- Home

- /

- Types

- /

- Quartz Tube

- /

- Infrared-Optimized Opaque U-Shaped Quartz...

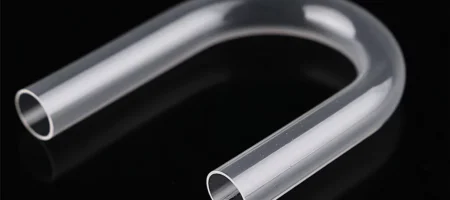

Infrared-Optimized Opaque U-Shaped Quartz Tube for Industrial Equipment-TOQUARTZ®

Key Features of Opaque U-Shaped Quartz Tube

TOQUARTZ® opaque U-shaped quartz tubes are manufactured using high-purity materials and precision bending processes to meet demanding industrial and laboratory requirements. These tubes combine exceptional thermal stability with superior optical and chemical properties.

Thermal Properties

- Operating temperature up to 1200°C continuous

- Short-term temperature resistance up to 1450°C

- Low thermal expansion coefficient: 5.5×10⁻⁷/°C

Optical Properties

- Emits infrared radiation in 5-15μm range when heated

- Optimized for infrared heating applications

- Controlled opacity for specific application requirements

Chemical & Mechanical Properties

- Excellent acid resistance (except HF)

- High chemical stability at elevated temperatures

- Density: 2.2 g/cm³

- Mohs hardness: 6.6

- Excellent electrical insulation properties

- 99.99% SiO₂ purity

- Controlled opacifying agents

- Low metallic impurity content (<5 ppm)

Technical Specifications & Sizes of Opaque U-Shaped Quartz Tube

TOQUARTZ® opaque U-shaped quartz tubes are available in standard sizes and can be customized according to specific application requirements. All products undergo rigorous quality control to ensure dimensional accuracy and material integrity.

Technical Specifications

| Property | Specification | Test Method |

| SiO₂ Content | 99.98% | ASTM C1607 |

| Density | 2.2 g/cm³ | ASTM C693 |

| Mohs Hardness | 6.6 | Standard Test |

| Melting Point | 1732°C | ASTM C24 |

| Continuous Operating Temperature | 1100°C | Internal Testing |

| Short-term Temperature Resistance | 1450°C | Internal Testing |

| Thermal Expansion Coefficient | 5.5×10⁻⁷/°C | ASTM E228 |

| Annealing Point | 1180°C | ASTM C336 |

| Softening Point | 1630°C | ASTM C338 |

| Acid Resistance | 30× higher than ceramic, 150× higher than stainless steel | Comparative Testing |

| Electrical Resistivity | 10,000× higher than ordinary glass | ASTM D257 |

Dimension Charts

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | Purity |

| AT-SY-MSG3001 | 10 | 9 | Customized | 99%-99.98% |

| AT-SY-MSG3002 | 12 | 11 | Customized | 99%-99.98% |

| AT-SY-MSG3003 | 15 | 13.2 | Customized | 99%-99.98% |

| AT-SY-MSG3004 | 18 | 15 | Customized | 99%-99.98% |

| AT-SY-MSG3005 | 20 | 18 | Customized | 99%-99.98% |

| AT-SY-MSG3006 | 32 | 28 | Customized | 99%-99.98% |

| AT-SY-MSG3007 | 50 | 45 | Customized | 99%-99.98% |

| AT-SY-MSG3008 | 80 | 70 | Customized | 99%-99.98% |

TOQUARTZ® Solving Industrial Applications & Challenges with

Opaque Quartz Tube Open Both Ends

Opaque U-Shaped Quartz Tube for Compact Thermal Processing Chambers

Key Advantages

-

Minimized chamber footprint

U-shape design reduces linear space by 38% compared to dual straight tubes in 300mm chambers. -

Enhanced thermal uniformity

±3°C temperature deviation across 180° bend zone verified in aerospace-grade test rigs. -

Reduced component count

Eliminates need for 2 reflectors and 1 coupling joint per unit, simplifying system by 25%.

TOQUARTZ® solution

A microelectronics OEM in Germany faced inconsistent heating in 280mm thermal chambers using dual straight quartz tubes. TOQUARTZ® delivered custom-bent opaque U-shaped quartz tubes with a 90° bend radius and ±0.2mm tolerance. This reduced chamber component count by 3 parts, improved thermal uniformity by 21%.

Opaque U-Shaped Fused Quartz Tube for Photonic Crystal Growth Systems

Key Advantages

-

Symmetrical thermal gradient control

±2.5°C deviation across both arms ensures uniform crystal lattice formation. -

Stray light suppression

Opaque walls reduce internal light scattering by 47%, improving optical purity. -

Dual-end heating compatibility

Supports synchronized heating from both ends, stabilizing growth zone within ±1.8°C.

TOQUARTZ® solution

A Canadian photonics lab reported 15% defect rates in photonic crystal wafers due to asymmetric heating and light interference. TOQUARTZ® supplied opaque U-shaped quartz tubes with matched wall opacity and bend symmetry. Post-implementation, defect rates dropped to 4.2%, and yield per batch increased by 19% over three production cycles.

Opaque U-Shaped Fused Silica Tube for Gas Phase Reaction Loops in Chemical Reactors

Key Advantages

-

Compact loop integration

U-shape reduces reactor loop length by 42%, enabling smaller reactor footprints. -

Radiant heat containment

Opaque surface reduces external heat loss by 33% in 900°C gas-phase environments. -

Corrosion resistance under HF exposure

Maintains structural integrity after 96-hour exposure to 5% HF at 800°C.

TOQUARTZ® solution

A specialty chemical plant in South Korea experienced 28% annual failure rate in quartz loops exposed to HF and SO₂ gases. TOQUARTZ® provided opaque U-shaped quartz tubes with 3.2mm wall thickness and enhanced acid resistance. After 6 months, failure rate dropped to 6%, and reactor downtime was reduced by 40 hours per quarter.

TOQUARTZ® Custom Opaque U-Shaped Quartz Tube Services

TOQUARTZ® specializes in custom opaque U-shaped quartz tube manufacturing to meet your exact specifications. Our engineering team works closely with customers to develop solutions for specialized applications requiring non-standard dimensions, bend angles, or material properties.

Technical Drawing Support

Our engineers can help refine your technical drawings or develop new designs based on your application requirements. We offer CAD assistance and prototype development for first-time projects.

Customization Options

- Custom bend angles (30°-180°)

- Special bend radius specifications

- Non-standard dimensions (up to 80mm OD)

- Variable opacity levels

- End treatments (fire polished, ground, flared)

Custom Order Process

- Submit technical requirements or drawings

- Receive engineering feedback within 48 hours

- Approve final design and quotation

- Production of sample/prototype (if required)

- Full production with quality inspection

- Delivery within 2-3 weeks (standard lead time)

Usage Guidelines for Opaque U-Shaped Quartz Tube

Proper handling, installation, and maintenance of opaque U-shaped quartz tubes will maximize their performance and operational lifespan. Follow these recommendations to ensure optimal results in your application.

Installation Recommendations

- Use non-metallic mounting hardware when possible to prevent contamination at high temperatures

- Allow 3-5mm expansion clearance for tubes used in high-temperature applications

- Ensure gradual heating/cooling rate (≤5°C/min) when first installing to prevent thermal shock

- Use silicone end caps or heat-resistant gaskets for sealing when required

Operational Parameters

- Maintain continuous operating temperature below 1100°C for maximum lifespan

- For temperatures above 1100°C (up to 1450°C), limit exposure to less than 30 minutes

- Avoid direct contact with alkali metals at high temperatures

- When used for fluid handling, maximum recommended flow rate: 8-10 m/s

Cleaning & Maintenance

- Clean with diluted isopropyl alcohol (IPA) or acetone for organic contaminants

- For mineral deposits, use diluted phosphoric or acetic acid (avoid hydrofluoric acid)

- Inspect regularly for microcracks, especially at bend points and ends

- Ultrasonic cleaning is suitable for internal contamination (when accessible)

Storage & Handling

- Store in original packaging with protective foam inserts

- Keep in dry environment (humidity <60% RH)

- Avoid stacking heavy items on tubes or bending points

- Use talc-free gloves when handling to prevent surface contamination

Need Engineering Support for Your Quartz Tube Application?

We provide free consultation to optimize your design for performance, durability, and cost-effectiveness.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is an opaque U-shaped quartz tube used for?

A: Opaque U-shaped quartz tubes are primarily used in infrared heating systems, UV sterilization equipment, laboratory analytical instruments, and high-temperature fluid/gas handling applications. The U-shape configuration allows for compact designs in equipment with space constraints, while the opaque property provides controlled infrared emission when heated. They’re particularly valuable in applications requiring precise thermal performance and chemical resistance.

Q: What are the temperature limitations of opaque U-shaped quartz tubes?

A: TOQUARTZ® opaque U-shaped quartz tubes can withstand continuous operating temperatures up to 1100°C and short-term exposure (under 30 minutes) to temperatures up to 1450°C. The thermal expansion coefficient of 5.5×10⁻⁷/°C provides excellent thermal shock resistance. For optimal lifespan, we recommend controlled heating and cooling rates (≤5°C/min) during initial installation and avoiding rapid temperature fluctuations above 900°C.

Q: What is the chemical resistance of your opaque U-shaped quartz tubes?

A: TOQUARTZ® opaque U-shaped quartz tubes offer exceptional chemical resistance, approximately 30 times higher than ceramic and 150 times higher than stainless steel when exposed to most acids. They are inert to almost all chemicals except hydrofluoric acid (HF) and concentrated phosphoric acid at high temperatures. The tubes maintain their chemical stability at elevated temperatures, making them suitable for aggressive chemical environments. This resistance extends to salt solutions, organic compounds, and most gases, including halogens at moderate temperatures.

Q: Can you custom fabricate U-shaped quartz tubes to specific dimensions?

A: Yes, we specialize in custom fabrication of opaque U-shaped quartz tubes. We can produce tubes with outer diameters from 8mm to 80mm with wall thicknesses from 1mm to 5mm. Custom bend angles range from 30° to 180°, and we can create special bend radii to meet your equipment specifications. Our engineering team can work from your technical drawings or help develop designs based on your application requirements.

Q: Does the U-shape design of opaque quartz tubes improve thermal efficiency compared to straight tubes?

A: Yes. The U-shaped geometry allows for a more compact thermal path, enabling heat to be reflected and concentrated within a smaller chamber volume. In infrared heating systems, this design improves energy utilization by up to 18%, as both arms of the tube contribute to uniform heat distribution. Additionally, the opaque surface enhances infrared emission in the 5–15μm range, making it ideal for enclosed thermal processing environments where space and energy efficiency are critical.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.