Contamination-Free Photovoltaic Quartz Glass for Precision Solar Processing

Designed for purity-critical solar applications, TOQUARTZ® quartz components minimize contamination and maximize yield in high-temperature, high-precision environments.

- Ultra-low impurity levels

- Stable under thermal cycling

- Ideal for solar cell lines

What is Photovoltaic Quartz Glass?

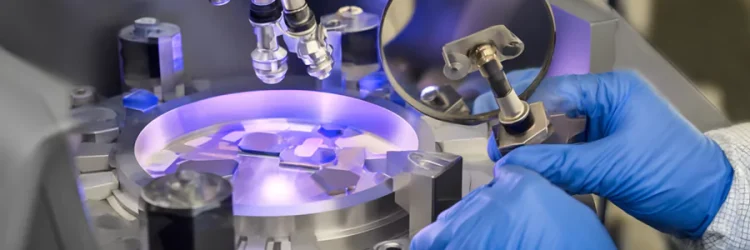

Photovoltaic Quartz Glass refers to high-purity quartz glass components specifically engineered for solar cell manufacturing processes. These specialized components are essential in various thermal processing stages of solar wafer and cell production, offering exceptional resistance to high temperatures and chemical corrosion while maintaining dimensional stability.

Premium Photovoltaic Quartz Glass Characteristics

TOQUARTZ® Photovoltaic Quartz Glass products deliver superior performance in demanding solar manufacturing environments, combining thermal stability with precise engineering to maximize production efficiency.

High Purity Composition

Manufactured from premium-grade materials with SiO₂ content up to 99.995%, minimizing the risk of contamination during critical solar cell production processes.

- Trace metal impurities <1ppm

- OH content <10ppm for specialized applications

- Ultra-low bubble content for optical clarity

Thermal Stability

TOQUARTZ® quartz glass components withstand extreme temperatures up to 1600°C with minimal deformation, ensuring reliable performance in high-temperature diffusion and annealing processes.

- Low thermal expansion coefficient (5.5×10⁻⁷/K)

- Excellent thermal shock resistance

- Maintains structural integrity during rapid heating cycles

Chemical Resistance

Highly resistant to acids, alkalis, and fluorine-based gases commonly used in solar cell fabrication, ensuring long service life and contamination-free processing.

- Resistant to HCl, and other aggressive chemicals

- Inert to molten salts used in processing

- Prevents contamination in critical manufacturing steps

Product Types of Photovoltaic Quartz Glass We Offer

Explore our full range of photovoltaic quartz glass components engineered for high-temperature, high-purity solar manufacturing environments.

Photovoltaic Quartz Glass Applications in Solar Manufacturing

TOQUARTZ® photovoltaic Quartz components play crucial roles throughout the solar cell manufacturing process, from silicon ingot growth to final cell processing, enabling higher efficiency and production yields.

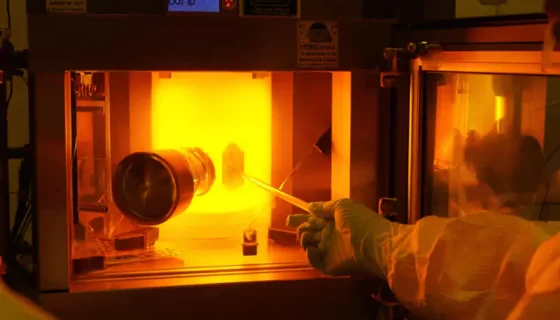

Diffusion Furnace Systems

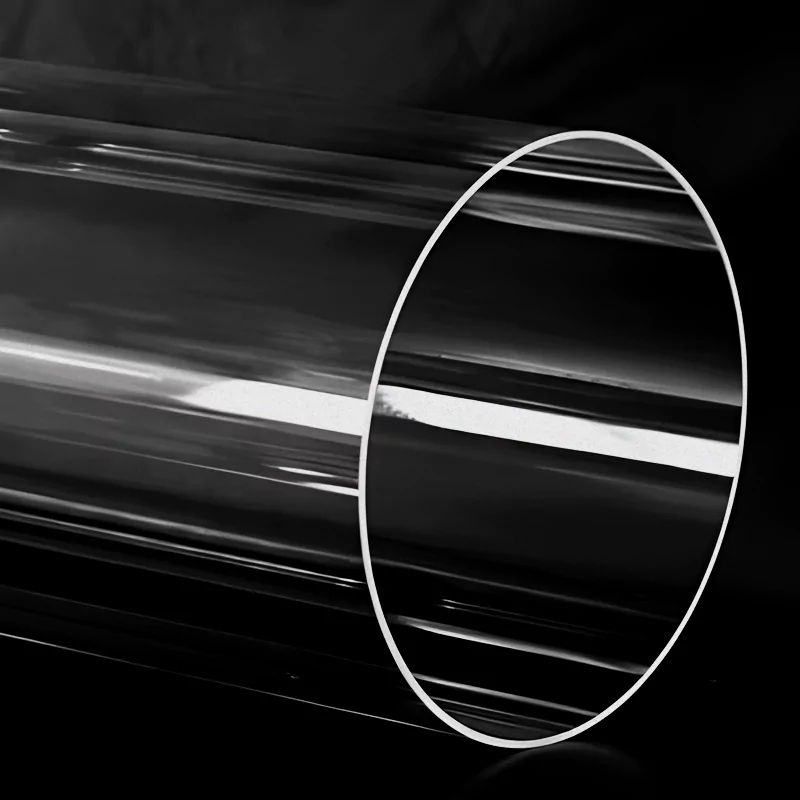

Photovoltaic quartz diffusion tubes are critical components in the doping process where phosphorus or boron is diffused into silicon wafers to create the P-N junction essential for solar cell functionality.

- Large diameter quartz process tubes (150-300mm)

- Quartz furnace doors

- Quartz wafer boats for precise wafer positioning

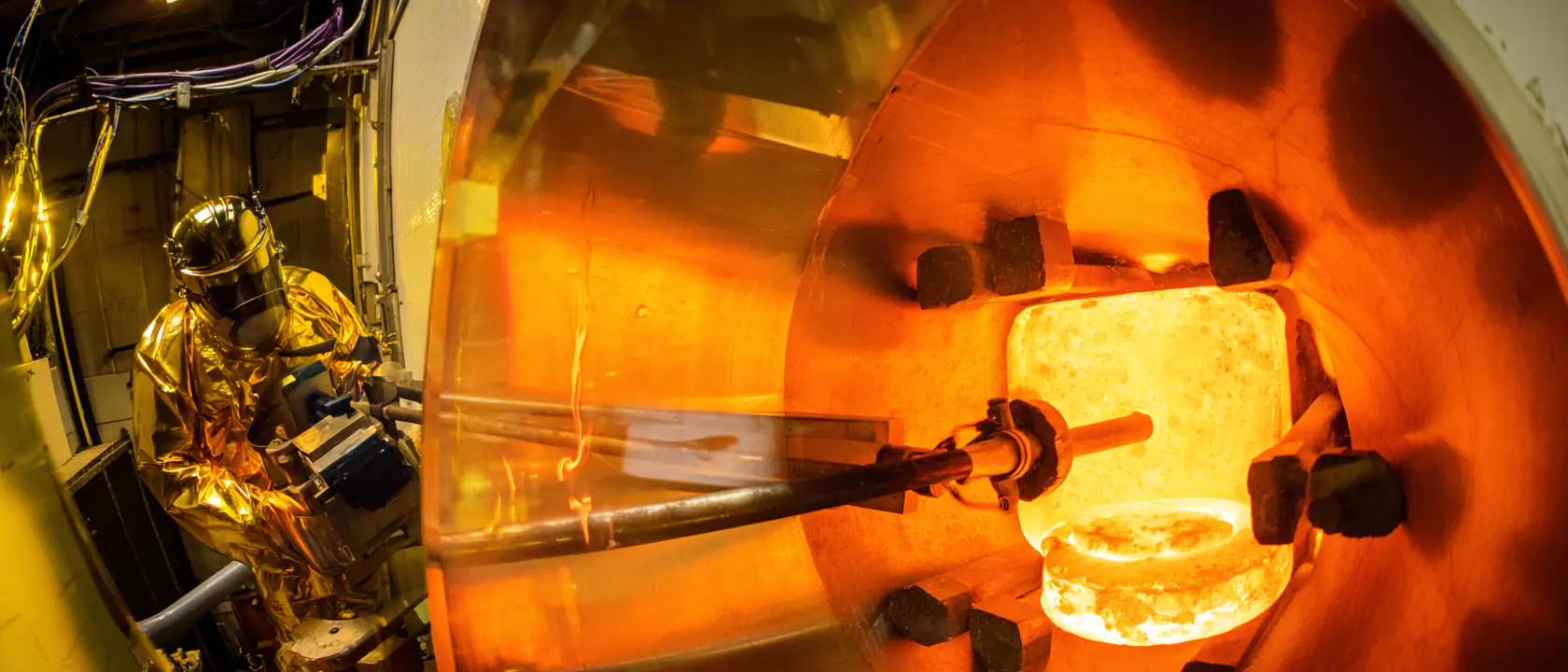

Silicon Ingot Growth

Photovoltaic quartz components are essential in silicon ingot growth, where polysilicon is melted and recrystallized. They must endure high temperatures and ensure purity to prevent contamination.

- Quartz crucibles for Czochralski (CZ) and directional solidification (DS) processes

- Quartz furnace doors for ingot growth chambers

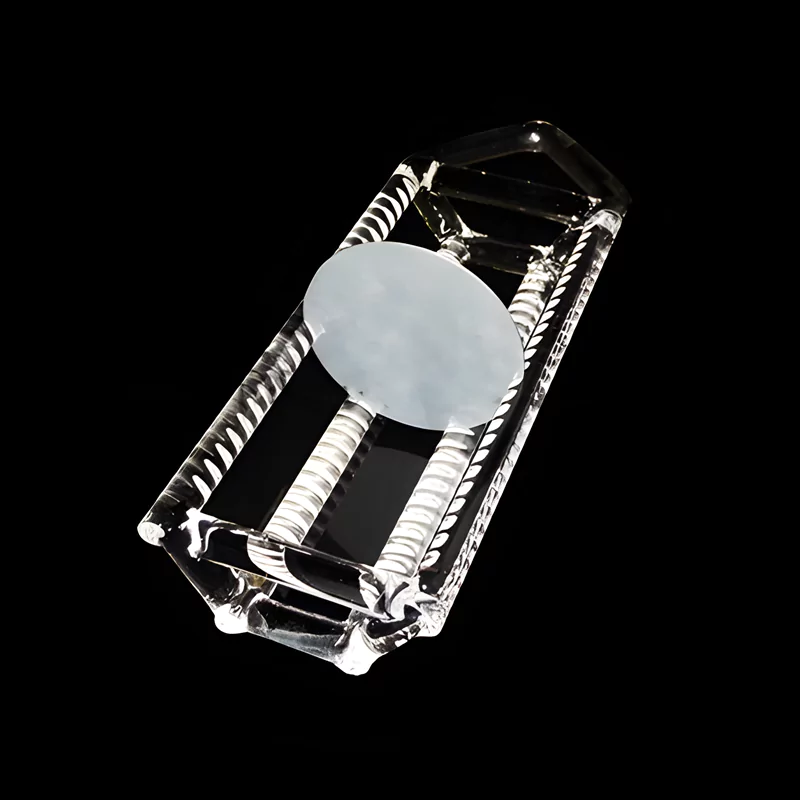

PECVD / LPCVD Equipment

Specialized quartz components for chemical vapor deposition systems enable the deposition of anti-reflective coatings, passivation layers, and other thin-film materials critical for high-efficiency solar cells.

- Quartz source bottles for precursor delivery

- Quartz process tubes for CVD reactors

- Quartz rings for plasma confinement

Wet Etching & Cleaning

Corrosion-resistant quartz tanks and containers handle aggressive chemical processes for wafer cleaning, texturing, and etching, essential for improving light absorption and removing surface damage.

- Square quartz tanks for chemical baths

- Spiral quartz waste bottles for safe disposal

- Quartz carriers for wet processing

Custom Photovoltaic Quartz Glass Solutions for Your Solar Production

TOQUARTZ® engineering team specializes in developing tailored Photovoltaic Quartz Glass components that perfectly match your specific production requirements, helping you optimize efficiency and reduce downtime.

Engineering Support

from Drawing to Delivery

TOQUARTZ® technical team works directly with your engineers to refine designs, recommend material specifications, and optimize dimensions for your specific equipment and processes.

- Drawing review and optimization

- Material selection guidance

- Technical feasibility assessment

Rapid Prototyping & Delivery

When production can't wait, our streamlined manufacturing process and in-stock materials allow us to produce and deliver custom quartz components in as little as 7-15 days.

- Expedited prototyping options

- Standard products shipped within 24 hours

- Transparent production timeline

Small Batch Customization

Unlike many manufacturers who require large minimum orders, we specialize in accommodating smaller custom batches, perfect for R&D projects, replacement parts, or specialized production runs.

- Low minimum order quantities

- Flexible production scheduling

- Cost-effective small-run production

Technical Specifications & Quality Assurance

TOQUARTZ® every Photovoltaic Quartz Glass component undergoes rigorous testing to ensure it meets or exceeds industry standards for purity, dimensional accuracy, and thermal performance, backed by our comprehensive quality management system.

Material Max. Purity ≥99.995%

TOQUARTZ® high-purity quartz achieves SiO₂ content of maximum 99.995%, with trace metal impurities below 1ppm, making it ideal for contamination-sensitive solar cell manufacturing processes.

| Element | Content (ppm) | Industry Standard |

| Al | <0.8 | <15 |

| Fe | <0.3 | <0.8 |

| Ti | <0.1 | <1.5 |

Dimensional Tolerance ±0.1mm

Precision fabrication ensures consistent dimensions critical for proper fit in solar manufacturing equipment, with standard tolerances of ±0.1mm for most applications.

| Parameter | Standard Tolerance | Premium Tolerance* |

| Diameter | ±0.1mm | ±0.08mm |

| Wall Thickness | ±0.1mm | ±0.08mm |

| Length | ±0.5mm | ±0.3mm |

| *Available for select products and specifications | ||

Thermal Resistance up to 1600°C

TOQUARTZ® photovoltaic quartz components maintain structural integrity and dimensional stability at extreme temperatures, with a thermal expansion coefficient of approximately 5.5×10⁻⁷/K.

| Property | Value |

| Working Temperature | Up to 1600°C |

| Softening Point | ~1730°C |

| Thermal Conductivity | 1.4 W/m·K at 20°C |

Full Process Quality Control

TOQUARTZ® comprehensive quality management system covers raw material inspection, in-process monitoring, and final product testing to ensure consistent performance and reliability.

- Raw material spectroscopic analysis

- Precision dimensional measurement

- Visual inspection for defects

- Stress analysis for thermal stability

- Final quality certification with each shipment

TOQUARTZ® Certifications

ISO 9001:2015

TOQUARTZ® quality management system ensures consistent product quality, process control, and continuous improvement in all manufacturing operations.

- Documented quality procedures

- Regular internal and external audits

- Employee training and competence

REACH Compliance

TOQUARTZ® products comply with EU REACH regulations, ensuring they contain no Substances of Very High Concern (SVHC) above the specified thresholds.

- Regular material testing

- Supplier compliance verification

- Documentation and reporting

RoHS Certification

All our quartz products are RoHS compliant, containing no restricted substances such as lead, mercury, cadmium, or other harmful materials.

- Third-party testing verification

- Material declaration documents

- Full compliance certification

FAQs About Photovoltaic Quartz Glass

Q: How does quartz purity affect solar cell manufacturing performance?

A: Quartz purity directly impacts contamination levels during high-temperature processes. Impurities such as Al, Fe, and Ti can diffuse into silicon wafers, reducing cell efficiency. Using ≥99.995% SiO₂ quartz minimizes metallic contamination and supports higher solar conversion rates.

Q: Why is thermal shock resistance critical for photovoltaic quartz glass components?

A: During processes like diffusion or annealing, quartz glass components are exposed to rapid heating and cooling cycles. Poor thermal shock resistance can lead to cracking or deformation. TOQUARTZ products are engineered to withstand ΔT > 1000°C without structural failure.

Q: How does photovoltaic quartz glass perform in corrosive wet etching environments?

A: Quartz is highly resistant to acids (HF, HCl, HNO₃) and alkalis, making it ideal for wet benches, etching tanks, and waste collection bottles. Its chemical inertness ensures long service life and prevents contamination of wafers during cleaning or texturing.

Q: Can TOQUARTZ provide photovoltaic quartz glass components for both monocrystalline and multicrystalline silicon production?

A: Yes. We supply quartz crucibles, liners, and accessories tailored for both Czochralski (CZ) monocrystalline and directional solidification (DS) multicrystalline processes, with options for different diameters, wall thicknesses, and thermal profiles.

Q: What surface treatments are available for photovoltaic quartz glass parts?

A: Depending on the application, TOQUARTZ offers flame polishing, acid cleaning, and anti-adhesion coatings (e.g., SiO₂ barrier layers) to enhance surface smoothness, reduce particle generation, and prevent silicon sticking in high-temperature environments.

Q: Why is dimensional tolerance important in photovoltaic quartz glass components?

A: Tight dimensional tolerances (±0.1mm or better) are essential for proper sealing, alignment, and thermal uniformity in furnace systems. Poor tolerances can lead to gas leakage, uneven heating, or mechanical stress during operation.