- Home

- /

- Types

- /

- Quartz Tube

- /

- Custom Rapid-Response Infrared Quartz...

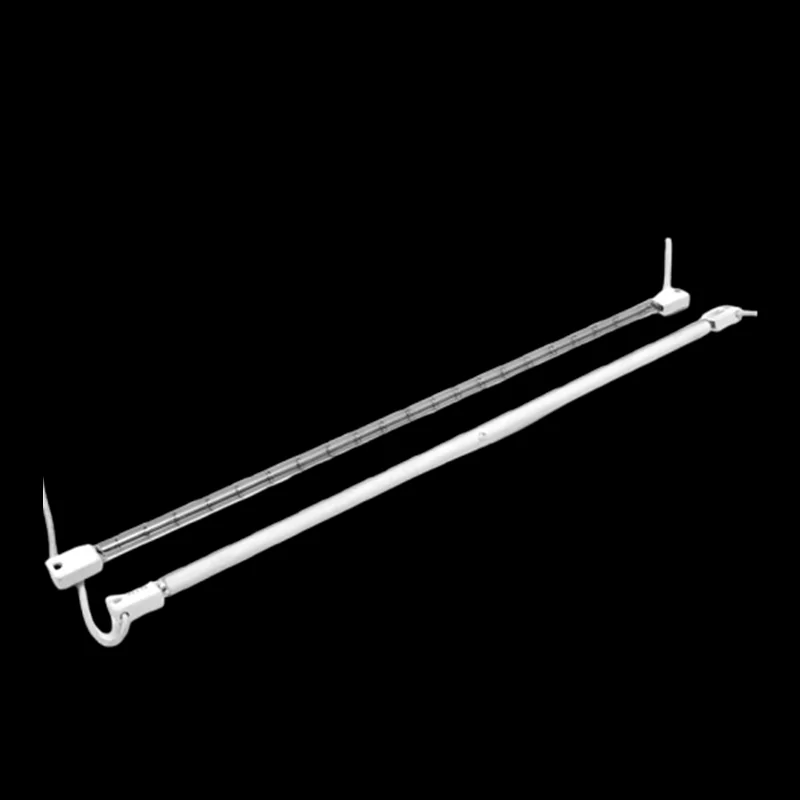

Custom Rapid-Response Infrared Quartz Heating Tube for Industrial Heating Systems-TOQUARTZ®

Key Features of Infrared Quartz Heating Tube

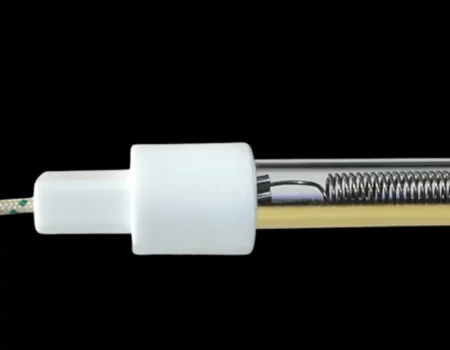

TOQUARTZ® infrared quartz heating tubes combine high-purity fused silica with advanced filament technology to deliver superior heating performance for industrial applications. These tubes offer exceptional thermal properties, chemical resistance, and customization flexibility.

Thermal Performance

- Operating temperature up to 800°C

- Peak heating temperature up to 900°C

- ≥95% electrical-to-heat conversion

Material Excellence

- High-purity quartz (≥99.99% SiO₂)

- Normal emissivity ≥88%

- Infrared wavelength: 1.5-12μm

Design Flexibility

- Multiple voltage options (24-380V)

- Custom power ratings (150-3500W)

- ±0.1mm dimensional precision

- SiO₂ Content: ≥99.99%

- Superior chemical resistance

- Thermal shock resistant design

Technical Specifications & Dimensions of Quartz Infrared Heating Tube

TOQUARTZ® infrared quartz heating tubes are manufactured to precise specifications with stringent quality control. The following tables outline the standard technical parameters and available models.

Technical Specifications

| Parameter | Specification | Tolerance |

| Voltage Range | 24, 36, 72, 100, 110, 115, 120, 220, 230, 240, 380V | ±5% |

| Power Range | 150-3500W | +5%, -10% |

| Electrical-Thermal Conversion Efficiency | ≥95% | – |

| Maximum Operating Temperature | ≤800°C | – |

| Electrical-Radiation Conversion Efficiency | ≥70% | – |

| Maximum Heating Temperature | ≤900°C | – |

| Normal Emissivity | ≥88% | – |

| Infrared Wavelength | 1.5-12μm | – |

| Color Temperature | 800-1500K | – |

| Average Lifespan | ≥6000 hours | – |

| Length Tolerance | – | ±2mm |

| Diameter Tolerance | – | ±0.05mm |

Size Chart

| Model | Diameter(mm) | Length(mm) | Voltage(V) | Power(W) |

| AT-SY-JRG001 | 8 | 120 | 220 | 300 |

| AT-SY-JRG002 | 10 | 120 | 220 | 300 |

| AT-SY-JRG003 | 11 | 220 | 220 | 700 |

| AT-SY-JRG004 | 12 | 120 | 220 | 300 |

| AT-SY-JRG005 | 12 | 160 | 220 | 300 |

| AT-SY-JRG006 | 12 | 180 | 220 | 300 |

| AT-SY-JRG007 | 12 | 205 | 220 | 300 |

| AT-SY-JRG008 | 12 | 220 | 220 | 300 |

| AT-SY-JRG009 | 12 | 230 | 220 | 300 |

| AT-SY-JRG010 | 12 | 250 | 220 | 300 |

| AT-SY-JRG011 | 12 | 260 | 220 | 300 |

| AT-SY-JRG012 | 12 | 280 | 220 | 300 |

| AT-SY-JRG013 | 12 | 300 | 220 | 300 |

| AT-SY-JRG014 | 12 | 330 | 220 | 300 |

| AT-SY-JRG015 | 14 | 330 | 220 | 300 |

| AT-SY-JRG016 | 18 | 400 | 110/220/380 | 100-5000 |

| AT-SY-JRG017 | 18 | 500 | 110/220/380 | 100-5000 |

| AT-SY-JRG018 | 18 | 600 | 110/220/380 | 100-5000 |

| AT-SY-JRG019 | 18 | 700 | 110/220/380 | 100-5000 |

| AT-SY-JRG020 | 18 | 800 | 110/220/380 | 100-5000 |

| AT-SY-JRG021 | 18 | 900 | 110/220/380 | 100-5000 |

| AT-SY-JRG022 | 18 | 1000 | 110/220/380 | 100-5000 |

| AT-SY-JRG023 | 18 | 1500 | 110/220/380 | 100-5000 |

| AT-SY-JRG024 | 18 | 1800 | 110/220/380 | 100-5000 |

| AT-SY-JRG025 | 22 | 180-1800 | 110/220/380 | 100-5000 |

| AT-SY-JRG026 | 25 | 180-1800 | 110/220/380 | 100-5000 |

| AT-SY-JRG027 | 28 | 180-1800 | 110/220/380 | 100-5000 |

| AT-SY-JRG028 | 32 | 180-1800 | 110/220/380 | 100-5000 |

TOQUARTZ® Solving Challenges with Infrared Quartz Glass Heating Tube

Infrared Quartz Heating Tubes for Food Processing Equipment

Key Advantages

-

Consistent thermal uniformity across ±2°C

Maintains temperature deviation within ±2°C over 1.2m heating length, ensuring even baking and drying. -

Reduced energy consumption by 18%

Optimized filament design and quartz emissivity reduce power usage by 18% compared to ceramic heaters. -

Downtime-free operation for 6,000+ hours

Tested lifespan exceeds 6,000 hours under 24/7 operation in 80°C ambient food packaging environments.

TOQUARTZ® solution

A German snack food packaging line experienced uneven sealing due to ±5°C temperature fluctuation, causing 7% product rejection. TOQUARTZ® supplied custom 220V/700W infrared quartz tubes with ±0.1mm precision and optimized filament layout. After integration, sealing uniformity improved by 92%, and energy usage dropped by 16%, saving €11,400 annually. No tube failure occurred in the first 7,000 hours of continuous operation.

Infrared Quartz Glass Heating Tubes for Plastic Processing

Key Advantages

-

Localized zone heating with ±0.1mm control

Supports precise thermal zoning in thermoforming molds with ±0.1mm dimensional accuracy. -

Hotspot elimination with <3% surface variance

Infrared wavelength tuning and filament spacing reduce surface temperature variance to under 3%. -

25% faster cycle time in vacuum forming

Rapid-response quartz tubes reduce heating time by 25%, increasing throughput in plastic forming lines.

TOQUARTZ® solution

A Polish vacuum forming OEM faced 12% defect rate due to uneven heating and slow cycle times. TOQUARTZ® delivered U-shaped quartz tubes with 18mm diameter, 900mm length, and 220V/1500W rating. Cycle time dropped from 18s to 13.5s, and defect rate fell to 2.1%, improving annual output by 21%. Customer reported ROI within 3.5 months due to reduced scrap and increased productivity.

Infrared Fused Silica Heating Tubes for Laboratory Equipment

Key Advantages

-

±0.05mm dimensional tolerance for precision fit

Ensures seamless integration into compact thermal analysis chambers with tight spatial constraints. -

Contamination-free operation in inert atmospheres

Fused silica purity ≥99.99% SiO₂ prevents outgassing or contamination during sensitive experiments. -

Stable output at 1,200°C for 4+ hours

Maintains thermal stability at 1,200°C for extended test durations without filament degradation.

TOQUARTZ® solution

A Japanese analytical instrument manufacturer required ultra-stable heating for thermal gravimetric analysis (TGA). Previous suppliers failed to meet ±0.1mm tolerance, causing 15% assembly rejection and unstable readings. TOQUARTZ® provided 12mm OD tubes with ±0.05mm tolerance and 1,000W tungsten filament. Post-integration, rejection rate dropped to 0.8%, and test repeatability improved by 11.3% across 50+ units. Customer extended TOQUARTZ® supply to two additional product lines within 6 months.

TOQUARTZ® Customized Services for Fused Silica Infrared Heating Tube

Beyond our standard offerings, TOQUARTZ® specializes in custom infrared quartz heating tube solutions tailored to your specific application requirements.

Dimensional Customization

- Custom diameters from 8mm to 32mm

- Specialized lengths up to 2000mm

- Precision tolerance up to ±0.05mm

Electrical Customization

- Custom voltage requirements (24-380V)

- Precise power output (150-5000W)

- Specialized terminal configurations

- Integrated temperature sensors

Performance Customization

- Optimized wavelength for specific materials

- Specialized reflective coatings

- Gold-plated terminals for enhanced conductivity

- Rapid heat-up filament design

Usage Guidelines for Infrared Quartz Heating Elements

Proper installation, operation, and maintenance of infrared quartz heating tubes ensures maximum performance and service life. Follow these guidelines to optimize your heating application.

Installation Guidelines

- Wear powder-free gloves when handling to prevent contamination

- Store in original packaging or on clean, soft surfaces to prevent scratches

- Avoid impact or point pressure that could cause microfractures

- Store in a clean, dry environment away from chemical vapors

Installation

- Ensure mating surfaces are clean and free from debris

- For vacuum applications, use appropriate vacuum-rated seals

- Avoid over-tightening or applying uneven pressure

- For high-temperature applications, allow for thermal expansion (0.5% at 1000°C)

Optimizing Performance

- Use reflective materials behind tubes to direct infrared energy toward target

- Position tubes at optimal distance from target material (typically 50-150mm)

- Consider using temperature controllers with PID functionality

- Avoid rapid on/off cycling when possible

- Keep operating voltage within ±5% of rated value

- Protect from mechanical vibration with proper mounting

Need Engineering Support for Your Heating System?

develop a custom solution for your specific requirements.

Contact us today for expert assistance.

Why Partner with TOQUARTZ

Direct Factory Advantage

As a direct manufacturer, we can cut out the numerous intermediate links.

Engineering Expertise

Technical team guides clients from material selection to design optimization, translating specs into deliverables.

Flexible Manufacturing

Handling standard & custom orders via small-batch expertise and prototyping rigor to meet urgent deadlines.

Quality

Assurance

Pre-shipment 3-step validation:

1. dimensional accuracy,

2. material purity ,

3. performance thresholds

Global Supply Chain

Reliable global logistics to industrial hubs (DE/US/JP/KR priority) with trackable milestones.

Releted Products

As a specialized manufacturer with direct factory capabilities, TOQUARTZ provides both standard and custom quartz solutions with engineering support throughout the specification and implementation process.

FAQ

Q: What is the difference between infrared quartz heating tubes and ceramic heating elements?

A: Infrared quartz heating tubes offer several advantages over ceramic elements: faster heat-up time (typically 30-60 seconds vs. 5-10 minutes), higher efficiency (≥95% vs. 70-80%), more precise temperature control, and longer lifespan in most applications. Quartz tubes also provide cleaner operation with no dust or contamination concerns.

Q: What is the maximum temperature an infrared quartz heating tube can achieve?

A: TOQUARTZ® standard infrared quartz heating tubes have a maximum operating temperature of 800°C and peak heating temperature of 900°C. For applications requiring higher temperatures, we offer specialized high-temperature variants capable of operating at up to 1100°C. The actual temperature achieved depends on power density, reflector design, and ambient conditions.

Q: How long do infrared quartz heating tubes typically last?

A: Under normal operating conditions, our infrared quartz heating tubes have an average lifespan of 6,000+ hours. Factors affecting lifespan include operating temperature, on-off cycling frequency, voltage stability, and environmental conditions. Proper installation and operation according to our guidelines can extend tube life by up to 30%.

Q: How quickly do infrared quartz heating tubes reach operating temperature?

A: TOQUARTZ® infrared quartz heating tubes typically reach 80% of their maximum operating temperature within 30-60 seconds, with full temperature achieved in 1-2 minutes. This rapid heating capability provides significant energy savings and process efficiency advantages compared to conventional heating elements that may require 5-15 minutes to reach operating temperature.

Q: Are infrared quartz heating tubes suitable for moisture-rich environments?

A: While quartz material itself is highly resistant to moisture, standard infrared quartz heating tubes should be protected from direct water exposure, especially when hot. For applications in high-humidity or moisture-rich environments, we offer specialized sealed designs with additional terminal protection. Please consult our technical team for recommendations specific to your environmental conditions.

Contact our engineering team for technical consultation and pricing. We’ll help you select the optimal specifications for your application requirements.