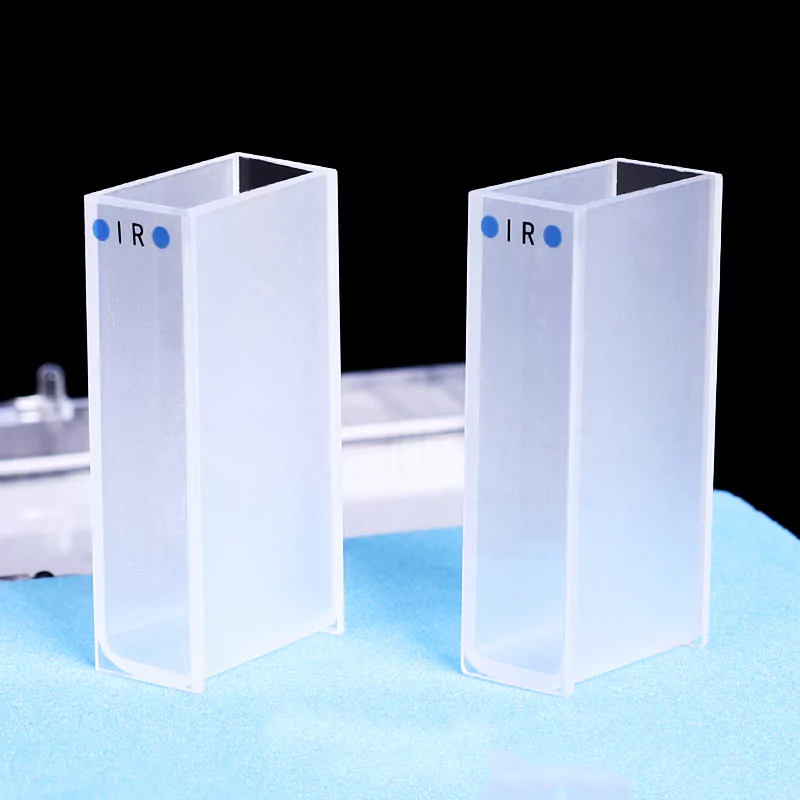

High-Transmission Quartz IR Cuvette For Spectroscopy & Process Monitoring Applications

TOQUARTZ® quartz IR cuvettes deliver unmatched IR transparency from 260–3500nm, ideal for FTIR, NIR, gas analysis, and chemical monitoring systems.

- 260–3500nm Full Spectrum Clarity

- ≥99.98% SiO₂ Material Verified

- Compatible With FTIR & NIR

TOQUARTZ® Fused Quartz IR Cuvette Product Range

TOQUARTZ® offers an extensive selection of quartz IR cuvettes designed to meet diverse analytical requirements. From standard to specialized fused quartz IR cuvette cells, our product line encompasses solutions for every spectroscopic application.

What Is a Quartz IR Cuvette?

A quartz IR cuvette is a specialized sample container made from high-purity quartz (silicon dioxide) designed specifically for infrared spectroscopy applications. These precision-engineered vessels allow infrared light to pass through samples with minimal interference, enabling accurate analysis of gases, liquids, and solutions across a wide spectral range (260nm-3500nm).

Key Properties of Quartz IR Cuvette Cell

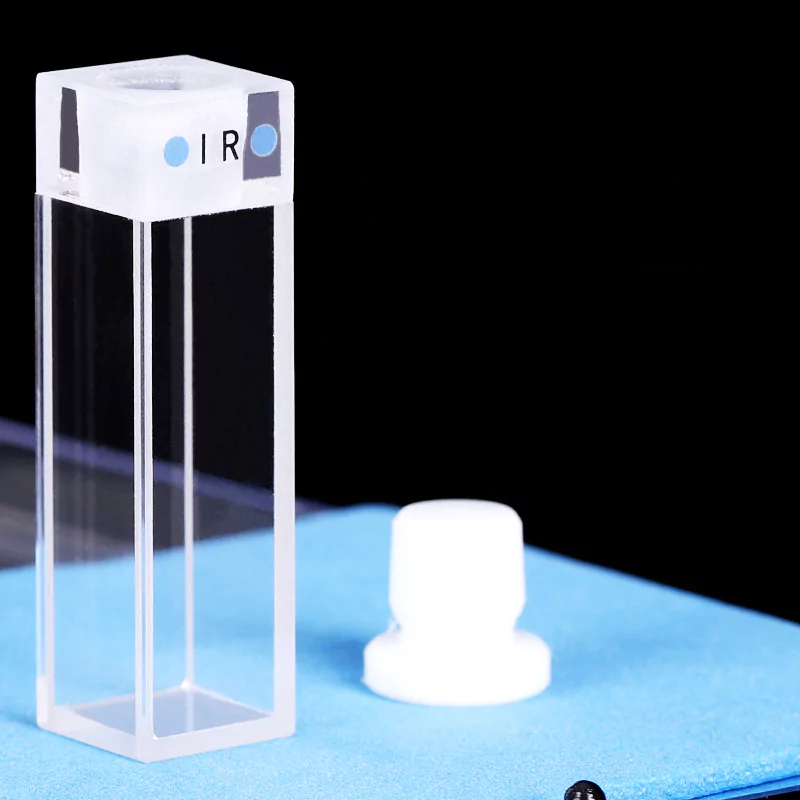

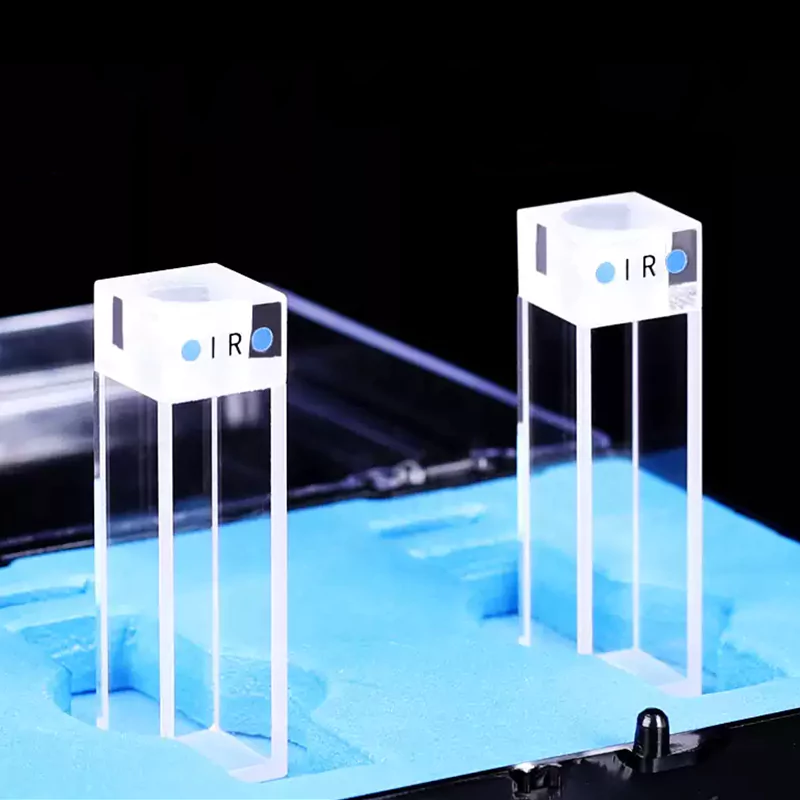

TOQUARTZ® comprehensive range of quartz IR cuvettes includes standard infrared cuvettes, micro IR cuvettes, sealed cuvettes with screw caps or stoppers, and custom-designed fused quartz IR cuvettes for specialized applications.

Material Properties

Quartz IR cuvettes are manufactured using ultra-pure fused silica, offering exceptional performance characteristics that make them ideal for demanding spectroscopic applications. Unlike standard glass cuvettes, fused quartz IR cuvettes provide superior transmission across a broader wavelength range with minimal absorption peaks.

- High purity (TOQUARTZ® offers 99.995% SiO₂ purity)

- Exceptional chemical resistance against acids, bases, and molten salts

- Superior thermal stability (withstands temperatures up to 1600°C)

- Excellent optical clarity with wide transmission range

- Low thermal expansion coefficient (5.5×10⁻⁷/°C)

Optical Performance

The optical performance of quartz IR cuvette cells is paramount for accurate spectroscopic analysis. IR fused quartz cuvettes from TOQUARTZ® deliver exceptional transparency across the 260nm-3500nm wavelength range with no absorption peaks, ensuring reliable data collection without material interference.

- High transmission across UV, visible, and IR spectra

- Minimal light scattering for clearer signals

- Polished surfaces (free from bubbles and scratches)

- Consistent path length for reproducible measurements

- Low autofluorescence for sensitive applications

TOQUARTZ® Fused Quartz IR Cuvette Applications

TOQUARTZ® quartz IR cuvette cells offer superior optical transmission across the 260-3500nm wavelength range. This exceptional performance makes TOQUARTZ® products ideal for FTIR spectroscopy, NIR analysis, environmental monitoring, and chemical process control applications.

Quartz IR Cuvette for Analytical Instrumentation (FTIR & NIR Analyzers)

TOQUARTZ® Quartz IR cuvettes serve as essential components in advanced analytical instruments, particularly in Fourier Transform Infrared (FTIR) and Near-Infrared (NIR) spectroscopy systems. Manufacturers of laboratory equipment rely on high-quality quartz glass IR cuvettes to ensure their instruments deliver accurate, reproducible results.

These IR fused silica cuvettes are integrated into:

- Benchtop and portable FTIR spectrometers

- Quality control analyzers for pharmaceutical applications

- Food composition analyzers

- Material identification and verification systems

- Educational and research-grade spectroscopy equipment

Fused Quartz IR Cuvette in Environmental Monitoring Applications

Environmental monitoring systems extensively utilize quartz IR cuvette cells for detecting and measuring pollutants, gas concentrations, and other environmental parameters. The exceptional chemical resistance of fused quartz IR cuvettes makes them ideal for analyzing corrosive or reactive samples without degradation.

Applications include:

- Air quality monitoring systems

- Industrial emission analyzers

- Water quality testing equipment

- Soil contamination detection instruments

- Greenhouse gas monitoring devices

Fused Silica IR Cuvette in Chemical Process Control Systems

In industrial settings, quartz IR cuvettes enable real-time monitoring and control of chemical processes. The thermal stability and chemical resistance of these quartz IR cuvette cells allow them to function reliably even in harsh production environments with corrosive chemicals or elevated temperatures.

Key implementations include:

- Inline process analyzers

- Reaction monitoring systems

- Quality assurance instruments

- Flow-through analysis cells

- High-temperature reaction vessels

Fused Quartz IR Cuvette Cell for Academic and Research Applications

Research institutions and university laboratories utilize quartz IR cuvettes for a wide range of scientific investigations. The versatility and customizability of quartz glass IR cuvettes make them suitable for specialized experiments requiring precise optical properties and chemical resistance.

Common research applications include:

- Novel material characterization

- Biological sample analysis

- Chemical reaction kinetics studies

- Custom spectroscopic setups

- Method development and validation

Quality Assurance for TOQUARTZ® Quartz IR Cuvette Cells

At TOQUARTZ®, we maintain rigorous quality control standards throughout the manufacturing process of our quartz IR cuvettes. Each quartz IR cuvette cell undergoes comprehensive testing to ensure compliance with international quality benchmarks.

ISO-Certified Processes

TOQUARTZ® manufacturing processes follow ISO standards, ensuring consistent quality and traceability for every quartz IR cuvette we produce.

REACH Compliance

All TOQUARTZ® fused quartz IR cuvettes comply with REACH regulations, ensuring they're free from harmful substances and safe for laboratory use.

RoHS Certification

TOQUARTZ® quartz IR cuvette cells meet RoHS standards, confirming they're manufactured without restricted hazardous substances.

TOQUARTZ Quality Control

AI-Powered Raw Material Vetting

Eliminate impurity risks in high-purity quartz sand (99.98% SiO₂ baseline, max. up to 99.995% )

Real-Time Process Optimization

Maintain precise dimensional tolerance during forming process

Multi-Axis Performance Validation

Ensure functionality under extreme operating conditions

Traceable Compliance Documentation

Guarantee material traceability for critical applications

Customer-Centric Quality Proofing

Align validation methods with client-specific operational demands

TOQUARTZ® Custom Manufacturing Capabilities and Services for

Quartz IR Cuvettes

TOQUARTZ® offers comprehensive support throughout the entire lifecycle of your quartz IR cuvette procurement, from initial design consultation to rapid delivery of finished products.

Engineering Support and Technical Consultation

TOQUARTZ® team of specialized engineers provides expert guidance for your quartz IR cuvette projects. We understand the critical optical and material requirements for spectroscopic applications and offer valuable technical input to optimize your fused quartz IR cuvette design.

Our technical support includes:

- Material selection assistance

- Design optimization for manufacturability

- Technical drawing review and refinement

- Prototype development and testing

- Performance validation against specifications

Precision Manufacturing

When timing is critical for your projects, TOQUARTZ® delivers quartz IR cuvette cells with industry-leading speed. Our streamlined production processes enable us to manufacture standard and custom fused quartz IR cuvettes with remarkably short lead times.

Our expedited services feature:

- 48-hour shipping for in-stock standard products

- Fast-track custom manufacturing (typically 1-2 weeks)

- Priority handling for urgent requirements

- Regular production updates

- Reliable delivery scheduling

TOQUARTZ® Delivers Quartz IR Cuvettes with No MOQ Requirements

TOQUARTZ® has revolutionized the procurement process for quartz IR cuvettes by eliminating minimum order constraints while maintaining exceptional quality standards for our quartz IR cuvette cells.

Efficient Manufacturing Processes

Our ability to supply high-quality quartz IR cuvettes without minimum order requirements stems from our optimized manufacturing processes. By implementing lean production methods and maintaining versatile manufacturing capabilities, TOQUARTZ® achieves economies of scale that benefit all order sizes.

Key advantages include:

- Flexible production lines capable of quick changeovers

- Standardized core processes with customizable finishing

- Efficient material utilization minimizing waste

- Strategic inventory management of base materials

- Vertically integrated manufacturing reducing dependencies

Direct Factory Supply Chain

As a direct manufacturer of quartz IR cuvette cells, TOQUARTZ® eliminates intermediaries from the supply chain, allowing us to offer factory-direct pricing and flexibility on fused quartz IR cuvettes regardless of order volume.

Our direct supply model provides:

- Elimination of distributor minimum order requirements

- Cost savings passed directly to customers

- Simplified communication between end-users and manufacturers

- Faster response to technical queries

- Greater flexibility in order specifications

Fused Quartz IR Cuvette Manufacturing Process丨TOQUARTZ

Precision Customization — No MOQ + Rapid Prototyping

Cross-Industry Solutions — Optics R&D + Chemical Labs

Innovative Manufacturing — High Accuracy + Bulk Accessibility

Why Choose TOQUARTZ® for Your Quartz IR Cuvette Needs

When selecting a supplier for precision quartz IR cuvettes, reliability and quality are paramount. TOQUARTZ® combines manufacturing excellence with responsive service to deliver superior fused quartz IR cuvettes that meet your exact specifications.

Custom Solutions Tailored to Your Specifications

TOQUARTZ® specializes in creating bespoke quartz IR cuvette solutions designed specifically for your application requirements. Our engineering team works directly with you to develop custom quartz IR cuvettes that perfectly match your technical specifications. Our customization capabilities include:

- Custom dimensions and wall thickness

- Specialized optical path lengths

- Various sealing options (screw caps, stoppers)

- Custom polishing and surface treatments

- Special shape configurations for unique applications

No Minimum Order Quantity Restrictions

Unlike many manufacturers who impose significant minimum order quantities, TOQUARTZ® provides flexible ordering options for quartz IR cuvettes. Whether you need a single specialized quartz glass IR cuvette for research or bulk quantities for production, we accommodate orders of any size without compromise on quality. Benefits include:

- Sample orders for testing and evaluation

- Small batch production for specialized applications

- Scalable ordering as your needs grow

- Cost-effective solutions for research projects

- Reduced inventory costs for specialized components

FAQs

Q: What is a quartz IR cuvette and how does it differ from standard glass cuvettes?

A: A quartz IR cuvette is a specialized sample container made from high-purity fused silica (SiO₂) designed specifically for infrared spectroscopy. Unlike standard glass cuvettes, quartz IR cuvettes offer superior transmission in the IR spectrum (260-3500nm), higher temperature resistance (up to 1600°C), and exceptional chemical resistance to acids, bases, and solvents.

Q: Why do you need a quartz IR cuvette for infrared spectroscopy applications?

A: Quartz IR cuvettes are essential for infrared spectroscopy because they provide minimal interference with IR radiation, allowing for accurate sample analysis. Standard glass absorbs significant portions of IR radiation, which can mask important sample signals. Quartz’s exceptional transparency in the IR range, chemical resistance, and thermal stability make it the optimal material for reliable spectroscopic measurements.

Q: What wavelength range do TOQUARTZ® quartz IR cuvettes cover?

A: TOQUARTZ® quartz IR cuvettes provide excellent transmission across the 260nm-3500nm wavelength range, covering ultraviolet, visible, and infrared regions. This broad spectral range makes them versatile for various analytical applications, from UV-Vis spectroscopy to mid-IR analysis, with minimal absorption peaks throughout the range.

Q: How to use quartz IR cuvette properly to maximize measurement accuracy?

A: To maximize measurement accuracy with quartz IR cuvettes: (1) Clean thoroughly between uses with appropriate solvents and allow to dry completely; (2) Handle only by non-optical surfaces to prevent fingerprints; (3) Ensure proper orientation with the optical path perpendicular to the light beam; (4) Calibrate your instrument with the same cuvette used for samples; (5) Store in a dust-free environment to maintain optical clarity.

Q: What is the difference between quartz glass IR cuvette and fused quartz IR cuvette?

A: Though often used interchangeably, there are subtle differences: “Fused quartz” typically refers to cuvettes made from naturally occurring quartz crystals melted at high temperatures, resulting in 99.995% pure SiO₂ with minimal hydroxyl content and excellent IR transmission. “Quartz glass” sometimes refers to synthetic fused silica made from silicon compounds. TOQUARTZ® products are high-purity fused quartz with exceptional optical and thermal properties.

Contact TOQUARTZ® Today for Your Quartz IR Cuvette Requirements

Ready to discuss your quartz IR cuvette needs? Our technical team is available to provide expert guidance and quotations for your specific requirements.

- Direct factory pricing with no intermediaries

- Expert engineering support for custom designs

- No minimum order quantity requirements

- Fast delivery with 24-hour shipping for stock items

- Comprehensive supply chain management services