- Home

- /

- Types

- /

- Quartz Cuvette

- /

- High-Precision IR Quartz Cuvettes...

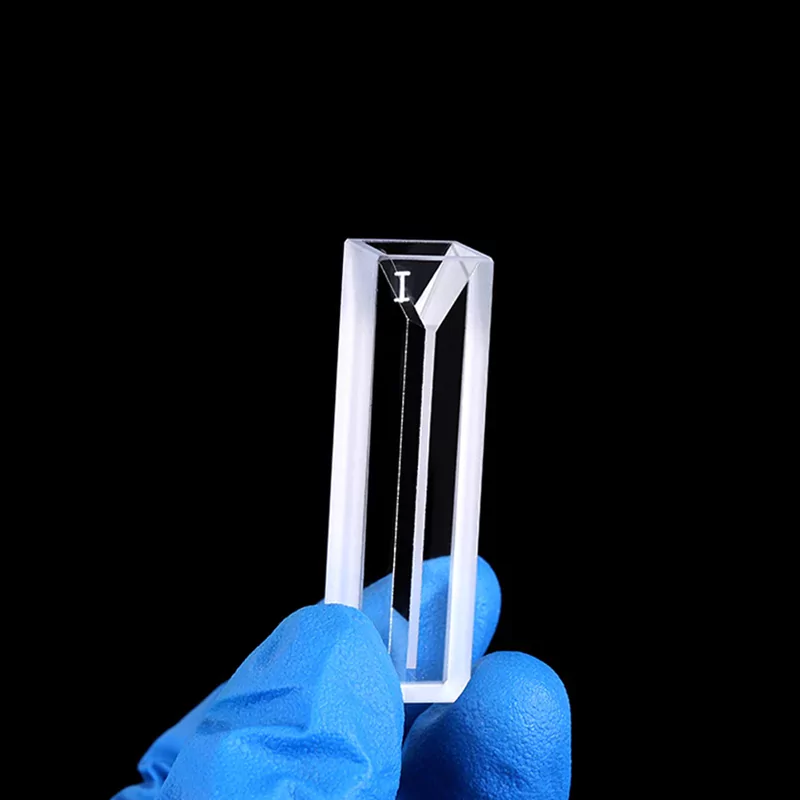

High-Precision IR Quartz Cuvettes for Spectroscopy -TOQUARTZ®

Features of IR Quartz Cuvette

TOQUARTZ® IR quartz cuvettes are manufactured from high-purity quartz material, specifically designed for infrared spectroscopic analysis applications. These precision-engineered optical components deliver consistent performance in chemical, pharmaceutical, and research settings.

Material Properties

Manufactured from 99.99% SiO₂ quartz material, ensuring minimal interference with spectroscopic measurements and reliable results.

Optical Properties

Transmission range from 260nm to 3500nm with no absorption peaks, ideal for both UV and IR spectroscopy applications.

Chemical Resistance

Stability against acids, bases, molten salts, and fluorinated gases, enabling analysis of corrosive substances without degradation.

Thermal Stability

Withstands temperatures exceeding 1100°C with low thermal expansion coefficient (5.5×10⁻⁷ /°C), maintaining dimensional stability during thermal analysis.

-

Stability against

corrosive substances

-

Transmission range

260-3500nm

-

Thermal stability

1100°C+

Technical Specifications & Dimensions of IR Quartz Glass Cuvette

Technical Specifications of IR Quartz Cuvette

| Parameter | Specification | Notes |

| Material | High-purity quartz (≥99.99% SiO₂) | Free from UV/IR interfering impurities |

| Transmission Range | 260-3500nm | No absorption peaks within range |

| Standard Path Lengths | 1, 2, 5, 10, 20, 50, 100mm | Custom path lengths available |

| Window Thickness | 1.25mm ±0.1mm | Optimized for IR transmission |

| Dimensional Tolerance | ±0.1mm | For standard products |

| Surface Finish | Polished, bubble-free, scratch-free | Optical grade finishing |

| Temperature Resistance | Up to 1100°C | Short-term exposure |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C | Low thermal expansion for stability |

| Chemical Resistance | Excellent for most acids/bases | Except HF and concentrated fluoride solutions |

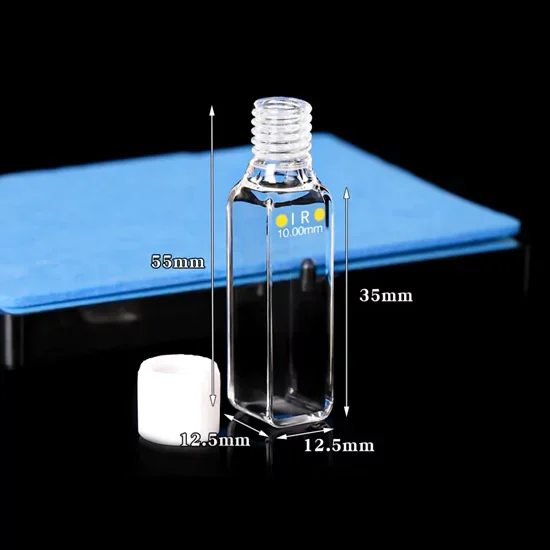

Size of of IR Quartz Cuvette

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-2001 | Micro IR quartz cuvette with lid(350ul-1750ul) slit (1-5mm) | 350ul, 700ul, 1050ul, 1400ul, 1750ul. |

10mm | 12.5×12.5×45 mm | 260nm-3500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-2002 | IR quartz cuvette(10mm) | 3.5ml | 10mm | 12.5×12.5×45 mm | 260nm-3500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-2002-1 | IR quartz cuvette(10mm) with cover | 3.5ml | 10mm | 12.5×12.5×45 mm | 260nm-3500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-2003 | IR quartz fluorescence cuvette cell with screw cap(10mm/3.5ml) | 3.5ml | 10mm | 12.5×12.5×55 mm | 300nm-3500nm |

| Item no. | Description | Capacity | Path Length | LxWxH | Wavelength Range |

| AT-BSM-2004 | IR quartz fluorescence cell with stopper(10mm) | 3.5ml | 10mm | 12.5×12.5×45 mm | 200nm-2500nm |

TOQUARTZ® Solving Challenges with IR Quartz Cuvettes

in Spectroscopy Applications

IR Quartz Cuvettes for Analytical Instrument Manufacturers

Key Advantages

- Each batch maintains ±0.05mm tolerance across 100+ units for automated system alignment.

- Deviation angle between cuvette windows <0.2°, ensuring beam alignment in FTIR/NIR systems.

- Transmission deviation across batches <1.5% at 2500nm, verified by spectrophotometric QC.

TOQUARTZ® solution

A U.S.-based FTIR spectrometer OEM reported misalignment issues due to inconsistent cuvette window angles, causing 6% signal loss.

TOQUARTZ® delivered cuvettes with <0.2° optical axis deviation, resolving alignment errors and improving signal-to-noise ratio by 12% in automated calibration tests.

IR Quartz Cuvettes for Medical Diagnostics Equipment

Key Advantages

- Path length tolerance within ±0.01mm for 1–2mm micro cuvettes, ensuring accurate absorbance in low-volume diagnostics.

- Sealed cuvettes withstand 3000g centrifugation for 10 minutes with zero leakage (validated in 50-unit test).

- Material integrity maintained after 100+ UV sterilization cycles at 254nm, suitable for reusable diagnostic workflows.

TOQUARTZ® solution

A Japanese IVD device manufacturer faced 4.5% false-negative rate in protein detection due to adhesive leaching from bonded cuvettes.

TOQUARTZ® supplied fusion-bonded IR quartz cuvettes, reducing assay interference and improving diagnostic accuracy by 9.3% in clinical validation.

IR Quartz Cuvettes for Research Laboratories

Key Advantages

- Cuvettes tested stable in 12 solvents including DMSO, THF, and acetonitrile for >48h without spectral drift.

- Cuvettes withstand 200°C to 25°C quenching in <5s with no microfractures (tested over 30 cycles).

- Each micro-volume cuvette batch includes gravimetric volume certificate (±1.5% accuracy at 100µL).

TOQUARTZ® solution

A Canadian university lab required cuvettes for solvent-switch kinetic studies involving THF and DMSO. Previous suppliers’ cuvettes showed 3% baseline drift after 24h.

TOQUARTZ® cuvettes maintained <0.5% drift over 48h, enabling reliable kinetic modeling in time-sensitive experiments.

Customization Services for TOQUARTZ® Fused Quartz IR Cuvettes

Custom Dimensions

- Non-standard optical path lengths

- Custom window thickness

- Specialized external dimensions

- Specialized external dimensions

- Rectangular, cylindrical, or specialized shapes

Specialized Features

- Sealed/stoppered designs

- Flow-through configurations

- Temperature control compatibility

- Specialty coatings

- Port/inlet adaptations

TOQUARTZ® Customization Process

Requirements Analysis

TOQUARTZ® engineers work with you to understand your application, specifications, and performance requirements.

Design & Engineering

We develop detailed design specifications and provide CAD drawings for your review and approval.

Prototype Production

We manufacture a prototype sample for testing and validation in your application environment.

Production & Delivery

Following approval, we proceed with production according to your volume requirements, typically with a 2-3 week lead time for custom orders.

How to Clean IR Quartz Cuvettes & Maintenance Guide

How to Clean IR Quartz Cuvettes

- Rinse with distilled water immediately after use

- For organic contaminants, use a 1:2 mixture of hydrochloric acid and ethanol

- For oil-based residues, rinse with petroleum ether

- For stubborn contaminants, specialized ultrasonic cleaning with the frosted side facing down is recommended

- Final rinse should be with distilled water (3x) followed by air drying

- Never use: alkaline solutions, abrasive materials, hard brushes, or fluoride-containing solutions

Proper Handling Techniques

- Always handle cuvettes by the frosted or non-optical sides

- Avoid touching optical windows to prevent fingerprints and contamination

- Use appropriate cuvette holders to prevent dropping or mechanical stress

- Allow samples to reach ambient temperature before placing in cuvettes to prevent thermal shock

- When inserting into instruments, ensure proper alignment with light path

IR Quartz Cuvette Solvent Compatibility

- Compatible with most organic solvents including acetone, methanol, ethanol, and hexane

- Compatible with most aqueous solutions and dilute acids

- Compatible with dilute bases (short exposure recommended)

- For uncertain compatibility, conduct small-scale tests or contact our technical support

- Incompatible with: hydrofluoric acid (HF), concentrated fluoride solutions, and long-term exposure to strong bases

Storage Recommendations

- Store clean, dry cuvettes in original protective case

- Keep in dust-free environment at room temperature

- Avoid direct sunlight and humidity

- For long-term storage, consider desiccant use to prevent moisture accumulation

- Periodically inspect stored cuvettes for any signs of deterioration

Need Technical Support for IR Quartz Cuvettes?

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the wavelength range of your IR quartz cuvettes?

A: TOQUARTZ® IR quartz cuvettes offer transmission across a spectral range from 260nm to 3500nm, covering UV, visible, and infrared regions. This makes them suitable for both UV and IR spectroscopy applications without the need for different materials.

Q: How do I clean IR quartz cuvettes without damaging them?

A: Clean IR quartz cuvettes by first rinsing with distilled water immediately after use. For organic contaminants, use a 1:2 mixture of hydrochloric acid and ethanol. For oil-based residues, rinse with petroleum ether. Always finish with three rinses of distilled water and air dry. Never use alkaline solutions, abrasive materials, or hard brushes. For stubborn contaminants, ultrasonic cleaning with the frosted side facing down is recommended.

Q: What solvents are compatible with IR quartz cuvettes?

A: IR quartz cuvettes are compatible with most laboratory solvents including water, alcohols (methanol, ethanol), acetone, chloroform, hexane, toluene, most dilute acids, and short exposure to dilute bases. They are not compatible with hydrofluoric acid (HF), concentrated fluoride solutions, or prolonged exposure to strong alkaline solutions. For special applications, please consult our technical team.

Q:What is the temperature limit for IR quartz cuvettes?

A: TOQUARTZ® IR quartz cuvettes can withstand temperatures up to 1100°C, making them suitable for high-temperature applications. However, for sealed cuvettes, the temperature limit depends on the sealing material used. Standard sealed cuvettes typically have a temperature limit of 80-120°C. For higher temperature applications, special high-temperature seals can be provided.

Q: What is the path length tolerance of your IR quartz cuvettes?

A: TOQUARTZ® standard IR quartz cuvettes have a path length tolerance of ±0.01mm for path lengths under 10mm and ±0.1mm for longer path lengths. This precision ensures reliable quantitative analysis and reproducible results. Custom path lengths with specific tolerances are available upon request.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.