Precision Optical Quartz Glass for

Analytical & Laser Systems

TOQUARTZ delivers precision quartz glass components engineered for analytical instruments, laser optics, and photonics applications across global industries.

- Spectroscopy-grade transmission

- High thermal & chemical stability

- Custom shapes and tolerances

What is Optical Quartz Glass and What is it Used For?

Optical quartz glass is a high-purity form of fused silica (SiO₂) specifically engineered for applications requiring exceptional optical transmission, thermal stability, and chemical resistance. Unlike regular glass, optical quartz glass offers superior transmission in ultraviolet (UV) and infrared (IR) wavelengths, making it indispensable for precision optical instruments, spectroscopy equipment, and laser systems.

At TOQUARTZ, we manufacture optical quartz glass components with SiO₂ purity of 99.99% or higher, ensuring minimal light scattering and absorption across a wide spectral range. Our products serve critical functions in analytical instruments, laser equipment, high-temperature viewing windows, and specialized laboratory applications where ordinary glass would fail.

Key Properties of Optical Quartz Glass

Optical quartz glass offers a combination of optical clarity, thermal resistance, and chemical durability—making it essential for high-performance scientific and industrial applications.

UV Transparency

Optical quartz glass enables maximum UV-C light transmission, critical for effective sterilization in medical and water treatment systems.

- Transmits ≥90% at 254nm wavelength

- Maintains clarity under prolonged UV exposure

- Ideal for UV lamp sleeves and disinfection chambers

Spectral Clarity

Optical quartz glass ensures high transmission and low autofluorescence, supporting precise measurements in spectroscopy instruments.

- Broadband transmission from 185–3500nm

- Minimal light absorption and scattering

- Suitable for UV-Vis, IR, and fluorescence cuvettes

Thermal Stability

Optical quartz glass withstands extreme temperatures while maintaining structural integrity and IR transparency in high-heat environments.

- Operates reliably up to 1600°C

- Low thermal expansion (5.5 × 10⁻⁷ /°C)

- Ideal for IR lamp covers and heating tubes

Product Types of Optical Quartz Glass We Offer

We provide a wide range of optical quartz glass components tailored for spectroscopy, laser systems, high-temperature environments, and custom laboratory applications.

High-purity quartz tubes for UV sterilization, IR heating, and laboratory applications.

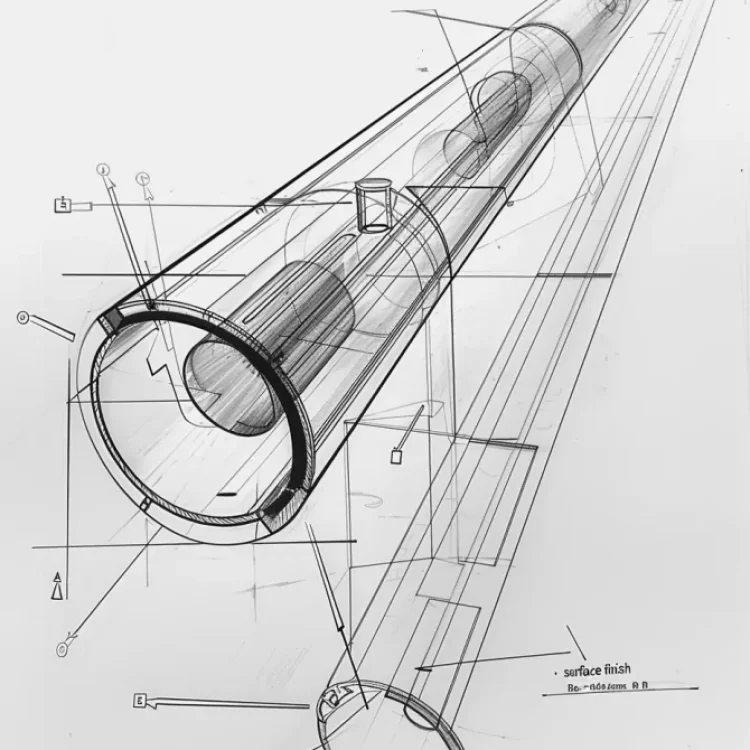

Precision quartz laser cavities and optical components for laser systems.

Applications of Optical Quartz Glass

TOQUARTZ® optical quartz glass components are engineered to perform in the most demanding environments where standard glass materials fail. Our products serve critical functions across multiple industries requiring precision optical performance, thermal stability, and chemical resistance.

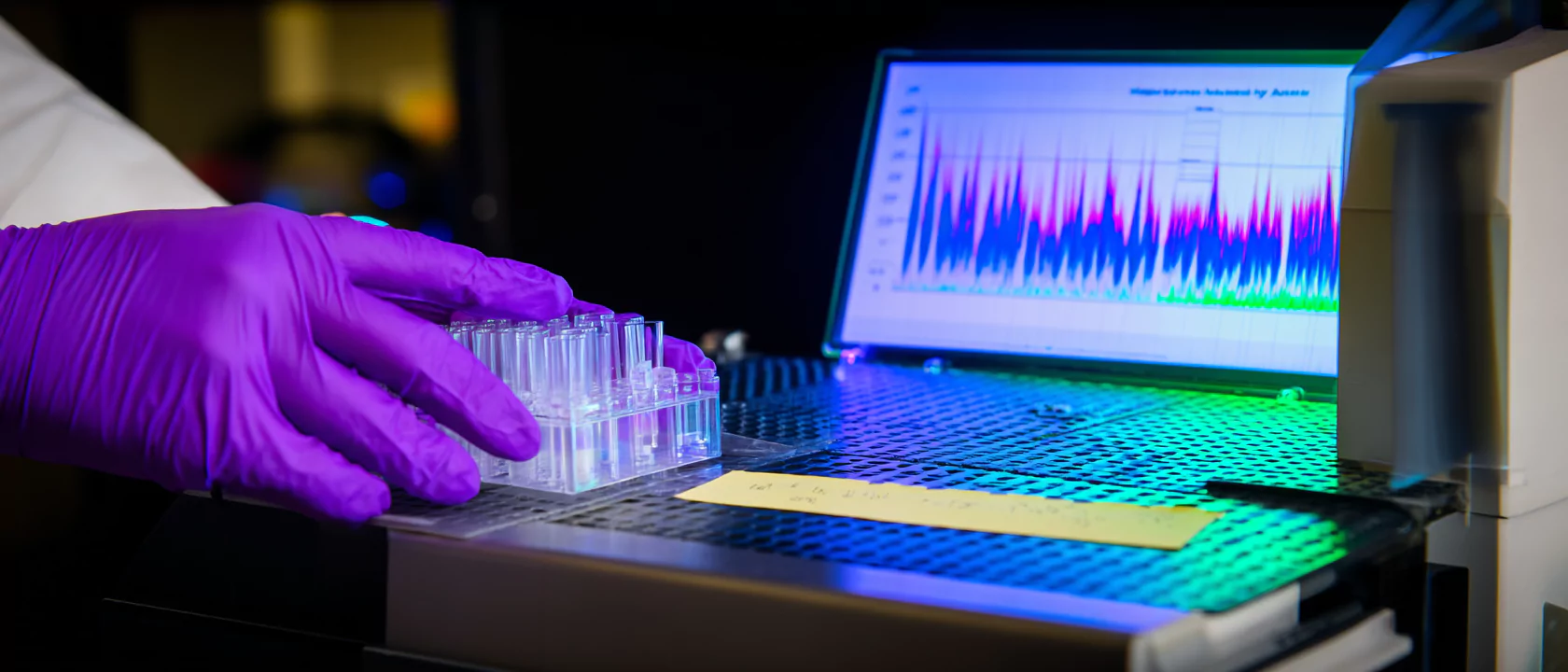

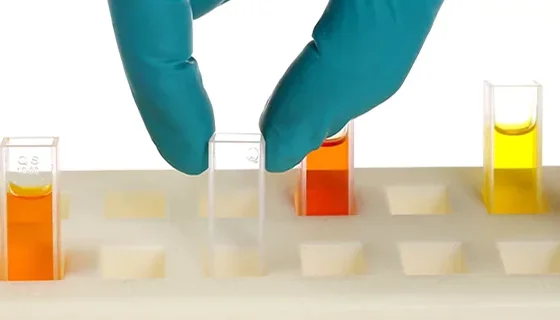

UV/IR Spectroscopy Instruments

TOQUARTZ® optical fused quartz galss is essential for spectroscopy applications requiring high transmission across UV, visible, and IR wavelengths.

- Quartz cuvettes for UV-Vis and IR sample analysis

- Optical windows in spectrometer light paths

- Flow-through quartz cells for liquid analysis

- Light shielding covers and beam splitters in optical benches

Laser Optical Systems

Optical quartz glass is critical for laser systems requiring high damage threshold, thermal stability, and precise optical properties.

- Laser cavity tubes

- Beam delivery components

- Optical isolators and windows

- Laser cutting and welding systems

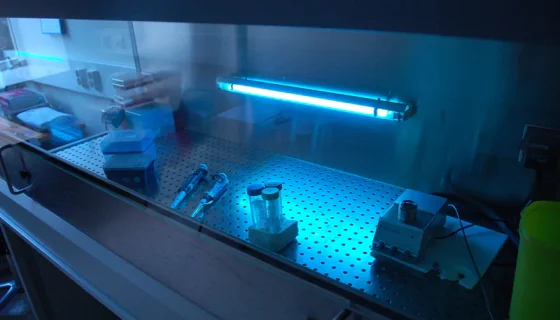

Quartz for UV Sterilization Systems

Optical quartz glass enables efficient UV-C transmission (185–254 nm), making it ideal for sterilization in medical, lab, and water treatment systems.

- UV lamp sleeves for water purification systems

- Protective quartz tubes in air sterilizers

- Quartz windows in medical UV disinfection chambers

- Flow-through quartz cells for inline UV reactors

High Temperature Environments

Optical quartz glass maintains structural integrity and optical clarity at extreme temperatures(up to 1600°C) where conventional materials degrade or fail.

- Industrial furnace viewing windows

- High-temperature process monitoring

- Thermal insulation components

Custom Optical Quartz Glass Solutions

TOQUARTZ® specializes in custom optical quartz glass fabrication, providing engineering support from concept to delivery. Our technical team works directly with you to develop components that meet your exact specifications and application requirements.

Engineering Support

from Concept to Drawing

TOQUARTZ® assist clients in transforming ideas into manufacturable optical quartz glass components with full technical guidance.

Precision Machining

to Your Specs

Fast turnaround on custom prototypes allows you to test and validate designs quickly, accelerating your development timeline.

Flexible Small-Batch Production

TOQUARTZ® supports low MOQ orders for custom optical quartz glass parts, ideal for R&D and pilot-scale projects.

Fast Turnaround with Stable Lead Times

Our streamlined process ensures rapid production of custom optical quartz glass with consistent delivery schedules.

From Drawing to Delivery

Technical Consultation

Our engineers review your requirements and provide material recommendations.

Drawing Assistance

We help refine your technical drawings or create them based on your specifications.

Prototype Development

Rapid sample production for testing and validation.

Production & Quality Control

Precision manufacturing with comprehensive quality inspection.

Fast Delivery

Efficient logistics and packaging for safe international shipping.

Quality Control & Certifications

TOQUARTZ® implements rigorous quality control measures throughout our manufacturing process, ensuring that every piece of quartz labware meets the highest standards for purity, dimensional accuracy, and performance reliability.

ISO 9001

TOQUARTZ® quality management system is certified to ISO 9001 standards, ensuring consistent quality and continuous improvement.

- Documented procedures

- Regular audits

- Process control

REACH Compliance

TOQUARTZ® optical quartz glass products comply with EU REACH regulations for safe chemical use and environmental protection.

- No restricted substances

- Material safety documentation

- Environmental compliance

RoHS Compliance

TOQUARTZ® products meet RoHS standards, ensuring they are free from hazardous substances restricted in electronic equipment.

- Lead-free materials

- No restricted heavy metals

- Compliance documentation

TOQUARTZ® Quality Testing Procedures

Material Purity Testing

We verify SiO₂ content of 99.995%, ensuring exceptional purity for sensitive applications.

Dimensional Inspection

Precision measurements confirm tolerances of ±0.1mm to ±0.2mm for critical dimensions.

Performance Testing

We validate thermal resistance, chemical compatibility, and optical performance under real-world conditions.

FAQs About Optical Quartz Glass

Q: What is the purity level of your optical quartz glass?

A: TOQUARTZ® optical quartz glass has a standard purity of ≥99.99% SiO₂, with total metallic impurities less than 10 ppm. This high purity ensures excellent optical transmission properties and thermal stability. For specialized applications requiring even higher purity, please contact our technical team to discuss your specific requirements.

Q: Can you help with technical drawings or design optimization?

A: Yes, our engineering team provides comprehensive technical support, including:

· Creating or refining technical drawings based on your specifications

· Design optimization for manufacturability and cost-efficiency

· Material recommendations based on your application requirements

· Tolerance analysis and suggestions

This service is offered at no additional cost as part of our commitment to ensuring your components perform optimally in your application.

Q: What is the difference between UV and IR grade quartz glass?

A: UV grade and IR grade quartz glass differ primarily in their hydroxyl (OH) content and resulting transmission properties:

UV grade quartz glass has higher OH content (typically 150-400 ppm) and offers excellent transmission in the ultraviolet range, particularly from 185-400nm. It’s ideal for UV spectroscopy, sterilization systems, and photolithography.

IR grade quartz glass has very low OH content (typically <20 ppm) and provides superior transmission in the infrared range, especially from 2.5-4.5μm where OH absorption bands would otherwise reduce transmission. It’s preferred for IR spectroscopy, thermal imaging, and IR laser applications.

TOQUARTZ offers both grades to suit your specific application requirements.

Q: What surface finishes are available for optical quartz glass components?

A: We offer several surface finish options for optical quartz glass components:

· Fire polished: Smooth, glossy finish achieved through flame treatment, suitable for non-critical optical applications

· Ground finish: Matte appearance with controlled roughness, typically Ra 0.4-1.6μm

· Precision polished: Optical-grade finish with Ra ≤0.01μm, for critical optical applications

· Annealed: Stress-relieved through controlled cooling, recommended for components subject to thermal cycling

The appropriate finish depends on your application requirements. Our technical team can recommend the optimal surface treatment for your specific needs.

Q: What are the dimensional tolerances you can achieve for optical quartz components?

A: Our standard manufacturing capabilities for optical quartz glass components include:

· Standard tolerance: ±0.2mm

· Precision tolerance: ±0.1mm

· High precision (select components): ±0.05mm

For extremely tight tolerances below ±0.05mm, we evaluate feasibility on a case-by-case basis. Please note that tighter tolerances may impact lead time and pricing.

Q: How do you ship optical quartz glass components internationally?

A: We have extensive experience shipping delicate optical quartz glass components worldwide. Our shipping process includes:

· Custom protective packaging with foam inserts and shock-absorbing materials

· Individual component wrapping to prevent surface contact

· Sturdy outer packaging designed for international transit

· Shipping via reliable carriers (DHL, FedEx, UPS) with tracking

· Complete export documentation to facilitate customs clearance

We ship to over 30 countries and have established efficient logistics channels to major markets including Germany, USA, Japan, Korea, Canada, Poland, and Mexico.