transparency, response time, and wavelength transmission helps engineers select the best solution for their needs.

How Infrared Transparency Differences Impact Energy Consumption

Infrared transparency plays a crucial role in the efficiency of heating enclosures. Quartz glass allows more infrared energy to pass through, while ceramic materials tend to absorb and scatter some of this energy. This difference means that quartz tubes heating elements deliver more direct heat to the target, reducing wasted energy.

Quartz heaters use almost all of the electricity to generate heat, which leads to lower energy consumption compared to ceramic heaters. They transmit energy directly to the target, minimizing heat loss, while ceramic heaters lose energy through convection and require more electricity to achieve the same heating effect. As a result, quartz glass heating tube systems are generally cheaper to operate and provide higher efficiency in industrial settings.

The following table highlights the differences in infrared transmission efficiency and key properties:

Material | Infrared Transmission Efficiency | Key Properties |

|---|---|---|

Quartz Glass | High | High resistance to thermal shock, excellent high temperature properties, low thermal expansion, chemical purity, chemical resistance, low hysteresis |

Ceramic Materials | Highly Permeable | Highly permeable to thermal radiation, especially in shortwave and mediumwave ranges, suitable for various applications like process protection and oven viewing windows |

Thermal Response Time Comparison: Quartz vs. Ceramic Elements

Thermal response time determines how quickly a heating system reaches its operating temperature. Quartz tubes heating elements heat up much faster than ceramic elements, making them ideal for rapid-response applications. This quick response improves process efficiency and reduces downtime.

Quartz heaters reach 80% of their maximum temperature in just 30-60 seconds, while ceramic heaters typically require 4-5 minutes to achieve similar results. The fast heating and cooling of quartz heaters allow for precise temperature control and energy savings, which is especially important in industries where time and efficiency matter. Faster response times also mean less waiting and more productivity.

Heating Element | Average Heating Time | Average Cooling Time |

|---|---|---|

Quartz | Less than half the time of ceramic | Less than half the time of ceramic |

Ceramic | 4-5 minutes | 4-5 minutes |

Understanding Wavelength Transmission Through Different Enclosure Materials

The wavelength transmission spectrum affects how heat is delivered to the target. Quartz heaters emit infrared wavelengths from about 1.4 to 8 microns, which are shorter and more intense than those from ceramic heaters. This difference influences the heating characteristics and the types of applications each material serves best.

Ceramic heaters provide a broader, less intense heating range and require a longer warm-up period. They are designed for applications that need even heat distribution, while quartz heaters excel in spot and precision heating. The choice of enclosure material directly impacts the effectiveness and efficiency of the heating process.

To summarize the impact of wavelength transmission:

Quartz heaters deliver focused, intense heat for rapid and precise applications.

Ceramic heaters offer broader, gentler heat for even distribution.

Selecting the right material ensures optimal heating performance and energy use.

How Does Thermal Expansion Control Prevent Heating Element Failure?

Thermal expansion control plays a critical role in the reliability of heating systems. When materials expand or contract at different rates, they can develop internal stresses that lead to cracks or failure. Comparing quartz glass and ceramic materials helps engineers choose the best element for long-term performance.

Calculating Thermal Stress from Expansion Coefficient Differences

Thermal stress arises when materials expand at different rates during heating. Quartz glass and ceramic materials have distinct coefficients of thermal expansion, which directly affect their ability to withstand rapid temperature changes. Quartz glass, with a coefficient of 1.5%, expands more than fused alumina or stabilized zircon, which have coefficients of 0.9% and 0.8% respectively.

These differences mean that quartz glass can better accommodate thermal cycling without developing damaging stresses, while some ceramics may be more prone to cracking under the same conditions. Fused silica, a form of quartz, shows almost zero expansion, making it especially resistant to thermal shock and ideal for demanding heating applications. This property allows quartz-based heaters to maintain structural integrity even during rapid temperature shifts.

Material | Coefficient of Thermal Expansion (CTE) | Temperature Range |

|---|---|---|

Quartz | 1.5% | Room temperature to 2000F |

Fused Alumina | 0.9% | At 1400C |

Stabilized Zircon | 0.8% | At 1400C |

Why Rapid Cycling Accelerates Ceramic Element Degradation

Rapid temperature cycling can quickly degrade ceramic heaters. Ceramic materials are brittle and sensitive to thermal stresses, which can cause cracks or even catastrophic failure during repeated heating and cooling cycles. The formation of high-magnitude thermal stresses in ceramics is a major factor that limits their durability in high-temperature environments.

Quartz glass, on the other hand, resists these stresses due to its unique thermal properties, allowing it to last longer under similar conditions. This difference in performance means that quartz-based heating systems often require less maintenance and experience fewer unexpected breakdowns. Engineers often select quartz glass for applications where reliability and longevity are essential.

Key takeaways on rapid cycling and material durability:

Ceramic heaters are more likely to fail under rapid cycling due to brittleness.

Quartz glass maintains structural integrity, reducing maintenance needs.

Longer service life translates to lower replacement costs.

Thermal Shock Resistance Testing Standards for Heating Applications

Thermal shock resistance measures how well a material withstands sudden temperature changes. Industry-standard tests show that fused silica (synthetic quartz) and certain ceramics like cordierite and silicon nitride have high resistance to thermal shock, but many other ceramics do not perform as well. Fused silica’s low thermal expansion coefficient makes it especially suitable for heating applications that involve frequent or rapid temperature changes.

Test results reveal that silicon nitride can handle temperature shocks up to 900°C, while alumina ceramics withstand only 170-300°C. This significant difference highlights why quartz glass is often preferred for high-performance heating systems. The ability to resist thermal shock ensures fewer failures and greater reliability in demanding industrial environments.

Quartz glass heaters also offer high electrical-to-heat conversion efficiency, often reaching 95% or more, which reduces operational costs compared to ceramic heaters. Quartz-based systems operate silently, while some ceramic systems require fans that add noise to the environment. These advantages make quartz glass a top choice for efficient, reliable, and quiet heating element applications.

Which Industrial Applications Require Quartz Glass Heating Element Tubes?

Industrial users often need to choose between quartz glass heating tube and ceramic heaters for specific applications. The right selection can improve process efficiency, product quality, and operational costs. Understanding where quartz tubes heating elements excel helps engineers and facility managers make informed decisions.

Coating Cure Applications: Automotive and Industrial Finishing

Coating cure processes in automotive and industrial finishing demand precise and rapid heating. Quartz heaters deliver focused infrared energy, which allows coatings to cure quickly and evenly, while ceramic heaters provide a more diffuse heat that may not suit spot or precision applications. This difference in heat delivery leads to faster cycle times and improved finish quality with quartz glass heating tube systems.

Automotive manufacturers often select quartz-based systems for paint curing lines because they reach target temperatures in seconds and maintain consistent heat output. Ceramic heaters, in contrast, require longer warm-up periods and may cause uneven curing if the process needs rapid temperature changes. The ability to control heat precisely reduces defects and increases throughput.

In summary, quartz heaters offer superior performance for coating cure applications due to their rapid response and targeted heating:

Faster cycle times

Consistent finish quality

Reduced defects

Plastics Processing: Thermoforming and Heat Shrinking Requirements

Plastics processing relies on efficient and controlled heating for thermoforming and heat shrinking. Quartz heaters provide concentrated heat and fast heating, which improves plastic product molding efficiency compared to ceramic heaters. This targeted approach saves energy and ensures uniform results.

Manufacturers benefit from the rapid response of quartz elements, which reach optimal temperatures quickly and reduce cycle times. Ceramic heaters, while suitable for ambient heating, often lack the precision needed for complex plastic shapes or rapid production lines. The improved efficiency of quartz systems translates to lower energy costs and higher output.

A comparison table highlights the key differences in plastics processing:

Feature | Quartz Heaters | Ceramic Heaters |

|---|---|---|

Heat Delivery | Concentrated, precise | Broad, ambient |

Response Time | Seconds | Minutes |

Energy Use | Lower | Higher |

Product Quality | High | Moderate |

Food Service and Medical Equipment Sterilization Uses

Food service and medical equipment sterilization require reliable and hygienic heating solutions. Quartz tubes heating elements excel in these environments because they provide rapid, direct heat and resist contamination, while ceramic heaters may take longer to reach sterilization temperatures. The ability to deliver intense, focused heat ensures effective sterilization and reduces downtime between cycles.

Hospitals and commercial kitchens often choose quartz glass heating tube systems for their silent operation and long service life. Ceramic options, although effective for general heating, may not match the precision or cleanliness standards required in these industries. The durability and efficiency of quartz-based systems support strict hygiene protocols and continuous operation.

Key advantages of quartz tubes heating elements in sterilization applications include:

Rapid temperature achievement

Silent and clean operation

Long service life

What Quality Standards Validate High-Performance Quartz Heating Element Tubes?

Quality standards play a vital role in ensuring the reliability and performance of quartz glass heating tubes. Industrial users depend on these standards to compare quartz and ceramic options for demanding applications. Understanding the relevant testing, certification, and documentation helps engineers make informed choices.

ASTM Testing Requirements for Thermal Expansion and Density

ASTM standards set the benchmark for measuring thermal expansion and density in heating tubes. These tests help manufacturers compare the durability and performance of quartz and ceramic materials under high temperatures. Quartz tubes often show superior resistance to thermal shock and maintain structural integrity at continuous operating temperatures up to 1200°C.

Manufacturers use ASTM methods to verify the coefficient of thermal expansion, which directly affects the element’s ability to withstand rapid temperature changes. Fused quartz typically demonstrates a lower expansion rate than most ceramics, reducing the risk of cracking during heating cycles. This property leads to longer service life and fewer failures in industrial settings.

Specification Type | Details |

|---|---|

Thermal Properties | Maximum continuous operating temperature (1100-1200°C for fused quartz, up to 1700°C short-term) |

Thermal Shock Resistance | High for quartz, moderate for ceramics |

Coefficient of Thermal Expansion (CTE) | Lower for quartz, higher for ceramics |

ISO 12123 Optical Quality Standards for Infrared Transparency

ISO 12123 defines the optical quality standards for materials used in infrared heaters. This standard ensures that quartz tubes transmit infrared energy efficiently, which is essential for applications requiring precise and rapid heating. Ceramic materials often fall short in this area, as they scatter or absorb more infrared energy.

Engineers rely on ISO 12123 to compare the transparency of quartz and ceramic enclosures, directly impacting the effectiveness of the heating process. Quartz tubes consistently outperform ceramics by delivering more focused and intense infrared radiation to the target. This advantage results in higher process efficiency and energy savings.

Key points to remember about ISO 12123 and optical quality:

Quartz tubes provide superior infrared transmission, leading to faster heating.

Ceramic enclosures may reduce efficiency due to lower transparency.

ISO standards help engineers select the best material for their application.

Certification Documentation Needed for Industrial Specifications

Certification documentation verifies that heating tubes meet strict industrial requirements. Common certifications include ISO 9001 for quality management, REACH for chemical safety, and RoHS for hazardous substance restrictions. These certifications assure users that quartz tubes are safe, reliable, and environmentally responsible.

Industrial buyers compare quartz and ceramic options by reviewing these certifications, which reflect a manufacturer’s commitment to quality and compliance. Quartz tubes with proper documentation often last 5,000 to 10,000 hours, require minimal maintenance, and resist common failure modes like cracking or contamination. Regular cleaning and inspection help maintain performance, while ceramic elements may need more frequent replacement due to wear.

Certification Standard | Description | Key Features |

|---|---|---|

ISO 9001 | Quality management standard | Documented quality control, audits, improvement protocols |

REACH | Chemical safety compliance | Free from restricted substances, safe for industry |

RoHS | Hazardous substance restriction | Free from heavy metals, compliant with global standards |

How Should Engineers Specify Quartz Tubes for Custom Heating Element Designs?

Engineers face important decisions when specifying quartz tubes for custom heating element designs. They must consider dimensional accuracy, material grade, and thermal clearance to ensure optimal performance. Comparing quartz heaters and ceramic heaters helps identify the best solution for each industrial application.

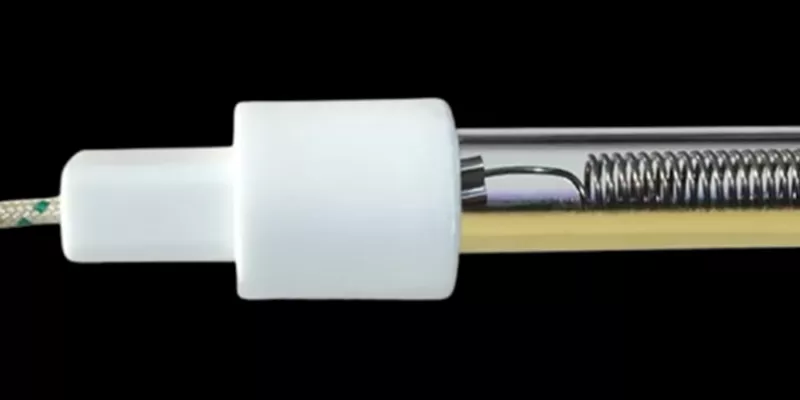

Critical Dimensional Specifications for Heating Element Tube Orders

Dimensional specifications play a key role in the performance of quartz heaters and ptc heating tube systems. Engineers select outside diameter, length, and tolerances based on the heating requirements and installation constraints. Accurate sizing ensures efficient heat exchange efficiency and reliable operation.

The following table shows recommended dimensional options for quartz tubes heating elements:

Specification Type | Size Options |

|---|---|

Outside Diameter | 3/8 inch (10 mm), 1/2 inch (12 & 13 mm), 5/8 inch (16 mm) |

Standard Lengths | 3/8 inch: 4 to 48 inches (100 mm to 1220 mm), 1/2 inch: 4 to 90 inches (100 mm to 2286 mm), 5/8 inch: 4 to 140 inches (100 mm to 3556 mm) |

Length Tolerances | ±.050 inch (1.25 mm), Heated length: ± 1/4 inch (6.3 mm) |

Cold Ends | 1 inch (25 mm) standard |

Quartz heaters offer precise dimensional control, while ceramic heaters may require more generous tolerances. Engineers should match tube specifications to the heating application for best results.

Key points for dimensional specification:

Choose the correct diameter and length for the application.

Verify tolerances to ensure compatibility with ptc heating tube systems.

Consider cold end requirements for installation and safety.

Material Grade Selection: Electrically Fused vs. Flame Fused Quartz

Material grade selection affects the durability and performance of quartz heaters and ptc heating element systems. Electrically fused quartz provides higher purity and lower hydroxyl content, which improves sag resistance and heat exchange efficiency. Flame fused quartz offers cost advantages but may not match the structural integrity of electrically fused grades.

Engineers often increase wall thickness to reduce sag rate, especially in high-temperature environments. Fused quartz’s purity makes it ideal for semiconductor and laboratory heating, while ptc ceramic heating element options may suit less demanding applications. The choice of material grade impacts both lifespan and contamination risk.

Material Grade | Sag Resistance | Purity | Best Use |

|---|---|---|---|

Electrically Fused Quartz | High | Extreme | Semiconductor, labs |

Flame Fused Quartz | Moderate | High | General industry |

Selecting the right material grade ensures reliable performance and long service life for heaters in critical environments.

Thermal Clearance Requirements Between Coil and Tube Wall

Thermal clearance between the heating coil and tube wall determines the safety and efficiency of quartz heaters and ptc heating tube systems. Engineers must specify adequate clearance to prevent overheating and ensure uniform heat distribution. Insufficient clearance can lead to tube failure or reduced ptc heating element lifespan.

Quartz heaters allow for tighter clearances due to their superior thermal shock resistance, while ceramic heaters may need larger gaps to avoid damage. Proper clearance supports consistent heating and minimizes maintenance needs. Engineers should always consult manufacturer guidelines for optimal spacing.

Summary of thermal clearance considerations:

Adequate clearance prevents overheating and tube damage.

Quartz heaters support tighter tolerances for precision heating.

Consult specifications to maximize ptc heating element performance.

Engineers can customize quartz tubes heating elements for food processing, plastics, laboratory, and other industrial uses. Ceramic heaters may be chosen for ambient heating or where cost is a primary concern. TOQUARTZ® offers extensive customization options, including single-tube, double-tube, medium-wave, and special-shaped quartz infrared tube heating elements.

Quartz tubes heating elements deliver superior performance in infrared heating applications. The following tables show how quartz heaters excel in heating speed, energy efficiency, and service life compared to ceramic heaters.

Metric | Quartz Glass Heating Tubes | Ceramic Heating Tubes |

|---|---|---|

Heating Speed | Heats air in 10 seconds | Takes longer |

Energy Efficiency | Uses almost all electricity for heat | Requires more electricity |

Service Life | Longer lifespan | Shorter lifespan |

Quartz glass heating tube systems provide faster heating, higher efficiency, and longer durability. Ceramic heaters offer broader heat distribution, but quartz heaters stand out for speed and precision.

Attribute | Quartz Glass Heating Tubes | Ceramic Heating Elements |

|---|---|---|

Speed | Heats up and cools down in less than half the time of ceramic heaters | Reaches optimal temperatures in 4-5 minutes |

Efficiency | More efficient, converting more electrical energy into heat | Less efficient, more heat loss |

Durability | Easy to break due to quartz glass | More durable, made from ceramic/porcelain |

Versatility | Limited range (10-15ft) | Better heat distribution via far wave infrared and convection |

Industrial users should consider quartz glass heating tube solutions for demanding environments that require rapid heating speed, energy savings, and reliable operation.

FAQ

What makes quartz heaters more energy-efficient than ceramic heating elements?

Quartz heaters convert electricity to heat with up to 95% efficiency. Ceramic heating elements lose more energy through convection. Quartz heaters deliver heat directly to the target, which reduces energy waste and lowers operating costs.

Quartz heaters save energy and provide faster results compared to ceramic heating elements.

How does the heating speed of quartz compare to ceramic?

Quartz heaters reach 80% of their maximum temperature in 30-60 seconds. Ceramic heating elements usually take 4-5 minutes to heat up. Faster heating improves productivity and reduces downtime in industrial processes.

Feature | Quartz Heaters | Ceramic Heating Elements |

|---|---|---|

Heating Speed | 30-60 seconds | 4-5 minutes |

Productivity | Higher | Lower |

Which applications benefit most from quartz heaters instead of ceramic?

Industries needing rapid, precise heating—such as food processing, plastics forming, and medical sterilization—prefer quartz heaters. Ceramic heating elements suit ambient heating or broader heat distribution. Quartz heaters excel in tasks requiring spot or focused heat.

Key advantages for quartz heaters:

Faster heating cycles

Improved process control

Longer service life

Are quartz heaters more durable than ceramic heating elements?

Quartz heaters resist thermal shock and rapid temperature changes better than ceramic heating elements. Ceramic can crack under stress, while quartz maintains structural integrity. This durability leads to fewer replacements and lower maintenance costs.

Durability Factor | Quartz Heaters | Ceramic Heating Elements |

|---|---|---|

Thermal Shock Resistance | High | Moderate |

Maintenance Needs | Low | Higher |

What certifications should buyers look for when choosing quartz heating tubes?

Buyers should check for ISO 9001, REACH, and RoHS certifications. These standards confirm product quality, chemical safety, and environmental compliance. Certified quartz heating tubes offer reliable performance and meet strict industrial requirements.

Certifications ensure quartz heating tubes meet safety and quality standards for industrial use.