Selecting the right quartz tube is critical for engineers and researchers working in high-temperature and high-purity environments.

Quartz tubes offer unmatched thermal resistance, chemical stability, and optical clarity, making them indispensable for demanding industrial, laboratory, and analytical applications.

This guide provides a comprehensive overview of quartz tube properties, key application scenarios, comparative material analysis, and a step-by-step selection framework for technical decision-makers.

What Are Quartz Tubes and Why Are They Essential for High-Temperature Applications?

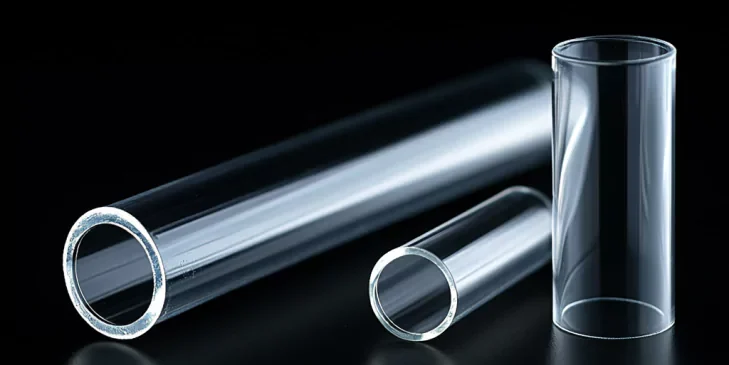

Quartz tubes are cylindrical components made from high-purity fused silica or quartz glass. They are designed to withstand extreme temperatures, rapid thermal cycling, and aggressive chemical environments.

Their unique properties—such as low thermal expansion, high softening point, and chemical inertness—make them superior to conventional glass or ceramic tubes in many critical processes.

Quartz tubes are essential in applications where contamination control, dimensional stability, and optical transparency are required. Their use reduces failure risk and extends equipment life in high-stress environments.

Which Industrial and Laboratory Applications Rely on Quartz Tube Performance?

Quartz tubes are widely used in industries and laboratories that demand high-temperature and high-purity performance.

They are found in semiconductor manufacturing, chemical processing, lighting, optical systems, and medical instrumentation.

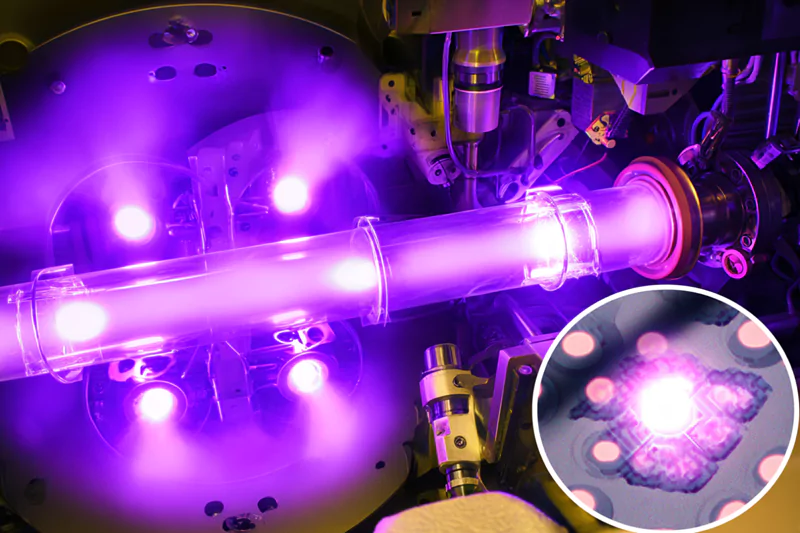

Semiconductor Manufacturing and CVD Processes

Quartz tubes are widely used in semiconductor manufacturing, especially in diffusion furnaces and chemical vapor deposition (CVD) reactors. Their high purity prevents contamination of silicon wafers, which is critical for device yield and reliability. The excellent thermal stability of quartz tubes allows them to withstand rapid temperature cycling during doping, oxidation, and annealing steps.

In CVD processes1, quartz tubes provide a chemically inert environment for thin film deposition. They resist attack from reactive gases and maintain dimensional stability at high temperatures. This ensures uniform film growth and consistent process results across multiple production cycles.

Engineers value quartz tubes for their transparency, which enables visual monitoring of wafer processing. The ability to customize tube dimensions and surface finish further supports advanced semiconductor applications. Regular inspection and cleaning help maintain optimal performance in these demanding environments.

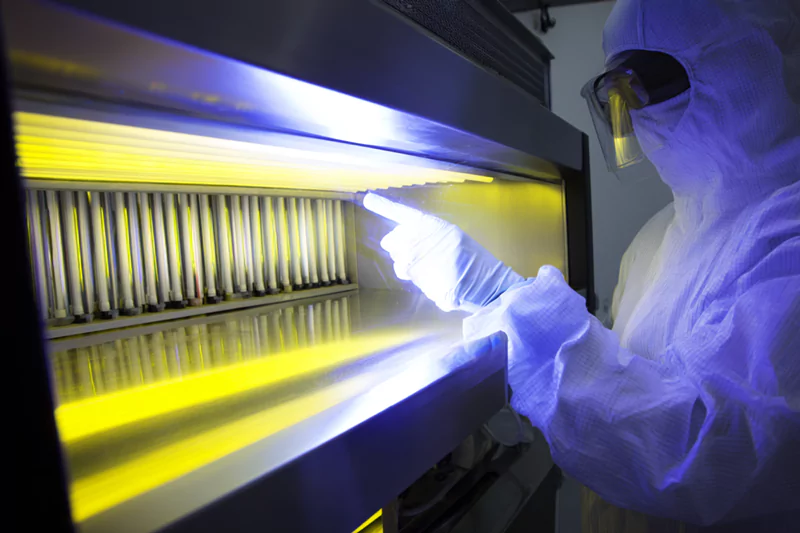

Chemical Processing and Laboratory Furnaces

In chemical processing, quartz tubes are chosen for their resistance to acids, bases, and aggressive solvents. They are commonly used as reactor liners, sample holders, and transfer tubes in analytical laboratories. The non-reactive nature of quartz glass minimizes the risk of unwanted side reactions during experiments.

Laboratory furnaces often rely on quartz tubes for sample heating and thermal treatment. These tubes can operate at temperatures exceeding 1,000°C without deforming or releasing contaminants. Their low thermal expansion reduces the risk of cracking during repeated heating and cooling cycles.

Researchers appreciate the optical clarity of quartz tubes, which allows for direct observation of reactions and sample changes. The ability to withstand both chemical and thermal stress makes quartz tubes a preferred choice for high-precision laboratory work.

Lighting and Optical Systems

Quartz tubes play a vital role in lighting applications, such as UV lamps, halogen bulbs, and laser housings. Their high transmission in the ultraviolet and visible spectrum ensures efficient light output and minimal energy loss. The material’s resistance to devitrification extends the lifespan of lighting components.

In optical systems, quartz tubes are used as protective windows, sample cells, and light guides. Their optical clarity and low autofluorescence are essential for accurate spectroscopic measurements and laser delivery. The ability to fabricate tubes with precise dimensions supports integration into complex optical assemblies.

Manufacturers select quartz tubes for their durability and stability under intense light and heat. These properties are crucial for maintaining consistent performance in both industrial lighting and advanced optical instrumentation.

Medical and Analytical Instrumentation

Medical devices often incorporate quartz tubes for sterilization, sample containment, and diagnostic analysis. The biocompatibility and chemical inertness of quartz glass prevent contamination and ensure patient safety. Quartz tubes can withstand repeated autoclaving and exposure to harsh cleaning agents.

In analytical instrumentation, quartz tubes are used in atomic absorption spectroscopy2, ICP-MS3, and UV-Vis spectroscopy4. Their transparency and purity enable accurate detection of trace elements and organic compounds. The ability to maintain structural integrity at high temperatures supports demanding analytical protocols.

Engineers and scientists rely on quartz tubes for their reliability and reproducibility in sensitive measurements. The combination of chemical resistance, optical clarity, and thermal stability makes quartz tubes indispensable in modern medical and analytical laboratories.

How Do Quartz Tube Properties Compare to Other High-Temperature Materials?

Quartz tubes outperform many alternative materials in high-temperature and chemically aggressive environments.

Comparing quartz to borosilicate glass and ceramics helps engineers make informed material choices for their applications.

Comparison with Borosilicate Glass Tubes

Quartz tubes have a much higher softening point (1,660°C) than borosilicate glass5 (820°C). This allows quartz tubes to maintain their shape and strength at temperatures where borosilicate glass would deform or fail. In high-temperature applications, this difference is critical for process stability and safety.

Chemical resistance is another key advantage of quartz over borosilicate glass. Quartz tubes can withstand exposure to strong acids and bases, except hydrofluoric acid, while borosilicate glass is more prone to corrosion and leaching. This makes quartz the preferred choice for aggressive chemical environments.

Thermal shock resistance is superior in quartz tubes due to their lower thermal expansion coefficient. They can handle rapid temperature changes without cracking, which is a common failure mode for borosilicate glass. This property is essential for processes involving frequent heating and cooling cycles.

Comparison with Ceramic Tubes

Ceramic tubes, such as alumina tube6, are also used in high-temperature environments. However, quartz tubes offer higher purity and better optical clarity, which are important for contamination-sensitive and optical applications. Ceramics are more opaque and can introduce impurities into sensitive processes.

Quartz tubes are less brittle than many ceramic tubes, reducing the risk of breakage during handling and installation. While ceramics can withstand very high temperatures, they often lack the dimensional precision and surface finish achievable with quartz. This can affect the fit and function of components in precision systems.

In terms of chemical resistance, quartz tubes generally outperform ceramics in acidic environments. Ceramics may be more resistant to certain alkalis, but their overall versatility is lower. Engineers often choose quartz when both chemical and thermal demands are high.

Advantages of Quartz Tubes in Extreme Conditions

Quartz tubes maintain structural integrity at temperatures up to 1,200°C and beyond. Their low thermal expansion and high purity prevent stress fractures and contamination, even under extreme thermal cycling. This reliability is crucial for mission-critical industrial and laboratory processes.

The optical clarity of quartz tubes enables real-time visual monitoring and precise light transmission. This is not possible with most ceramics or standard glass materials. Such transparency is valuable in applications like spectroscopy7, UV curing8, and laser systems.

Quartz tubes are also highly customizable, allowing for tight dimensional tolerances and specialized features. This flexibility supports integration into complex equipment and unique process requirements. For engineers facing extreme conditions, quartz tubes provide a proven, high-performance solution.

What Technical Specifications Should You Consider When Selecting Quartz Tubes?

Selecting the right quartz tube requires careful evaluation of technical parameters.

Key factors include temperature resistance, chemical compatibility, dimensional tolerances, and custom requirements.

Temperature Resistance and Thermal Shock Properties

Temperature resistance is a primary consideration when selecting quartz tubes for demanding environments. High-purity quartz tubes can operate continuously at temperatures between 1,050°C and 1,200°C, with short-term exposure up to 1,600°C. Their low thermal expansion coefficient allows them to withstand rapid temperature changes without cracking.

Thermal shock resistance is measured by the maximum temperature difference (ΔT) the tube can endure in a short time. Quartz tubes typically handle ΔT values above 200°C, making them suitable for processes involving frequent heating and cooling cycles. This property helps prevent sudden failures and extends the service life of the tube.

Engineers should always verify the manufacturer’s specified temperature ratings and test data. Matching the tube’s thermal properties to the application ensures safe operation and reduces maintenance costs. Proper selection minimizes the risk of thermal stress fractures during use.

Chemical Resistance and High-Purity Standards

Quartz tubes are highly resistant to most acids, bases, and solvents, except hydrofluoric acid and strong alkalis. This chemical inertness protects both the tube and the process from unwanted reactions or contamination. High-purity quartz (≥99.995% SiO₂) is essential for semiconductor, laboratory, and analytical applications.

Purity is verified using advanced analytical techniques such as ICP-OES9 or GDMS10. These tests detect trace metallic impurities that could compromise sensitive processes. Consistent high purity ensures reliable results and compliance with industry standards.

When selecting quartz tubes, always request purity certificates and third-party test reports. Confirm that the supplier meets international standards such as ASTM and ISO. High-purity and chemical resistance are critical for maintaining process integrity and product quality.

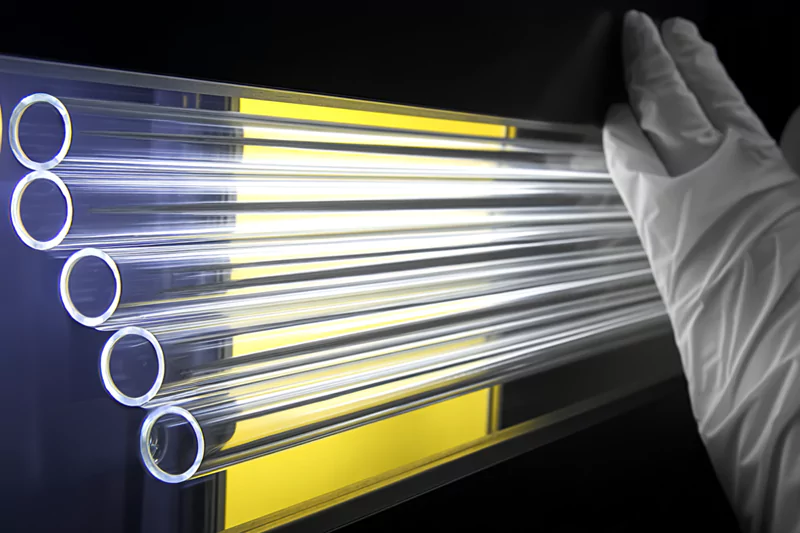

Dimensional Tolerances and Custom Specifications

Dimensional tolerances define the allowable variation in tube diameter, wall thickness, and length. Standard quartz tubes are available in a range of sizes, with typical tolerances of ±0.2–0.5 mm. Tight tolerances are important for applications requiring precise fits and consistent performance.

Custom specifications may include special shapes, ports, bends, or surface finishes. Engineers should communicate all critical dimensions and features to the supplier during the ordering process. Customization ensures the tube integrates seamlessly with existing equipment and meets unique process requirements.

Accurate dimensions and proper customization reduce installation time and minimize the risk of leaks or misalignment. Always confirm feasibility and lead time for custom orders. Working closely with the supplier helps achieve the best results for specialized applications.

How to Choose the Right Fused Silica Tube for Your Specific Application?

A systematic selection process ensures the chosen tube meets all technical and operational requirements.

Consider application type, cost, supplier reliability, and customization options.

Step-by-Step Selection Based on Application Type

Start by identifying the process environment—temperature, chemicals, and mechanical stresses. Match these to the appropriate grade and dimensions of quartz tube. For semiconductor or analytical use, prioritize ultra-high purity and tight tolerances.

Evaluating Cost, Availability, and Supplier Factors

Compare suppliers for price, lead time, and technical support. Request third-party test reports and check for ISO/ASTM certifications. Consider total cost of ownership, including expected lifespan and maintenance needs.

Customization Tips for Unique Requirements

For non-standard applications, work with suppliers who offer custom fabrication. Specify all critical parameters, including ports, bends, and surface finish. Confirm feasibility and lead time before finalizing your order.

Many engineers assume all high-temperature tubes perform equally, but this misconception can lead to costly failures. Quartz tubes maintain structural integrity at 1200°C while alumina tubes begin to soften above 1000°C. Always verify the continuous operating temperature rating and thermal expansion coefficient compatibility with your system design to prevent thermal stress fractures during temperature cycling.

What Quality Standards and Testing Methods Ensure Quartz Tube Reliability?

Reliable performance depends on adherence to international standards and rigorous testing.

Key standards include ISO 9001, ASTM C100, and industry-specific protocols for purity and dimensional accuracy.

International Standards (e.g., ISO, ASTM)

Quartz tubes should comply with ISO 9001 for quality management and ASTM C100 for dimensional and purity requirements. These standards ensure consistent manufacturing and traceability.

Common Testing Methods: Thermal Shock, Purity Analysis, and More

Thermal shock tests expose tubes to rapid temperature changes to check for cracking. Purity is analyzed using ICP-OES or GDMS. Dimensional checks use calipers or coordinate measuring machines (CMM).

Certification and Supplier Audits for Reliability

Request certificates of analysis and audit supplier facilities for process control. Reliable suppliers provide full documentation, batch traceability, and support for custom testing if needed.

Conclusion

Quartz tubes are the backbone of high-temperature and high-purity applications. Informed selection and rigorous quality control ensure safe, reliable, and efficient operation.

Selecting the right quartz tube for your application is a critical engineering decision. Leverage TOQUARTZ’s direct factory supply, engineering support, and rapid delivery to ensure your project’s success—contact us for expert guidance and custom solutions.

FAQ (Frequently Asked Questions)

What is the maximum continuous operating temperature for quartz tubes?

Most high-purity quartz tubes can operate continuously at 1,050–1,200°C, with short-term exposure up to 1,600°C.

How do I verify the purity and quality of a quartz tube before purchase?

Request third-party test reports (e.g., ICP-OES), check for ISO/ASTM certifications, and review supplier documentation for batch traceability.

What factors should I consider when ordering custom quartz tubes?

Specify all critical dimensions, purity requirements, surface finish, and any special features. Confirm feasibility and lead time with your supplier.

How do quartz tubes compare to borosilicate or ceramic tubes for high-temperature use?

Quartz tubes offer higher purity, better thermal shock resistance, and superior chemical stability, making them preferable for demanding applications.

References:

-

Learn how CVD processes work in semiconductor manufacturing and why quartz tubes are essential for achieving high-quality thin film deposition. ↩

-

Learn how atomic absorption works and why it's essential for detecting trace elements in scientific analysis. ↩

-

Learn how ICP-MS works and why it's essential for detecting trace elements with high sensitivity in scientific analysis. ↩

-

Learn about UV-Vis spectroscopy to see its importance in detecting trace elements and compounds. ↩

-

Exploring borosilicate glass properties can help in applications requiring thermal resistance and durability. ↩

-

Explore this link to understand the diverse applications and benefits of alumina tubes in high-temperature settings. ↩

-

Discover how spectroscopy works and why quartz tubes are essential for accurate measurements in scientific research and industry. ↩

-

Discover how UV curing technology accelerates processes and improves product quality in industries like printing, electronics, and manufacturing. ↩

-

Exploring this link will provide you with a deeper understanding of ICP-OES, its applications, and significance in ensuring purity. ↩

-

Learn how GDMS works to ensure material purity and why it's crucial for meeting industry standards in sensitive applications. ↩