- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Fluorescence Cuvette

- /

- Evaporation-Controlled Quartz Fluorescence Cuvette...

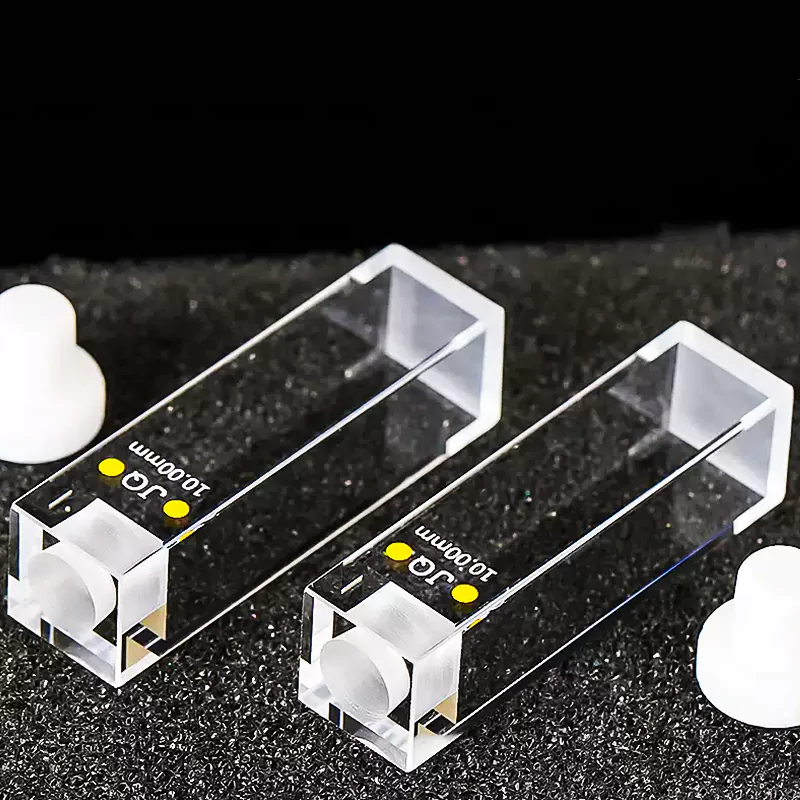

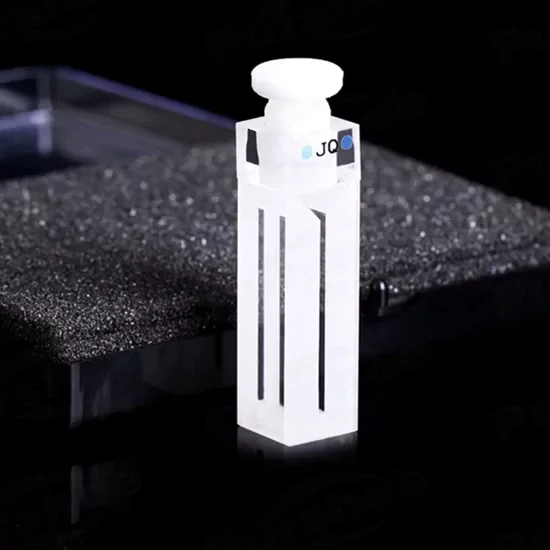

Evaporation-Controlled Quartz Fluorescence Cuvette with PTFE Stoppers for Sample Integrity -TOQUARTZ®

Features of Quartz Fluorescence Cuvette with PTFE Stoppers

TOQUARTZ® high-purity quartz cuvettes combine precision manufacturing with superior material properties to deliver exceptional performance for your spectroscopic analysis needs. Each feature is designed to enhance measurement accuracy, extend product lifespan, and ensure reliable results.

Material Purity

Manufactured from premium grade fused quartz with ≥99.98%(max. up to 99.995%) SiO₂ content, ensuring minimal impurities and superior optical performance across the entire UV-Vis-NIR spectrum (190-2500nm).

PTFE Stopper Design

Chemically inert PTFE stoppers provide airtight sealing for sample preservation, preventing evaporation and contamination during extended analysis periods or sample storage.

Optical Properties

Highly controlled light path lengths (±0.1mm tolerance) and wall thickness uniformity ensure consistent, reproducible spectroscopic measurements and minimal optical distortion.

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

Technical Specifications & Dimensions of Quartz Fluorescence Cuvette with PTFE Stoppers

Technical Specifications

| Parameter | Value |

| 1. Physical Properties | |

| Density | 2.2 g/cm³ |

| Fracture Modulus | ≥350MPa |

| Thermal Expansion Coefficient | 5.5×10-7/℃ |

| Thermal Conductivity | 120-160W/m·K |

| Surface Finish | Optically polished |

| 2. Chemical Properties | |

| SiO2 Content | ≥99.98% (max. up to 99.995% SiO2) |

| Acid Resistance | Excellent (except HF) |

| Alkali Resistance | Excellent |

| Solvent Resistance | Excellent for all organic solvents |

| OH Content | ≤30ppm |

| 3. Optical Properties | |

| Transmission Range | 200-2500nm |

| Refractive Index (at 589.3nm) | 1.4585 |

| Transmission at 200nm | ≥80% |

| Transmission at 500nm | ≥93% |

| Fluorescence | Minimal |

Size Chart

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6008 | 350μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 1mm | 1mm | 350μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6008-1 | 350μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 70mm | 70mm | 350μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016 | 350μl standard Quartz Fluorescence Cuvette with PTFE Stopper | 10mm | 350μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-2 | 700μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 10mm | 10mm | 700μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-2-1 | 700μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 20mm | 20mm | 700μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-3 | 1400μl Quartz Fluorescence Cuvette Cell with PTFE Stopper | 10mm | 1400μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-4 | 1750μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 5mm | 5mm | 1750μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-4-1 | 1750μl Quartz Fluorescence Cuvette with PTFE Stopper Path Length 10mm | 10mm | 1750μl | 12.5×12.5x45mm |

| Model | Description | Path Length | Volume | Outline Dimension |

| AT-BSM-6016-1 | 3500μl Quartz Fluorescence Cuvette with PTFE Stopper | 10mm | 3500μl | 12.5×12.5x45mm |

TOQUARTZ® Solving Challenges in Fluorescence Spectroscopic Analysis with Quartz Fluorescence Cuvette with PTFE Stoppers

Quartz Fluorescence Cuvette with PTFE Stopper in Pharmaceutical Stability Testing

Key Advantages

-

Minimized evaporation over 72-hour exposure

PTFE stopper limits sample loss to <0.5% during ICH Q1B photostability tests. -

Sealing integrity under controlled light stress

Maintains airtight seal under 25–40°C light chamber conditions for 3 days. -

Prevents oxidation of light-sensitive APIs

Reduces oxygen ingress by >95% compared to open-top cuvettes.

TOQUARTZ® solution

A pharmaceutical R&D lab in Germany observed 7–10% sample loss during 48-hour photostability tests using open cuvettes, leading to invalidated ICH Q1B data. After switching to TOQUARTZ® Quartz Fluorescence Cuvette with PTFE Stopper, sample mass loss dropped to 0.4%, and fluorescence signal drift was reduced by 85%, enabling consistent, compliant API degradation profiling.

Quartz Fluorescence Cuvette with PTFE Stopper in Environmental Water Pollutant Detection

Key Advantages

-

Preserves volatile organics during UV exposure

Reduces PAH evaporation by 92% under 254nm excitation for 30 minutes. -

Prevents photodegradation in batch testing

PTFE stopper blocks ambient oxygen, stabilizing fluorescence intensity. -

Enables accurate detection at ppb levels

Maintains signal integrity for naphthalene at 0.5 ppb concentration.

TOQUARTZ® solution

An environmental testing lab in Ontario reported inconsistent PAH readings during multi-sample fluorescence runs, with signal loss exceeding 18% due to evaporation. Using TOQUARTZ® Quartz Fluorescence Cuvette with PTFE Stopper, signal retention improved to 97.6% across 12 samples, ensuring accurate quantification of trace pollutants in compliance with EPA Method 8310.

Quartz Fluorescence Cuvette with PTFE Stopper in Protein Folding Kinetics Using Time-Resolved Fluorescence

Key Advantages

-

Maintains constant buffer concentration

Prevents >5% volume loss during 60-minute thermal ramp assays. -

Seals denaturants under high-temperature conditions

PTFE stopper resists urea vapor at 70°C without deformation. -

Supports reproducible kinetic curve acquisition

Reduces fluorescence baseline drift by 80% over time-course runs.

TOQUARTZ® solution

A structural biology lab in Kyoto faced inconsistent folding half-time data due to buffer evaporation in open cuvettes during 65°C kinetic assays. After adopting TOQUARTZ® Quartz Fluorescence Cuvette with PTFE Stopper, volume loss was reduced to <1%, and kinetic curve reproducibility improved from ±12% to ±2.1%, enabling reliable modeling of folding intermediates.

TOQUARTZ® Customization Options for Quartz Fluorescence Cuvette with PTFE Stoppers

Stopper Customization Options

- Custom stopper diameter for neck fit

- Material selection: PTFE, PFA, silicone

- Stopper hardness customization for sealing force

- Stopper taper angle for tight sealing

- Stopper with central hole for injection access

- Stopper with vent channel for pressure release

- Stopper surface texture for robotic gripping

- Stopper sterilization compatibility (autoclave, EO)

Dimensional Customization

- Custom stopper fit for tight sealing

- Modified neck diameter for stopper compatibility

- Adjusted cuvette height for instrument clearance

- Optimized stopper-seat depth for stability

- Stopper-cuvette interface for thermal expansion

- Custom stopper taper angle for precision fit

Design Adaptations

- Stopper-compatible design for vertical holders

- Modified top opening for robotic arms

- Dual-cap design for sampling access

- Stopper groove for anti-slip handling

- Stopper alignment notch for repeatable sealing

- Stopper-locking design for transport stability

Usage and Care Guidelines

Handling Instructions

- Always handle cuvettes by the non-optical sides or top edges to prevent fingerprints and contamination on optical windows.

- Insert and remove PTFE stoppers with gentle pressure, avoiding twisting motions that could create stress on the quartz.

- When filling, leave approximately 2-3mm space below the stopper to accommodate thermal expansion of liquids.

- Avoid rapid temperature changes that could create thermal stress (maximum recommended rate: 5°C/minute).

- Never heat sealed cuvettes in closed systems due to pressure buildup risk.

Cleaning Procedures

- Rinse immediately after use with appropriate solvent compatible with your samples.

- For general cleaning, use dilute laboratory detergent followed by thorough rinsing with distilled water.

- For stubborn residues, soak in 10% HCl solution (avoid HF which attacks quartz).

- Rinse thoroughly with ultrapure water after cleaning.

- Air dry or use filtered compressed air/nitrogen for rapid drying.

- Clean PTFE stoppers separately using compatible solvents.

Storage Recommendations

- Store clean, dry cuvettes in original packaging or dedicated dust-free containers.

- For long-term storage, keep PTFE stoppers separate from cuvettes to prevent sticking.

- Avoid storing in areas with fluctuating temperatures or high humidity.

- Keep away from corrosive vapors that could deposit on optical surfaces.

- Consider using dedicated storage racks to prevent contact between optical surfaces.

Maintenance Tips

- Periodically inspect optical surfaces under bright light for scratches or contamination.

- Check PTFE stoppers for deformation or contamination and replace if necessary.

- For precision applications, verify path length periodically using calibration standards.

- Avoid using abrasive materials that could scratch optical surfaces.

- Replace cuvettes if any cracks or chips develop, as these compromise structural integrity.

Need a custom quartz fluorescence cuvette solution?

Send us your requirements or existing drawings for a prompt quotation.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the sealing performance of the Quartz Fluorescence Cuvette with PTFE Stopper?What is the sealing performance of the Quartz Fluorescence Cuvette with PTFE Stopper?

A: The PTFE stopper provides an airtight seal, limiting evaporation to less than 0.5% over 72 hours under standard photostability testing conditions. This ensures consistent sample concentration during long-duration fluorescence assays.

Q: Can the Quartz Fluorescence Cuvette with PTFE Stopper be used for volatile organic compounds?

A: Yes, the stopper minimizes evaporation of volatile analytes such as PAHs or solvents like ethanol and toluene. It is ideal for environmental fluorescence analysis at ppb-level sensitivity.

Q: Is the Quartz Fluorescence Cuvette with PTFE Stopper compatible with temperature-controlled assays?

A: Yes, it withstands thermal ramps up to 70°C with no deformation or leakage. It is suitable for protein folding kinetics and thermal denaturation studies.

Q: How does the stopper prevent sample oxidation during photostability testing?

A: With the PTFE lid properly sealed, evaporation is reduced to less than 0.5% over 24 hours, ensuring stable fluorescence signal in kinetic studies.

Q: Can the Quartz Fluorescence Cuvette with PTFE Stopper be used with automated sampling systems?

A: Custom stopper designs are available for robotic compatibility. We offer stopper modifications for autosampler access and mechanical gripping.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.