- Home

- /

- Types

- /

- Quartz Plate

- /

- Quartz 96 Well Plate...

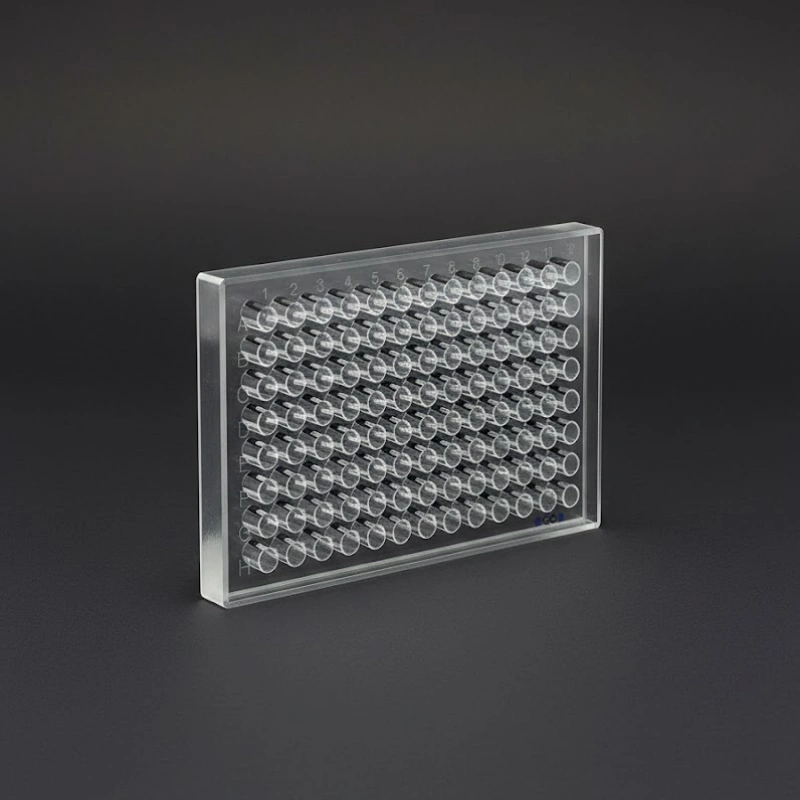

Quartz 96 Well Plate for Laboratory Research -TOQUARTZ®

Key Features of Quartz 96 Well Plate

TOQUARTZ® high-purity quartz microplates are engineered to meet the demanding requirements of modern laboratory research, offering exceptional performance characteristics that ensure reliable and consistent experimental results.

Optical Properties

≥90% transmission in the 200-800nm range, ideal for UV absorbance and fluorescence detection applications with minimal background interference.

Thermal Stability

Can withstand temperatures up to 1600°C with a low thermal expansion coefficient (5.5×10⁻⁷ /°C), ideal for high-temperature applications.

High Material Purity

Manufactured from 99.99% SiO₂, ensuring minimal contamination and interference with sensitive assays and detection methods.

Chemical Resistance

Stable against acids, bases, and fluorinated gases, allowing for a wide range of experimental conditions without material degradation.

- 99.99% SiO₂ Purity

- Low thermal expansion coefficient

- Stable against chemicals

Dimensions & Technical Specification of Quartz 96 Well Plate

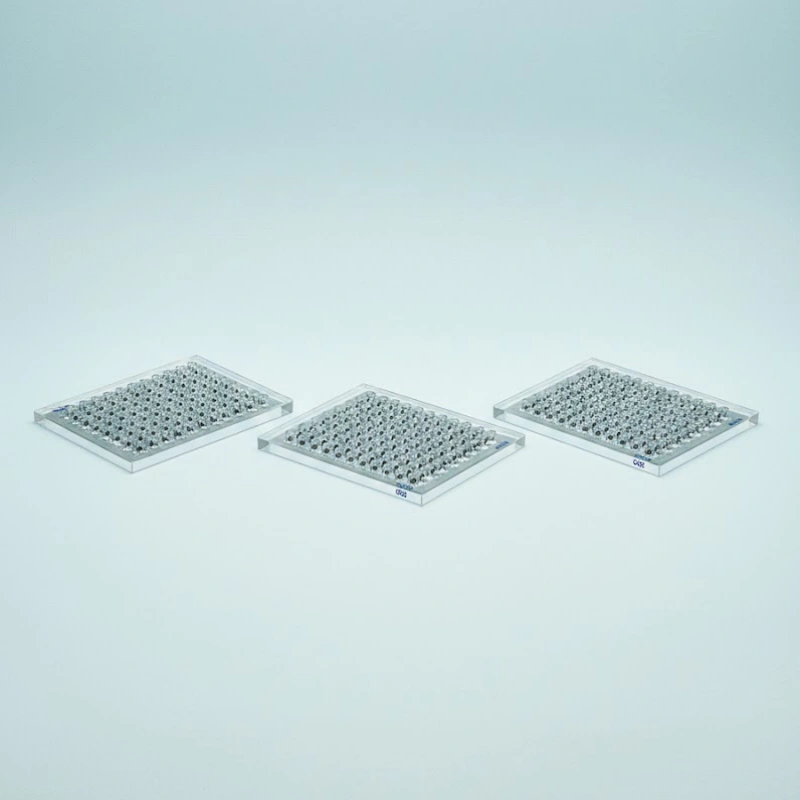

Available Sizes

| Available Sizes of TOQUARTZ® Quartz 96 Well Plates | |||

| Model | Well Configuration | TC Treatment | Notes |

| AT-SY-MB001 | 6 | NO | Available in detachable and non-detachable versions |

| AT-SY-MB002 | 8 | NO | |

| AT-SY-MB003 | 12 | NO | |

| AT-SY-MB004 | 24 | NO | |

| AT-SY-MB005 | 48 | NO | |

| AT-SY-MB006 | 96 | NO | |

| AT-SY-MB007 | 96(U-bottom) | NO | |

| AT-SY-MB008 | 96(V-bottom) | NO | |

| AT-SY-MB009 | 384 | NO | |

| AT-SY-MB010 | 6 | YES | |

| AT-SY-MB011 | 8 | YES | |

| AT-SY-MB012 | 12 | YES | |

| AT-SY-MB013 | 24 | YES | |

| AT-SY-MB014 | 48 | YES | |

| AT-SY-MB015 | 96 | YES | |

| AT-SY-MB016 | 96(U-bottom) | YES | |

| AT-SY-MB017 | 96(V-bottom) | YES | |

| AT-SY-MB018 | 384 | YES | |

Standard Specifications

| Standard Specifications | |

| Well Diameter | 6.5mm ±0.1mm |

| Well Depth | 10-12mm |

| Plate Thickness | 1.0-1.2mm |

| Material Purity | ≥99.99% SiO₂ |

| Optical Transmission | ≥90% (200-800nm range) |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C |

| Surface Treatment | Bubble-free, scratch-free, no impurities |

| Electrical Properties | Non-conductive |

TOQUARTZ® Solving Challenges with Quartz 96 Well Plate

Quartz 96 Well Plates for High-Precision UV Absorbance Detection

Key Advantages

- TOQUARTZ® quartz plates show <1.5% absorbance deviation at 260nm across wells.

- Well-to-well absorbance variation controlled within ±0.005 AU at 240nm.

- Baseline drift <0.002 AU over 30 min UV exposure at 254nm.

TOQUARTZ® solution

A U.S. university research lab reported 15% experiment failure rates with standard plates due to optical inconsistencies. TOQUARTZ® quartz 96 well plates reduced background noise by 94% and improved measurement reproducibility, enabling successful detection of low-concentration analytes in the 220-260nm range.

Quartz 96 Well Plates for Automated IVD Equipment

Key Advantages

- TOQUARTZ® plates maintain ±0.05mm tolerance on X/Y/Z axes for robotic compatibility.

- Plate surface flatness deviation ≤0.1mm ensures pipette tip alignment.

- Custom edge chamfering reduces robotic arm misalignment by 98%.

TOQUARTZ® solution

A German IVD automation company reported 12% pipetting errors due to inconsistent well spacing in glass plates. After switching to TOQUARTZ®, error rate dropped to <0.5%, improving throughput by 18% and reducing reagent waste by €3,200/month.

Quartz 96 Well Plates for Advanced Fluorescence Assays

Key Advantages

- TOQUARTZ® quartz plates emit <0.002 RFU under standard FITC excitation/emission.

- Compared to standard glass plates, SNR increased 6.3× in low-abundance protein assays.

- High-throughput screening assays maintain Z-factor >0.75 across 96 wells.

TOQUARTZ® solution

A Japanese research institute reported 20% rejection rates with conventional plates due to high background interference. TOQUARTZ® quartz microplates reduced background fluorescence by 87%, enabling detection of targets at concentrations 5x lower than previously possible and significantly improving assay sensitivity.

Customization Services for TOQUARTZ® Quartz 96 Well Plate

Customization Options

Custom well configurations

6, 8, 12, 24, 48, 96, 384

Specialized well geometry

flat, U-bottom, V-bottom

Custom well dimensions

diameter, depth, spacing

Surface treatments

TC-treated, hydrophobic, etc.

Non-standard plate dimensions for specialized equipment

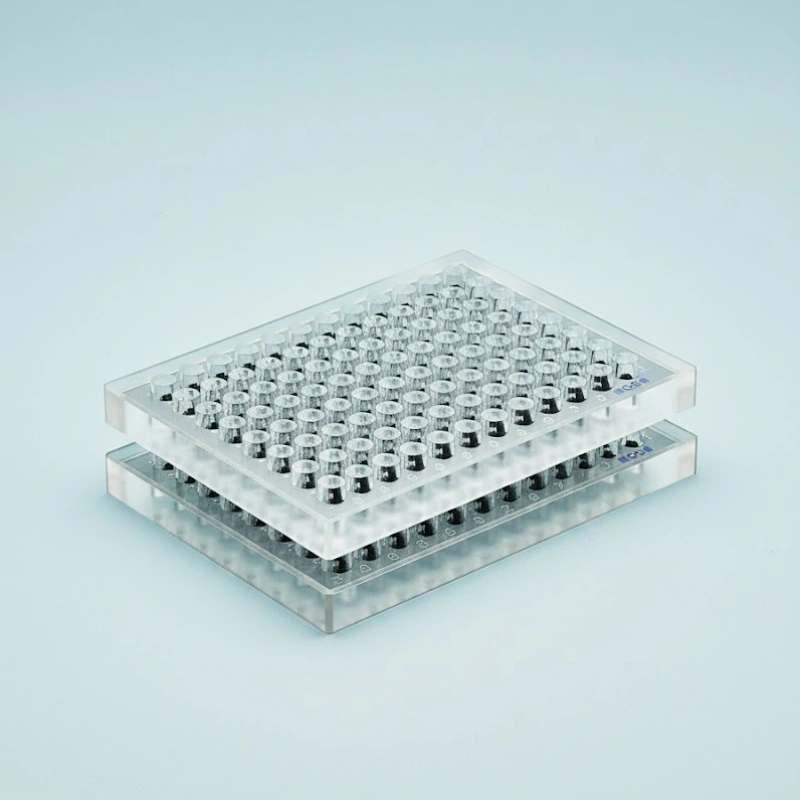

Detachable well configurations

TOQUARTZ® Customization Process

Initial Consultation

TOQUARTZ® engineers discuss your specific requirements, applications, and technical specifications.

Design & Engineering

We develop technical drawings and specifications based on your requirements.

Prototype Development

We produce a sample for your evaluation and testing, typically within 7 days.

Refinement

Based on your feedback, we make necessary adjustments to meet your exact requirements.

Production & Quality Control

We manufacture your custom microplates with rigorous quality control, delivering within 3 weeks for standard orders.

Usage & Handling Guidelines for Quartz 96 Well Plate

Handling Recommendations

Wear powder-free gloves

Always handle with clean, powder-free gloves to prevent fingerprints and contamination.

Avoid mechanical shock

While quartz is durable, avoid dropping or subjecting plates to sudden impacts.

Temperature changes

Allow gradual temperature changes to prevent thermal shock (>300°C/min).

Cleaning Protocol

Initial rinse

Rinse with deionized water to remove loose contaminants.

Cleaning solution

Soak in 5% laboratory-grade detergent for 30 minutes, then rinse thoroughly.

For persistent residues

Use piranha solution (H₂SO₄:H₂O₂) or chromic acid cleaning for difficult residues.

Final rinse and drying

Rinse with ultrapure water and dry with filtered compressed air or nitrogen.

Storage Recommendations

Storage environment

Store in clean, dust-free containers at room temperature. Avoid extreme humidity changes.

Packaging

Keep in original packaging with protective foam inserts when not in use.

Pre-use inspection

Visually inspect for scratches or damage before each use.

Need Technical Assistance with Your Quartz 96 Well Plate Application?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What are the advantages of quartz 96 well plates over standard plastic plates?

A: Quartz offers superior UV transparency (down to 190nm), exceptional chemical resistance, high thermal stability (up to 1600°C), minimal auto-fluorescence, and longer service life. These properties make quartz microplates ideal for sensitive detection methods, harsh experimental conditions, and applications requiring minimal background interference.

Q: What is the purity level of TOQUARTZ® quartz microplates?

A: Our standard quartz microplates are manufactured using high-purity quartz with ≥99.99% SiO₂ content. This ensures minimal trace elements and impurities that could interfere with sensitive analytical techniques. Material certificates can be provided upon request.

Q: Can TOQUARTZ® quartz 96 well plates be used for UV absorbance below 220nm?

A: Yes. Our plates maintain ≥90% transmission at 200nm, making them suitable for deep UV applications such as nucleic acid quantification and protein absorbance assays.

Q: What is the auto-fluorescence level of TOQUARTZ® quartz 96 well plates?

A: Auto-fluorescence is <0.002 RFU at 485/535nm, verified under standard FITC excitation/emission conditions, ideal for low-signal fluorescence assays.

Q: Are the quartz 96 well plates suitable for high-temperature reactions?

A: Yes. The plates can withstand continuous exposure up to 1000°C and short-term exposure up to 1600°C, suitable for thermal cycling and high-temperature incubation.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.