High-Performance InIndustrial Quartz Glass for Extreme Process Environments

Built to perform in the harshest industrial conditions, TOQUARTZ® delivers quartz glass components that meet the demands of high-load, high-stress applications.

- Withstands 1600°C+ heat

- Stable in corrosive media

- Custom shapes & tolerances

What is Industrial Quartz Glass?

Industrial quartz glass is an engineered material consisting of high-purity silicon dioxide (SiO₂) that has been melted and formed into various shapes for industrial applications. Unlike standard glass, industrial quartz glass offers exceptional thermal, chemical, and optical properties that make it indispensable in extreme environments where other materials would fail.

Key Properties of Industrial Quartz Glass

At TOQUARTZ, we specialize in manufacturing premium industrial quartz glass components with 99.995% SiO₂ purity, catering to industries that require materials capable of withstanding extreme temperatures, corrosive environments, and precise specifications.

Thermal Stability

TOQUARTZ® industrial quartz glass components maintain structural integrity at extreme temperatures, making them ideal for high-heat applications.

- Temperature resistance up to 1600°C+

-

Low thermal expansion coefficient:

5.5×10⁻⁷/°C - Excellent thermal shock resistance

- High thermal conductivity (120-160 W/m.K)

Chemical Resistance

TOQUARTZ® industrial quartz glass products remain stable in aggressive chemical environments where other materials would rapidly deteriorate.

- Resistant to most acids and bases

- Stable against molten salts

- Inert to fluorinated gases

- Non-reactive with most chemicals at high temps

Mechanical Properties

TOQUARTZ® industrial quartz glass offers outstanding strength and durability for demanding industrial applications.

- Fracture modulus up to 350MPa+

- Extremely low friction coefficient

- High-flow velocity durability

- Excellent electrical insulation properties

Product Ranges of Industrial Quartz Glass We Offer

From standard components to custom fabricated solutions, TOQUARTZ delivers high-performance quartz glass products engineered for your specific application.

Quartz Tubes

Precision engineered quartz tubing for high-temperature and corrosive environments.

Quartz Heating Elements

High-performance quartz components designed for infrared heating applications.

Specialized Quartz Components

Purpose-built quartz equipment for specific industrial applications.

Quartz Connection Components

Precision-engineered quartz connections for vacuum and gas systems.

Industrial Quartz Glass Applications

TOQUARTZ® industrial quartz glass products serve critical functions across multiple industries where extreme conditions demand exceptional material performance.

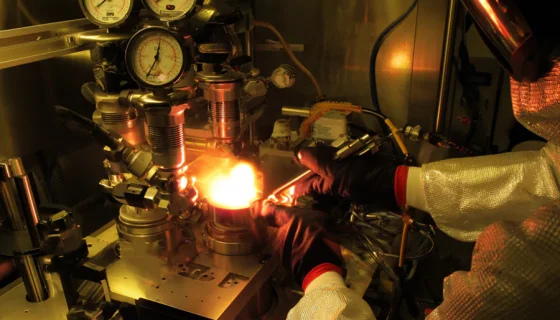

Infrared Heating Systems

TOQUARTZ® industrial quartz glass heating tubes and plates provide superior performance for industrial heating applications.

- Industrial drying systems

- Plastic thermoforming equipment

- Food processing heating elements

- Automotive paint curing lines

Industrial Furnaces & Kilns

Industrial quartz glass components are essential for high-temperature industrial furnaces across multiple sectors.

- Metal heat treatment furnaces

- Glass processing equipment

- Ceramic sintering kilns

- Furnace viewing ports & doors

Vacuum Systems

TOQUARTZ® industrial quartz glass vacuum components offer excellent sealing properties and visual transparency.

- Vacuum coating equipment

- Vacuum drying systems

- Protective atmosphere chambers

- Observation windows & viewports

Chemical Processing

TOQUARTZ® industrial quartz glass components resist corrosion in aggressive chemical environments.

- Acid handling systems

- Fluorinated gas equipment

- Molten salt containment

- Reaction vessels & piping

Environmental Technology

TOQUARTZ® industrial quartz glass products are critical for environmental monitoring and treatment systems.

- Industrial waste gas treatment

- Liquid waste collection systems

- High-temperature filtration

- Combustion monitoring equipment

Specialized Equipment

TOQUARTZ® industrial quartz glass meets specialized needs across various industrial applications.

- Glass blowing & forming equipment

- Specialized lighting systems

- Insulation for high-voltage systems

- Custom industrial machinery components

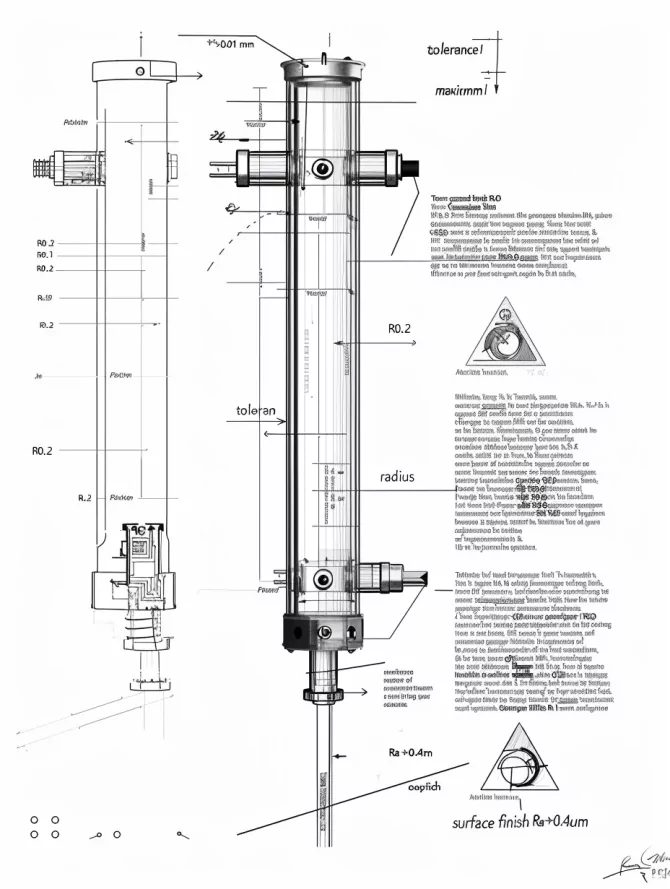

Custom Industrial Quartz Glass Solutions

TOQUARTZ® specializes in creating custom industrial quartz glass components tailored to your exact specifications and application requirements.

Technical Drawing Support

We assist with technical drawings and design optimization.

Precision Dimensional Control

Tolerances of ±0.2mm for most dimensions.

Rapid Turnaround

2-4 week delivery for most custom orders.

Small Batch Capability

No MOQ restriction. Low MOQ order welcomed.

From Drawing to Delivery

Technical Consultation

TOQUARTZ® engineering team works with you to understand your application requirements and material specifications.

Design & Engineering

We assist with technical drawings or work from your provided specifications to create the perfect solution.

Prototyping & Testing

For new designs, we can produce small-batch prototypes to validate performance before full production.

Production & Quality Control

Our precision manufacturing process ensures your components meet exact specifications with rigorous QC.

Global Delivery

Fast, secure shipping to your facility with comprehensive supply chain management.

Assurance of TOQUARTZ® Industrial Quartz Glass

Our industrial quartz glass products meet rigorous quality standards and offer superior performance for demanding applications.

TOQUARTZ® Technical Specifications

| Parameter | Value |

| Material Purity | ≥99.995% SiO₂ |

| Maximum Operating Temperature | 1600°C+ |

| Thermal Expansion Coefficient | 5.5×10⁻⁷ /°C |

| Thermal Conductivity | 120-160 W/m.K |

| Dimensional Tolerance | ±0.2mm (standard) |

| Fracture Modulus | Up to 350MPa+ |

| Chemical Resistance | Excellent against acids, bases, and fluorinated gases |

| Surface Finish Options | Polished, Frosted, Opaque (available for most products) |

Quality Certifications & Standards

ISO 9001 Certified

TOQUARTZ® industrial quartz glass production follows ISO 9001 quality management standards, ensuring consistent product quality and manufacturing processes.

- Documented quality control procedures

- Regular process audits

- Continuous improvement protocols

REACH Compliant

All TOQUARTZ industrial quartz glass products comply with European Union REACH regulations for chemical safety.

- Free from restricted substances

- Safe for industrial applications

- Environmentally responsible materials

RoHS Compliance

TOQUARTZ® industrial quartz glass products meet RoHS standards for restriction of hazardous substances.

- Free from restricted heavy metals

- Compliant with global standards

- Safe for use in regulated equipment

FAQs About Industrial Quartz Glass

Q: What is the maximum temperature that your industrial quartz glass can withstand?

A: TOQUARTZ® industrial quartz glass products can withstand continuous operation at temperatures up to 1600°C. For short-term exposure, they can handle temperatures up to 1800°C, though we recommend staying within the continuous operation range for extended applications. The thermal shock resistance is also excellent, allowing rapid temperature changes without cracking.

Q: How does industrial quartz glass perform in corrosive chemical environments?

A: TOQUARTZ® industrial quartz glass offers exceptional chemical resistance. It is inert to most acids (except hydrofluoric acid), bases, molten salts, and fluorinated gases, even at elevated temperatures. This makes it ideal for chemical processing equipment, waste handling systems, and any application involving corrosive substances. The high-purity SiO₂ composition (≥99.995%) ensures minimal reactivity and contamination risk.

Q: Can you produce complex shapes or assemblies with industrial quartz glass?

A: Yes, we specialize in fabricating complex quartz glass shapes and assemblies. Our capabilities include custom bends at precise angles, multi-part assemblies, spiral configurations, and components with multiple connections or ports. We can work from your engineering drawings or collaborate with you to design components that meet your specific requirements. Our engineering team can provide design assistance to ensure manufacturability and performance.

Q: How does the thermal expansion of industrial quartz glass compare to other materials?

A: Quartz glass has an extremely low thermal expansion coefficient of approximately 5.5×10⁻⁷ /°C, which is significantly lower than most metals, ceramics, and other glass types. This property makes it excellent for applications involving thermal cycling or temperature gradients, as it resists cracking from thermal stress. It’s particularly valuable when mating with other materials in assemblies where differential expansion could cause issues.

Q: What surface finishes are available for industrial quartz glass components?

A: We offer several surface finishes for our quartz glass components: Fire-polished for maximum clarity and smoothness, mechanical polishing for specific dimensional requirements, frosted/etched for light diffusion, and ground surfaces for specific applications. Each finish affects optical properties, chemical resistance, and mechanical characteristics differently. We can recommend the most appropriate finish based on your application requirements.

Q: Can industrial quartz glass be joined to other materials?

A: Yes, quartz glass can be joined to various materials using different techniques. For metal-to-quartz connections, we typically use compression fittings, O-ring seals, or specialized glass-to-metal seals. Quartz can also be joined to other glass types using graded seals that accommodate differences in thermal expansion. For temporary connections, we can provide ground joint interfaces, flanged connections, or custom connection solutions based on your specific requirements.