- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Micro Cuvette

- /

- Micro Volume Sealed Quartz...

Micro Volume Sealed Quartz Cuvette with PTFE Stoppers for Spectrophotometry Applications -TOQUARTZ®

Features of Quartz Cuvette with PTFE Stoppers

TOQUARTZ® quartz cuvettes with PTFE stoppers are manufactured from high-purity quartz material, offering exceptional optical and physical properties for your most demanding laboratory applications. Each cuvette is precision-crafted to ensure consistent performance in UV-Vis spectroscopy and fluorescence analysis.

Secure PTFE Stoppers

Premium PTFE stoppers provide excellent chemical resistance and reliable sealing, preventing sample evaporation and contamination during storage or analysis.

Optical Transmission

Wide spectral range from 200nm to 2500nm with no absorption peaks, ideal for UV-Vis spectroscopy and fluorescence applications requiring precise light transmission.

Material Purity

Made from high-purity quartz (≥99.98% SiO₂, up to 99.995%), ensuring excellent optical clarity and chemical stability for accurate spectroscopic measurements.

Chemical Resistance

Excellent resistance to acids, bases, and organic solvents. Can withstand strong chemicals and high temperatures up to 1100°C, suitable for demanding laboratory environments.

- SiO2 Purity ≥99.98%, up to 99.995%

- 10mm Standard Path Length

- Customization Available

Technical Specifications & Dimensions of Quartz Cuvette with

PTFE Stoppers

Technical Specifications

Physical Properties

| Parameter | Specification |

| Material | High-purity quartz (≥99.98% SiO2, up to 99.995%) |

| Stopper Material | PTFE (Polytetrafluoroethylene) |

| Mechanical Strength | Fracture modulus >350MPa |

| Thermal Expansion Coefficient | 5.5×10-7/℃ |

| Thermal Conductivity | 120–160 W/m.K |

Chemical Properties

| Parameter | Specification |

| Acid Resistance | Excellent (except HF) |

| Base Resistance | Excellent |

| Solvent Resistance | Excellent |

| PTFE Stopper | Inert to most chemicals |

Optical Properties

| Parameter | Specification |

| Transmission Range | 200-2500nm |

| Transmittance | >80% (Paired Testing) |

| Refractive Index | 1.46 at 589.3nm |

| Absorption Peaks | None within operational range |

| Path Length Accuracy | ±0.1mm |

| Stray Light Reduction | >99% with black walls |

Size Chart

| Model | Description | Wavelength | Path Length |

Volume | Transmittance | Outline Dimension | Slit |

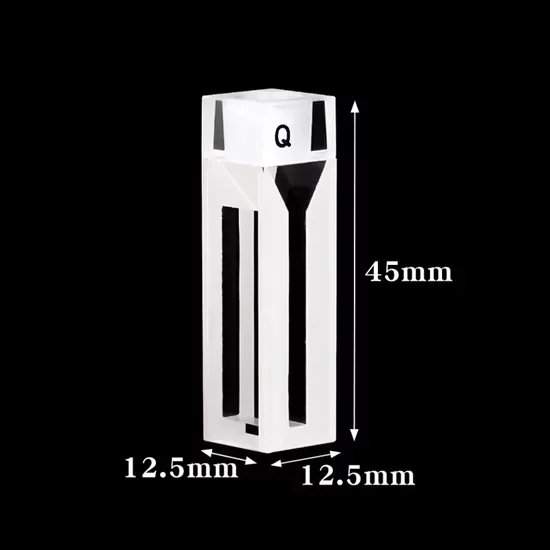

| AT-BSM-4032 | 350μl Quartz Cuvette with PTFE Stopper | 200nm-2500nm | 10mm | 350μl | >80% (Paired Testing) | 12.5×12.5x53mm | 1mm |

| Model | Description | Wavelength | Path Length |

Volume | Transmittance | Outline Dimension | Slit |

| AT-BSM-4006 | 1050μl Quartz Cuvette with PTFE Stopper | 200nm-2500nm | 10mm | 1050μl | >80% (Paired Testing) | 12.5×12.5×45 mm | 3mm |

| Model | Description | Wavelength | Path Length |

Volume | Transmittance | Outline Dimension | Slit |

| AT-BSM-4012 | 1400μl Quartz Cuvette with PTFE Stopper | 200nm-2500nm | 10mm | 1400μl | >80% (Paired Testing) | 12.5×12.5×45 mm | 4mm |

TOQUARTZ® Solving Critical Challenges in Spectroscopy Applications with Quartz Cuvette with PTFE Stopper

Quartz Cuvette with PTFE Stopper in Cannabis Extract Potency Testing

Key Advantages

-

Reduces ethanol evaporation to <0.6% during 30-minute UV-Vis runs

PTFE stopper maintains solvent stability in volatile cannabis extract matrices. -

Ensures THC/CBD concentration drift stays within ±1.1% across 5 replicates

Prevents potency misreporting caused by solvent loss during analysis. -

Withstands repeated exposure to ethanol and acetone without material degradation

Maintains cuvette integrity after 50+ cleaning cycles with cannabis solvents.

TOQUARTZ® solution

A licensed cannabis testing lab in Colorado reported ±4.3% variance in THC readings due to ethanol evaporation in open-top cuvettes, leading to failed audits. After switching to TOQUARTZ® Quartz Cuvette with PTFE Stopper, variance dropped to ±1.1% across 5 replicates. This allowed the lab to meet state-mandated repeatability thresholds and reduce retesting frequency by 40%, saving over $6,000/month in labor and materials.

Quartz Cuvette with PTFE Stopper in Pharmacokinetic (PK) Studies of Rare Disease Drugs

Key Advantages

-

Preserves 100% of 500μl plasma samples over 48-hour multi-timepoint testing

PTFE stopper prevents evaporation during extended PK sampling windows. -

Maintains analyte stability with <0.3% deviation in AUC calculations

Eliminates concentration drift caused by oxygen or solvent loss. -

Enables 6+ timepoint reads from a single micro-volume patient sample

Supports full PK profiling from irreplaceable rare disease biospecimens.

TOQUARTZ® solution

A biotech firm conducting Phase I PK studies on a rare enzyme therapy faced 15% sample loss using open cuvettes, compromising AUC and Cmax data. After adopting TOQUARTZ® Quartz Cuvette with PTFE Stopper, they retained full sample volume across 6 timepoints with <0.3% deviation in analyte concentration. This improved data integrity and reduced biologic waste, saving $12,800 per study cycle.

Quartz Cuvette with PTFE Stopper in Academic Photostability Research of Light-Sensitive Compounds

Key Advantages

-

Limits solvent loss to <0.5% during 60-minute UV irradiation at 254nm

PTFE stopper prevents evaporation under continuous photostability testing. -

Reduces oxygen ingress by 90% compared to open cuvettes

Enables accurate kinetic modeling of oxygen-sensitive photodegradation. -

Supports reproducible degradation curves with <2% variance across trials

Ensures consistency in light-exposure experiments using volatile solvents.

TOQUARTZ® solution

A European photochemistry lab studying riboflavin degradation observed 9% solvent loss and inconsistent half-life data using open cuvettes. After switching to TOQUARTZ® Quartz Cuvette with PTFE Stopper, solvent loss dropped below 0.5%, and variance in degradation rate constants was reduced to <2%. This enabled publication of validated kinetic models and improved reproducibility across 3 independent research teams.

TOQUARTZ® Customization Options for Quartz Cuvette with PTFE Stoppers

Dimensional Customization

- Modified Internal Volume: Internal volume can be adjusted from 100μl to 3ml based on your sample requirements.

- Tailored Outer Dimensions: We customize height, width, and depth to match your spectrophotometer holder.

- Wall Thickness Adjustment: Wall thickness of the quartz micro cuvette with PTFE stopper can be fine-tuned for optical or thermal needs.

- Optical Window Positioning: We can reposition optical windows to suit dual-beam or side-illumination instruments.

- Stopper Fit Calibration: Stopper interface is calibrated to ensure airtight sealing with your custom dimensions.

Stopper Customization Options

- Stopper Material Options: Choose from PTFE, silicone, glass, or rubber based on chemical resistance and temperature needs.

- Stopper Shape & Fit: Customize conical, flat, or threaded designs to match your instrument or sealing preference.

- Color-Coded Stoppers: Add color coding for sample identification or workflow management.

- Sterile or Pre-cleaned Options: Available for sensitive biological or pharmaceutical applications.

- Stopper Size Tolerance Control: Ensure tight fit with precision machining for leak-proof performance.

Custom Design Process

- Consultation: Our engineers work with you to understand the specific application of your Quartz Cuvette with PTFE Stopper and define key customization needs.

- Design & Quote: We provide detailed drawings and a quotation based on your required Quartz Cuvette with PTFE Stopper dimensions, volume, and stopper type.

- Prototype: A sample Quartz Cuvette with PTFE Stopper is produced for functional testing, dimensional verification, and optical performance evaluation.

- Approval: You review and approve the prototype Quartz Cuvette with PTFE Stopper to ensure it meets your instrument compatibility and sealing expectations.

- Production: We begin full-scale production of your customized Quartz Cuvette with PTFE Stopper, followed by strict quality control and timely delivery.

Usage Guide of Quartz Cuvette with PTFE Stoppers

Handling & Cleaning

-

Always handle with gloves

Fingerprints contain oils that can affect optical performance. Use lint-free gloves when handling optical surfaces. -

Clean immediately after use

Rinse with appropriate solvent, then with distilled water. For thorough cleaning, use mild detergent solution, rinse thoroughly, and air dry. -

For stubborn residues

Soak in 50% nitric acid solution for 30 minutes, then rinse thoroughly with distilled water. Avoid hydrofluoric acid, which will etch quartz. -

Final cleaning with ethanol/acetone

For optical surfaces, a final rinse with spectroscopic-grade ethanol or acetone can remove any remaining residues before air drying.

Storage & Maintenance

-

Store in original packaging

When not in use, store cuvettes in their original containers or dedicated cuvette storage boxes to prevent dust accumulation and physical damage. -

PTFE stopper maintenance

Clean PTFE stoppers separately with mild detergent. Ensure they are completely dry before reuse. Replace if deformed or damaged. -

Regular inspection

Periodically check for scratches, chips, or etching that could affect optical performance. Hold against light to check for residues or imperfections. -

Temperature considerations

While quartz can withstand high temperatures, avoid rapid temperature changes which may cause thermal stress. Allow heated cuvettes to cool gradually.

Best Practices for Measurement

- Handle only by the frosted or non-optical surfaces

- Wipe optical surfaces with lint-free lens tissue

- Ensure consistent orientation in the instrument

- Allow temperature equilibration before measurement

- Check for bubbles before measurement

- Ensure stopper is securely inserted for volatile samples

Need Technical Consultation?

We can assist with material selection, design optimization, and technical specifications.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: Does the Quartz Micro Cuvette with PTFE Stopper prevent solvent evaporation during UV-Vis analysis?

A: Absolutely. The PTFE stopper significantly reduces evaporation, maintaining solvent volume within ±0.5% during 30–60 minute runs.

Q: Is the Quartz Micro Cuvette with PTFE Stopper compatible with ethanol or acetone-based samples?

A: Yes, both the quartz body and PTFE stopper are chemically inert to common solvents like ethanol, acetone, and methanol.

Q: Can the PTFE stopper be sterilized for use in biological assays?

A: Yes, the PTFE stopper can be autoclaved or chemically sterilized without deformation or loss of sealing performance.

Q: Does the Quartz Micro Cuvette with PTFE Stopper support repeated measurements from the same sample?

A: Yes, the sealed design allows for multi-timepoint readings without sample degradation or volume loss.

Q: Is there a risk of cross-contamination when reusing the Quartz Micro Cuvette with PTFE Stopper?

A: With proper cleaning protocols, the cuvette and stopper can be reused safely; PTFE is non-porous and easy to decontaminate.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.