- Home

- /

- Types

- /

- Quartz Tube

- /

- Light-Scattering Industrial Opaque Quartz...

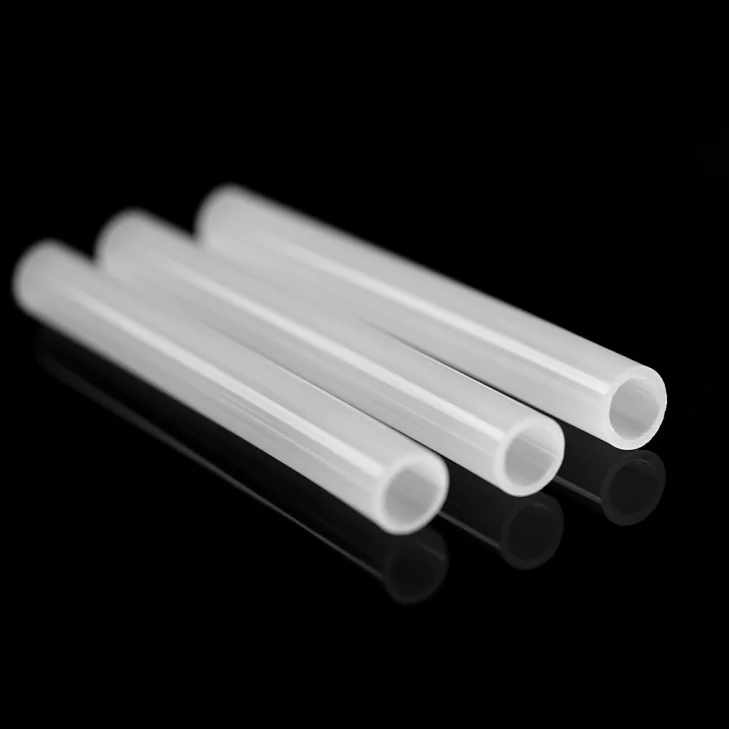

Light-Scattering Industrial Opaque Quartz Tube Open Both Ends for Heating Units-TOQUARTZ®

Key Features of Opaque Quartz Tube Open Both Ends

TOQUARTZ® opaque quartz tubes with open ends feature exceptional material properties that ensure reliable performance in demanding industrial applications. The milky white appearance is achieved through controlled manufacturing processes, offering optimal light diffusion while maintaining the inherent benefits of high-purity fused silica.

Thermal Properties

- Maximum continuous operating temperature: 1100-1200°C

- Short-term maximum temperature: 1450°C

- Low thermal expansion coefficient: 5.5×10⁻⁷ /°C

- High thermal shock resistance

Chemical Properties

- High purity: ≥99.98% SiO₂

- Excellent resistance to most acids and chemicals

- Acid resistance: 30× higher than ceramics, 150× higher than stainless steel

- Inert to most gases and liquids at high temperatures

Optical Properties

- Optimal diffusion of IR radiation (5-15 μm wavelength)

- Visible light transmission: >93%

- UV light transmission at 185nm: >85%

- Stable optical properties at high temperatures

- High purity: ≥99.98% SiO₂

- Short-term maximum temperature: 1450°C

- Visible light transmission: >93%

Technical Specifications & Sizes of Frosted Quartz Tube Open Both Ends

TOQUARTZ® opaque quartz tubes are available in a wide range of dimensions to meet diverse industrial requirements. All specifications can be customized according to your project needs.

Technical Specifications

| Property | Specification |

| Material | Fused Silica (SiO₂) |

| Purity | 99.98% |

| Density | 2.2 g/cm³ |

| Mohs Hardness | 6.6 |

| Melting Point | 1732°C |

| Continuous Operating Temperature | 1100°C |

| Short-term Max Temperature | 1450°C |

| Visible Light Transmission | ≥93% |

| UV Transmission (185nm) | ≥85% |

| Electrical Resistivity | 10,000× higher than standard glass |

| Annealing Point | 1180°C |

| Softening Point | 1630°C |

| Critical Point | 1100°C |

Dimension Charts

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | Purity |

| AT-SY-MSG1001 | 1 | 0.25 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1002 | 2 | 1.5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1003 | 2 | 5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1004 | 5 | 4.5 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1005 | 5 | 4.2 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1006 | 5 | 4 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1007 | 10 | 8 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1008 | 15 | 14 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1009 | 20 | 16 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1010 | 50 | 45 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1011 | 100 | 80 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1012 | 150 | 125 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1013 | 200 | 180 | 20-2000 | 99%-99.98% |

| AT-SY-MSG1014 | 1-500 | 0.25-450(Custom) | 20-2000 | 99%-99.98% |

TOQUARTZ® Solving Industrial Applications & Challenges with

Opaque Quartz Tube Open Both Ends

Opaque Quartz Tube Open Both Ends for Infrared Heating Systems

Key Advantages

-

Optimized IR wavelength diffusion (5–15μm)

Milky quartz structure enhances IR radiation uniformity by 18% in 5–15μm range. -

Reduced thermal gradient across heating zones

Tube wall opacity ensures <±3°C variation across 1m heating length. -

Extended operational lifespan under thermal cycling

Maintains structural integrity after 1000+ cycles between 200°C–1100°C.

TOQUARTZ® solution

A German thermoforming equipment OEM faced uneven heating issues causing ±7°C deviation across heating zones, leading to 12% product rejection. After switching to TOQUARTZ® opaque quartz tubes, IR distribution uniformity improved by 22%, reducing rejection rate to under 3% and increasing heater lifespan by 40%.

Opaque Fused Quartz Tube Open Both Ends for Laboratory Equipment

Key Advantages

-

Dimensional tolerance stability at high temperatures

Maintains ±0.2mm tolerance after 50 hours at 1000°C in inert atmosphere. -

Non-contaminating surface for sensitive reactions

99.98% SiO₂ purity ensures <0.01 ppm leaching in acid/base environments. -

Low fluorescence under UV/IR exposure

Tube surface emits <0.5% background signal under 254nm UV excitation.

TOQUARTZ® solution

A U.S. analytical instrument manufacturer reported 15% calibration drift due to fluorescence interference from standard quartz tubes. TOQUARTZ® opaque quartz tubes reduced background signal by 87%, enabling stable readings over 6 months and cutting recalibration frequency by 50%.

Opaque Fused Silica Tube Open Both Ends for UV Sterilization Systems

Key Advantages

-

High UV-C transmission at 185nm (≥85%)

Controlled opacity allows 87% UV-C pass-through with uniform dispersion. -

Surface resistivity against UV-induced degradation

Surface degradation rate <0.2% after 500 hours of continuous UV-C exposure. -

Structural integrity under pressurized flow systems

Withstands 1.5 bar internal pressure at 80°C without microcrack formation.

TOQUARTZ® solution

A Japanese water treatment system integrator experienced 20% UV output loss after 300 hours due to tube degradation. TOQUARTZ® opaque quartz tubes maintained 92% UV-C output after 500 hours, extending maintenance intervals by 60% and improving sterilization efficiency by 18%.

TOQUARTZ® Custom Opaque Quartz Tube Open Both Ends Services

TOQUARTZ® offers comprehensive customization services for opaque quartz tubes, tailored to your specific application requirements and technical specifications.

Dimensional Customization

- Custom outer diameters: 1-500mm

- Custom inner diameters: 0.25-450mm

- Custom lengths: 20-2000mm

- Wall thickness variations

Structural Modifications

- Custom end treatments

- Flared or flanged ends

- Side port additions

- Ground glass joints

Material Specifications

- Adjustable opacity levels

- UV transmission optimization

- Purity levels up to 99.995%

- Specialized thermal properties

Usage Guidelines for Opaque Quartz Tube Open Both Ends

Proper handling, installation, and maintenance of opaque quartz tubes are essential to ensure optimal performance and extended service life in industrial applications.

Handling & Storage

- Handle with clean gloves to prevent surface contamination

- Maintain at least 5mm clearance for thermal expansion

- Use silicone or graphite gaskets for sealing

- Avoid rapid temperature changes during initial heating

- Use specialized quartz clamps or supports

Maintenance & Storage

- Clean with acetone or isopropyl alcohol, never with alkaline solutions

- Inspect regularly for microcracks using UV light

- Store in original packaging or dedicated containers Maintain in dry environment (<40% humidity)

- Replace tubes when visible devitrification occurs

Maximizing Service Life

- Implement gradual temperature ramping (100°C/hour) during initial heating cycles

- Rotate tubes 90° every 500 hours of operation to ensure even heating

- Clean with diluted hydrofluoric acid (5%) only when absolutely necessary and with proper safety protocols

Need Technical Assistance for Opaque Quartz Tube Open Both Ends?

Get expert advice on material selection, specifications, and custom solutions.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is an opaque quartz tube used for?

A: Opaque quartz tubes (also called milky or translucent quartz tubes) are primarily used in infrared heating systems, UV sterilization equipment, laboratory apparatus, industrial furnaces, and light source protection. Their key advantages include high temperature resistance (up to 1200°C), excellent thermal shock resistance, superior chemical resistance, and optimal light diffusion properties that make them ideal for applications requiring controlled radiation distribution.

Q: What is the maximum operating temperature for opaque quartz tubes?

A: TOQUARTZ® opaque quartz tubes can operate continuously at temperatures up to 1100-1200°C. For short-term applications, they can withstand temperatures up to 1450°C. The material has a melting point of 1732°C, softening point of 1630°C, and annealing point of 1180°C. It’s important to note that continuous operation near the maximum temperature may reduce the service life, and proper thermal ramping procedures should be followed to maximize durability.

Q: What is the chemical resistance of opaque quartz tubes?

A: Opaque quartz tubes exhibit exceptional chemical resistance, approximately 30 times greater than ceramics and 150 times greater than stainless steel when exposed to acids. They are inert to most chemicals, including strong acids, organic solvents, and corrosive gases, especially at elevated temperatures. The only significant exception is hydrofluoric acid (HF), which can etch and dissolve silica-based materials. This excellent chemical resistance makes them ideal for laboratory equipment, chemical processing, and aggressive industrial environments.

Q: How should opaque quartz tubes be cleaned and maintained?

A: For optimal maintenance, clean opaque quartz tubes with acetone, isopropyl alcohol, or mild acid solutions (except HF). Avoid alkaline cleaners as they can damage the surface. For stubborn deposits, a solution of dilute sulfuric acid can be effective. Always handle with clean gloves to prevent oils and contaminants from affecting performance. Inspect regularly for devitrification (whitish, rough appearance) which indicates approaching end-of-life. Store in dry environments to prevent moisture absorption which can affect high-temperature performance.

Q: How do opaque quartz tubes for IR heating enhance energy efficiency?

A: Opaque quartz tubes enhance IR heating efficiency through optimal radiation diffusion. According to thermal efficiency studies from the International Journal of Heat and Mass Transfer, milky quartz tubes provide up to 18% more uniform heat distribution compared to clear tubes, leading to energy savings of 8-12% in industrial heating applications. The controlled light scattering properties create more consistent surface temperatures on target materials, reducing hotspots and improving process quality while lowering overall energy consumption.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.