- Home

- /

- Types

- /

- Quartz Plate

- /

- Quartz Heating Element for...

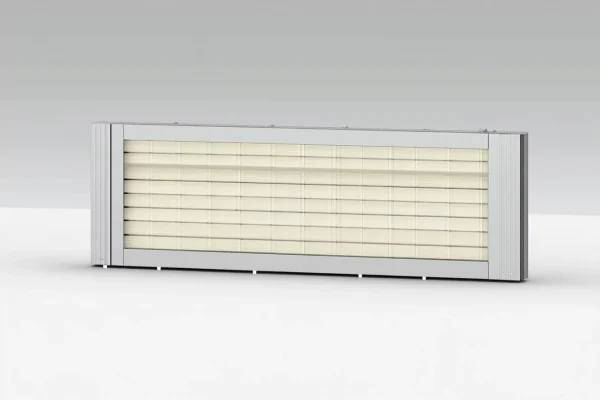

Quartz Heating Element for Industrial Applications -TOQUARTZ®

Key Features of Quartz Heating Element

TOQUARTZ® quartz heating elements combine exceptional thermal properties with superior durability, making them ideal for precision heating applications across laboratory, medical, and industrial environments.

Rapid Thermal Response

Reaches operating temperature within 1 minute, with high thermal conductivity (120-160 W/m.K) for efficient and uniform heat distribution.

High Temperature Resistance

Withstands extreme temperatures up to 1600°C, making it ideal for high-temperature industrial processes.

Excellent Electrical Insulation

Provides dielectric strength ≥40kV/mm, ensuring safe operation in electrical heating applications while maintaining thermal efficiency.

Superior Corrosion Resistance

Highly resistant to acids, alkalis, molten salts, and fluorinated gases, ensuring longevity in harsh chemical environments.

- thermal conductivity 120-160 W/m.K

- Withstands temperatures of 1600°C

- dielectric strength ≥40kV/mm

Technical Specifications & Dimensions of Quartz Heating Element

| Model | Dimensions (mm) | Power Range (W) | Wavelength Range (μm) | Average Weight (g) | Average Lifespan |

| AT-SY-J001 | 247×22.5×62.5 | 150 – 1000W | 1.5 – 8μm | 403g | 10,000 hours |

| AT-SY-J002 | 123.5×22.5×62.5 | 150 – 500W | 1.5 – 8μm | 210g | 10,000 hours |

| AT-SY-J003 | 247×62.5×59 | 150 – 1000W | 1.5 – 8μm | 403g | 10,000 hours |

| AT-SY-J004 | 123.5×62.5×59 | 125 – 500W | 1.5 – 8μm | 268g | 10,000 hours |

| Technical Parameters | |

| Rated Voltage (V) | 380, 220, 110, 55 (Standard: 220V) |

| Heating Power (W) | 300-1000 (Standard: 325, 400, 500, 650, 800, 1000) |

| Thermal Response | Within 1 minute |

| Installation Type | Plug-in, typically non-stainless steel imported material |

| Surface Temperature (°C) | Low: 100-460°C, Medium: 500-580°C, High: 700-1100°C |

| Spectral Range (μm) | 2.5-6 |

| Spectral Emissivity | 0.92 (at wavelengths 4-8μm; 11-25μm) |

| Thermal Conductivity | 120-160 W/m.K |

| Thermal Expansion Coefficient | 1.1×10⁻⁶/K |

TOQUARTZ® Solving Critical Challenges with Quartz Heating Elements

Quartz Heating Elements for Laboratory Equipment Manufacturing

Traditional ceramic heating elements often suffer from uneven heating, slow response times, and limited temperature ranges, compromising experimental results and equipment reliability.

Key Advantages

- Precision temperature uniformity (±2°C across surface)

- Ultra-fast heating response (60 seconds to operating temperature)

- High-purity material (max. 99.995% SiO₂) prevents sample contamination

- Compatible with analytical instruments requiring stable thermal platforms

TOQUARTZ® solution

A German laboratory equipment manufacturer reported inconsistent results with their thermal analysis instruments due to temperature fluctuations.

TOQUARTZ provided custom quartz heating elements with ±0.2mm dimensional precision and superior thermal uniformity, reducing their calibration issues by 87% and extending equipment service intervals by 40%.

Quartz Heating Elements for Medical Device Sterilization Systems

Traditional heating technologies often struggle with maintaining precise sterilization temperatures, resulting in incomplete sterilization or damaged medical instruments.

Key Advantages

- Stable sterilization temperature control at ±2°C over 8-hour cycles

- Ultra-clean quartz surface with <0.03% impurity content ensures zero biological contamination

- Resistance to repeated exposure to hydrogen peroxide plasma and formaldehyde gas

TOQUARTZ® solution

A Japanese medical device manufacturer struggled with inconsistent heating in their sterilization equipment, resulting in an 18% rejection rate.

TOQUARTZ engineered custom quartz heating elements with precise ±0.15mm thickness tolerance, ensuring perfect contact with heating elements. This solution reduced their rejection rate to under 2% and improved energy efficiency by 22%.

Quartz Heating Elements for Industrial Drying Systems

Conventional heating elements frequently develop hotspots, crack under thermal stress, or fail prematurely in continuous operation, causing costly production downtime.

Key Advantages

- 24/7 sustained operation up to 72 hours without thermal fatigue

- Surface temperature uniformity deviation <5°C over 300mm range

- Zero-crack performance during 50 rapid heating/cooling cycles (ΔT 600°C)

TOQUARTZ® solution

An American manufacturer of industrial drying equipment faced recurring failures with their heating elements, with cracks developing after just 5 days of continuous operation.

TOQUARTZ provided high thermal conductivity quartz heating elements with enhanced thermal shock resistance, extending operational life to over 10,000 hours and eliminating unplanned downtime that had previously cost $8,500 per incident.

Customization Services for TOQUARTZ® Quartz Heating Element

- Dimensional Customization

Custom sizes, thicknesses, and shapes to fit your specific equipment requirements.

- Surface Treatment Options

Specialized surface finishes including polishing, etching, or coating to enhance optical properties, thermal performance, or chemical resistance.

- Performance Optimization

Tailored thermal properties, wavelength emission characteristics, and power handling capabilities to match your specific application requirements.

- Custom Mounting Solutions

Specialized mounting features, connection points, or integration elements designed to seamlessly fit into your existing equipment or systems.

- Electrical Configuration

Custom voltage, power ratings, and connection types to match your specific power supply and control systems for optimal performance.

- Small Batch Production

Flexible manufacturing capabilities allowing for small production runs of custom designs, ideal for specialized equipment or prototype development.

- TOQUARTZ® Customization Process

Technical Consultation

TOQUARTZ® engineers discuss your application requirements, operating conditions, and performance expectations to understand your needs.

Design & Prototyping

We develop detailed specifications and create prototypes for testing and validation in your specific application environment.

Production & Quality Control

Following approval, we manufacture your custom quartz heating plates with rigorous quality control to ensure consistent performance.

Delivery & Support

We provide fast delivery with comprehensive documentation and ongoing technical support for your custom products.

Usage Guide for Quartz Heating Element

Installation Recommendations

- Ensure mounting surfaces are clean, flat, and free of debris

- Use appropriate thermal interface materials when necessary

- Maintain recommended clearances for proper ventilation

- Verify electrical connections are secure and properly insulated

Troubleshooting Tips

- If uneven heating occurs, check for proper mounting and contact

- For slow heating response, verify power supply and connections

- If discoloration appears, check operating temperature ranges

- Contact our technical support for persistent performance issues

Operation Best Practices

- Gradually increase power during initial heating cycles

- Avoid thermal shock by preventing rapid cooling with liquids

- Operate within specified voltage and power ratings

- Use appropriate temperature controllers for precise regulation

Maintenance & Storage

- Clean only when fully cooled using appropriate non-abrasive methods

- Inspect regularly for cracks, discoloration, or connection issues

- Store in dry, clean environment with protective packaging

- Avoid stacking heavy items on plates during storage

Ready to optimize your heating system?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What makes quartz heating plates superior to ceramic alternatives?

A: Quartz heating plates offer several advantages over ceramic options, including faster thermal response (60 seconds vs. 3-5 minutes), higher temperature capability (up to 1600°C vs. typically 800-1000°C for ceramics), superior thermal shock resistance, and better chemical inertness. These properties result in longer service life and more consistent performance in demanding applications.

Q: How do I determine the right power rating for my application?

A: Power requirements depend on several factors including the target temperature, heating rate, thermal mass of the heated object, insulation, and ambient conditions. Our engineering team can help calculate the optimal power rating based on your specific application parameters. As a general guideline, laboratory applications typically require 300-500W, while industrial processes may need 650-1000W.

Q: What is the maximum operating temperature for your quartz heating plates?

A: TOQUARTZ® standard quartz heating plates can operate continuously at temperatures up to 1100°C and can withstand short-term exposure to temperatures up to 1600°C. The specific maximum operating temperature depends on the model, power rating, and application environment. We offer low-temperature (100-460°C), medium-temperature (500-580°C), and high-temperature (700-1100°C) variants to match your requirements.

Q: Are your quartz heating plates compatible with vacuum environments?

A: Yes, TOQUARTZ® quartz heating plates are suitable for vacuum applications up to 10⁻⁶ Torr. For high-vacuum or ultra-high-vacuum applications, we offer specially prepared plates with minimal outgassing characteristics. Please specify vacuum requirements when ordering to ensure proper material selection and processing.

Q: Can you provide integrated temperature control systems with your heating plates?

A: Yes, we offer complete heating solutions including temperature controllers, power supplies, and mounting hardware. Our integrated systems can be configured with PID controllers for precise temperature regulation, programmable ramp/soak profiles, and digital interfaces for computer control. Please specify your control requirements when requesting a quote.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.