- Home

- /

- Types

- /

- Quartz Tube

- /

- Compact Spiral Design Opaque...

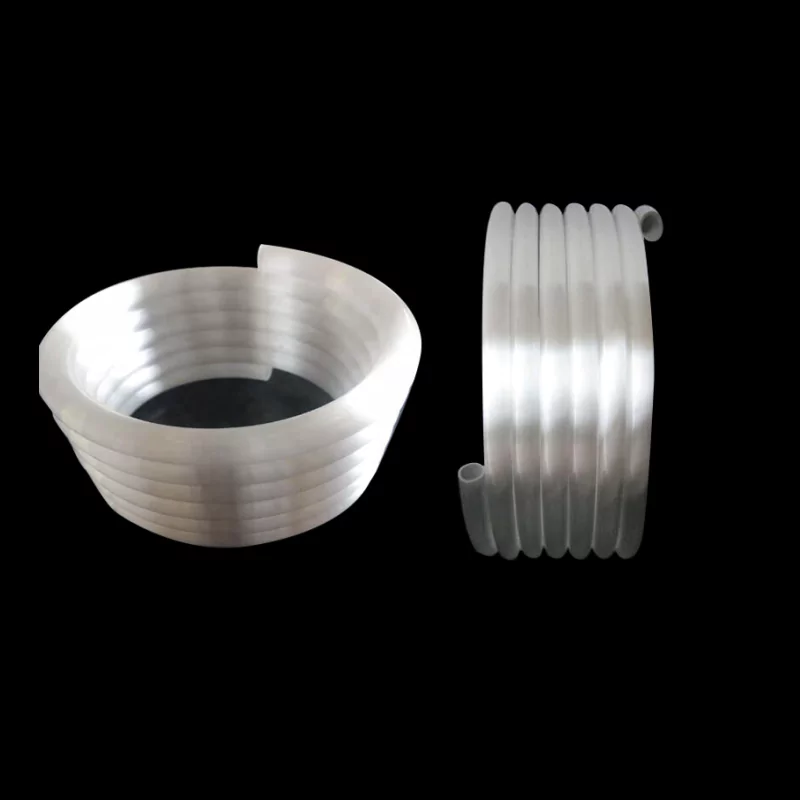

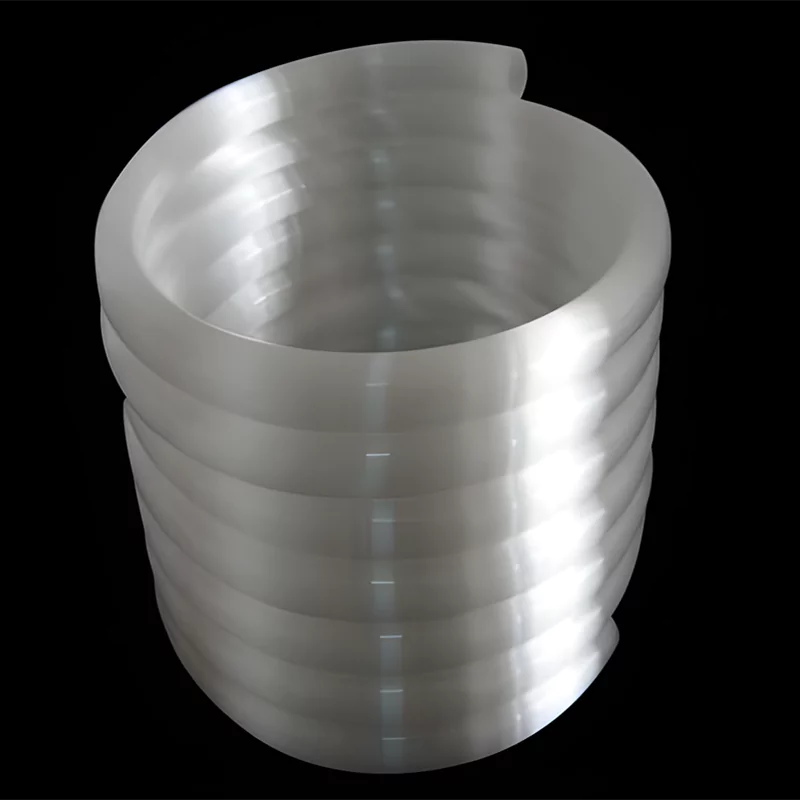

Compact Spiral Design Opaque Spiral Quartz Tube for High-Precision Heating-TOQUARTZ®

Key Features of Opaque Spiral Quartz Tube

TOQUARTZ® opaque spiral quartz tubes are manufactured using high-purity quartz materials and advanced processing technologies to meet rigorous industrial requirements for thermal stability, optical performance, and chemical resistance.

Precision Engineering

Manufactured to tight tolerances (±0.2mm) for reliable fitment in industrial equipment. Spiral structure engineered for optimal heat distribution and mechanical stability, with custom coil spacing available.

Optimized Optical Properties

The milky white appearance results from controlled micro-bubble dispersion, enabling efficient emission of 5-15µm infrared wavelength radiation and optimal light diffusion for UV applications.

Thermal Performance

Continuous operating temperature of 1100°C, with short-term capability up to 1450°C. Low thermal expansion coefficient (5.5×10⁻⁷/°C) enables excellent thermal shock resistance.

- Material purity: 99.98% SiO₂

- Infrared emission: 5-15μm wavelength

- Custom diameters: 15-80mm available

Technical Specifications & Sizes of Opaque Spiral Quartz Tube

TOQUARTZ® opaque spiral quartz tubes are manufactured to precise specifications, ensuring compatibility with your equipment and applications. All products undergo rigorous quality testing to verify dimensional accuracy and material properties.

Technical Specifications

| Property | Value | Unit/Note |

| Silicon Dioxide (SiO₂) | 99.98 | % |

| Density | 2.2 | g/cm³ |

| Mohs Hardness | 6.6 | – |

| Melting Point | 1732 | °C |

| Operating Temperature | 1100 | °C (continuous) |

| Short-term Temperature Limit | 1450 | °C |

| Acid Resistance | 30× ceramics, 150× stainless steel | Comparative |

| Visible Light Transmission | ≥93 | % |

| UV Transmission (185nm) | ≥85 | % |

| Electrical Resistivity | 10,000× regular glass | Comparative |

| Annealing Point | 1180 | °C |

| Softening Point | 1630 | °C |

| Critical Point | 1100 | °C |

Dimension Charts

| Model | Outer Diameter (mm) | Inner Diameter (mm) | 长度 (mm) | Purity (%) |

| AT-SY-MSG5001 | 15 | 13 | Customized | 99%-99.98% |

| AT-SY-MSG5002 | 30 | 27 | Customized | 99%-99.98% |

| AT-SY-MSG5003 | 50 | 47 | Customized | 99%-99.98% |

| AT-SY-MSG5004 | 60 | 56 | Customized | 99%-99.98% |

| AT-SY-MSG5005 | 80 | 75 | Customized | 99%-99.98% |

TOQUARTZ® Solving Industrial Applications & Challenges with

Opaque Spiral Quartz Tube

Opaque Spiral Quartz Tube for Infrared Heating Systems

Key Advantages

-

Optimized Spiral Pitch for Uniform IR Emission

Custom 8–12 mm spiral pitch ensures <±3% temperature deviation across 300mm heating zone. -

Extended Thermal Cycling Life

Withstands >1,000 thermal cycles between 200°C–1100°C without microcrack formation. -

Energy Efficiency Boost in Closed Systems

Improves IR reflectivity by 18% compared to clear quartz, reducing energy loss in enclosed heaters.

TOQUARTZ® solution

A German industrial oven manufacturer faced inconsistent heating in a 1.2m chamber, causing ±7°C deviation and 12% product rejection. TOQUARTZ® supplied opaque spiral quartz tubes with optimized coil geometry, reducing deviation to ±2°C. The client reported a 22% drop in energy consumption and eliminated thermal hotspots.

Opaque Spiral Quartz Glass Tube for UV Sterilization Equipment

Key Advantages

-

Micro-Bubble Matrix for Uniform UV Diffusion

Achieves 92% uniformity in UV-C intensity at 254nm across 360° exposure field. -

Lamp Life Extension via Thermal Buffering

Reduces lamp surface temperature fluctuation by 15%, extending UV lamp life by 1,200 hours. -

Enhanced Sterilization Efficiency

Improves microbial kill rate by 17% in water treatment systems using 185nm UV spectrum.

TOQUARTZ® solution

A U.S. water sterilization OEM reported uneven UV exposure in a 500L/min flow system, leading to 8% microbial test failures. TOQUARTZ® provided opaque spiral quartz tubes with calibrated diffusion layers, improving UV uniformity and reducing failure rate to <1%.

Opaque Spiral Fused Silica Tube for Laboratory and Industrial Furnaces

Key Advantages

-

Contamination-Free High-Purity Structure

99.98% SiO₂ purity with <5 ppm metallic impurities ensures zero contamination in inert gas reactions. -

Thermal Field Homogenization in Spiral Design

Delivers <±2°C temperature gradient in 400mm reaction zone under 1000°C operation. -

Compact Spiral Geometry for Space-Limited Furnaces

Reduces chamber footprint by 25% while maintaining equivalent thermal output.

TOQUARTZ® solution

A Japanese lab furnace integrator encountered inconsistent reaction yields due to ±6°C thermal drift in a 400mm zone. TOQUARTZ® delivered spiral quartz tubes with precision coil spacing and verified thermal mapping, reducing drift to ±1.8°C.

TOQUARTZ® Customization Services for Opaque Spiral Quartz Tubes

At TOQUARTZ®, we understand that standard products may not always meet your specific requirements. Our comprehensive customization services for opaque spiral quartz tubes help you achieve optimal performance in your unique applications.

Dimensional Customization

- Custom outer diameters (5mm to 150mm)

- Custom wall thickness (1mm to 5mm)

- Variable spiral pitch and spacing

- Custom length configurations

Material Optimization

- Adjustable opacity levels

- UV or IR transmission optimization

- Various SiO₂ purity grades (99%-99.98%)

- Trace element doping for specific properties

Assembly Integration

- Custom end fittings and flanges

- Ground joint configurations

- Multi-tube assemblies

- Complete heating element assemblies

Usage Guidelines for Opaque Spiral Quartz Tube

Proper handling, installation, and maintenance of opaque spiral quartz tubes will maximize their performance and service life. Follow these guidelines to ensure optimal results in your applications.

Handling and Installation

- Wear clean, powder-free gloves when handling to prevent surface contamination

- Avoid direct contact between quartz surfaces and metal components

- Use silicone or PTFE gaskets for sealing connections

- Allow 2-3mm expansion clearance for thermal expansion

- Support spiral sections evenly to prevent structural stress

- Verify all connections are secure before operation

Note: For specialized applications requiring flanges or custom end fittings, contact our technical team for installation guidance.

Heating and Cooling Procedures

- Implement gradual heating at a rate of 10-15°C per minute

- For applications exceeding 800°C, use a 5-10°C per minute ramp rate

- Allow natural cooling to 300°C before introducing forced cooling

- Avoid direct contact with cold surfaces when hot

- Maintain even heating across the spiral structure

- For continuous operation, implement periodic cool-down cycles

Note: While quartz has excellent thermal shock resistance, gradual temperature changes will maximize service life, especially for larger diameter tubes.

Cleaning and Maintenance

- Clean with deionized water and isopropyl alcohol (avoid hydrofluoric acid)

- For stubborn deposits, use diluted phosphoric acid (10%) followed by thorough rinsing

- Perform visual inspection for cracks or devitrification regularly

- Replace tubes showing signs of surface crystallization

- Store in clean, dry environment when not in use

- Protect from physical impact and vibration

Note: Opaque spiral quartz tubes can be safely ultrasonically cleaned in appropriate solutions when necessary.

Safety Considerations

- Always verify operating temperature is within specified limits

- Install thermal monitoring to prevent overheating

- Use appropriate protective equipment when handling hot tubes

- Ensure proper ventilation in enclosed applications

- Follow industry-specific safety regulations

- Maintain documentation of operating conditions and maintenance

Note: While quartz itself is chemically inert, extreme temperatures can cause reactions with surrounding materials. Verify material compatibility in your specific application.

Need Technical Consultation?

or design a custom solution for your unique requirements.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the difference between opaque and transparent spiral quartz tubes?

A: Opaque (milky) spiral quartz tubes contain micro-bubbles that scatter light, providing more uniform heat distribution and diffuse light emission. Transparent tubes allow direct light transmission. The opaque version is preferred for heating applications and UV diffusion, while transparent tubes are typically used where direct light transmission is needed.

Q: What is the maximum operating temperature for opaque spiral quartz tubes?

A: TOQUARTZ® opaque spiral quartz tubes can operate continuously at temperatures up to 1100°C, with short-term exposure capability up to 1450°C. The actual maximum operating temperature depends on the specific application, wall thickness, and thermal cycling conditions. For high-temperature applications, we recommend consulting with our technical team.

Q: Are opaque spiral quartz tubes electrically conductive?

A: No, standard opaque spiral quartz tubes are excellent electrical insulators, with resistivity approximately 10,000 times higher than regular glass. This makes them ideal for applications requiring electrical isolation. For specialized applications requiring conductivity, we offer custom solutions with conductive coatings or dopants.

Q: Can opaque spiral quartz tubes be used in UV applications?

A: Yes, TOQUARTZ® opaque spiral quartz tubes transmit up to 85% of UV light at 185nm wavelength, making them suitable for UV sterilization and disinfection systems. The opaque nature helps diffuse the UV light, creating more uniform exposure. For applications requiring specific UV transmission characteristics, we offer customized material formulations.

Q: Are your opaque spiral quartz tubes resistant to thermal shock?

A: Yes, quartz has excellent thermal shock resistance due to its low coefficient of thermal expansion (5.5×10⁻⁷/°C). However, for optimal performance and longevity, we recommend gradual heating and cooling, particularly for larger diameter tubes and when operating near maximum temperature limits.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.