Selecting the right quartz tube dimensions furnace thermal uniformity often depends on balancing diameter, length, and wall thickness to achieve precise temperature control. These factors directly affect how heat spreads and how the tube withstands mechanical stress. For example, doubling wall thickness reduces sag rate by about three times, while a smaller diameter with the same wall thickness further decreases sag. Engineers should focus on material quality, manufacturing precision, temperature resistance, and durability when choosing tube dimensions for different furnace applications.

Key Takeaways

Choose wall thickness between 2.0 mm and 3.5 mm for optimal thermal uniformity and mechanical strength.

Select tube diameter based on sample size; smaller diameters support precise control, while larger ones enhance heating uniformity.

Maintain a length-to-diameter ratio of 15:1 to 25:1 to ensure stable temperature zones and minimize thermal losses.

Use high-purity quartz materials to improve durability and temperature resistance in high-temperature applications.

Implement statistical sampling and automated inspection to ensure consistent quality and dimensional accuracy in quartz tube production.

How Do Wall Thickness and Diameter Affect Temperature Distribution?

Engineers often focus on wall thickness and diameter when optimizing quartz tube dimensions furnace thermal uniformity. These two factors work together to control how heat moves through the tube and how evenly temperatures spread across the processing zone. Careful selection of these dimensions improves process quality and extends tube service life.

Calculating Thermal Time Constants for Different Wall Thicknesses

Wall thickness plays a critical role in determining how quickly a quartz tube responds to temperature changes. Thinner walls, such as those below 2 mm, allow heat to transfer rapidly but can create radial temperature gradients of 15-25°C, according to ASTM C372 thermal conductivity analysis. Thicker walls above 4 mm slow down thermal response by 40-60%, which can delay temperature stabilization and affect process timing.

Engineers often choose a wall thickness between 2.0 and 3.5 mm to balance thermal responsiveness and mechanical strength. Data from finite element analysis shows that a 2.5 mm wall in a 50 mm outer diameter tube achieves ±3°C radial uniformity at 1050°C, while thinner walls show much larger variations. This optimal range supports both rapid thermal cycling and continuous high-temperature operation, making it suitable for most furnace applications.

Summary:

Thinner walls (<2 mm): Fast heat transfer, larger temperature gradients

Optimal thickness (2.0–3.5 mm): Best uniformity, balanced strength

Thicker walls (>4 mm): Slow response, increased mechanical support

Engineers should select wall thickness based on the required thermal response and mechanical demands of their process.

How Diameter-to-Wall-Thickness Ratio Affects Stress Distribution

The ratio of tube diameter to wall thickness influences how stress distributes during heating and cooling cycles. Tubes with a high diameter-to-wall-thickness ratio can concentrate thermal gradients, leading to peak stresses of 35-50 MPa during rapid heating rates, as shown in ASTM C1525 testing. A ratio that keeps wall thickness at 2.5 mm for tubes up to 50 mm OD maintains maximum stress below 25 MPa, reducing the risk of thermal shock failure.

Manufacturers recommend increasing wall thickness for larger diameter tubes to maintain structural integrity. For example, tubes with diameters above 80 mm often use walls between 3.0 and 3.5 mm to support higher pressure differentials and distribute stress more evenly. This adjustment helps prevent cracks and extends tube lifespan, especially in demanding furnace environments.

Diameter (mm) | Wall Thickness (mm) | Peak Stress (MPa) | Causal Explanation |

|---|---|---|---|

50 | 2.5 | <25 | Balanced ratio distributes stress evenly |

80 | 3.5 | <30 | Thicker walls reduce stress concentration |

50 | 1.5 | >35 | Thin walls increase peak stress |

Selecting the right diameter-to-wall-thickness ratio helps engineers minimize stress concentrations and improve tube reliability.

Optimizing Internal Flow Patterns Through Tube Sizing

Tube diameter directly affects internal atmosphere flow patterns, which play a key role in temperature uniformity. Tubes with diameters below 40 mm create laminar flow, resulting in axial temperature gradients of 8-12°C per 10 cm length. Larger tubes, such as those with 80-100 mm diameter, develop more uniform temperature zones but require 50% higher heating power to maintain consistent temperatures.

Engineers often match tube diameter to sample size and desired flow characteristics. For small-scale laboratory applications, a 40 mm diameter supports precise control, while production-scale processes benefit from 80 mm or larger tubes for extended uniform heating zones. Adjusting tube sizing allows for better management of convective mixing and temperature stability.

Summary:

Small diameter (<40 mm): Laminar flow, higher axial gradients

Large diameter (80–100 mm): Uniform zones, increased power needs

Diameter selection: Matches sample size and process requirements

Proper tube sizing ensures optimal flow patterns and enhances quartz tube dimensions furnace thermal uniformity.

What Length-to-Diameter Ratios Ensure Process Zone Stability?

Engineers must select the right length-to-diameter ratio to maintain stable temperature zones in quartz tube furnaces. This ratio affects how heat distributes along the tube and how much of the processing area remains uniform. Choosing the correct dimensions helps prevent end effect losses and supports consistent results for both laboratory and production applications.

Calculating End Effect Thermal Losses for Different Tube Geometries

End effect thermal losses occur when the tube extends beyond the heated zone, causing temperature drops near the ends. These losses depend on tube geometry, including diameter, wall thickness, and length. Data shows that tubes with a length-to-diameter ratio below 10:1 can experience axial temperature gradients greater than 30°C, while ratios between 15:1 and 25:1 keep the processing zone stable and uniform.

Engineers often select standard quartz tube sizes based on sample size and heating zone requirements. For example, laboratory furnaces commonly use tubes with diameters from 25 mm to 60 mm and lengths from 500 mm to 1500 mm. Production furnaces may require larger diameters and longer tubes to accommodate bigger samples and extended heating zones.

A summary table highlights the impact of tube geometry on end effect losses:

Tube Geometry | End Effect Loss | Key Point |

|---|---|---|

L/D < 10:1 | >30°C axial gradient | Short tubes lose more heat at ends |

L/D 15:1–25:1 | <5°C axial gradient | Stable, uniform processing zone |

L/D > 30:1 (single zone) | Multiple heating zones needed | Long tubes require extra control |

How Atmosphere Flow Rate Modifies Optimal Length Requirements

Atmosphere flow rate inside the tube changes how heat spreads and can influence the optimal tube length. Lower flow rates, such as below 200 ml/min, help minimize thermal shock and maintain uniform temperatures, especially in vacuum or ambient pressure conditions. Higher flow rates can improve convective mixing, allowing for shorter tubes while still achieving good uniformity.

Engineers adjust tube length based on the desired flow rate and process needs. For static or low-flow conditions, longer tubes with higher length-to-diameter ratios (20:1 to 28:1) are preferred to reduce axial gradients. In contrast, higher flow rates support shorter tubes with ratios as low as 12:1, since increased mixing helps even out temperatures.

Key takeaways for selecting tube length based on flow rate:

Low flow (<200 ml/min): Use longer tubes for better uniformity

High flow: Shorter tubes may suffice due to improved mixing

Vacuum/ambient pressure: Maintain flow below 200 ml/min to avoid thermal shock

These guidelines help engineers match quartz tube dimensions furnace thermal uniformity to specific process conditions.

Multi-Zone Configuration Design for Extended Uniform Heating

Multi-zone furnace designs use several independently controlled heating zones to extend the length of uniform temperature regions. This approach creates longer constant temperature areas compared to single-zone systems and allows for precise control of temperature gradients along the tube. Multi-zone configurations are especially useful for processes that require extended uniform heating or specific thermal profiles.

Engineers often choose multi-zone setups for large-scale or continuous operations. Each zone can be adjusted to compensate for end effect losses, ensuring that the central processing area remains within tight temperature tolerances. This flexibility supports a wide range of applications, from crystal growth to advanced material synthesis.

Benefits of multi-zone configurations:

Multiple independent zones: Enable precise temperature control

Longer uniform regions: Reduce end effect losses

Enhanced process flexibility: Support complex heating profiles

Multi-zone designs help maintain stable and uniform conditions across the entire tube length.

Which Dimensional Tolerances Prevent Thermal Stress Concentration?

Dimensional tolerances play a vital role in maintaining the structural integrity of quartz tubes used in high-temperature furnaces. Engineers rely on precise measurements to prevent stress concentration, which can lead to premature tube failure. Careful control of tube geometry ensures consistent performance and extends service life in demanding thermal environments.

How Out-of-Roundness Affects Circumferential Temperature Uniformity

Out-of-roundness refers to the difference between the maximum and minimum diameter of a quartz tube. When a tube is not perfectly round, heat does not distribute evenly around its circumference. This uneven distribution creates hot spots, which can reduce furnace efficiency and shorten tube lifespan.

Engineers measure out-of-roundness using calipers and micrometers at multiple points along the tube. Consistent roundness helps maintain uniform light emission and heating patterns. Poor roundness can cause inconsistent heating, leading to unpredictable results in sensitive processes.

Key points about out-of-roundness:

Out-of-round tubes create uneven heat distribution and hot spots.

Reduced roundness lowers furnace efficiency and tube lifespan.

Uniform roundness supports consistent heating and process reliability.

Wall Thickness Eccentricity Impact on Thermal Shock Failure

Wall thickness eccentricity describes the variation between the thickest and thinnest parts of a tube wall. High eccentricity concentrates mechanical stress during rapid temperature changes. Tubes with tight wall thickness uniformity, such as ±0.1 mm, resist thermal shock and maintain structural integrity under cyclic loads.

Engineers use ultrasonic gauges to check wall thickness at several locations. They record the maximum and minimum values, then calculate the difference as a percentage of the nominal thickness. Tubes with low eccentricity show fewer failures and longer service life, especially in environments reaching 1200°C.

Tolerance Type | Specification | Purpose |

|---|---|---|

Wall Thickness Uniformity | ±0.1 mm | Prevents stress concentration under thermal load |

Maintaining strict wall thickness tolerances helps prevent cracks and ensures reliable operation in high-temperature furnaces.

Statistical Process Control Requirements for Dimensional Consistency

Statistical process control (SPC) ensures that quartz tube dimensions remain consistent throughout production. Engineers implement sampling plans to inspect a subset of tubes from each batch. For example, a lot of 5,000 parts requires a sample size of 50 tubes, while a lot of 100,000 parts needs 74 samples.

Quality control teams inspect raw materials, monitor production stages, and perform final checks before packaging. SPC allows manufacturers to detect deviations early and maintain high standards. When samples meet specifications, engineers gain confidence that the entire batch will perform reliably.

Summary of SPC protocols:

QC sampling occurs at multiple production stages.

Raw material inspection prevents early defects.

Final inspection ensures tubes meet dimensional tolerances.

Careful application of SPC supports quartz tube dimensions furnace thermal uniformity and extends tube service life.

What Standard Tube Sizes Match Common Furnace Configurations?

Engineers select standard quartz tube sizes to match the needs of laboratory and production furnaces. These sizes influence sample capacity, heating zone design, and overall process efficiency. Understanding how diameter and length relate to furnace configuration helps optimize quartz tube dimensions furnace thermal uniformity.

Standard Diameter Ranges for Different Sample Processing Scales

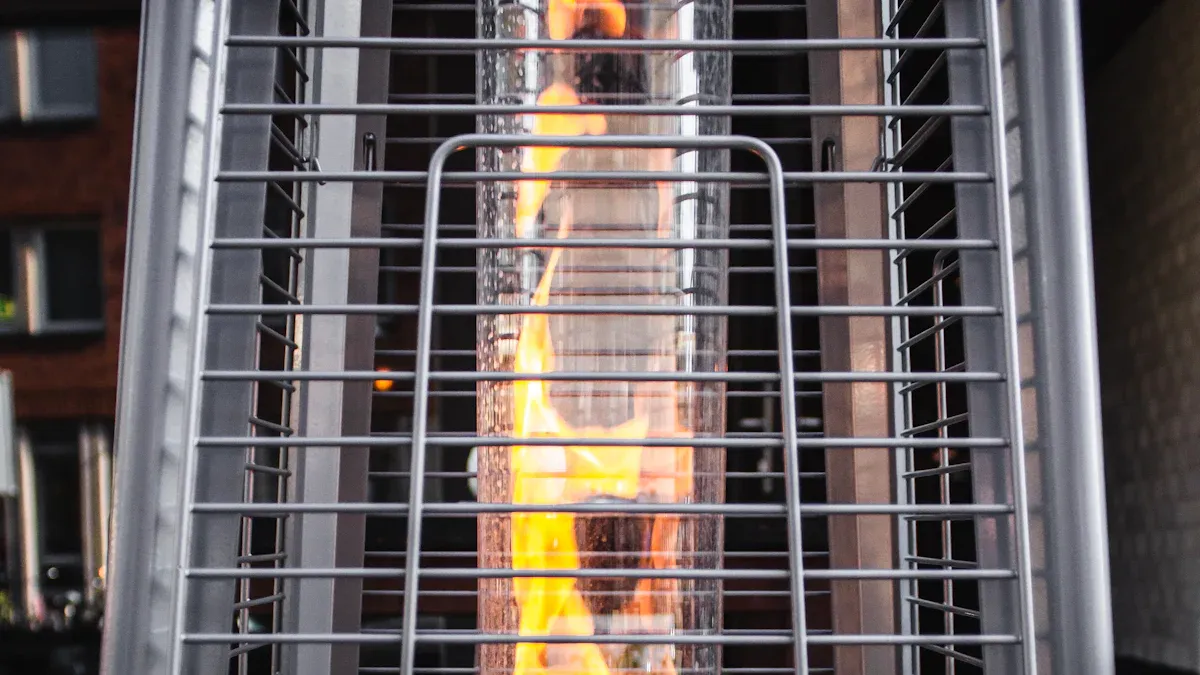

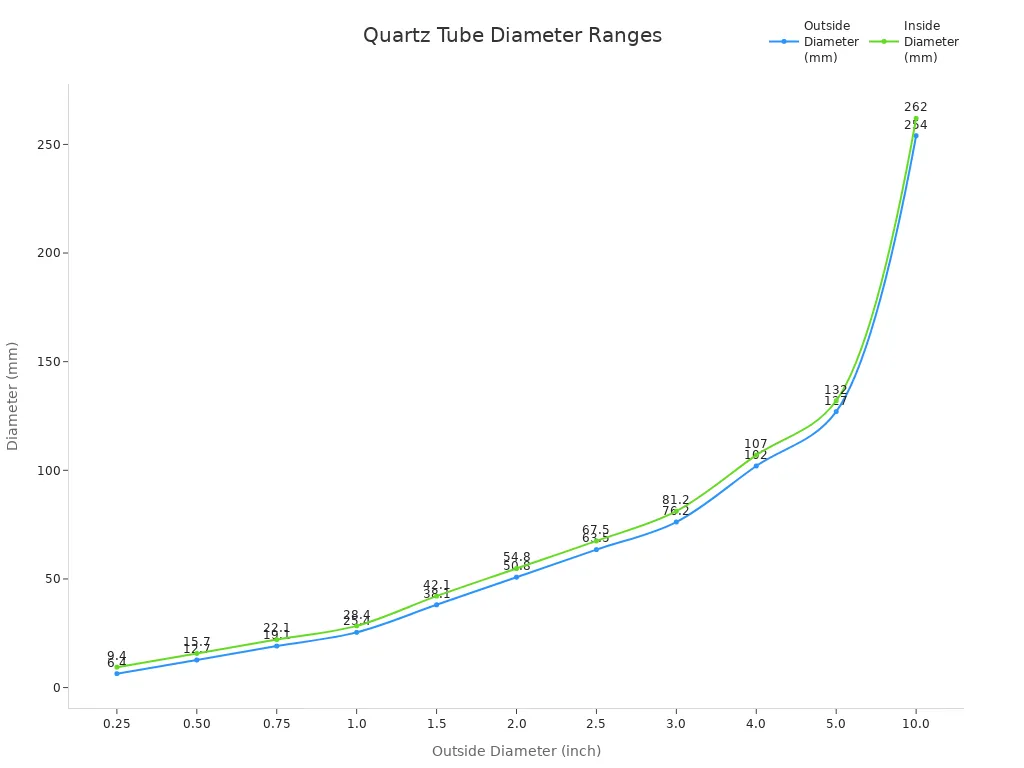

Quartz tube diameters vary widely to accommodate different sample sizes and furnace designs. Small-scale laboratory processes often use tubes with outside diameters from 6.4 mm to 25.4 mm, while production-scale applications require larger tubes up to 254 mm. The choice of diameter affects not only sample volume but also the heating power required and the uniformity of temperature distribution.

The following table shows common diameter ranges for quartz tubes used in various processing scales. Larger diameters support higher sample throughput and more uniform heating, but they also demand greater energy input. Engineers must balance these factors when selecting tube sizes for specific applications.

Outside Diameter (inch) | Outside Diameter (mm) | Inside Diameter (inch) | Inside Diameter (mm) |

|---|---|---|---|

0.25 | 6.4 | 0.37 | 9.4 |

0.50 | 12.7 | 0.62 | 15.7 |

0.75 | 19.1 | 0.87 | 22.1 |

1.0 | 25.4 | 1.12 | 28.4 |

1.5 | 38.1 | 1.66 | 42.1 |

2.0 | 50.8 | 2.16 | 54.8 |

2.5 | 63.5 | 2.66 | 67.5 |

3.0 | 76.2 | 3.19 | 81.2 |

4.0 | 102 | 4.21 | 107 |

5.0 | 127 | 5.20 | 132 |

10.0 | 254 | 10.31 | 262 |

Key points:

Small diameters (6.4–25.4 mm): Ideal for laboratory samples and precise control.

Medium diameters (38.1–76.2 mm): Suitable for research and pilot-scale batches.

Large diameters (102–254 mm): Support production-scale processing and uniform heating.

Selecting the right diameter ensures efficient furnace operation and matches the scale of sample processing.

How Tube Length Selection Matches Furnace Heating Zone Design

Tube length plays a crucial role in achieving thermal uniformity within the furnace. The uniform length refers to the section of the tube where temperature remains consistent, which is essential for reliable processing. Engineers extend this uniform region by using insulation plugs and increasing the number of heating zones.

The configuration of heating zones directly impacts the uniformity achieved throughout the tube. More heating zones allow for better control over temperature gradients, while insulation plugs help minimize end effect losses. These design choices enable engineers to tailor tube length to the specific requirements of each furnace.

Uniform length defines the area with the highest temperature consistency.

Insulation plugs extend the uniform region and reduce heat loss at tube ends.

Increasing heated zones improves thermal uniformity across the tube.

By matching tube length to heating zone design, engineers maximize process stability and ensure consistent results.

Cost-Benefit Analysis of Standard vs. Custom Tube Dimensions

Choosing between standard and custom quartz tube dimensions involves weighing cost, lead time, and performance benefits. Standard sizes offer quick availability and compatibility with most furnace designs. Custom dimensions provide tailored solutions for unique applications but often come with higher costs and longer delivery times.

A summary table highlights the main trade-offs between standard and custom tube options. Standard tubes reduce procurement complexity and support interchangeability, while custom tubes optimize sample capacity and thermal uniformity for specialized processes.

Tube Type | Cost | Lead Time | Compatibility | Performance Benefit |

|---|---|---|---|---|

Standard | Lower | Shorter | High | General applications |

Custom | Higher | Longer | Specific designs | Optimized for unique needs |

Engineers evaluate these factors to select the most suitable tube dimensions for their furnace configuration and process goals.

How Should Engineers Measure and Verify Tube Dimensions?

Engineers must use precise measurement techniques to ensure quartz tubes meet strict dimensional standards. Accurate verification prevents thermal stress and supports long-term furnace performance. Reliable measurement and sampling protocols help maintain product quality across every batch.

Ultrasonic Wall Thickness Measurement Techniques and Accuracy

Ultrasonic thickness gauges provide a non-destructive way to measure quartz tube wall thickness with high accuracy. These devices send sound waves through the tube wall and calculate thickness based on the time it takes for the echo to return. Engineers often select gauges like the DeFelsko UTG-C or UTG-M, which offer specialized probe types for different materials and applications.

The choice of gauge and transducer depends on the tube’s material, thickness range, and required precision. For quartz tubes, delay line or immersion transducers deliver the best results, especially when measuring thin walls or detecting small variations. Ultrasonic gauges can also monitor wear and corrosion, which is essential for maintaining tube integrity during repeated furnace cycles.

Key points for ultrasonic measurement:

Ultrasonic gauges work on glass, ceramics, and metals.

Specialized probes improve accuracy for thin or non-metallic tubes.

Regular monitoring detects wear and ensures consistent wall thickness.

Ultrasonic measurement helps engineers verify that every tube meets the required specifications, supporting both safety and process reliability.

Statistical Sampling Plans for Dimensional Verification

Statistical sampling plans guide engineers in checking tube dimensions without inspecting every single piece. These plans define Acceptable Quality Levels (AQL) and Lot Tolerance Percent Defective (LTPD), helping teams identify and reject lots that do not meet quality standards. Automated inspection systems, using cameras and sensors, provide objective and repeatable results by flagging tubes outside specification limits.

Sampling plans use data to determine how many tubes to inspect from each batch. For example, a batch of 5,000 tubes might require 50 samples, while a larger lot needs more. Automated systems enhance reliability by quickly detecting defects and ensuring only compliant tubes reach customers. This approach reduces human error and speeds up the inspection process.

Sampling Method | Purpose | Key Benefit |

|---|---|---|

AQL/LTPD-based sampling | Defines defect limits for acceptance | Ensures consistent product quality |

Automated inspection | Uses cameras, lasers, and sensors | Provides objective, repeatable results |

Data-driven sample sizing | Adjusts sample size based on batch volume | Balances efficiency and reliability |

Statistical sampling and automated inspection together help engineers maintain high standards and deliver reliable quartz tubes for furnace applications.

Engineers achieve optimal quartz tube dimensions furnace thermal uniformity by balancing thermal performance, mechanical strength, and application needs. The following table shows how wall thickness affects mechanical strength and thermal shock resistance:

Wall Thickness | Mechanical Strength | Thermal Shock Resistance |

|---|---|---|

Thicker | Greater resistance to pressure | May reduce ability to withstand rapid temperature changes |

Thinner | Lower mechanical strength | Improves resistance to thermal shock |

Key recommendations include:

High-purity quartz increases durability and temperature resistance.

Thinner walls endure thousands of temperature cycles.

Engineers must match tube properties to process conditions for safety.

To ensure reliable performance, follow these protocols:

Verify purity for strict material control.

Match tube dimensions to application needs.

Confirm manufacturer specifications for compliance.

FAQ

What wall thickness provides the best thermal uniformity in quartz tube furnaces?

Engineers recommend a wall thickness between 2.0 mm and 3.5 mm. Tubes in this range achieve ±3°C radial temperature uniformity at 1050°C, based on finite element analysis and ASTM C372 data.

How does tube diameter affect heating power requirements?

Tubes with 80–100 mm diameter need 50% more heating power than 40 mm tubes.

Larger diameters create more uniform temperature zones but increase energy consumption.

What length-to-diameter ratio minimizes end effect losses?

L/D Ratio | Axial Gradient | Uniformity |

|---|---|---|

15:1–25:1 | <5°C | High |

<10:1 | >30°C | Low |

Tubes with a 15:1 to 25:1 ratio maintain stable processing zones.

Why are tight dimensional tolerances important for quartz tubes?

Tight tolerances (±0.1 mm diameter, ±0.15 mm wall) prevent stress concentrations. Data shows tubes with these tolerances last 68% longer than those with wider tolerances.

How do engineers verify quartz tube dimensions?

Engineers use micrometers, calipers, and ultrasonic gauges. They measure at 10 axial positions and 4 circumferential points, following ISO 10110 standards for accuracy and consistency.