Engineered-Strength Quartz Labware for

Advanced Laboratory Applications

High-performance quartz labware engineered to withstand thermal, chemical, and mechanical challenges across diverse research conditions.

- Withstands extreme conditions

- Resists chemical corrosion

- Supports complex experiments

Why Quartz Is Used In Making Labware?

Quartz is used in making labware because of its exceptional properties that make it ideal for demanding laboratory environments. Unlike standard glass, fused quartz provides superior thermal stability, chemical resistance, and optical clarity that are essential for accurate scientific research and industrial applications.

Premium Quartz Labware for Extreme Laboratory Conditions

TOQUARTZ® supplies high-performance laboratory quartzware engineered to withstand the most demanding research and industrial environments. Our quartz labware combines exceptional purity with precision manufacturing to deliver reliable performance in critical applications.

Thermal Properties

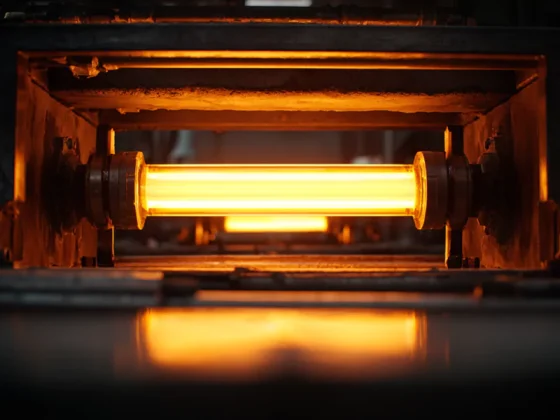

TOQUARTZ® quartz labware withstands extreme temperatures up to 1600°C with minimal thermal expansion, making it perfect for high-temperature applications where standard glassware would fail.

-

Low thermal expansion coefficient

(5.5×10⁻⁷ /°C) - Exceptional thermal shock resistance

- Maintains structural integrity at high temperatures

Chemical Resistance

TOQUARTZ® quartz glassware offers exceptional resistance to acids, alkalis, and corrosive chemicals, ensuring experiment integrity and extending product lifespan in harsh conditions.

- Resistant to most acids (except HF)

- Impervious to common laboratory chemicals

- Minimal contamination risk for sensitive analyses

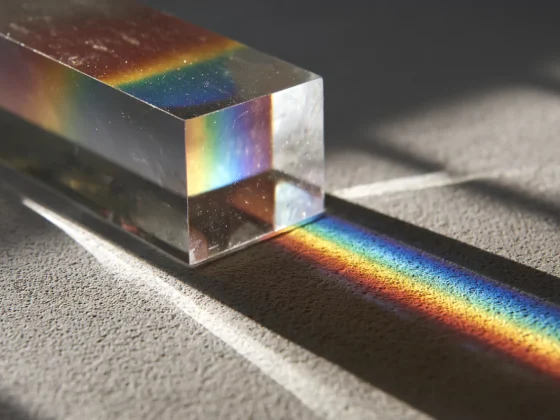

Optical Properties

TOQUARTZ® high-purity quartz offers exceptional transparency from UV to IR wavelengths, making it ideal for spectroscopy, photochemistry, and optical applications.

- Excellent UV-IR transmission (170-2500nm)

- Low autofluorescence for sensitive detection

- Consistent optical clarity batch-to-batch

TOQUARTZ® Comprehensive Quartz Labware Range

From standard parts to complex custom shapes, our quartz labware selection addresses the needs of scientific research, instrumentation, and industrial experimentation.

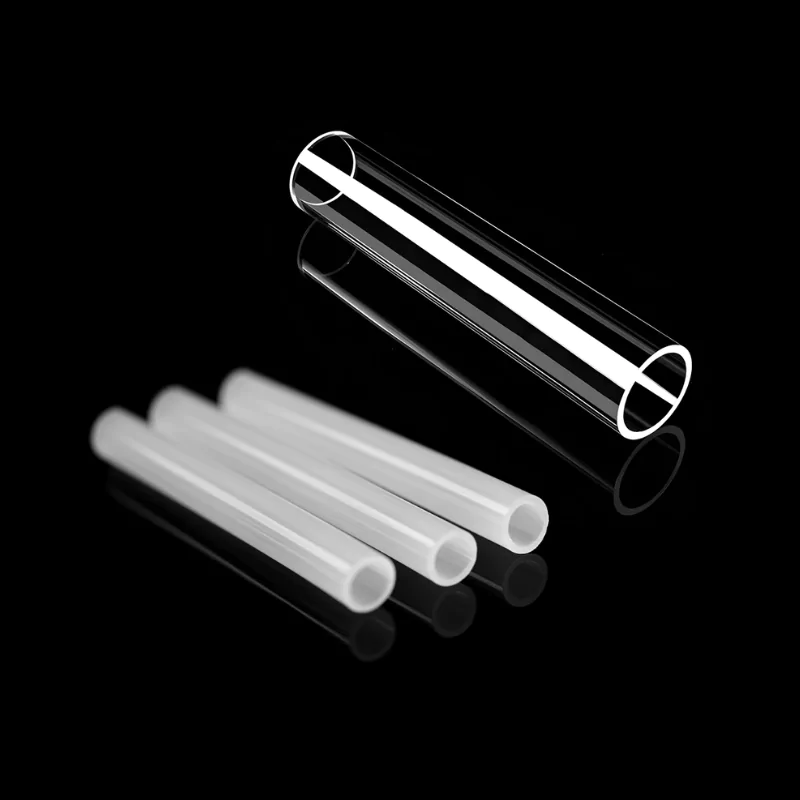

High-purity quartz tubes for high-temperature applications, including clear tubes, opaque tubes, U-shaped tubes, and specialized configurations.

Precision-crafted quartz cuvettes for spectrophotometry, offering superior optical clarity and durability for accurate analytical results.

High-temperature quartz crucibles for material processing, sample preparation, and thermal analysis in demanding laboratory environments.

Precision-cut quartz plates for optical windows, sample substrates, and specialized laboratory applications requiring optical clarity.

Laboratory-grade quartz beakers and flasks for high-temperature reactions, sample preparation, and corrosive media handling.

Specialized quartz components designed to your exact specifications, including reactors, boats, rods, and custom apparatus.

Applications of Quartz Labware in Laboratory Environments

Quartz labware plays a critical role in modern laboratories, supporting high-temperature reactions, chemical analysis, optical measurements, and custom equipment integration.

High Temperature Research Applications

Quartz labware excels in extreme thermal environments where standard glassware would fail, supporting critical high-temperature processes in research and industry.

- Material science furnace applications up to 1600°C

- Ceramic and metal alloy research using quartz crucibles

- High-temperature reaction vessels for materials synthesis

Analytical Chemistry & Spectroscopy

Quartz cuvettes and optical components support precise spectroscopic analysis from UV to IR wavelengths, delivering reliable results for critical analytical applications.

- UV-VIS spectrophotometry with quartz cuvettes

- Fluorescence analysis for biochemical applications

- Flow-through optical cells for continuous monitoring

Corrosive Media Processing

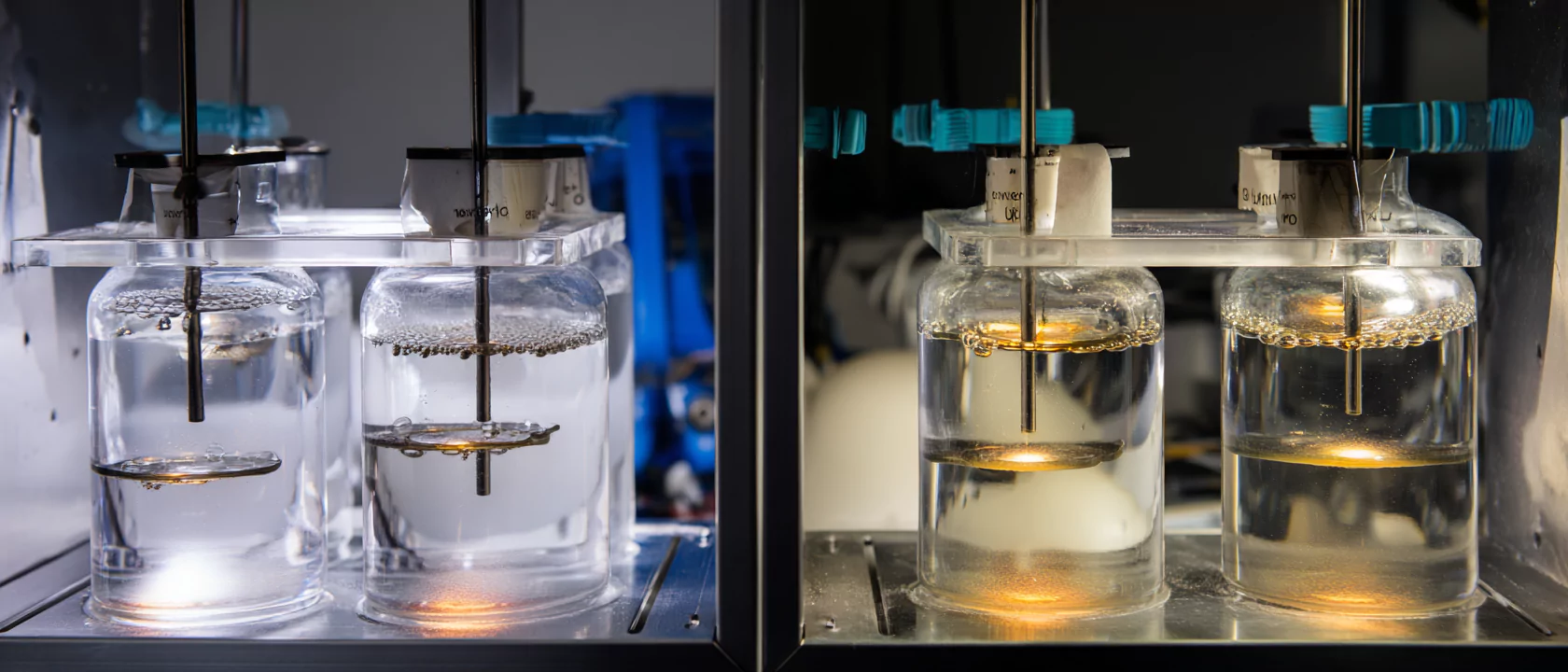

Quartz reaction vessels and containment systems provide exceptional resistance to acids, bases, and aggressive chemicals for safe handling of corrosive substances.

- Acid digestion procedures using quartz digestion tubes

- Alkali processing in quartz containers

- Hazardous chemical handling with quartz laboratory vessels

Advanced Research & Development

Custom quartz labware components support cutting-edge research across multiple fields, from materials science to biochemistry and environmental analysis.

- Custom quartz apparatus for specialized experiments

- Environmental trace analysis using quartz components

- Material processing and analysis using quartz boats

Custom Quartz Labware Engineering Solutions

TOQUARTZ® specializes in crafting precision quartz labware tailored to your exact specifications, from concept through production. Our engineering team works directly with you to ensure your custom components meet the demanding requirements of your research or industrial applications.

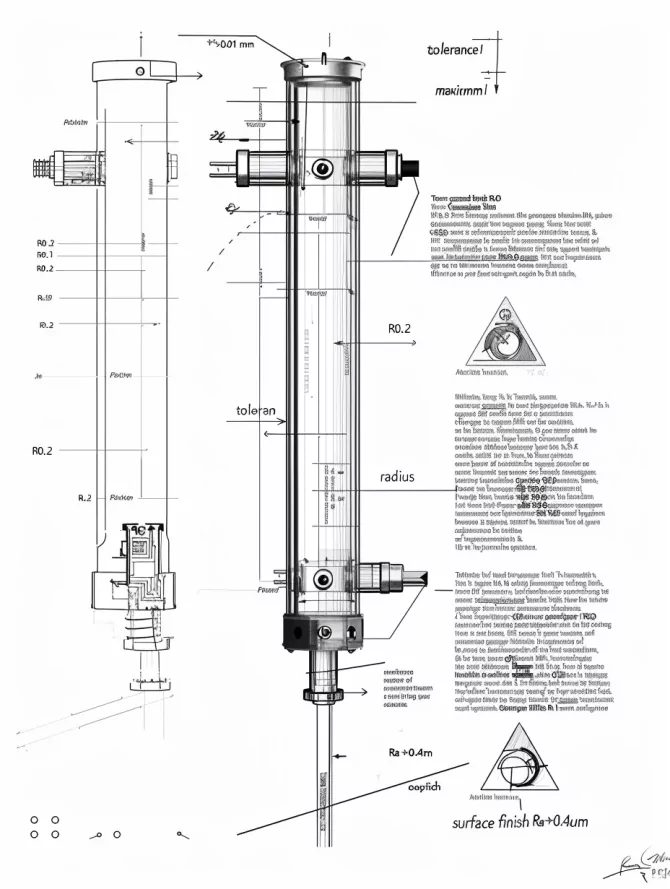

Technical Drawing Support

Our engineers assist with optimizing your designs for manufacturability while maintaining critical specifications and performance requirements.

Rapid Prototyping

Fast turnaround on custom prototypes allows you to test and validate designs quickly, accelerating your development timeline.

Precision Manufacturing

We achieve tight tolerances for your custom quartz components, with many products manufactured to ±0.1mm precision.

No MOQ Restriction

We accommodate smaller production runs, making custom quartz solutions accessible for specialized research needs and product development.

TOQUARTZ® Custom Design Process

Requirement Analysis

We collaborate with you to understand your specific needs, technical requirements, and application parameters.

Design & Engineering

Our engineers create or refine technical drawings, optimizing for both performance and manufacturability.

Prototype Development

We quickly produce prototype samples for your testing and validation, with rapid turnaround times.

Production & Quality Control

Following approval, we manufacture your custom quartz components with rigorous quality control at every step.

Delivery & Support

We ensure prompt delivery and provide ongoing technical support for your custom quartz components.

Quality Assurance for Our Quartz Labware

TOQUARTZ® implements rigorous quality control measures throughout our manufacturing process, ensuring that every piece of quartz labware meets the highest standards for purity, dimensional accuracy, and performance reliability.

ISO 9001 Certified Quality Management

TOQUARTZ® ISO 9001 certification demonstrates our commitment to consistent quality and continuous improvement in manufacturing processes and customer satisfaction.

- Documented procedures for consistent manufacturing

- Regular internal and third-party audits

- Continuous improvement methodology

REACH & RoHS Compliance

TOQUARTZ® quartz products comply with REACH and RoHS regulations, ensuring they’re free from restricted substances and safe for laboratory and industrial use.

- Free from hazardous substances

- Environmentally responsible manufacturing

- Compliant with international standards

TOQUARTZ® Quality Testing Procedures

Material Purity Testing

We verify SiO₂ content of 99.995%, ensuring exceptional purity for sensitive applications.

Dimensional Inspection

Precision measurements confirm tolerances of ±0.1mm to ±0.2mm for critical dimensions.

Performance Testing

We validate thermal resistance, chemical compatibility, and optical performance under real-world conditions.

FAQs About Quartz Labware

Q: What is the purity level of your quartz materials?

A: TOQUARTZ® standard quartz products are manufactured using high-purity fused silica with SiO₂ content of 99.995%. This exceptional purity level is suitable for most laboratory and industrial applications, including those requiring minimal contamination and high optical clarity.

Q: Do you provide technical assistance for custom quartz designs?

A: Yes, TOQUARTZ® engineering team provides comprehensive technical support for custom quartz components. We can work from your existing drawings or collaborate with you to develop new designs. Our expertise includes optimizing designs for manufacturability, suggesting material options, and addressing specific performance requirements.

Q: Can TOQUARTZ® fabricate quartz components based on custom drawings or physical samples?

A: Yes. We accept custom CAD drawings (STEP, PDF, DXF) or real samples for reverse engineering. Our engineers provide feedback on manufacturability, and often assist in optimizing designs for better performance or cost efficiency.

Q: How resistant is your quartz labware to heat and thermal shock?

A: All TOQUARTZ® products are made of fused silica with SiO₂ ≥ 99.995%, providing excellent thermal resistance. Products safely withstand continuous use at 1100°C and short-term exposure up to 1600°C, while maintaining structural integrity and low thermal expansion (coefficient of 5.5×10⁻⁷ /°C).

Q: Is your quartz glass resistant to acid and alkali corrosion?

A: Yes. Fused quartz is highly resistant to acids and bases, including HNO₃, HCl, NaOH and sulfuric acid environments. Only hydrofluoric acid (HF) and hot phosphoric acid (H₃PO₄) can etch quartz structure. This makes it ideal for chemical reaction vessels and digestion tubes.

Q: Do you offer quartz components suitable for UV or IR optical experiments?

A: Yes. TOQUARTZ® quartz cuvettes, plates and windows offer excellent transmission in UV (190–320nm) and IR (up to 2.5µm). They’re low-autofluorescence and made with optical-grade fused silica, making them suitable for spectrophotometric, fluorescence, infrared and Raman applications.