Engineers face critical material selection decisions daily. Wrong glass choices lead to equipment failure and costly downtime. Understanding quartz glass versus ordinary glass differences ensures optimal performance.

Quartz glass offers superior temperature resistance, UV transmission, and chemical inertness compared to ordinary glass, making it essential for high-performance applications in laboratory instruments, industrial heating systems, and optical equipment where standard glass cannot meet demanding operational requirements.

This comprehensive analysis examines the fundamental differences between these materials, helping you make informed procurement decisions for your specific applications.

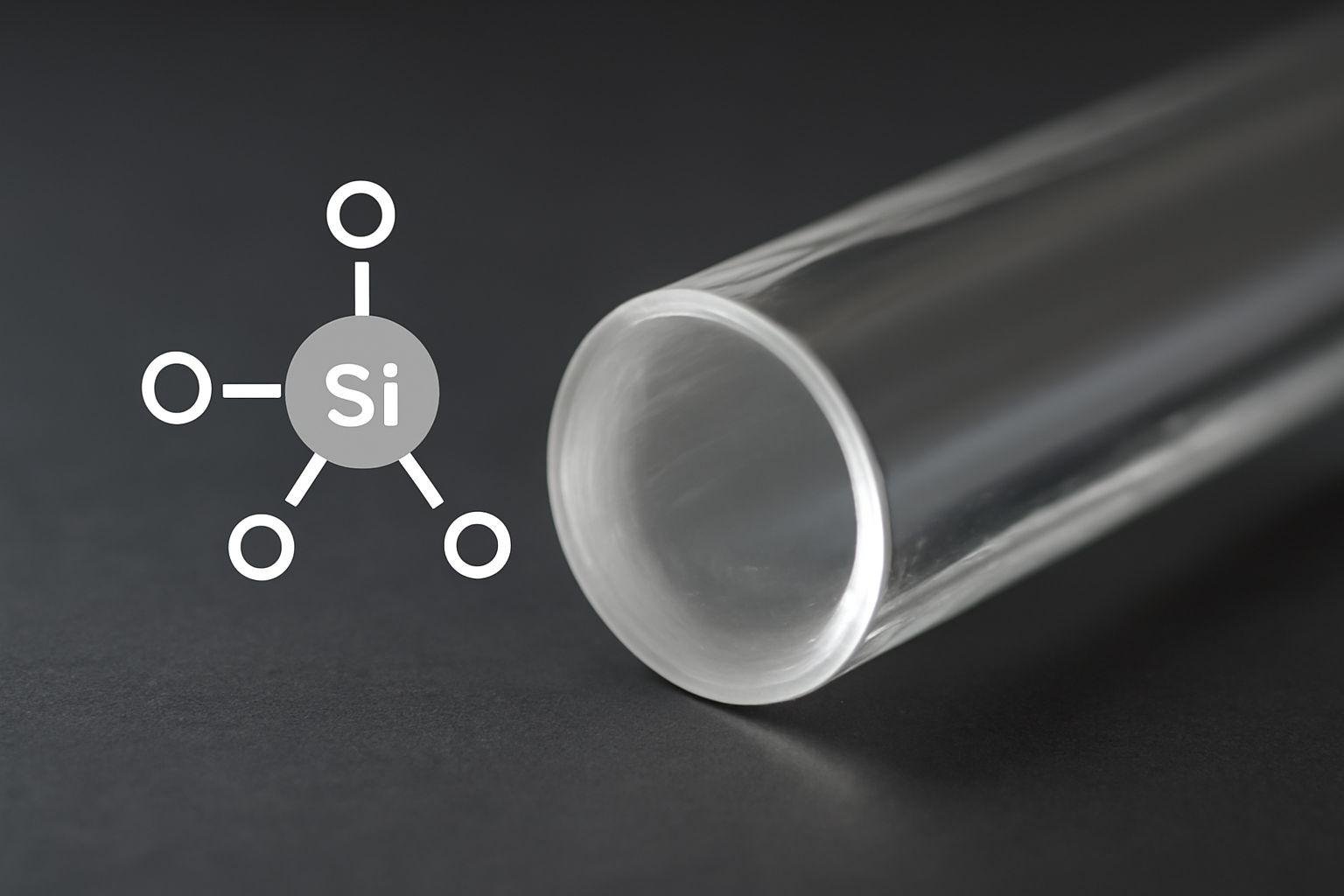

What Makes Quartz Glass Unique in Composition?

Material composition determines performance capabilities. Standard glass limitations become apparent under demanding conditions. Quartz glass provides unmatched purity for critical applications.

Quartz glass consists of 99.99% pure silica (SiO₂), while ordinary glass contains multiple oxides including sodium, calcium, and boron, resulting in fundamentally different thermal, optical, and chemical properties.

The manufacturing process involves melting high-purity silica sand at temperatures exceeding 2000°C, creating an amorphous structure with minimal impurities. This contrasts sharply with ordinary glass production, which intentionally incorporates flux materials like sodium carbonate to lower melting temperatures and reduce manufacturing costs.

Ordinary glass typically contains 70-75% silica mixed with sodium oxide, calcium oxide, and other additives that modify properties but introduce thermal stress points. These compositional differences directly impact performance in demanding environments.

Composition Comparison

| Glass Type | SiO₂ Content | Na₂O Content | Other Oxides | Purity Level |

|---|---|---|---|---|

| Quartz Glass | 99.99% | 0% | <0.01% | Ultra-high |

| Borosilicate | 80-85% | 2-5% | 10-15% | High |

| Soda-lime | 70-75% | 12-16% | 10-18% | Standard |

| Float Glass | 72-75% | 13-15% | 10-15% | Commercial |

What is the difference in thermal expansion coefficient between ordinary glass and quartz glass?

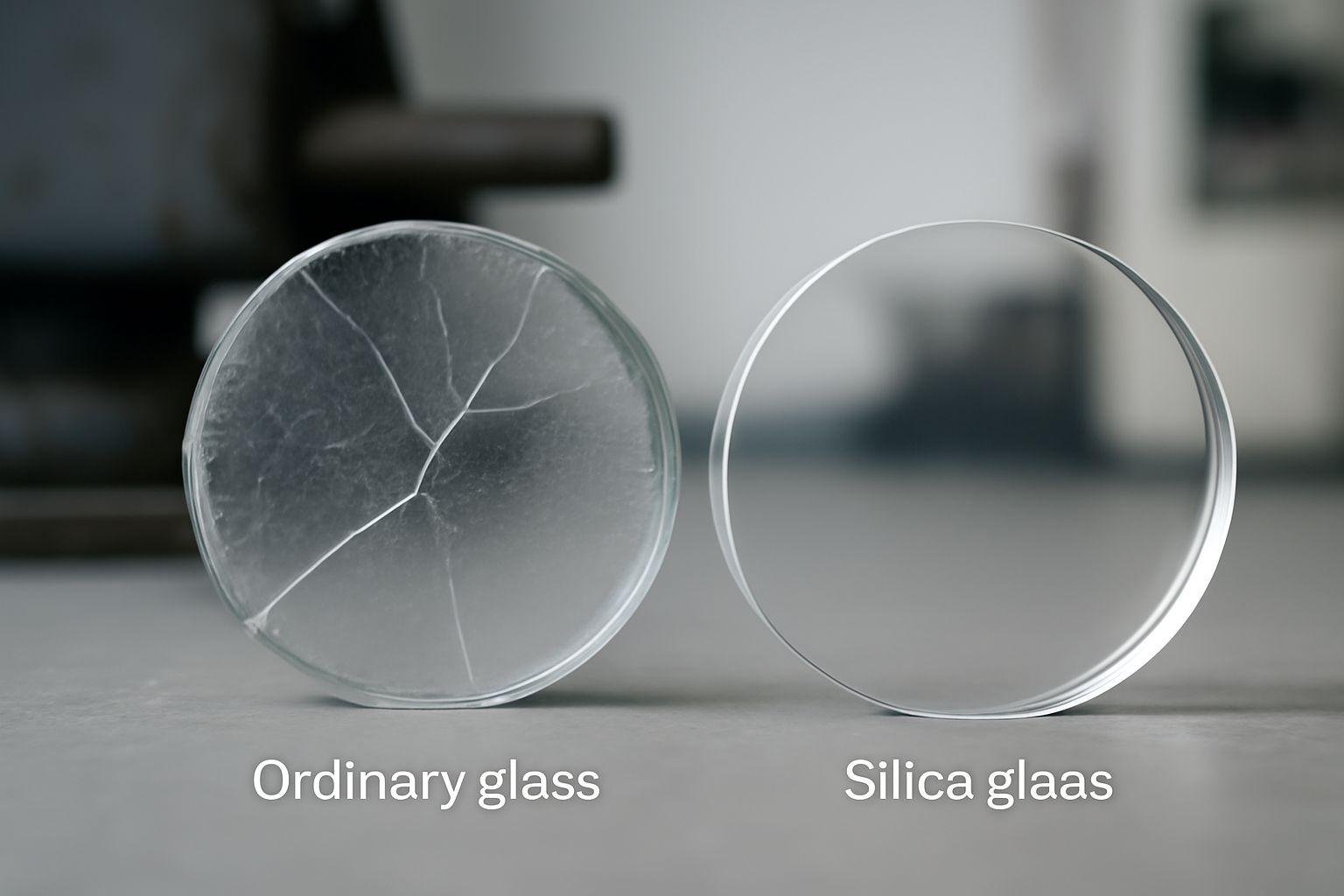

Traditional glass formulations prioritize manufacturability over performance. Thermal expansion mismatches cause frequent failures. Silica glass eliminates these fundamental limitations through superior material properties.

Ordinary glass exhibits thermal expansion coefficients 10-20 times higher than silica glass, while containing impurities that limit maximum operating temperatures to 500°C compared to silica glass's 1200°C capability.

The coefficient of thermal expansion for ordinary glass ranges from 80-100 × 10⁻⁷/°C, creating significant stress during temperature cycling. This fundamental property difference explains why ordinary glass cracks under rapid heating or cooling, while silica glass maintains structural integrity.

Manufacturing techniques also differ substantially. Ordinary glass uses batch melting with recycled cullet, introducing potential contaminants. Silica glass requires specialized high-temperature furnaces and controlled atmospheres, ensuring consistent purity levels essential for demanding applications.

Performance Comparison

| Property | Ordinary Glass | Silica Glass | Performance Ratio |

|---|---|---|---|

| Max Temperature | 500°C | 1200°C | 2.4x higher |

| Thermal Expansion | 90×10⁻⁷/°C | 5.5×10⁻⁷/°C | 16x lower |

| Thermal Shock Resistance | Poor | Excellent | Superior |

| UV Transmission | <10% | >90% | 9x better |

Which Glass Offers Better High Temperature Performance?

Temperature stability determines equipment reliability. Ordinary glass fails catastrophically under thermal stress. Quartz glass maintains structural integrity across extreme temperature ranges.

Quartz glass operates continuously at 1000°C and withstands thermal shock up to 1200°C, while ordinary glass softens at 600°C and experiences thermal stress failure above 300°C temperature differentials.

The superior thermal shock resistance of quartz glass stems from its ultra-low thermal expansion coefficient and high thermal conductivity. Industrial heating applications routinely subject components to rapid temperature changes that would shatter ordinary glass within minutes.

My experience with furnace manufacturers confirms that quartz glass tubes maintain dimensional stability even during emergency cooling procedures. Ordinary glass components require gradual temperature ramping and controlled cooling cycles, limiting process flexibility and increasing operational complexity.

Temperature Performance Data

| Temperature Range | Ordinary Glass | Quartz Glass | Advantage |

|---|---|---|---|

| Continuous Use | 450°C | 1000°C | 2.2x higher |

| Peak Temperature | 600°C | 1200°C | 2x higher |

| Thermal Shock | 150°C ΔT | 1000°C ΔT | 6.7x better |

| Annealing Point | 510°C | 1215°C | 2.4x higher |

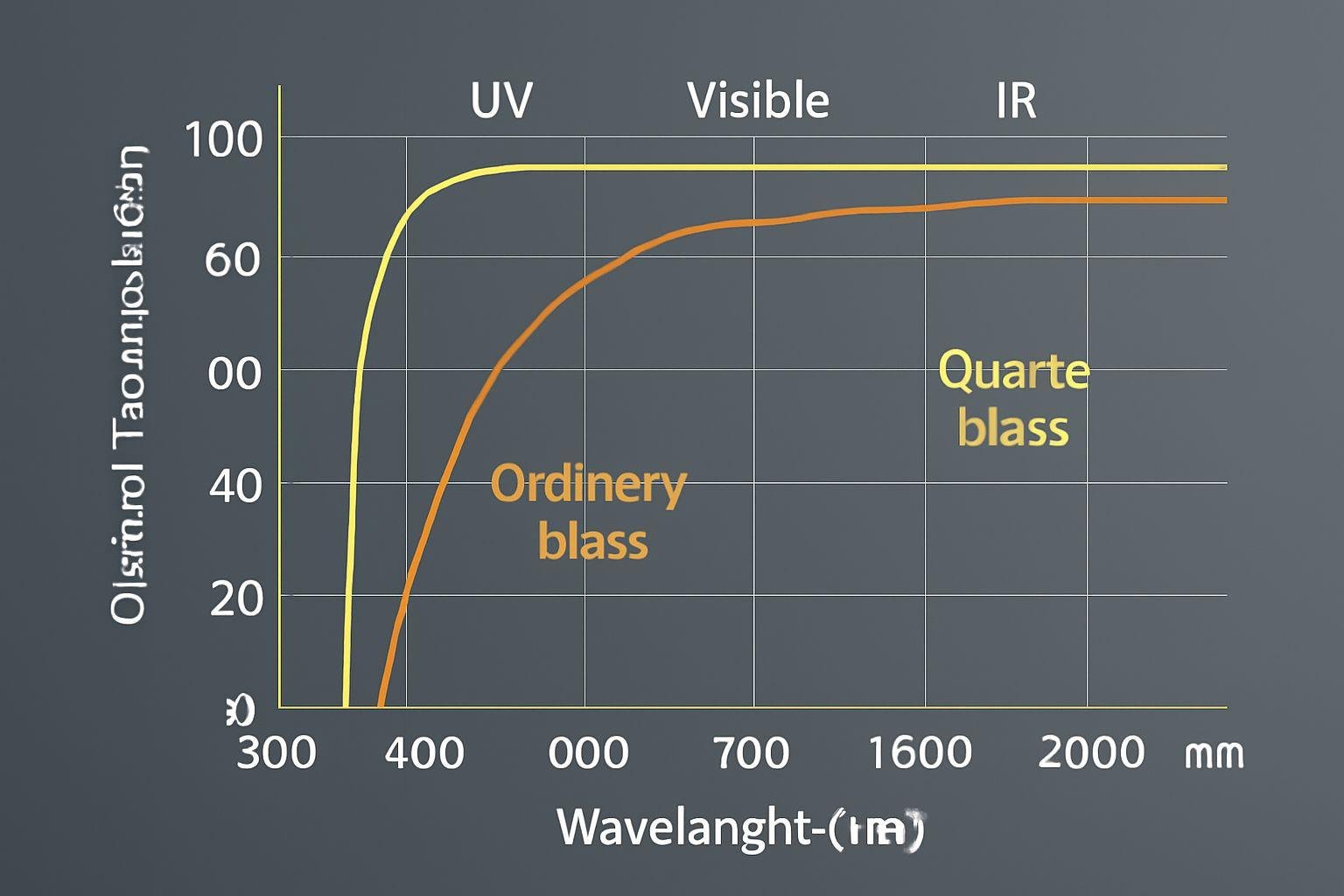

What Are the Optical Transmission Property Differences?

Optical clarity determines instrument accuracy. Standard glass blocks critical wavelengths. Quartz glass enables full spectrum transmission for precise measurements.

Quartz glass transmits over 90% of light from 200nm to 2500nm wavelengths, while ordinary glass blocks UV radiation below 320nm and shows reduced transmission above 2000nm, limiting analytical and optical applications.

How Does UV Transmission Compare Between Glass Types?

UV applications require specialized materials. Ordinary glass absorbs harmful radiation, limiting functionality. Quartz glass enables complete UV spectrum utilization.

Laboratory UV sterilization systems depend on transparent materials that won't degrade under constant exposure. Ordinary glass containing iron oxide and other transition metals absorbs UV radiation, reducing sterilization effectiveness and requiring frequent replacement.

Which Glass Provides Better Infrared Transparency?

Infrared heating demands efficient energy transfer. Glass composition affects thermal radiation transmission. Material selection directly impacts heating efficiency and energy consumption.

Quartz glass maintains excellent IR transmission up to 3500nm wavelength, enabling efficient radiant heating applications. Industrial heating elements using quartz tubes achieve 30-40% higher energy efficiency compared to metal-enclosed systems, reducing operational costs significantly.

Optical Properties Comparison

| Wavelength Range | Ordinary Glass | Quartz Glass | Application Impact |

|---|---|---|---|

| UV-C (200-280nm) | 0% | >85% | Sterilization systems |

| UV-B (280-320nm) | <5% | >90% | Phototherapy equipment |

| Visible (380-750nm) | >90% | >92% | Optical instruments |

| Near-IR (750-2500nm) | 80-85% | >90% | Heating applications |

How Do Chemical Resistance Properties Compare?

Chemical compatibility prevents contamination. Ordinary glass reacts with acids and alkalis. Quartz glass provides inert performance across pH ranges.

Quartz glass exhibits exceptional resistance to acids, alkalis, and organic solvents with minimal leaching, while ordinary glass dissolves in hydrofluoric acid and shows significant alkali attack above pH 9, causing contamination in analytical applications.

The chemical inertness of quartz glass makes it essential for pharmaceutical and semiconductor applications where contamination must be eliminated. Ordinary glass releases sodium and calcium ions that interfere with sensitive analytical measurements and compromise product purity.

Laboratory glassware manufacturers specify quartz components for trace analysis work because ordinary glass contributes measurable contamination levels. This becomes critical in environmental testing, pharmaceutical development, and materials research where detection limits approach parts-per-billion levels.

Chemical Resistance Data

| Chemical Environment | Ordinary Glass | Quartz Glass | Resistance Rating |

|---|---|---|---|

| Strong Acids (pH 1-2) | Moderate | Excellent | 5x better |

| Strong Alkalis (pH 12-14) | Poor | Good | 10x better |

| Organic Solvents | Good | Excellent | 2x better |

| High Temperature Acids | Poor | Excellent | Superior |

Which Applications Favor Quartz Glass Over Ordinary Glass?

Application requirements determine material selection. Performance demands guide engineering choices. Understanding specific advantages enables optimal component specification.

Laboratory analytical instruments, UV sterilization systems, and high-temperature industrial processes require quartz glass properties that ordinary glass cannot provide, including UV transparency, thermal shock resistance, and chemical inertness.

When Do Laboratory Applications Require Quartz Glass?

Analytical precision demands material purity. Contamination affects measurement accuracy. Quartz glass eliminates interference sources in critical applications.

Spectrophotometry requires transparent cuvettes that don't absorb target wavelengths or contribute background signals. Laboratory managers consistently choose quartz cuvettes for UV-visible analysis because ordinary glass creates measurement errors and requires frequent calibration corrections.

Why Do Industrial Heating Systems Choose Quartz Glass?

Energy efficiency drives material selection. Thermal performance affects operational costs. Quartz glass enables superior heat transfer and process control.

Industrial furnace manufacturers specify quartz tubes for radiant heating elements because the material withstands rapid temperature cycling without degradation. Manufacturing processes requiring precise temperature control benefit from quartz glass's predictable thermal properties and long service life.

Which Optical Instruments Need Quartz Glass Components?

Optical clarity determines instrument performance. Wavelength transmission affects measurement capability. Quartz glass enables full spectrum analysis across UV, visible, and IR ranges.

High-end microscopy and laser systems incorporate quartz windows and lenses because ordinary glass introduces optical aberrations and limits wavelength range. Research instruments requiring UV fluorescence detection specifically demand quartz components for reliable operation.

When Should You Choose Ordinary Glass Instead?

Cost considerations influence material selection. Application requirements determine necessity. Understanding limitations guides appropriate choices for budget-sensitive projects.

Ordinary glass suits applications below 400°C with visible light requirements and moderate chemical exposure, offering significant cost savings where quartz glass's premium properties aren't essential for performance.

Decorative lighting, architectural glazing, and general laboratory containers perform adequately with ordinary glass when extreme conditions aren't present. The 5-10x cost difference makes ordinary glass attractive for high-volume applications with moderate performance requirements.

How Do Manufacturing Costs and Pricing Compare?

Economic factors affect procurement decisions. Material costs impact project budgets. Understanding price structures enables informed supplier selection and specification optimization.

Quartz glass typically costs 5-15 times more than ordinary glass due to high-purity raw materials, specialized manufacturing equipment, and energy-intensive production processes requiring temperatures above 2000°C.

Production complexity drives pricing differences significantly. Quartz glass manufacturing requires specialized electric arc furnaces and controlled atmospheres, while ordinary glass uses conventional batch furnaces with lower energy requirements. Raw material costs also vary substantially, with high-purity silica commanding premium prices compared to standard sand and flux materials.

Custom manufacturing adds additional complexity, particularly for precision-machined components requiring tight tolerances. However, the longer service life and superior performance often justify higher initial costs through reduced replacement frequency and improved process reliability.

Cost Comparison Analysis

| Cost Factor | Ordinary Glass | Quartz Glass | Price Ratio |

|---|---|---|---|

| Raw Materials | $0.50/kg | $8.00/kg | 16x higher |

| Manufacturing Energy | $2.00/kg | $15.00/kg | 7.5x higher |

| Finished Components | $5-20/piece | $50-300/piece | 10-15x higher |

| Total Lifecycle Cost | Higher replacement | Lower replacement | Varies by application |

Conclusion

Quartz glass provides superior performance for demanding applications requiring high temperature resistance, UV transmission, and chemical inertness, while ordinary glass offers cost-effective solutions for moderate-performance requirements. Material selection depends on balancing performance requirements against budget constraints for optimal procurement decisions. Understanding these fundamental differences ensures appropriate glass specification for your specific application needs.