- Home

- /

- Types

- /

- Quartz Cuvette

- /

- Quartz Fluorescence Cuvette

- /

- Gas-Tight Quartz Atomic Gas...

Gas-Tight Quartz Atomic Gas Cell Cuvettes for Fluorescence Spectroscopy -TOQUARTZ®

Features of Quartz Atomic Gas Cell Cuvette

TOQUARTZ® atomic gas cell cuvettes are manufactured using advanced high-temperature fusion techniques to ensure superior optical quality and precision. Our manufacturing process produces gas cells with exceptional transparency, dimensional accuracy, and gas-tight sealing.

Material Properties

- High-purity quartz (≥99.98%, up to 99.995% SiO₂) for minimal chemical interference

- Excellent chemical resistance against acids, bases, and fluorinated gases

- Low thermal expansion coefficient (5.5×10⁻⁷ /°C) for dimensional stability

Design Features

- Precision-engineered gas inlet/outlet tubes for controlled flow or sealed operation

- Gas-tight sealing with leak rates <10⁻⁹ atm·cc/sec for sensitive experiments

- Available with standard or custom path lengths for specific application needs

- Compatible with standard laboratory fittings for seamless integration

Optical Performance

- Broad spectral transmission range (120-4500nm) with no absorption peaks

- UV transmission (>90% at 200nm) for UV spectroscopy applications

- Precision-polished optical surfaces with minimal scatter

- Bubble-free and inclusion-free material for distortion-free optical path

- Wall thickness consistency within ±0.1mm

- Scratch-free optical surfaces with <λ/10 flatness

- Customization Services Available

Technical Specifications & Dimensions of Quartz Atomic Gas Cell Cuvette

Technical Specifications

| Parameter | Specification |

| 1. Physical Properties | |

| Material | High-purity fused quartz (up to 99.995% SiO₂) |

| Density | 2.2 g/cm³ |

| Thermal Expansion Coefficient | 5.5 × 10-7/℃ (20-320°C) |

| Thermal Conductivity | 1.4 W/m·K at 20°C |

| 2. Chemical Properties | |

| Chemical Composition | ≥99.995% SiO₂ |

| Impurity Content | Al <20 ppm, Ca <1 ppm, Fe <1 ppm, K <1 ppm, Li <1 ppm, Na <1 ppm |

| Chemical Resistance | Excellent resistance to acids, alkalis, and halogens (except HF) |

| Gas Permeability | Helium: <10-11 cm2/s at 20°C |

| 3. Optical Properties | |

| Transmission Range | 120-4500 nm |

| UV Transmission (10mm path) | >80% at 170nm, >90% at 200nm |

| Refractive Index | 1.458 at 546.1 nm (20℃) |

| Surface Quality | 80-50 scratch-dig per MIL-PRF-13830B |

| Flatness | <λ/10 at 632.8 nm |

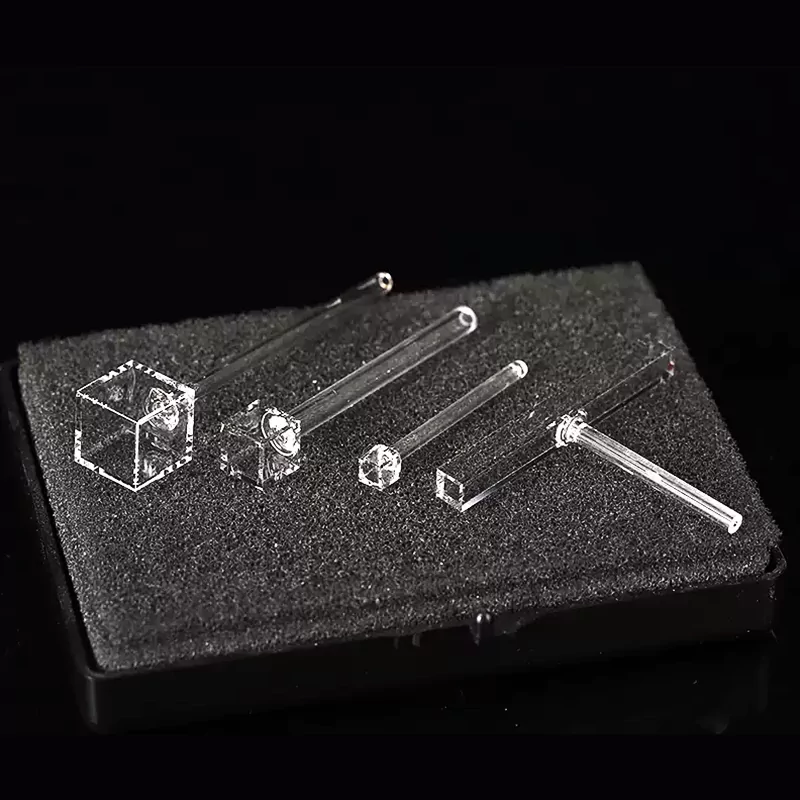

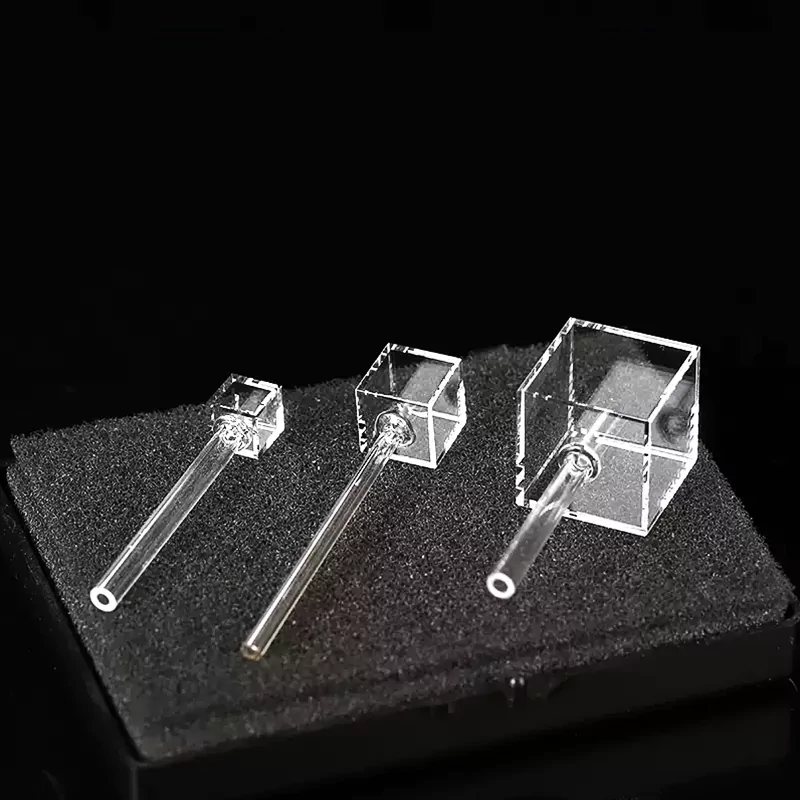

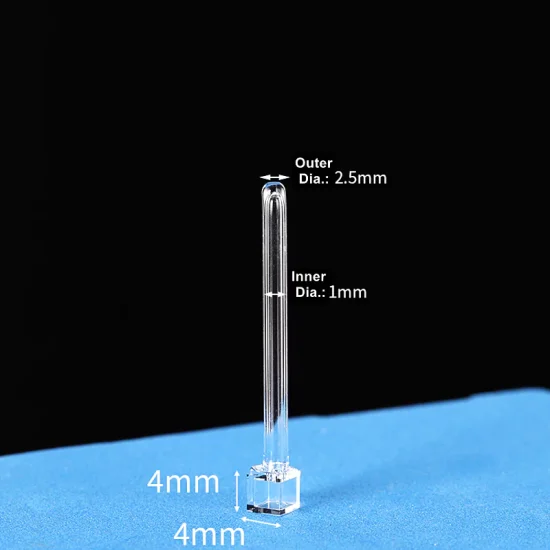

Size Chart

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

| AT-BSM-6031-1 | Quartz gas cell cuvette | 4mm | 4mm | 4mm | 2.5mm | 1mm |

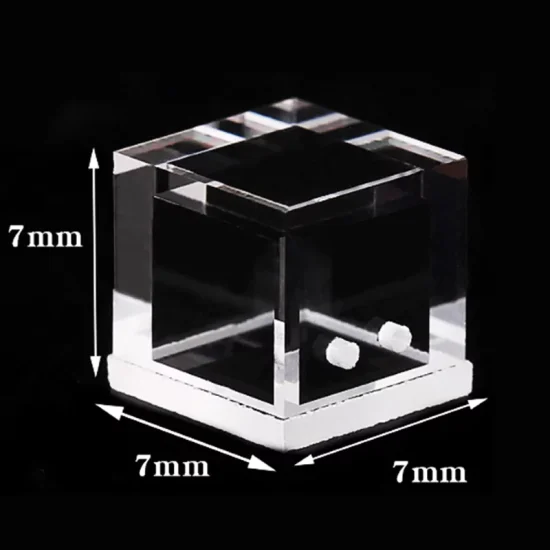

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

| AT-BSM-6031-6 | Quartz gas cuvette with dual bore | 7mm | 7mm | 7mm | / | / |

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

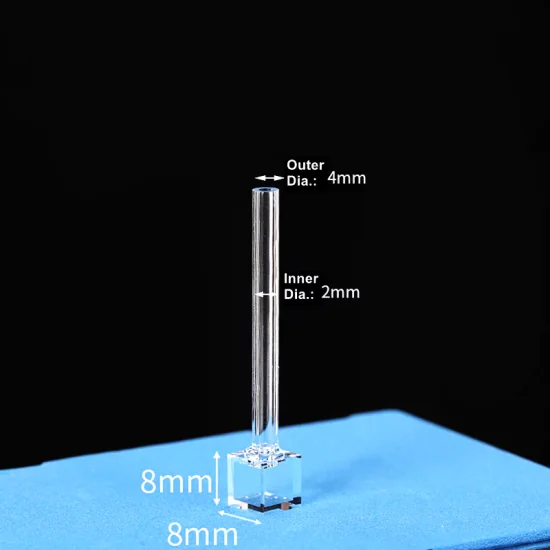

| AT-BSM-6031-2 | Quartz fluorescence cuvette with gas chamber | 8mm | 8mm | 8mm | 4mm | 2mm |

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

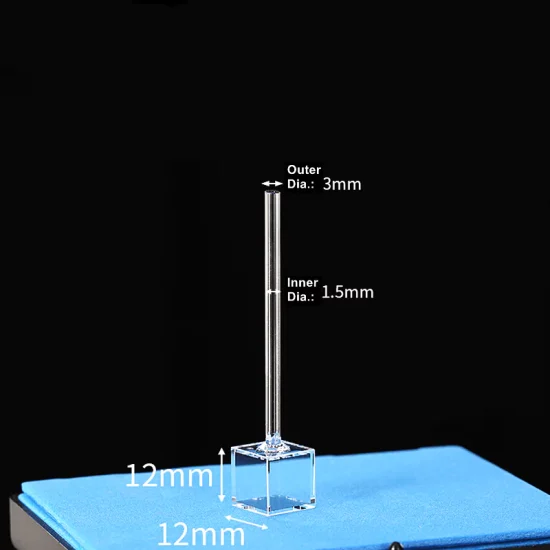

| AT-BSM-6031-3 | Quartz spectroscopy gas cell | 12mm | 12mm | 12mm | 3mm | 1.5mm |

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

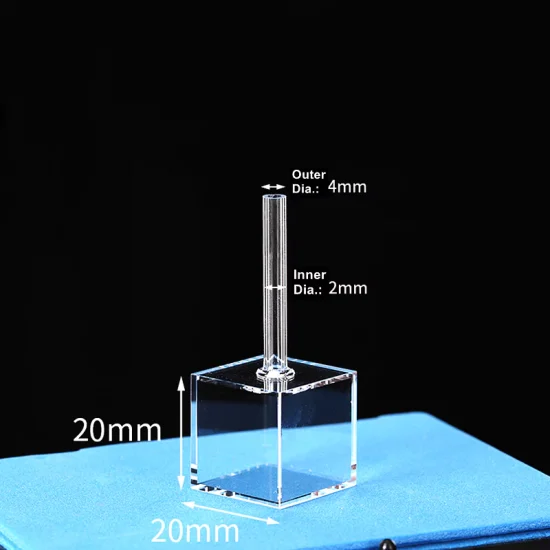

| AT-BSM-6031-4 | Quartz cuvette for atomic absorption | 20mm | 20mm | 20mm | 4mm | 2mm |

| Model | Description | Length | Width | Height | Outer Dia. | Inner Dia. |

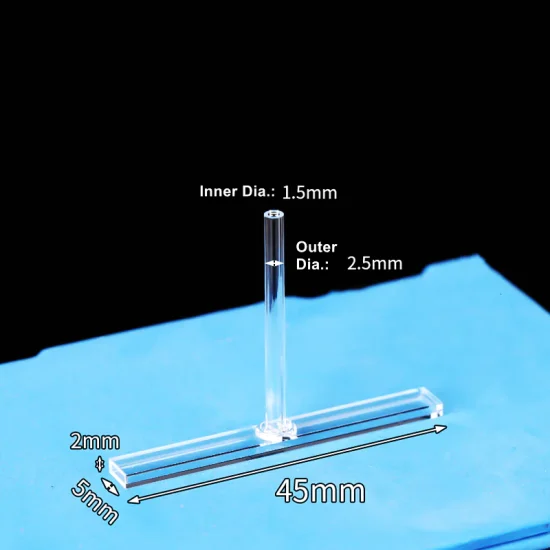

| AT-BSM-6031 | Quartz Atomic Gas Cell Cuvette | 45mm | 5mm | 2mm | 2.5mm | 1.5mm |

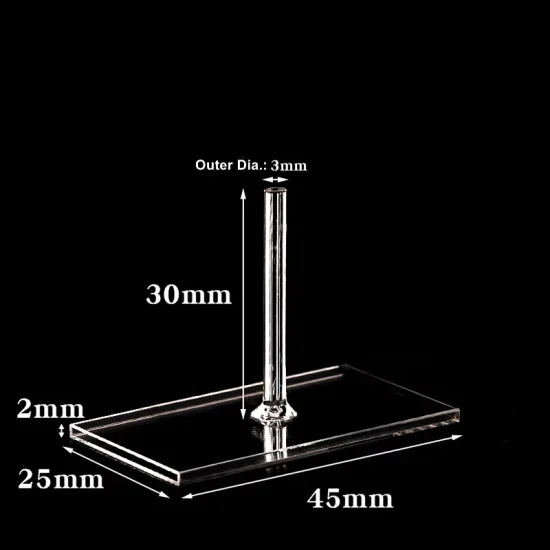

| Model | Description | Length | Width | Height1 | Outer Dia. | Height2 |

| AT-BSM-6031-5 | Quartz optical gas cell | 45mm | 25mm | 2mm | 3mm | 30mm |

TOQUARTZ® Solving Critical Challenges with Quartz

Atomic Gas Cell Cuvette

Real-Time VOC Detection in Industrial Emissions Using Quartz Atomic Gas Cell Cuvette

Key Advantages

-

Surface roughness <5nm Ra for anti-fog optical clarity

Prevents condensation of VOCs like formaldehyde during continuous sampling. -

Corrosion resistance validated in 500h benzene/toluene exposure

Maintains >95% optical transmission after prolonged chemical exposure. -

Integrated KF16 flange with 0.01mm concentricity tolerance

Ensures leak-free automation-ready connection to industrial gas lines.

TOQUARTZ® solution

A South Korean petrochemical plant reported 3–4 cuvette failures/month due to VOC-induced etching and fogging. TOQUARTZ® supplied chemically polished gas cells with anti-fog quartz and KF flanges, reducing cuvette replacement frequency by 80% and stabilizing calibration drift within ±1.2% over 6 months.

Fluorescence-Based Breath Biomarker Detection in Medical Diagnostics Using Quartz Atomic Gas Cell Cuvette

Key Advantages

-

Background fluorescence <0.05% at 280nm excitation

Enables detection of trace biomarkers like isoprene at ppb levels. -

Micro-volume chamber design (≤1.5mL dead volume)

Optimized for single-breath sampling with minimal dilution error. -

Biocompatible fused sealing with EO sterilization compatibility

Supports clinical-grade hygiene standards for repeated patient use.

TOQUARTZ® solution

A US-based medtech startup faced 12% false-positive rates in acetone breath tests due to cuvette autofluorescence and sample dilution. TOQUARTZ® delivered ultra-low background micro-chambers with EO-sterilizable seals, reducing false positives to 1.8% and enabling successful IRB approval for clinical trials.

Laser-Induced Fluorescence (LIF) in Combustion Diagnostics Using Quartz Atomic Gas Cell Cuvette

Key Advantages

-

UV-grade quartz with >92% transmission at 193nm

Ensures accurate excitation of OH and NO radicals in deep-UV LIF systems. -

Thermal shock resistance up to 1100°C with <0.5% deformation

Maintains structural integrity during rapid heating in flame-front diagnostics. -

Optical window flatness <λ/10 at 248nm

Minimizes beam distortion and preserves spatial resolution in laser sheet imaging.

TOQUARTZ® solution

A combustion research lab in Germany experienced 28% signal loss due to window warping in standard cuvettes after 3–5 flame tests. TOQUARTZ® delivered LIF-optimized gas cells with UV-grade quartz and thermal-resistant joints, enabling over 50 test cycles with <3% signal drift and eliminating the need for weekly replacements.

TOQUARTZ® Custom Quartz Atomic Gas Cell Cuvette Solutions

Design Consultation

- Technical drawing review and optimization

- Material selection guidance

- Optical path length optimization

- Compatibility assessment for your specific gases

- Cost-effective design recommendations

Customization Options

- Custom dimensions and shapes

- Specialized inlet/outlet configurations

- Window angle optimization for optical access

- Integration with standard laboratory fittings

- Multi-chamber and specialized flow designs

Specialized Customization for Atomic Gas Cell Applications

- Variable path length designs for concentration-dependent studies (10mm to 200mm)

- High-temperature compatible seals for elevated temperature experiments (up to 800°C)

- Multi-port configurations for complex gas mixing or sampling requirements

- Integration with heating/cooling elements for temperature-controlled spectroscopy

- Anti-reflection coatings for specialized wavelength applications

Usage and Care Guidelines

Handling and Installation

- Always handle cuvettes with clean gloves to prevent fingerprints and contamination on optical surfaces.

- When connecting gas lines, avoid over-tightening fittings which may cause stress fractures. Use torque specifications provided with your specific model.

- Install with proper support along the cell body to avoid cantilever stress that may lead to breakage.

- When using in optical setups, ensure proper alignment to minimize strain on mounting points.

Cleaning and Maintenance

- Clean optical surfaces with high-purity acetone, methanol, or specialized optical cleaning solutions followed by filtered compressed air drying.

- For persistent contamination, use 2% solution of laboratory-grade detergent followed by thorough rinsing with deionized water.

- Periodically check gas connections for leaks using appropriate leak detection methods for your application.

- If used with corrosive gases, flush with inert gas after each use to prevent internal surface degradation.

Operational Considerations

- Maintain pressure within specified limits (typically ±1 bar from atmospheric for standard cells). For high-pressure applications, use specially designed cells.

- For temperature-controlled applications, implement gradual heating/cooling (max 5°C/min) to prevent thermal shock.

- When using UV light sources, monitor for potential solarization effects in long-term applications.

- If mechanical vibration is present in your setup, use dampening mounts to protect the cell from stress fractures.

Storage and Transportation

- Store in original packaging or dedicated container with appropriate cushioning to prevent physical damage.

- Maintain in a clean, dry environment away from chemicals that could damage or contaminate the cuvette.

- For sealed gas cells, verify pressure conditions before long-term storage or transportation to prevent stress on seals.

- Label with handling instructions if transferring between laboratory teams or shipping to collaborators.

Need Help Selecting the Right Quartz Atomic Gas Cell Cuvette?

With over 15 years of experience in quartz manufacturing, we can suggest solutions that enhance your experimental results and reduce operational costs.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What makes Quartz Atomic Gas Cell Cuvettes suitable for fluorescence-based gas analysis?

A: Quartz Atomic Gas Cell Cuvettes are designed with sealed or semi-sealed chambers and extended inlet/outlet tubes, allowing precise control of gas flow. Their high UV transparency (≥90% at 200nm) ensures accurate excitation of gas-phase molecules. The low background fluorescence of high-purity quartz minimizes signal interference. These features are essential for sensitive fluorescence detection.

Q: How do Quartz Atomic Gas Cell Cuvettes minimize background fluorescence in LIF experiments?

A: TOQUARTZ® uses ultra-pure quartz (≥99.995% SiO₂) with minimal trace metal content to reduce autofluorescence. The material is thermally annealed and optically polished to eliminate internal defects. This ensures a clean optical path for laser-induced fluorescence (LIF) diagnostics. As a result, signal-to-noise ratios are significantly improved.

Q: How do Quartz Atomic Gas Cell Cuvettes handle low-concentration gas samples?

A: Our cuvettes feature micro-volume chambers with minimal dead space, enhancing sensitivity for trace gas detection. This is critical in applications like breath biomarker analysis or environmental VOC monitoring. The sealed design prevents sample dilution or contamination. Combined with high optical clarity, this enables ppb-level detection.

Q: How do Quartz Atomic Gas Cell Cuvettes maintain optical alignment during use?

A: Each cuvette is manufactured with optical window flatness <λ/10 and parallelism <0.02mm. This ensures minimal beam distortion and consistent fluorescence excitation. The rigid quartz structure resists deformation under pressure or heat. These properties are essential for high-resolution fluorescence imaging.

Q: Are Quartz Atomic Gas Cell Cuvettes suitable for multi-gas fluorescence analysis?

A: Yes, multi-port designs are available for simultaneous or sequential gas introduction. This is useful in reaction kinetics studies or gas mixing experiments. The cuvettes maintain optical clarity across multiple gas cycles. TOQUARTZ® supports custom chamber geometries for complex fluorescence workflows.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.