- Home

- /

- Types

- /

- Quartz Cuvette

- /

- High Precision Quartz Cuvette...

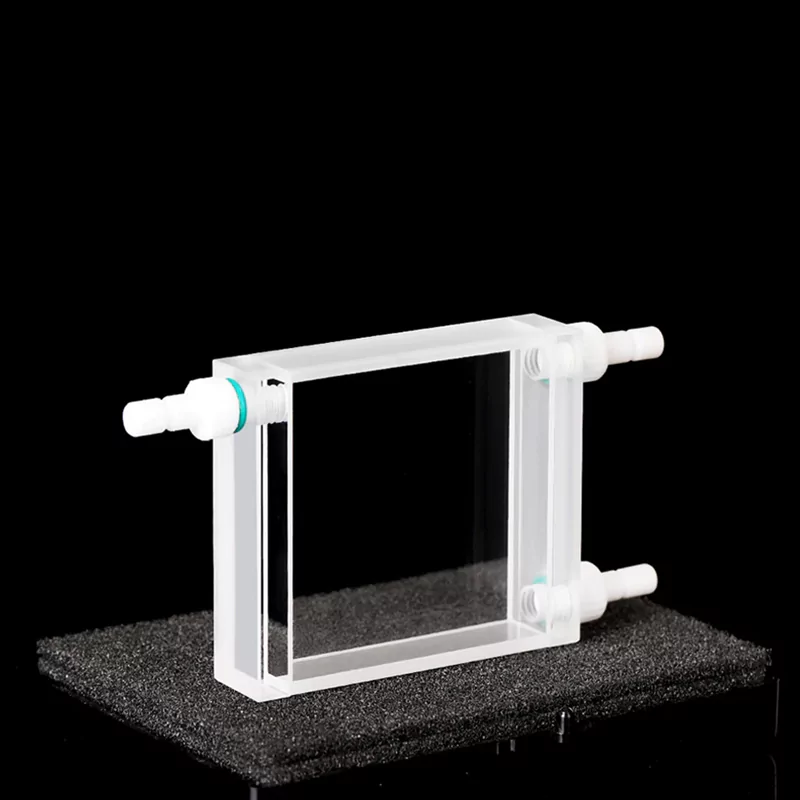

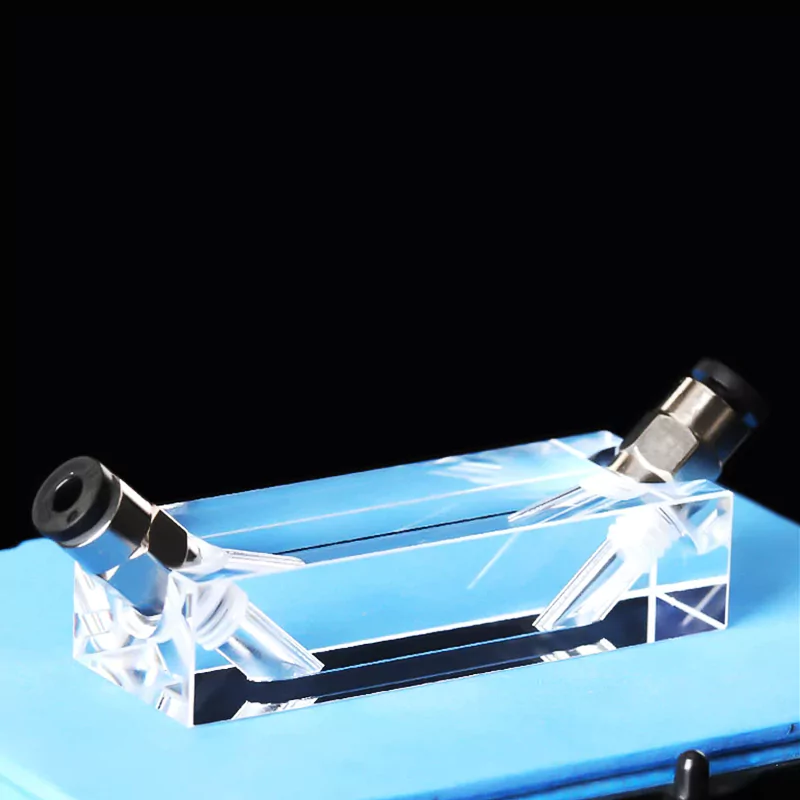

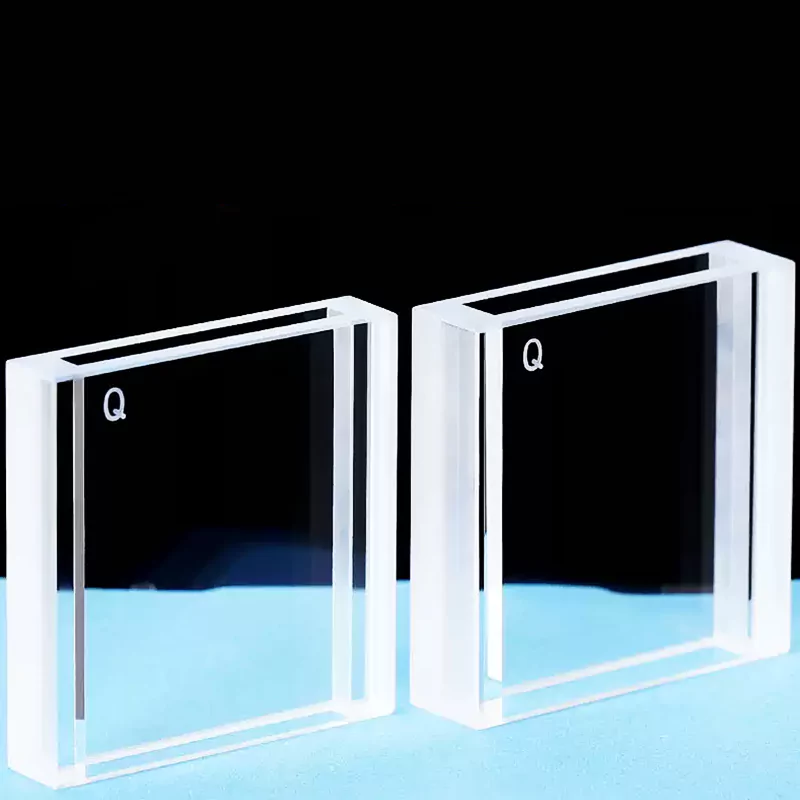

High Precision Quartz Cuvette Flow Cell for UV-Vis & IR Analysis -TOQUARTZ®

Featuring >99.98% high-purity quartz material with excellent optical transmission range (200nm-2500nm) and precision-engineered flow channels. Ideal for analytical instruments, medical diagnostics, and environmental monitoring equipment.

Features of Quartz Cuvette Flow Cell

TOQUARTZ® quartz cuvette flow cells are engineered for precision spectroscopic analysis applications requiring continuous sample flow. Manufactured from high-purity fused silica, these flow cells deliver exceptional optical performance and chemical durability required for demanding analytical applications.

Material Properties

-

High Purity Quartz:

99.995% SiO₂ content ensures minimal interference with spectroscopic measurements -

Chemical Resistance:

Exceptional stability against acids, bases, and organic solvents -

Thermal Stability:

Maintains structural integrity at temperatures up to 1100°C -

Low Expansion Coefficient:

5.5×10⁻⁷/K ensures dimensional stability during temperature fluctuations

Optical Performance

-

Wide Spectral Range:

Excellent transmission from 200nm to 2500nm with no absorption peaks -

Precision Optical Windows:

Surface flatness <λ/10 for accurate light path consistency -

Low UV Cutoff:

Suitable for deep UV applications down to 170nm -

Minimal Autofluorescence:

Ensures accurate fluorescence measurements without background interference

- Wide Spectral Range (200-2500nm)

- Thermal Stability (1100°C+)

- Custom Design Support

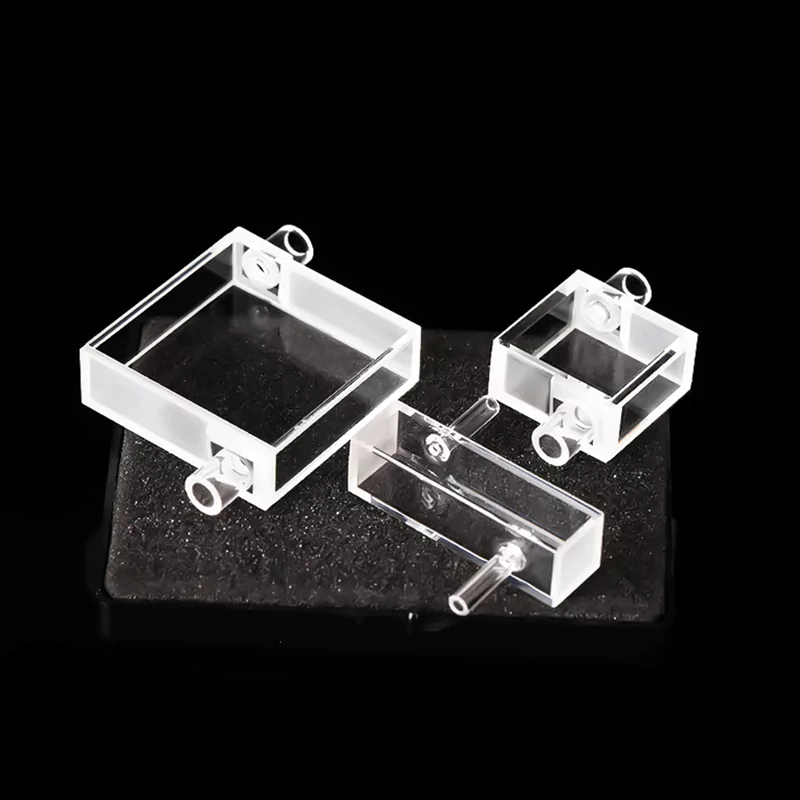

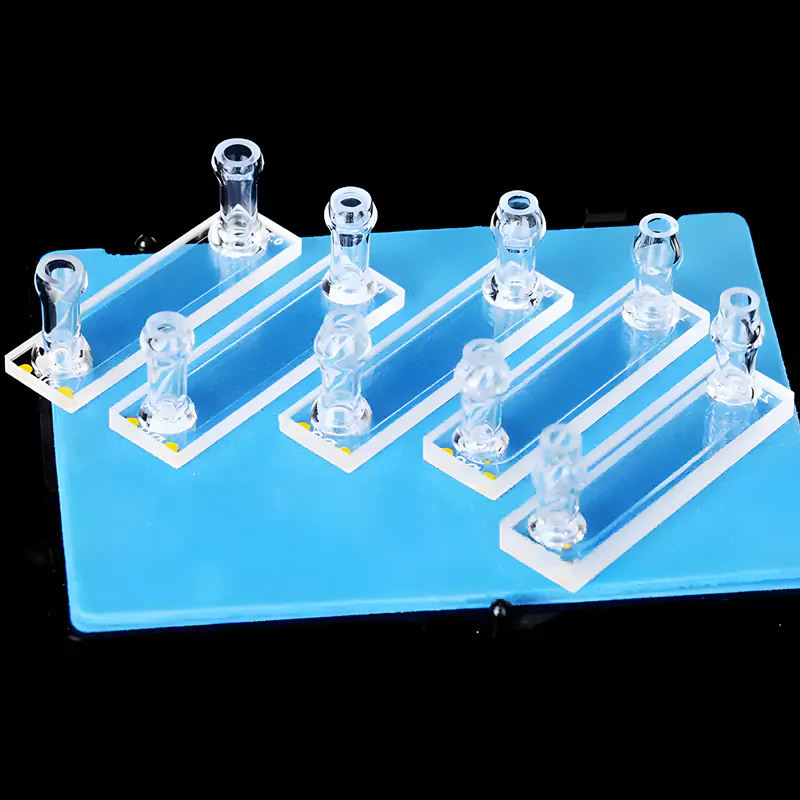

Quartz Glass Cuvette Flow Cell Design

-

Precision Flow Channels:

Optimized for laminar flow and minimal sample carryover -

Multiple Path Lengths:

Available from 0.1mm to 100mm to match application requirements

-

Connection Options:

Luer lock, barbed, threaded, and custom fittings available -

Dimensional Precision:

Manufacturing tolerance of ±0.1mm ensures reliable optical alignment

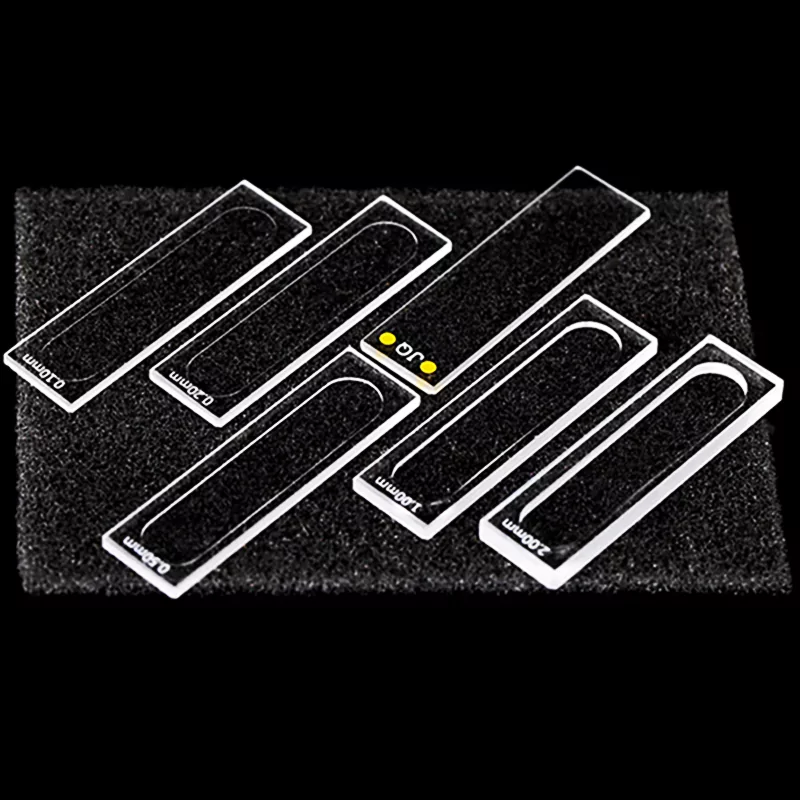

Technical Specifications & Dimensions of Quartz Cuvette Flow Cell

Technical Specifications of Quartz Flow Cuvette

| Parameter | Specification |

| Material | High purity fused quartz (>99.98% SiO₂) |

| Optical Transmission Range | 200nm – 2500nm |

| Standard Path Lengths | 1mm, 2mm, 5mm, 10mm, 20mm, 50mm, 100mm |

| Dimensional Tolerance | ±0.1mm (±0.05mm available for select models) |

| Optical Window Flatness | <λ/10 |

| Thermal Expansion Coefficient | 5.5×10⁻⁷/K |

| Surface Roughness | Ra<0.01μm |

| Maximum Operating Temperature | 1100°C |

| Flow Channel Diameter Options | 0.5mm, 0.8mm, 1mm, 1.5mm, 2mm (custom available) |

| Connection Types | Luer lock, barbed, threaded (M6, M8), custom |

Size of of Fused Quartz Cuvette Flow Cell

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

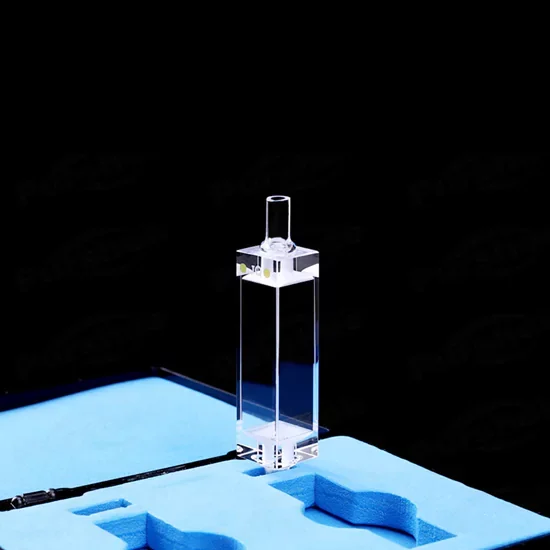

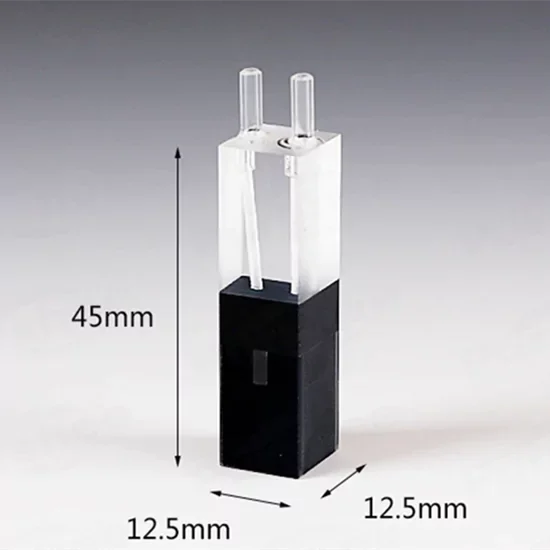

| AT-BSM-8001 | 3.5ml Quartz fluorescence flow cuvette with glass tube | 3.5ml | 10mm | 12.5×12.5x45mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-8002 | Quartz flow cuvette with M6 threaded connectors for lab | 200ul | 10mm | 12.5×12.5x35mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-8003 | Quartz flow cuvette cell Central Height 8.5mm | 32ul | 10mm | 12.5×12.5x35mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-8003-1 | Quartz flow cuvette cell | 800ul | 10mm | 12.5×12.5x35mm | 200nm-2500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-8004 | Quartz flow cuvette with glass tube | 100ul | 10mm |

12.5×12.5x45mm | 200nm-2500nm |

TOQUARTZ® Solving Solving Challenges with Quartz Cuvette Flow Cells

Fused Quartz Cuvette Flow Cells for Analytical Instrumentation

These components must integrate seamlessly into UV-Vis, IR, and fluorescence spectrophotometers while maintaining measurement accuracy and reproducibility across batches.

The flow channel design is critical for laminar flow patterns that prevent turbulence and ensure consistent sample presentation to the light path.

Key Advantages

- Optical window flatness <λ/10 ensures sub-nanometer wavelength accuracy in UV-Vis systems.

- Flow channel deviation <±0.05mm guarantees consistent light path alignment across batches.

- Integrated Z-path design reduces turbulence by 35%, improving signal stability in fluorescence detection.

TOQUARTZ® solution

A German analytical instrument manufacturer reported that inconsistent flow cell dimensions with ±0.2mm tolerance led to a 12% rejection rate and caused optical path misalignment.

TOQUARTZ® provided flow cells manufactured to ±0.1mm tolerance, reducing rejection rates to less than 2% and ensuring reliable spectrophotometer performance.

Quartz Flow Cuvette for Medical Diagnostic Equipment

These applications demand flow cells with minimal carryover between samples, biocompatible surfaces, and precise optical properties.

The flow cells must perform consistently through thousands of measurement cycles while maintaining compatibility with cleaning protocols and sterilization methods used in clinical environments.

Key Advantages

- Inner surface Ra<0.01μm minimizes protein adsorption and ensures <0.5% sample carryover.

- Biocompatible fused quartz supports 10,000+ cycles of blood/urine analysis without degradation.

- Compatible with ethanol, peracetic acid, and UV sterilization protocols used in clinical labs.

TOQUARTZ® solution

A European IVD device manufacturer faced inconsistent test results due to protein residue in polymer flow cells.

TOQUARTZ® provided ultra-smooth quartz flow cells (Ra<0.01μm), reducing carryover from 2.3% to 0.4% and improving test repeatability by 18%.

Quartz Cuvette Flow Cells for Environmental Monitoring

These applications often involve continuous exposure to corrosive samples, temperature fluctuations, and need for long-term deployment without maintenance.

Flow cells must provide reliable data for water quality analysis, pollutant detection, and process monitoring in industrial settings.

Key Advantages

- Maintains dimensional stability after 1,000 hours in pH 3–11 cycling, verified by <0.02mm deformation.

- Withstands continuous exposure to NaClO, H₂SO₄, and NH₄OH without surface etching or clouding.

- Operates reliably from -20°C to 90°C in field deployments with <1% drift in absorbance baseline.

TOQUARTZ® solution

A Canadian water quality monitoring equipment manufacturer experienced frequent flow cell failures due to corrosion when analyzing samples with fluctuating pH levels.

TOQUARTZ® provided high-purity quartz flow cells with enhanced acid/base resistance, extending the average service life from 8 months to over 2 years and reducing field maintenance requirements by 70%.

Customization Services for TOQUARTZ® Quartz Flow Cuvette

Design Assistance

TOQUARTZ® engineers provide technical guidance to optimize flow cell designs for your specific application requirements, including flow dynamics, optical path, and interface considerations.

Prototype Development

Rapid production of custom prototypes allows you to verify performance in your application before committing to larger production runs. Typical prototype delivery in 1-2 weeks.

Production Scaling

From small batch orders to large production runs, we maintain consistent quality and dimensional accuracy across all quantities, with transparent lead times and flexible delivery schedules.

Custom Fused Quartz Flow Cell Capabilities

Custom Path Lengths

From micro-volume (0.1mm) to extended paths (100mm+)

Specialized Flow Patterns

Z-path, serpentine, spiral, or custom channel geometries

Multi-Channel Designs

Parallel flow paths for simultaneous measurement of multiple samples

Interface Adaptation

Custom fittings to match your existing system connectors

Specialized Window Geometries

Angled, wedged, or specialized optical surfaces

Instrument Integration

Custom designs for direct integration into your instrument

Usage Guide of Fused Quartz Flow Cuvette

Handling & Installation

-

Handle with Care:

Quartz is relatively fragile. Always handle flow cells gently and avoid applying pressure to optical windows. -

Proper Tubing Connection:

Ensure tubing fits properly without excessive force. Over-tightening connections can crack the flow cell. -

Flow Rate Control:

Begin with low flow rates and gradually increase to operating conditions to prevent pressure spikes. -

Avoid Air Bubbles:

Ensure flow systems are properly primed to eliminate air bubbles that can disrupt measurements.

Cleaning Procedure

-

Regular Flushing:

After each use, flush with distilled water (3 times) to remove sample residue. -

Organic Contamination:

For organic residue, use a 50:50 mixture of ethanol and diethyl ether, followed by distilled water rinse. -

Stubborn Deposits:

For difficult contaminants, use specialized quartz cleaning solution for no more than 10 minutes, then rinse thoroughly. -

Avoid:

Never use alkaline solutions, detergents, abrasive cleaners, or brushes. Avoid prolonged exposure to hydrofluoric acid or high concentration fluoride solutions.

Storage & Maintenance

-

Dry Storage:

After cleaning, allow flow cells to dry completely by flushing with air or drying in a dust-free environment. Store in original protective case. -

Regular Inspection:

Periodically inspect flow cells for scratches, cracks, or deposits. Check optical clarity by running baseline measurements. -

Solvent Compatibility:

While quartz is resistant to most chemicals, verify compatibility with new solvents before extended use, especially with concentrated alkalis. -

Temperature Control:

Avoid rapid temperature changes that can stress the quartz material. Allow flow cells to gradually reach operating temperature.

Need a Custom Quartz Cuvette Flow Cell Solution?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the wavelength range for TOQUARTZ® quartz cuvette flow cells?

A: TOQUARTZ® high-purity quartz flow cells provide excellent transmission across a wide spectral range from 200nm in the deep UV to 2500nm in the infrared region. Unlike glass cuvettes that absorb below 320nm, quartz flow cells are essential for UV spectroscopy applications and offer no absorption peaks throughout their transmission range.

Q: What is the proper quartz cuvette cleaning procedure for quartz flow cell?

A: For routine cleaning, flush the flow cell with distilled water three times after use. For organic contaminants, use a 50:50 mixture of ethanol and diethyl ether followed by distilled water rinse. For stubborn deposits, specialized quartz cleaning solutions can be used briefly (less than 10 minutes) followed by thorough rinsing. Never use alkaline solutions, detergents, abrasive cleaners, or brushes that can damage the quartz surface.

Q: What is the solvent compatibility of quartz cuvette flow cells?

A: Quartz flow cells are compatible with most laboratory solvents including water, alcohols, acetone, acetonitrile, DMSO, THF, hexane, toluene, chloroform, and dilute acids. They resist most organic and inorganic compounds. However, hydrofluoric acid (HF) and concentrated fluoride solutions should be avoided as they can etch quartz. Concentrated alkaline solutions should also be used with caution for prolonged periods.

Q: What is the typical absorbance range for quartz flow cells?

A: The absorbance range depends on the flow cell path length and your instrument’s capabilities. With TOQUARTZ® flow cells, you can measure absorbances from as low as 0.001 AU to over 3.0 AU depending on your detector sensitivity. For high absorbance samples, shorter path lengths (0.1-1mm) are recommended, while low concentration samples benefit from longer path lengths (10-100mm) to enhance sensitivity.

Q: What is the difference between Z-path and linear flow cells?

A: Z-path flow cells feature inlet and outlet ports on opposite sides with a Z-shaped flow channel, offering better flow dynamics and reduced bubble trapping. Linear flow cells have a straight flow path with ports typically on the same side. Z-path designs are preferred for automated systems and continuous flow applications, while linear designs are often simpler and more economical for basic applications.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.