SiO₂ purity plays a crucial role in the performance of quartz tubes heating elements. Even a slight change in purity alters resistance to devitrification, infrared transmission, and service life, especially under high temperature or intense watt density. Commercial quartz tubes often reach 99.99% or higher SiO₂ content, as shown below:

Purity Level | Application |

|---|---|

99.99%+ | Semiconductor use |

Engineers and buyers who understand how purity levels affect both technical outcomes and long-term costs make better material choices for demanding applications.

Key Takeaways

SiO₂ purity of at least 99.99% is essential for quartz tubes to prevent devitrification and ensure long service life.

Metallic impurities lower the crystallization temperature, reduce mechanical strength, and decrease infrared transmission, leading to higher energy costs.

Low hydroxyl (OH) content in quartz enhances infrared transmission, improving heating efficiency and reducing energy waste.

Engineers should use testing standards like ICP-MS and FTIR to verify quartz purity and ensure optimal performance in high-temperature applications.

Selecting premium quartz grades can significantly lower total operating costs by minimizing energy waste and reducing downtime.

What Purity Level Prevents Devitrification in High-Temperature Heating Applications?

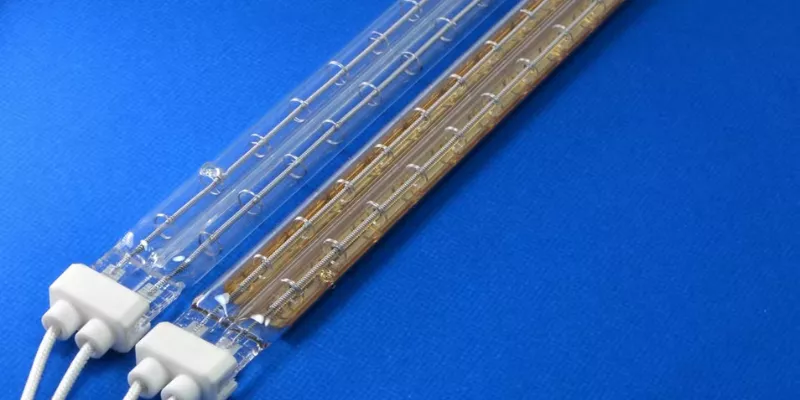

Quartz tubes heating elements face extreme thermal stress during operation, especially in industrial environments where temperatures often exceed 950°C. The purity of SiO₂ in these tubes determines their resistance to devitrification, which is the unwanted transformation from amorphous to crystalline structure. Understanding why high purity matters helps engineers select materials that maximize service life and maintain consistent performance.

Understanding Devitrification Mechanisms in Fused Quartz Glass

Devitrification occurs when fused quartz glass transitions from an amorphous state to a crystalline phase under high temperatures. This process introduces microcracks and reduces the tube’s mechanical strength. Internal stresses develop due to uneven cooling and phase changes, which can lead to tube failure.

The presence of hydroxyl groups and impurities accelerates devitrification, lowering the thermal stability of quartz tubes heating elements. These factors increase the risk of surface crystallization, especially near heating coils where local temperatures spike. Over time, devitrification causes a drop in infrared transmission and shortens service life.

Mechanism | Description |

|---|---|

Thermal Stress during Cooling | Uneven temperature distribution leads to internal stress. |

Phase Transition Stress | Volume differences between phases cause microcracks. |

Influence of Impurities | Hydroxyl groups and contaminants promote devitrification and reduce stability. |

How Metallic Impurities Lower Crystallization Temperature Thresholds

Metallic impurities such as aluminum, sodium, potassium, iron, and titanium act as devitrification agents in quartz tubes heating elements. These elements form strong chemical bonds within the glass, making them difficult to remove and increasing the risk of crystallization. Alkali metals like sodium and potassium serve as fluxing agents, which lower the temperature at which devitrification begins.

Higher concentrations of these impurities not only reduce the crystallization temperature but also decrease the mechanical strength of the tubes. The presence of these metals can increase dielectric loss and affect the optical properties, leading to reduced service life and efficiency. Engineers must monitor impurity levels to ensure reliable performance in high-temperature applications.

Key Impacts of Metallic Impurities:

Lower devitrification onset temperature

Reduced mechanical strength

Decreased infrared transmission

Shortened service life

Purity Requirements for Different Operating Temperature Ranges

Quartz tubes heating elements require specific SiO₂ purity levels to withstand different temperature ranges. Tubes with SiO₂ content of at least 99.99% can operate continuously at temperatures up to 1200°C and tolerate short-term exposure up to 1450°C. Lower purity levels increase the risk of cracking, deformation, and rapid devitrification.

Manufacturers recommend using quartz tubes with ≥99.99% purity for applications above 950°C to prevent structural failure and maintain high infrared transmission. Data from TOQUARTZ and industry sources show that tubes with this purity maintain over 92% transmission after thousands of hours at 1100°C, while lower purity tubes degrade much faster.

Temperature Range | Recommended SiO₂ Purity Level |

|---|---|

Up to 800°C | ≥99.99% |

Up to 1000°C | ≥99.99% |

Up to 1200°C | ≥99.99% |

Selecting the right purity level ensures that quartz tubes heating elements deliver reliable performance, minimize downtime, and extend service life in demanding environments.

Why Does Impurity Content Affect Infrared Transmission Efficiency?

Impurity content in quartz tubes heating elements directly impacts how efficiently they transmit infrared energy. Even small amounts of metallic or hydroxyl impurities can create absorption bands that block or scatter infrared light. Understanding why these impurities matter helps engineers select the right material for maximum heating efficiency and longer service life.

Infrared Absorption Bands Created by Common Metallic Impurities

Metallic impurities such as iron, titanium, and aluminum introduce specific absorption bands in the infrared spectrum. These bands overlap with the wavelengths emitted by heating coils, reducing the amount of usable energy that passes through the tube. The presence of hydroxyl groups, often influenced by metallic impurities, further increases infrared absorption.

The peak decomposition of the IR absorption at around 3600 cm−1 showed that most OH structures were ‘free Si−OH’ without the hydrogen bond, indicating that the presence of OH groups, influenced by metallic impurities, contributes to infrared absorption in quartz tubes.

Manufacturers find it difficult to completely eliminate OH impurities, but lower levels allow for higher IR transmission. Some grades of quartz contain metallic impurities from manufacturing, which can also limit UV and IR transmission.

The presence of OH impurity is difficult to limit, but it is key to allow highest levels of IR transmission. The Infrared grades have some metallic impurities from manufacture, which limit their UV transmission.

Key reasons why impurities affect IR transmission:

Metallic impurities create absorption bands

OH groups increase IR absorption

Transmission loss reduces heating efficiency

Calculating Energy Loss from Transmission Degradation

Energy loss in quartz tubes heating elements occurs when impurities absorb or scatter infrared light. Even a small drop in transmission can lead to significant energy waste over time. For example, a 3-5% reduction in IR transmission can lower delivered energy density and increase operating costs.

Purity Level | Impurity Content (ppm) | Typical Transmission Loss (%) |

|---|---|---|

Ultra-High Purity | Up to 5 ppm | <1 |

GE Fused Quartz | Less than 25 ppm | 1-3 |

Standard Commercial | 50-150 ppm | 5-10 |

A production line using 180 kW for heating can waste over 15,000 kWh per month if transmission drops by just 10%. This energy loss translates to thousands of dollars in extra costs each year. Engineers must consider both the initial material cost and the long-term energy savings when selecting quartz tubes.

How Impurity-Induced Absorption Accelerates Over Operating Life

Impurities not only cause immediate transmission loss but also accelerate further degradation during use. As quartz tubes heating elements operate, devitrification and surface deposits increase, especially in tubes with higher impurity content. This process leads to a faster decline in IR transmission and a shorter service life.

Tubes with less than 20 ppm total metallic impurities maintain high energy delivery for thousands of hours. In contrast, tubes with 80-150 ppm impurities can lose up to 25% efficiency within 3,500 hours. Over time, the need for more frequent replacements and higher energy use increases total operating costs.

Summary of impurity effects over time:

Higher impurity content speeds up transmission loss

Service life decreases as absorption increases

Frequent replacements raise maintenance costs

Does OH Content Affect Thermal Properties and Infrared Wavelength Transmission?

The hydroxyl (OH) content in quartz tubes heating elements plays a decisive role in their ability to transmit infrared energy and maintain structural integrity at high temperatures. Engineers often evaluate OH levels to optimize both heating efficiency and tube longevity. Understanding why low-OH quartz performs better helps buyers select the right material for demanding heating applications.

OH Content Impact on 2.7-2.8 Micron Infrared Absorption

Low OH content in quartz glass directly improves infrared transmission, especially in the 2.7-2.8 micron range. This wavelength is critical for many industrial heating processes, including polymer curing and coating applications. Tubes with less than 30 ppm OH content allow more infrared energy to pass through, increasing heating efficiency.

Grade Type | OH Content Level |

|---|---|

Standard | < 10 ppm |

Specialized | < 1 ppm |

Higher OH levels create molecular vibration absorption bands that overlap with the emission spectrum of heating coils. This overlap leads to energy loss and reduced process speed. Engineers choose low-OH quartz to maximize throughput and minimize wasted energy.

Summary Points:

Low OH content boosts IR transmission

High OH content increases absorption losses

Efficient heating relies on optimal OH levels

Viscosity Changes and Dimensional Stability at High Temperatures

OH content also influences the viscosity and dimensional stability of quartz tubes heating elements during prolonged exposure to high temperatures. Low-OH quartz maintains its shape and resists sagging, which is vital for horizontal heating arrays and long tube spans. Increased OH content accelerates devitrification and reduces viscosity, making tubes more prone to deformation.

Low OH- content reduces the sag rate at diffusion temperatures, which is important for maintaining dimensional stability.

Increased OH- content leads to a higher rate of devitrification, which negatively impacts dimensional stability.

The viscosity of fused quartz decreases with increasing temperature and OH- content, affecting its flowability.

Dimensional stability ensures consistent energy delivery and reduces maintenance needs. Engineers prefer low-OH quartz for applications where tube deformation could disrupt production or cause costly downtime.

When to Specify Low-OH Electrically Fused vs. Flame Fused Quartz

Choosing between electrically fused and flame-fused quartz depends on the application's temperature and purity requirements. Electrically fused quartz, produced in a vacuum or dry atmosphere, contains less than 30 ppm OH and offers superior resistance to devitrification and deformation. Flame-fused quartz, made in a hydrogen/oxygen flame, typically has 150-200 ppm OH, which limits its use at higher temperatures.

Quartz Type | OH Content | Max Use Temp | Deformation Resistance |

|---|---|---|---|

Electrically Fused | < 1 – 30 ppm | High | Strong |

Flame Fused | 150 – 200 ppm | Moderate | Lower |

Low-OH electrically fused quartz is ideal for heating element applications that demand high purity, maximum use temperature, and long service life. Engineers specify this material to ensure reliable performance and minimize replacement cycles.

What Testing Standards Verify Quartz Purity and Optical Performance?

Engineers rely on strict testing standards to ensure quartz tubes heating elements meet demanding performance requirements. These standards help verify purity, detect impurities, and confirm optical properties before installation. Understanding why each test matters allows buyers to select the right material for their application and avoid costly failures.

ICP-MS Analysis Requirements for Metallic Impurity Quantification

Manufacturers use ICP-MS (Inductively Coupled Plasma Mass Spectrometry) to measure metallic impurities in quartz. This method detects trace elements at very low concentrations, which is essential for high-purity applications. ICP-OES (Optical Emission Spectroscopy) also serves as a reliable tool for impurity analysis.

ICP-MS requires careful sample preparation, often involving specific digestion techniques to dissolve quartz for accurate measurement. These tests identify metals like iron, aluminum, sodium, and potassium, which can lower the devitrification threshold and reduce service life. By quantifying impurities, engineers can compare material grades and select quartz that meets strict purity standards.

ICP-MS detects trace metallic impurities

Sample digestion ensures accurate results

Low impurity levels extend tube service life

FTIR Spectroscopy for OH Content and Absorption Band Detection

FTIR (Fourier Transform Infrared) spectroscopy helps identify hydroxyl (OH) content and other absorption bands in quartz. Engineers use FTIR to analyze the O-H stretching region around 3500 cm-1, which reveals the presence of hydrous defects. The absence of significant absorption bands in this region indicates low OH content, which is ideal for high-temperature use.

FTIR also detects specific defects, such as AlOH, LiOH, and BOH, by their unique absorption bands. These defects can impact infrared transmission and heating efficiency. By understanding why FTIR results matter, buyers can choose quartz with optimal optical properties for their process.

Defect Type | Absorption Band (cm⁻¹) | Impact |

|---|---|---|

AlOH | 3310, 3378, 3430 | Reduces IR transmission |

LiOH | 3470–3482 | Increases absorption |

BOH | 3595 | Affects heating uniformity |

ASTM E903 Transmission Testing Across Infrared Heating Wavelengths

ASTM E903 sets the standard for measuring infrared transmission in quartz tubes. This test evaluates how much IR energy passes through the material across the 2.5–10 micron range, which is critical for heating element performance. High transmission values confirm that the quartz will deliver energy efficiently to the target.

Engineers use ASTM E903 results to compare premium, standard, and flame-fused grades. Premium grades show over 95% transmission at peak wavelengths, while lower grades may fall below 85%. By understanding why these results matter, buyers can balance energy efficiency, replacement frequency, and downtime costs.

High IR transmission means better efficiency

Premium grades reduce energy waste

Testing guides cost-effective material selection

What Material Grade Selection Criteria Optimize Cost-Performance Balance?

Selecting the right material grade for quartz tubes heating elements is essential for balancing performance and cost. Engineers must consider not only the initial price but also long-term efficiency, maintenance, and downtime. Understanding why each grade performs differently helps buyers make informed decisions for their specific applications.

Premium vs. Standard Electrically Fused Quartz Performance Comparison

Premium electrically fused quartz offers higher purity and lower hydroxyl content than standard grades. This difference results in better resistance to devitrification, higher infrared transmission, and longer service life. Premium grades maintain over 95% direct infrared emission, while standard grades may show slightly lower values.

The performance gap becomes more apparent in demanding environments. Premium quartz heats up quickly, reaching full output in as little as 30 seconds, and cools down to 50% output in under 15 seconds. These fast response times allow operators to turn off elements between production runs, saving energy and reducing wear.

Key performance advantages of premium grades:

Faster heat-up and cool-down times

Higher direct infrared emission

Longer operational life

Total Cost of Ownership Calculation Including Energy and Downtime

Total cost of ownership includes more than just the purchase price. Energy efficiency and downtime play major roles in long-term expenses. Clear quartz tubes heating elements deliver up to 95% direct infrared energy, minimizing wasted power and lowering monthly utility bills.

Downtime costs can add up quickly in industrial settings. Quick delivery and replacement options for premium grades help minimize production interruptions. When elements heat and cool rapidly, operators can pause equipment between jobs, further reducing energy use.

Feature | Clear Quartz | Satin Quartz |

|---|---|---|

Infrared Energy Emission | 95% direct IR radiation | 35% absorbed, longer wavelength |

Heat Up Time | Full output in 30s | N/A |

Cool Down Time | 50% output in under 15s | N/A |

Efficient material selection reduces both energy and downtime costs, leading to significant savings over the equipment’s lifetime.

Application-Based Decision Framework for Material Grade Selection

Engineers use a structured framework to select the optimal quartz material grade for each application. This process ensures that the chosen material meets all technical and operational requirements. The framework evaluates optical, thermal, and chemical properties, as well as supplier reliability.

Step | Evaluation Focus | Acceptance Standard | Measurement / Reference |

|---|---|---|---|

1 | Identify optical/thermal | ISO 9050 / ASTM E228 | CTE ≤ 0.55 × 10⁻⁶/K |

2 | Verify wall uniformity | SEMI E172 | ±0.5 mm tolerance |

3 | Confirm purity/bubble class | ICP & Visual | OH⁻ ≤ 50 ppm, ≤ B3 |

4 | Validate chemical resistance | HF Resistance Test | <0.5 mg/cm² loss |

5 | Review supplier capability | CPK Audit | ≥1.67 |

6 | Establish cleaning/retirement | SOP Tracking | 2000 h or T(350 nm) –8% |

This decision framework helps ensure that each installation achieves the best balance of performance, reliability, and cost.

SiO₂ purity directly shapes the performance and service life of quartz tubes heating elements. High purity and low OH content help maintain thermal stability and energy efficiency in demanding environments. To achieve reliable results, engineers should reference key industry standards:

SiO₂ purity of at least 99.9%

Thermal stability above 1,050°C

Compliance with ISO 9001, SEMI F57, and RoHS

Selecting materials based on these criteria ensures optimal operation and reduces long-term costs.

FAQ

Why does SiO₂ purity matter for heating element tube service life?

High SiO₂ purity prevents devitrification and maintains infrared transmission. Tubes with ≥99.98% purity last longer and resist structural failure.

Tip: Engineers choose high-purity quartz to reduce downtime and replacement costs.

How do metallic impurities affect infrared heating efficiency?

Metallic impurities create absorption bands that block infrared energy. This reduces heating efficiency and increases energy costs.

Key effects:

Lower transmission

Higher energy waste

Shorter tube lifespan

What is the difference between electrically fused and flame-fused quartz?

Electrically fused quartz contains less OH and fewer impurities. It resists deformation at high temperatures and maintains better infrared transmission. Flame-fused quartz has higher OH content, which limits its use in demanding applications.

How can buyers verify quartz tube purity?

Buyers use ICP-MS to measure metallic impurities and FTIR to check OH content. ASTM E903 tests infrared transmission.

Test | Purpose |

|---|---|

ICP-MS | Impurity detection |

FTIR | OH analysis |

ASTM E903 | IR transmission |

Why should engineers consider total cost of ownership when selecting quartz tubes?

Total cost includes energy efficiency, replacement labor, and downtime. Premium quartz reduces energy waste and replacement frequency, saving money over time.

Note: Long-term savings often outweigh initial material costs.