- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Flow-Through Cuvette

- /

- Low-Drift Quartz Flow Cell...

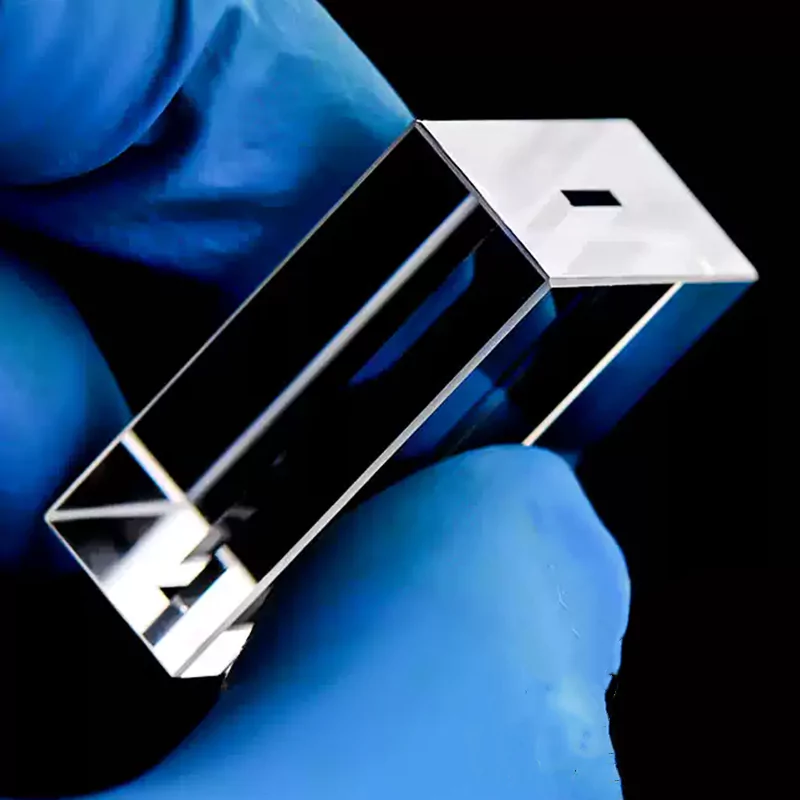

Low-Drift Quartz Flow Cell for ZETA Potential Analyzers in Academic Labs-TOQUARTZ®

Features of Quartz Flow Cell for ZETA Potential Analyzers

TOQUARTZ® Quartz Flow Cell for ZETA Potential Analyzer is engineered to meet the precision, durability, and optical clarity demanded by laboratories and analyzer manufacturers. Its design addresses critical needs in zeta potential measurements, UV-Vis spectroscopy, and small-volume fluid analysis.

Stable Physical Properties

- Dual pathlength 1 mm / 5 mm with tolerance ±0.1 mm.

- Internal volume ~130 µL optimized for low-sample applications.

- Fracture modulus ≥350 MPa provides mechanical stability under pressure.

Optical Transparency

- Transmission range 190–2500 nm ensures accurate UV-Vis readings.

- Four seamless windows minimize baseline drift in spectroscopic analysis.

- Optical distortion reduced to <0.3% deviation across pathlengths.

Chemical and Thermal Resistance

- Withstands acids, alkalis, and organic solvents except HF.

- Maintains structural integrity up to 1200 °C continuous operation.

- Surface roughness <5 nm reduces fouling and extends service life.

- SiO2 Purity ≥99.98%, up to 99.995%

- Chemical Resistance to Harsh Reagents

- Customization Services Available

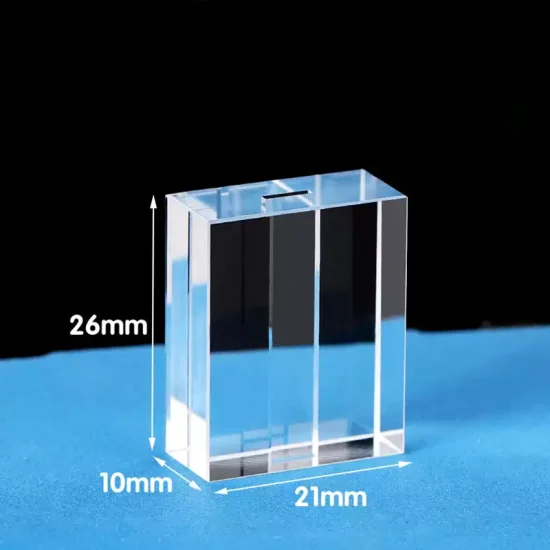

Technical Specifications & Dimensions of Quartz Flow Cell for ZETA Potential Analyzers

Technical Specifications

| Property | Specification |

| Optical Transmission | 190–2500nm, ≤0.3% deviation, four clear windows |

| Mechanical Strength | Fracture modulus ≥350MPa, density 2.2 g/cm^3, Mohs hardness 7 |

| Thermal Resistance | Continuous use ≤1200°C, thermal conductivity 120–160W/m·K, expansion ≤0.55×10^-6/K |

| Chemical Stability | Resistant to acids, alkalis, organic solvents; not resistant to HF |

| Surface & Purity | SiO2 ≥99.98%, surface roughness <5nm, refractive index 1.46 |

Size Chart

| Model | Description | Path Length |

Volume | Outline Dimension |

| AT-BSM-8041 | 130μl Quartz Flow Cell for ZETA Potential Analyzer | 1mm/5mm | 130μl | 21*10*26mm |

TOQUARTZ® Solving Challenges in Spectroscopic Analysis with Quartz Flow Cell for ZETA Potential Analyzers

Nanoparticle Research in Academic Laboratories Using Quartz Flow Cell for ZETA Potential Analyzer

Key Advantages

-

Low-Volume Chamber

— 130 µL design enables reliable analysis of rare samples. -

Dual Pathlength Stability

— 1 mm and 5 mm maintain reproducibility in charge studies. -

Minimal Baseline Drift

— Seamless quartz transparency ensures optical accuracy.

TOQUARTZ® solution

An academic nanomaterials lab experienced inconsistent results when analyzing 100 nm colloids with conventional cuvettes, leading to retests in 25% of runs. With TOQUARTZ® Quartz Flow Cell for ZETA Potential Analyzer, baseline stability improved, and repeat testing was reduced by more than two-thirds.

Protein Stability Testing in Biopharmaceutical QC Using Quartz Flow Cell for ZETA Potential Analyzer

Key Advantages

-

Buffer Compatibility

— Quartz resists acidic and alkaline buffer degradation. -

Pathlength Precision

— Accurate chamber design supports sensitive stability tests. -

Optical Clarity

— High transmission from 190–2500 nm reduces background noise.

TOQUARTZ® solution

A QC team testing monoclonal antibody formulations faced a 15% error rate due to buffer-induced degradation in glass cells. After switching to TOQUARTZ® Quartz Flow Cell for ZETA Potential Analyzer, reproducibility improved by 80%, accelerating batch approvals and reducing production delays.

Inline Monitoring of Colloids in Pilot Plants Using Quartz Flow Cell for ZETA Potential Analyzer

Key Advantages

-

Thermal Resistance

— Reliable operation under continuous conditions up to 1200 °C. -

Four Optical Windows

— Supports stable UV-Vis detection in flowing systems. -

Durable Quartz Structure

— Resists pressure and turbulence in fluid streams.

TOQUARTZ® solution

A chemical pilot plant reported $6,000 per month in downtime from cuvette failures during inline monitoring. Integrating TOQUARTZ® Quartz Flow Cell for ZETA Potential Analyzer provided 1,000+ hours of uninterrupted measurement, cutting operational losses and ensuring consistent product testing.

Customization Solutions for Your Specific Applications

Pathlength and Volume Adaptation

Request optimized internal dimensions for different sample analysis scenarios.

-

Dual Pathlength

— Options balance sensitivity and reproducibility across studies. -

Small Volume

— Chamber design supports precise analysis with limited samples. -

Stable Flow

— Flow-through geometry ensures consistent measurement conditions.

Optical Window Customization

Optical surfaces can be designed to meet specific spectral or clarity demands.

-

Window Alignment

— Precision geometry minimizes baseline noise in UV-Vis data. -

Surface Finish

— Polished quartz reduces scattering and improves consistency. -

Multi-Window Design

— Supports flexible optical paths for advanced instruments.

Material and Treatment Options

Material grades and surface treatments enhance compatibility with unique sample types.

-

Quartz Grades

— Selection aligns performance with laboratory application needs. -

Protective Coating

— Added treatment resists damage from aggressive media. -

Surface Control

— Smooth finish lowers risk of sample fouling or deposits.

Product Usage Guideline

Operating Instructions

- Always align the optical windows properly to avoid baseline drift.

- Introduce samples gradually to maintain stable flow conditions in the chamber.

- Use only recommended sample volumes to ensure reproducible pathlength results.

- Flush with deionized water before each measurement to prevent contamination.

Cleaning Guidelines

- Rinse immediately after analysis with DI water to remove residues.

- For proteins or polymers, apply neutral detergent followed by thorough rinsing.

- Avoid abrasive tools or hydrofluoric acid that damage quartz surfaces.

- Dry the cell with filtered air to prevent water spots on windows.

Storage Recommendations

- Keep the cell in a clean, dust-free protective box when not in use.

- Store at stable room temperature to avoid thermal stress on quartz walls.

- Avoid exposure to direct sunlight that may alter optical performance.

- Separate from sharp or metallic objects that may scratch window surfaces.

Troubleshooting Tips

- If signal drift occurs, inspect optical windows for scratches or residues.

- For inconsistent readings, check chamber cleanliness and proper sample loading.

- If reduced transparency is observed, repeat cleaning with neutral detergent.

- Replace the cell only if physical cracks or severe optical distortion are visible.

Advance Research with Quartz Flow Cell for ZETA Potential Analyzer

Contact our engineers today for customized support and technical consultation.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: How does the Quartz Flow Cell for ZETA Potential Analyzer improve baseline stability in nanoparticle research?

A: The Quartz Flow Cell for ZETA Potential Analyzer features molded quartz walls with seamless clarity, reducing optical distortion and baseline drift. This design minimizes repeat testing in zeta potential studies. As a result, researchers gain consistent charge measurement data across multiple runs.

Q: What chemical environments can the Quartz Flow Cell for ZETA Potential Analyzer tolerate?

A: The Quartz Flow Cell for ZETA Potential Analyzer is resistant to acids, alkalis, and most organic solvents. Hydrofluoric acid is the only major exception. This chemical stability ensures long service life during protein or polymer buffer testing.

Q: How does the Quartz Flow Cell for ZETA Potential Analyzer maintain accuracy under thermal stress?nds Open handle frequent solvent changes?

A: The Quartz Flow Cell for ZETA Potential Analyzer can operate continuously at temperatures up to 1200 °C. Its low thermal expansion coefficient (≤0.55 × 10⁻⁶/K) maintains structural integrity during heating. This prevents distortion of optical readings in demanding test conditions.

Q: How does the Quartz Flow Cell for ZETA Potential Analyzer reduce downtime in quality control labs?

A: The Quartz Flow Cell for ZETA Potential Analyzer uses durable quartz resistant to chemical and thermal damage. This reduces cell replacement frequency compared to standard glass or polymer cuvettes. QC labs benefit from fewer interruptions and more efficient workflows.

Q: What problems does the Quartz Flow Cell for ZETA Potential Analyzer solve in protein stability testing?

A: The Quartz Flow Cell for ZETA Potential Analyzer withstands buffer environments that degrade other cuvettes. It maintains clarity and pathlength precision under repeated runs. This prevents inconsistent readings and accelerates batch release approvals.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.