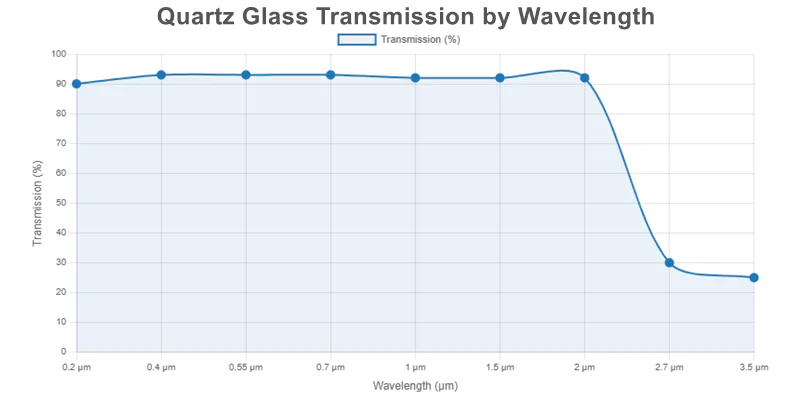

Quartz glass transmission is the percentage of light passing through quartz glass at specific wavelengths. For optical design, understanding these properties ensures optimal efficiency and precise material selection.

Engineers and designers must consider not only the transmission values but also the underlying physical mechanisms, application-specific requirements, and procurement factors. The following guide provides a structured approach to mastering quartz glass transmission for advanced optical applications.

What Is Quartz Glass Transmission and Why Is It Critical for Optical Applications?

Quartz glass transmission defines how much light at a given wavelength passes through the material. Its high transmission in UV and visible ranges is essential for precision optics.

Quartz glass is widely used in optical systems due to its exceptional transmission from deep UV to IR, low absorption, and minimal scattering. These properties are crucial for applications such as lithography1, laser processing, and analytical instrumentation, where even minor losses can impact system performance.

Quartz Glass Transmission Properties Overview

| Property | Typical Value/Range | Context/Condition |

|---|---|---|

| UV Transmission (200 nm) | >90% per 1 mm | High-purity fused silica |

| Visible (400–700 nm) | >93% per 1 mm | Standard optical grade |

| Near-IR (1000–2000 nm) | >92% per 1 mm | Low-OH content |

| Mid-IR (2.7/3.5 μm) | Drops sharply | OH⁻ absorption peaks |

How Do Physical Properties of Quartz Glass Determine Its Transmission Across UV, Visible, and IR Wavelengths?

The intrinsic properties of quartz glass—such as band structure, hydroxyl content, and microscopic defects—directly influence its transmission across the spectrum.

Understanding these relationships enables engineers to predict performance and select the right material for each application.

Physical Factors Affecting Transmission

| Factor | Impacted Wavelength(s) | Effect on Transmission | Typical Value/Threshold |

|---|---|---|---|

| Bandgap (eV) | <200 nm (UV) | Sets UV cutoff | ~8.3 eV (~150 nm) |

| OH⁻ Content (ppm) | 2.7/3.5 μm (IR) | Increases absorption at IR peaks | <10 ppm for high IR transmission |

| Vacancy/Inclusion Density | 400–700 nm (Visible) | Increases scattering, reduces clarity | <1 ppm for high-performance optics |

Band Structure and UV Cutoff Mechanism

The electronic band structure of quartz glass determines its UV cutoff. Photons with energies above the bandgap (~8.3 eV, ~150 nm) are absorbed via electronic transitions, limiting deep UV transmission. This quantum mechanical property is fundamental for applications below 200 nm, such as excimer laser optics.

Influence of Hydroxyl Content on IR Transmission Windows

Hydroxyl (OH⁻) groups introduce absorption peaks at 2.7 μm and 3.5 μm.2 Higher OH⁻ content narrows the IR transmission window. Reducing OH⁻ from 1000 ppm to <10 ppm can improve IR transmission by over 20% at these wavelengths, which is critical for IR fiber and sensor applications3.

Wavelength-Selective Scattering from Microscopic Defects

Microscopic defects, such as vacancy clusters and inclusions, scatter visible light, reducing transmission in the 400–700 nm range. Monte Carlo simulations reveal that even sub-ppm levels of inclusions can cause measurable scattering losses, highlighting the importance of ultra-pure quartz for high-performance visible optics.

What Are the Typical Transmission Values of Fused Silica at Key Wavelengths?

Fused silica offers outstanding transmission across UV, visible, and IR ranges, making it a preferred material for demanding optical applications.

Transmission values vary with purity, thickness, and wavelength. The table below summarizes key benchmarks.

Fused Silica Transmission Benchmarks

| Wavelength (nm/μm) | Transmission (% per 1 mm) | Grade/Condition |

|---|---|---|

| 200 | >90 | High-purity, low Fe³⁺ |

| 254 | >92 | UV sterilization grade |

| 355 | >93 | Laser optics |

| 1064 | >93 | IR laser optics |

| 2700 (2.7 μm) | 60–80 | Low-OH, high-purity |

| 3500 (3.5 μm) | 40–70 | Low-OH, high-purity |

How Do Absorption and Scattering Affect Quartz Glass Transmission in High-Power Optical Systems?

Absorption and scattering are key factors in high-power optical systems, influencing efficiency, beam quality, and component lifespan.

Understanding these effects enables engineers to optimize system design and maintenance schedules.

Absorption and Scattering Impact Factors

| Factor | Typical Value/Range | System Impact |

|---|---|---|

| Absorption (%) | <0.1 per cm | Minimizes thermal lensing |

| Surface Roughness (Ra, nm) | <0.5 | Reduces surface scattering |

| Lifetime (pulses) | >1 million | Predicts transmission degradation |

Nonlinear Absorption-Induced Thermal Lensing

In 10 kW-class laser systems, each 0.1% absorption can cause measurable thermal lensing, shifting the focal point and degrading beam quality. Accurate modeling is essential for system stability.

Power Loss Allocation Between Bulk and Surface Scattering

For surfaces polished to Ra <0.5 nm, bulk scattering dominates power loss. Quantitative models help engineers allocate loss budgets and specify surface quality.

Predictive Algorithms for Transmission Degradation Due to Damage Accumulation

Using Mie scattering theory, engineers can simulate transmission degradation over millions of laser pulses, supporting predictive maintenance and component replacement planning.

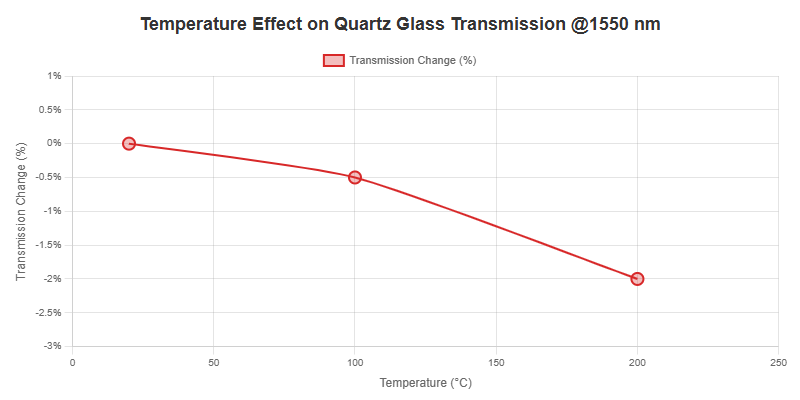

What Are the Effects of Temperature on Optical Equipment Quartz Glass Transmission?

Temperature changes can alter quartz glass transmission by affecting refractive index, inducing thermal expansion, and increasing phonon-related absorption.

For example, transmission at 1550 nm may decrease by up to 2% when temperature rises from 20°C to 200°C. Engineers must account for these effects in high-temperature or thermally cycled environments.

Temperature Impact on Transmission

| Temperature (°C) | Transmission Change (%) | Wavelength (nm) | Notes |

|---|---|---|---|

| 20 | 0 | 1550 | Reference |

| 100 | -0.5 | 1550 | Slight decrease |

| 200 | -2.0 | 1550 | Noticeable decrease |

How Does High-Purity Quartz Glass Transmission Impact Laser and DUV Lithography Systems?

High-purity quartz glass is essential for advanced laser and lithography systems, where transmission and material uniformity directly affect performance and yield.

Applications such as DUV/EUV lithography and high-power lasers demand strict control over impurities, transmission, and uniformity.

Laser and Lithography Performance Factors

| Parameter | Typical Value/Threshold | Impact on System Performance |

|---|---|---|

| Fe³⁺ Content (ppm) | <0.1 | Maintains >90% at 193 nm |

| Transmission @ 1064/355 nm | >99.5% | Supports >15 J/cm² damage threshold |

| Transmission Gradient | <0.1%/cm | Controls CDU in lithography |

DUV/EUV Lithography Metal Impurity Thresholds

In DUV/EUV lithography, even trace Fe³⁺ above 0.1 ppm can reduce 193 nm transmission by several percent, impacting pattern fidelity and throughput.

Transmission Dependence of Nanosecond Laser Damage Thresholds

High transmission (>99.5%) at 1064 nm and 355 nm correlates with increased laser-induced damage thresholds (>15 J/cm²), ensuring component longevity in high-power laser systems.

Compensation Strategies for Wavefront Distortion Induced by Nonuniformity

Transmission gradients below 0.1%/cm are essential to minimize wavefront distortion, which is critical for controlling critical dimension uniformity (CDU) in advanced lithography.

Why Do Engineers Prefer Quartz Glass Transmission Over Vitreous Silica Transmission for Precision Optics?

Quartz glass is preferred over vitreous silica when superior UV transmission, lower impurity levels, and higher resistance to radiation-induced darkening are required.

Fused silica is ideal for high-precision optics, laser systems, and semiconductor lithography, while vitreous silica may be suitable for less demanding, cost-sensitive applications.

Quartz Glass vs Vitreous Silica Selection Criteria

| Criteria | Quartz Glass (Fused Silica) | Vitreous Silica |

|---|---|---|

| UV Transmission | Excellent | Moderate |

| Impurity Level | Very Low | Higher |

| Radiation Resistance | High | Moderate |

| Cost | Higher | Lower |

| Typical Applications | Lithography, lasers | General optics, lamps |

How Should Engineers Specify Quartz Glass Transmission Requirements for Custom Optical Components?

Defining precise transmission requirements is essential for custom optical components, ensuring system-level performance and cost-effectiveness.

Engineers should use a systematic approach, considering system efficiency, spectral weighting, and digital verification.

Transmission Specification Approaches

| Approach | Description | Example/Condition |

|---|---|---|

| System-Level Allocation | Back-calculate from total efficiency | EUV lithography: >99.8% per optic |

| Spectral Band Weighting | Assign weights to UV, VIS, IR bands | IR weight: 0.2 if less critical |

| Digital Twin Verification | Simulate with OptiWave/Zemax using real data | Virtual validation before purchase |

System-Level Transmission Budget Allocation

For EUV lithography4, each component may require >99.8% transmission to meet overall throughput goals. This is achieved by allocating tolerances from the system-level efficiency target.

Spectral Band-Weighted Transmission Specification

Transmission requirements should be weighted according to the application's spectral priorities. For instance, IR transmission may be assigned a 0.2 weighting factor if less critical than UV or visible.

Digital Twin-Driven Virtual Verification Workflow

Digital modeling tools like OptiWave5 and Zemax6 enable virtual verification of transmission specifications, integrating real material data for accurate performance prediction before fabrication.

What Quality Standards and Test Methods Ensure Reliable Quartz Glass Transmission?

Reliable transmission is ensured by adherence to international standards and rigorous testing methods.

Standards such as ISO 10110-77, ASTM F21838, and MIL-PRF-13830B9 define requirements for optical material transmission and surface quality.

Transmission Quality Standards and Testing Methods

| Standard/Test Method | Description | Application Context |

|---|---|---|

| ISO 10110-7 | Optical material transmission | General optics |

| ASTM F2183 | UV/visible/IR transmission testing | Laboratory, industrial |

| MIL-PRF-13830B | Surface quality for optics | Military, aerospace |

| Spectrophotometry | Measures transmission across spectrum | All optical components |

| Laser Calorimetry | Quantifies absorption losses | High-power optics |

| Interferometric Analysis | Assesses surface flatness/quality | Precision optics |

What Procurement Factors Influence the Cost and Lead Time of High-Transmission Quartz Glass?

Procurement decisions for high-transmission quartz glass depend on purity, size, manufacturing technology, and material source.

Understanding these factors helps buyers optimize cost, lead time, and performance.

Procurement Cost and Lead Time Factors

| Factor | Typical Value/Range | Impact on Procurement |

|---|---|---|

| Purity Grade (per 0.01% incr.) | Significant cost increase | Especially at 193 nm |

| Blank Diameter (mm) | Up to 300 | Growth rate ~1 mm/h, longer lead time |

| Recycled Material Cycles | ≤3 | UV transmission degrades after 3 uses |

Purity Grade vs. Cost Index Model

Each 0.01% increase in 193 nm transmission can raise material costs significantly, especially for ultra-high-purity grades. Cost models help balance performance and budget.

Impact of Large-Diameter Blank Growth Technology on Delivery

Large-diameter blanks (e.g., Φ300 mm) require slow crystal growth rates (~1 mm/h), extending lead times. Early planning is essential for large-scale optics projects.

Recycled Material Transmission Performance Validation

Recycled quartz sand can be reused up to three cycles before UV transmission degrades beyond acceptable limits. Validation testing ensures recycled material meets application requirements.

Conclusion

Quartz glass transmission plays a pivotal role in determining the efficiency, reliability, and performance of advanced optical systems. By understanding the underlying physical mechanisms, transmission benchmarks, and application-specific requirements, engineers can make informed decisions that directly impact system success.

Navigating the complexities of quartz glass transmission selection presents a significant engineering challenge. Leverage the expertise of TOQUARTZ’s engineering team, backed by 20+ years of manufacturing experience and direct factory supply, for a complimentary consultation on your custom quartz glass requirements.

FAQ (Frequently Asked Questions)

What is the difference between high-purity quartz glass and standard quartz glass for optical applications?

High-purity quartz glass contains fewer impurities, resulting in higher UV transmission, lower absorption, and better resistance to radiation-induced darkening, making it ideal for precision optics and lithography.

How can I verify the transmission quality of quartz glass before purchasing?

Request spectrophotometry test reports and certifications such as ISO 10110-7 or ASTM F2183 from your supplier. These documents provide objective data on transmission performance.

What factors should I consider when specifying custom quartz glass components?

Consider system-level transmission requirements, spectral weighting, and digital simulation results. Collaborate with your supplier to define tolerances and verify performance using virtual modeling tools.

How does recycled quartz glass compare to virgin material in terms of transmission?

Recycled quartz glass can maintain acceptable UV transmission for up to three cycles. Beyond this, transmission may degrade, so validation testing is essential for critical applications.

References:

-

Discover how lithography works in advanced optical systems and why quartz glass is essential for achieving high precision and efficiency. ↩

-

Discover the scientific explanation behind OH⁻ absorption peaks in the IR spectrum and how they impact fiber and sensor performance. ↩

-

Discover how improved IR transmission enhances fiber and sensor performance, and learn about cutting-edge uses in telecommunications, sensing, and imaging. ↩

-

Learn how EUV lithography revolutionizes chip production with higher precision and why it's crucial for next-generation semiconductors. ↩

-

Explore this link to understand how OptiWave enhances digital modeling and improves design accuracy. ↩

-

Discover the advantages of Zemax in optical design and how it can streamline your workflow. ↩

-

Exploring this link will provide you with detailed insights into the standards for optical material transmission. ↩

-

This resource will help you understand the specific requirements and guidelines set by ASTM F2183 for optical materials. ↩

-

Learn about MIL-PRF-13830B to understand its critical standards for optical surface quality and why it's widely referenced in the optics industry. ↩